Professional Documents

Culture Documents

March 2015 1427458365 82

March 2015 1427458365 82

Uploaded by

Kiều ChâuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

March 2015 1427458365 82

March 2015 1427458365 82

Uploaded by

Kiều ChâuCopyright:

Available Formats

Volume : 4 | Issue : 3 | Mar 2015 ISSN - 2250-1991

Research Paper Biotechnology

Fermentation of Cashew Apple (Anacardium

Occidentale) Juice Into Wine by Different Saccharomyces

Cerevisiae Strains: A Comparative Study

Department of Biotechnology, Shivaji University Kolhapur, India

O. A. Apine

416004.

* Prof. Jyoti P. Department of Biochemistry, Shivaji University Kolhapur, India 416004

Jadhav *Corresponding author

Cashew nut production is the primary aim for the cashew tree cultivation. Large numbers of cashew apples were considered

as a major agriculture waste. This work is focused on the development of alcoholic product by using cashew apple juice.

Two different yeastSaccharomyces cerevisiae NCIM 3311 and NCIM 3282strains were used for fermentation with cell

ABSTRACT

count 107 CFU/ml. Fermentation was performed by using 10% of inoculum at 24±2°C. After each 24 h sample aliquot

was withdrawn from the flask to monitor soluble sugar concentrations, pH and dry matter contents. Among volatile

compounds, major alcohols and volatile acids were analysed after every 24 h using the gas GC-MS and GC-FID system.

After fermentationprocess the products were stabilized under refrigerationfor a period of 25 days. After the analysis of

physicochemical properties and volatiles, strain NCIM 3311 was found to be better with 12 % alcohol after fermentation

compared with the other NCIM 3282.

KEYWORDS Cashew apple, wine,Saccharomyces cerevisiae, GC-MS, GC-FID

Introduction physico-chemical composition and volatiles. Furthermore, cer-

Most of the countries around the world are being actively en- tain prime parameters such as pH,soluble solids, and dry mat-

gaged in the cultivation of cashew (Anacardium occidentale ter contents were also monitoreddaily during fermentation.

L.), with Brazil, India, Vietnam and Nigeria as the main culti-

vation centers. The primary aim of the cashew tree cultivation Materials and Methods

is for production of cashew nuts. Cashew apples were consid- Microorganisms and media

ered as a ‘Gold Mine’ of wasteland as it requires low inputs Two strains of Saccharomyces cerevisiae were used in this

for production (Attri, 2009). In India harvesting of the cashew study. Freeze-dried yeast strains Saccharomyces cerevisiae

starts from February and lasts till the end of May or early June. NCIM 3282, and Saccharomyces cerevisiae NCIM 3311 was

Cashew tree bears cashew nut (true fruit) and cashew apple obtained from National Collection of Industrial Microorgan-

(pseudo fruit), accounting for 10 % and 90 % of the total isms (Pune, Maharashtra, India). The yeasts were propagat-

fruit weight respectively (Talasila, 2012) ed in a sterile nutrient broth composed of 2 % w/v glucose,

0.1% yeast extract, 0.2 % peptone, 0.5 % sodium chloride

Cashew apples are elongated, round or pear-shaped fibrous (pH 5.0) and routinely maintained on the agar based slants of

fruits. The fully developed cashew apple would be firm, juicy, same nutrient composition earlier mentioned.

without any shade of green color and is easily detachable

from the plant. The flavor, aroma and sugar concentrations Must and inoculum preparation

are very high, and acidity and astringency are low at fully de- Fully ripe cashew apple yellow variety, Vengurla 7 officially

veloped stage (de Figueiredo, 2002). 30 million metric tons of developed by Regional Fruit Research Station Vengurle, Ma-

cashew apples are produced yearly in the world and 20 lakh harashtra, India. Cashew apples used for the study were col-

tons in India (Mandal,1985; Michodjehoun-Mestres, 2009). lected from the Vaibhavwadi (16° 29’ 47’ N, 73° 44’ 45’E)

About 10–15 tons of cashew apples are produced for every region and immediately processed. The fruits were washed

ton of cashew nut (Attri,2009). Cashew apple is a non-climac- and sanitized; any defective fruits were sorted out in the lab-

teric fruit found in three colors yellow, orange and red, with oratory. During washing nuts attached to cashew apple were

the same pale yellow pulp, weighs about 75– 80 g (Maciel, separated. Then cashew apples were steamed for 5 min, again

1986). Cashew apple can be consumed raw and possesses washed with cool fresh water to bring the cashew apples to

good characteristics for utilization due to its fleshy pulp, soft room temperature and then pressed to obtain the integral

peel, lack of seeds, high sugar content and strong exotic fla- non-pulpy juice and filtered. The must was prepared by mix-

vor (Garruti, 2003). Neither the cashew apples nor the juice ing cashew apple juice with sucrose so as to increase natural

extracted from the fruits is completely utilized in India, despite brix 16° to 28° additionally 0.1 g/l of diammonium phosphate

of having promising nutritional and medicinal properties; large added. The pH was adjusted to 4.0 with citric acid solution.

amounts of cashew apples are being wasted in the field after The juice was sterilized overnight with 100 ppm of potassi-

nut separation. um metabisulphite under refrigeration (4°C). Pre-inoculum

was prepared by inoculating loopful of respective yeast strains

Wine making would be better option to preserve nutraceuti- grown on the agar based slants was added to 150 ml of liquid

cals and more value to the cashew apples. It could provide a medium containing cashew apple juice diluted at 1:1 (Juice:

better alternative to process the large number of fruits dur- distilled water) along with broth based medium components

ing the peak harvest period whereby reducing its wastage due earlier mentioned. The culture was maintained aerobically for

to rapid post-harvest deterioration.Wine from cashew apples 48 h yielding a count of 107 CFU/ml. The CFU was calculated

is like a real gold mine from the waste if processed and pro- by using neubauer chamber, this fermented Cashew juice was

moted properly. In this study the attempt has been made to then used as inoculum.

ferment fresh and ripe cashew apple juice to wine using two

different Saccharomyces cerevisiae, denominated as NCIM Fermentation condition

3282 and NCIM 3311. The products were evaluated for their Replicate fermentation was carried out in 5 l capacity Erlen-

6 | PARIPEX - INDIAN JOURNAL OF RESEARCH

Volume : 4 | Issue : 3 | Mar 2015 ISSN - 2250-1991

meyer flask with a 3 l volume of cashew apple juice to which ability, high sugar and water content, and overall chemical

10 % (v/v) inoculum was added. The flasks were maintained composition (Ward and Ray, 2006). Some of them could en-

at room temperature for brix stabilization then maintained at hance local or international markets by appropriate utilization

20° C throughout fermentation process. Fermentations were processes, and fermentation remains as a technological at-

conducted for 7 days using a simple batch system under static tempt of such utilization (Onwuka and Awam, 2001; Muniz,

conditions. 2006). Despite the high level of tannin content (causing astrin-

gency), cashew apples could be processed into beverage ow-

Physico-chemical composition ing to its fleshy pulp, soft peel and lack of seeds, high sugar

During the fermentation process, an aliquot was removed af- concentration and strong exotic flavor. However, it has been

ter every 24 h for the analysis. The total soluble solids (Brix), underutilized, and the development of a new product to mini-

pH, dry matter and optical density (600 nm) were measured mize the apple waste includes fermentation of the juice, yield-

throughout the fermentation process with samples taken at ing an alcoholic beverage such as wine (Muniz, 2006).

the indicated time points by using a refractometer (ATAGO,

Japan), pH meter (Metrolim, Switzerland) and spectrophotom- Physico-chemical composition

eter (UV mini-1240, Shimadzu, Kyoto, Japan). Besides these Cashew apple juice (Filtered through 1-mm-meshsieve) and

determinations, other physico-chemical characteristics such as products during fermentation process were analyzed for their

total acidity, alcohol content, and total reducing sugars were physico-chemical composition (Table1). The fermentation car-

determined in final wine products, according to the methods ried out with different strains (Saccharomyces cerevisiae NCIM

described by Analysis of the Association of Official Analytical 3282 and NCIM 3311) lasted for 168 h, and after this period,

Chemists (AOAC 2000). All analyses were performed in tripli- prior to pasteurization and maturation the physicochemical

cate in three distinct sets of fermentations. characteristics of cashew apple wine were determined (Table

2). From the data presented in (Table 1) it could be observed

GC-FID and GC-MS analysis that there was a continued decrease in soluble solid content

Volatile extraction by HS-SPME was carried out with 50/30μm during the fermentation process. The consumption pattern

layer of divinylbenzene–carboxen–polydimethylsiloxane (DVB- of sugars during fermentation, performed with both strains

CAR-PDMS) (Supelco Co, Bellefonte, USA) fibre that was ex- (NCIM 3311 and NCIM 3282), can be observed in Fig.1a.

posed to the sample headspace for a specified time.After ex- There was a similarity in the reduction profile for both the

traction, the SPME assembly was removed from the headspace strains. This result was in accord with soluble solids profile

vial and inserted directly into the injection port of the GC. The during fermentation process. The viable yeast cell populations

SPME fibre was immediately thermally desorbed for 3 min at of pure cultures of S. cerevisiae 3282 and S. cerevisiae 3311

250 °C in the SPME-specific liner of the injector port of ei- showed comparable increase in the cell count up to day 120

ther the GC-FID or GC–MS. The volatile flavour compounds of h of the fermentation then declined towards the end of the

wine were initially identified using a GC–MS and only major fermentation Fig. 1b.

alcohols and volatile acids were included in the study. Quan-

titative analysis of the volatile compounds performed by using The pH reduction during the fermentation by with strain

a GC equipped with a flame ionization detector (FID). Sample NCIM 3311 and NCIM 3282 were reduced by 0.4 and 0.6

preparation was based on the method of (Chen, 2006) with respectively. Thus, both these products are within the val-

modifications. External individual standard solutions were pre- ue which guarantees the microbiological quality of wines

pared and diluted with 10% cashew apple juice-based aque- (ToresNeto, 2006).The decrease in dry matter content espe-

ous solutions to obtain a range of concentrations, except that cially fermentation carried out by NCIM 3311 strain was more

ethanol standard was diluted in 100% cashew apple juice. than NCIM 3282 strain.The reduction of dry matter was main-

The selected volatiles included ethanol (1000- 15,000 ppm ly responsible for the dryness of the wine. The wine ferment-

(v/v)), isoamyl alcohol (0.01- 0.17 ppm), isoamyl acetate and ed with NCIM 3311 strain was comparatively drier like white

(0.004-0.1 ppm) and 2-phenylethyl alcohol (0.04-2.00 ppm). grape wine. Wine fermented by NCIM 3282 strain was con-

All calibration curves had R 2 values of at least 0.98. The sam- sidered to be mild compared with white grape wine and the

ples were diluted with water prior to extraction and subjected wine fermented with NCIM 3311.

to analysis. Triplicate analyses were performed for each sample

The results of physico-chemical parameters of cashew apple

GC-FID juice and fermented wine from the same juicewas analysed

Agilent 7890 A gas chromatograph equipped with a FID and with and without inoculation with the two strains (NCIM 3282

a capillary column stabilwax- DA (30m × 0.25mm × 0.25 µ). and NCIM 3311) of S. cerevisiae, after fermentation wine

Helium was the carrier gas with a velocity of 1.5 ml/min and pasteurized and stored for a maturation period of 25 days

oven temperature was held 120 °C for 2 min and then raised are presented in Table 2. The data obtained on the analyz-

at 5 °C with 15 min hold. The injector and detector tempera- ed variables of soluble solids and dry matter contents of the

ture were 230 °C and 260 °C respectively. uninoculated medium was higher as compared to fermented

wines prepared by inoculation with the strain of NCIM 3311

GC-MS analysis of S. cerevisiae. Lower values were observed (Table 2) for dry

Agilent 5975 C series GC-MS system was used for analysis. matter content in the wine fermented with NCIM 3311. Re-

Separation of volatile compounds was achieved by using sta- ducing sugars were lower by about 10 g l -1, in the wine fer-

blewax DA, with dimensions of 60 m × 250 µm × 0.25 µm. mented with the NCIM 3311 strain when compared to wine

Helium was used as a carrier gas with a velocity of 1 ml/min. fermented with the NCIM 3282 strain. Alcohol content in the

The oven temperature was initially at 60°C for 10 min then fermented product with NCIM 3311 strain was 12 % against

10°C/min rise up to 230°C for 18 min then kept for 45 min. a concentration of 10% in the fermented wine prepared with

The mass spectrometer operated in the electron impact mode NCIM 3282 strain, representing a gain in its efficiency of 10%

with a source temperature of 200 °C, an ionizing voltage of in alcohol production by strain NCIM 3311 over that of strain

70 eV, and a transfer line temperature of 250 °C. All the anal- NCIM 3282. This conclusion is drawn from the solids soluble

ysis was done in scan mode using MSD Chemstation software, data (Table 1) and total reducing sugars (Table 2). Earlier re-

the mass spectrometer scanned masses from 48 to 400 m/z ported studies on the Saccharomyces cerevisiae strains SCP

at a rate of 3.41 scan/s. Peak identification was carried out by and SCThas alcohol content of 10 % and 11 % respectively

comparison of the volatile sample mass spectra with spectra in ( S. Arauja, 2011). Torres Neto, 2006 reported an alcohol con-

the NIST Mass Spectral Database. tent of 11.5% in the fermented cashew apple wine inoculated

with S. cerevisiae, used in bread making, with two stages of

Results and Discussion must enrichment, while in another study conducted by (Garru-

Many tropical fruits such as mango, jackfruit, banana and ti, 2006) reported a lower alcohol content (8.5%) in cashew

cashew apple have been shown to be suitable for fermenta- apple wine obtained with the S. bayannus strain. In addition

tion, mainly because of their appropriate taste, flavor, avail- to the above data, it was observed that during the maturation

7 | PARIPEX - INDIAN JOURNAL OF RESEARCH

Volume : 4 | Issue : 3 | Mar 2015 ISSN - 2250-1991

and stabilization period of cashew apple wine, the parameters Apart from its nutritional value cashew apples in India were

such as dry matter content, soluble solids, and pH suffered mi- considered as a major waste, lack of processing technolo-

nor variations between the two products at the end of 168 gies and market campaigning is the most definite reason for

h of fermentation (Table 1). The yield calculated from alcohol the wastage. Except fenny and pectin those are the main

production following the procedure described by Hang et al. cashew apple products produced in India. Wine from cash-

(Hang, 1981) was 92.30 % for the product inoculated with ew apple juice would be a better option to develop as value

NCIM 3311 strain of S. cerevisiae, while in case of strain NCIM added product. In present study the cashew apple wines ob-

3282 it was observed 76.92 %. tained with both strains of NCIM 3282 and NCIM 3311 are

characterized as mild, less structured, and of adequate flavor.

The fermented beverages produced with cashew apple juice Among the two strains NCIM 3282 and NCIM 3311 of S. cer-

inoculated with NCIM 3282 strain had a yield of about 76.30 evisiae tried in this work for the preparation of cashew ap-

% and its productivity rate was 0.47 g l-1h-1, which is compar- ple wines, the strain NCIM 3311 was found to be better and

atively lower than the beverages obtained by the usage of the more efficient for alcohol production than the wine ferment-

NCIM 3311 strain.The titratable acidity of cashew apple wines ed by NCIM 3282 strain. The kinetic study of principal volatile

was 76.8 and 71.65in the wines obtained byusing strain NCIM compounds such as major alcohols and volatile acids present

3311 and NCIM 3282 of S. cerevisiae, respectively,which in cashew apple wine marks promising flavour and aroma

demonstrates that the fermented cashew apple winesobtained profile of wine. Cashew wine, prepared by fermentation of

in this work had a medium total acidity whencompared to dry, cashew apple juice using S. cerevisiae NCIM 3311, would be

red and white grape wine. This analysis is quite relevant since, another good prospect for the alcoholic beverage industry.

in general, the lower concentrations of total acidity in red However, more research may be conducted to find out the

andwhite wines results in attributes of soft wines with more- method forreduction of tannin concentration in cashew apple

structure and more complex aromas (Tsukatani, 2003). must and, consequently, inwine to minimize the astringent fla-

vor

Kinetic changes of selected volatiles during fermentation

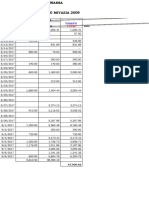

During the fermentation, the yeasts along with presence of Table 1.Physicochemical characters of a cashew apple

some non-saccharomyces yeast during fermentation released juice fermented with two strains (NCIM 3282 and NCIM

secondary products such as higher alcohols, esters, acids and 3311) of S. cerevisiae

carbonyl compounds in general mixed culture helps in produc-

ing a wider range and higher amounts of volatiles than the Fermenta- Wine from strain 3282 Wine from strain 3311

tion (h)

pure cultures. Among the principal chemical classes represent-

ing aroma of fermented products, alcohols was the group that Soluble Dry Soluble Dry

contributed to a larger number of constituents. The so called solids pH extract solids pH extract

“higher alcohols” are formed from the metabolism of amino (Brix) (g l-1) (Brix) (g l-1)

acids present in wine or resulting from degradation of protein

from yeast cells (Rodriguez-Amaya, 2004). When these are 0.0 26.0 4.01 25.29 26.0 4.01 30.13

present in wine, they contribute positively to the aroma char-

acterization of the drink, but when they are present at levels 24.0 23.0 3.70 21.33 22.0 3.80 25.33

greater than 400 mgl-1 they characterize for an unpleasant

odor and may detract from the overall quality of the beverage 48.0 20.0 3.70 19.28 18.0 3.80 19.06

(Rapp, 1979). Ethanol, isobutyl alcohol (2-methyl-1-propanol),

72.0 17.0 3.60 18.84 12.0 3.60 16.75

isoamyl alcohol (3-methyl-1-butanol) and 2-phenylethanol

were the major alcohols produced during the cashew apple 96.0 14.0 3.60 18.15 9.0 3.60 10.18

juice fermentation. The kinetic changes of the alcohols were

varied among the cultures, whereas the final amounts of al- 120.0 9.0 3.60 17.33 5.0 3.60 10.09

cohols at day 168h varied significantly with the S. cerevisiae

3311 constantly producing the higher amounts of each type 144.0 9.0 3.50 16.31 5.0 3.60 08.59

of alcohols except for phenylethyl alcohol compared with S.

cerevisiae 3282. While S. cerevisiae 3282 produced signifi- 168.0 9.0 3.50 15.27 3.0 3.60 05.50

cantly greater amount of phenyl ethyl alcohol compared with

NCIM 3311 (Fig. 2). Table 2Physico chemicalt parameters of cashew apple juice

and wine elaborated with S. cerevisiae strains (NCIM3282

The profile of production and degradation of fatty acids of and NCIM 3311).

C2 to C8 was similar in both the fermentation except for hex-

anoic and heptanoic acids in S. cerevisiae 3282. Butyric and Characteristics Must without S. cerevisiae

inoculum strain

hexanoic acids present at relatively high concentrations in

the juice were utilized during fermentation to trace levels by NCIM 3311 NCIM 3282

both cultures. For the yeast cultures, acid formation and uti-

lization trends are similar S. cerevisiae 3311while S. cerevisiae

3282 showed better production of heptanoic acid (Enanthic pH 4.2±0.00 3.6±0.00 3.5±0.00

acid) which is also known as wine oil. Esters developed from

the acid during aging process add to the varital aroma of the Soluble solids 26.00± 0.00 3.2±0.00 5.2±0.00

wine. Acetic acid was constantly produced throughout the fer-

mentation with S. cerevisiae 3311 and S. cerevisiae 3300high- Dry Matter 29.68±0.23 6.52±0.02 16.51±0.12

est amount of acetic acid (Fig. 3). Non-Saccharomyces yeasts

have been associated with high acetic acid production, thus, Total reducing 119.21± 0.00

sugar 6.05±0.25 14.87±0.50

are considered as spoilage yeasts (Pretorius, 2000). They are

also important as precursors for esters formation during ag-

ing (Amerine, 1983). Cashew apple fruit is rich in amino ac- Protein 0.43±0.00 NR 0.02±0.00

ids such as alanine, serine, leucine, pH, phenylalanine, proline,

glutamic acid, tyrosine, and aspartic acid. The aromatic phenyl Nitrogen 0.007±0.05 NR NR

ethyl alcohol detected in this study could be derived from the

amino acid phenylalanine. The presence of this compound is Total acidity 3.61±0.00 76.8±0.00 71.65±2.5

important as it is known to impart herbaceous aroma in the

fermented beverages (Garruti, 2006).

Alcohol NR 12.00±0.00 10.00± 0.00

Conclusion

8 | PARIPEX - INDIAN JOURNAL OF RESEARCH

Volume : 4 | Issue : 3 | Mar 2015 ISSN - 2250-1991

Fig. 2 Changes in alcohol in cashew wine during fermen-

Fig.1 a) Evolution of yeast as a viable cell count and b) tationwith S. cerevisiae 3282 ( ),and S. cerevisiae 3311( )

Brix changes in cashew wine during fermentation with S. a) Ethanol, b) Isobutyl alcohol, c) Isoamyl alcohol and d)

cerevisiae 3282 ( ), S. cerevisiae 3311 ( ) Phenylethyl alcohol

9 | PARIPEX - INDIAN JOURNAL OF RESEARCH

Volume : 4 | Issue : 3 | Mar 2015 ISSN - 2250-1991

Fig. 3 Changes in volatile acids in cashew wine during fer-

mentationwith S. cerevisiae 3282 ( ), and S. cerevisiae 3311

( ) a) Acetic acid, b) Butyric acid, c) Hexanoic acid and d)

Heptanoic acid

REFERENCES

Amerine, M. A., Roessler, E. B. (1983) Wines—their sensory evaluation. W.H. Freeman, New York | Analysis of the Association of Official Analytical Chemists AOAC (2000)

17th edition, Arlington, VA, AOAC International | Araujo, S. M., Silva,F. C., Moreria, S. S. J., Narendra, N., Soura, R. R. (2011) Biotechnological process for obtaining new

fermented products from cashew apple fruit by Saccharomyces cerevisiae strains, Journal of Industrail Microbiology Biotechnology,38, 1161–1169. DOI 10.1007/s10295-

010-0891-6 | Attri, B. L. (2009) Effect of initial sugar concentration on the physicochemical characteristics and sensory qualities of cashew apple wine. Natural Product Radi-

ance. 8:374–379 | Chen, Y., Begnaud, F., Chaintreau, A., Pawliszyn, J. (2006). Quantification of perfume compounds in shampoo using solid-phase microextraction. Flavour

Fragrance Journal. 21, 822-832. DOI: 10.1002/ffj.1734 | | de Figueiredo, R. W., Lajolo, F. M., Alves, R. E., Filgueiras, H. A. C. (2002) Physical-chemical changes in early dwarf

cashew pseudo fruits during development and maturation. Food Chemistry, 77 (3), doi: 10.1016/S0308-8146(01)00358-2 | Garruti, D. S., Franco, M. R. B., da Silva M. A. A.

P., Janzantti, N. S., Alves, G. L. (2003) Evaluation of volatile flavour compounds from cashew apple (Anacardium occidentale L.) juice by the Osme gas chromatography/ol-

factometry technique. Journal of Science of Food Agriculture, 83,1455–1462. DOI: 10.1002/jsfa.1560 | Hang, Y. D., Lee, C. Y., Woodams, E. E. (1981) Production of alcohol

from apple pomace. Applied Environmental Microbiology, 42(6), 1128–1132. doi 0099-2240/81/121128-02$02.00/0 0099-2240/81/121128-02$02.00/0 | Lambrechts, M.

G., Pretorius, I. S. (2000) Yeasts and its importance to wine aroma- a review. South African Journal of Enology Viticulture. 21:97–129 | Maciel, M. I., Hansen, T. J., Aldinger,

S. B., Laboes J. N. (1986) Flavor chemistry of cashew apple juice. Journal of Agriculture and Food Chemistry, 34 (5), 923–927. DOI: 10.1021/jf00071a039 | Mandal, R. C.,

Dhandar, D. G., Dhume, C. V. (1985) Cashew apple liquorindustry in Goa.ActaHorticulturae (ISHS), 108:172–175 | Michodjehoun-Mestres, L., Souquet, J. M., Fulcrand, H.,

Bouchut, C., Reynesa, M., Brillouet, J. M. (2009) Monomeric phenols of cashew apple (Anacardium occidentale L.). Food Chemistry, 112 (4), 851-857. doi:10.1016/j.food-

chem.2008.06.056 | Muniz, C. R., Borges, M. D. F., Freire, F. D. C. O. (2006) Tropical and subtropical fruit fermented beverages. In Microbial Biotechnology in Horticulture

Vol. 2; (R.C. Ray and O.P. Ward, eds.), in press, Science Publishers, Enfield, NH. | Onwuka, U. N., Awam, F. N. (2001) The potential for baker’s yeast (Saccharomyces cerevisiae)

in the production of wine from banana, cooking banana and plantain. Food Service Technology. 1 (3-4), 127–132. DOI: 10.1046/j.1471-5740.2001.00027.x | Rapp. A.,

Knipser, W. (1979) 3,7-Dimethyl-okta-1, 5-dien-3, 7-diol EineneueterpenoideVerbindung des Trauben-und Wein aromas. Vitis 18:229–233 | Talasila, U., Khan, K. B. (2012)

Quality, spoilage and preservation of cashew apple juice: A review, Journal of Food Science and Technology, DOI 10.1007/s13197-013-0931-0 | Torres Neto, A. B., Silva, M.

E., Silva, W. B., Swarnakar, R., Silva F. L. H. (2006) Cinética e caracterizaçãofísico-química do fermentado do pseudofruto do caju (Anacardium occidentale L.). Quim Nova

29(3):489–492. doi:10.1590/S0100-40422006000300015 | Tsukatani, T., Miwa, T., Furukawa.M., Costanzo, R. C. (2003) Detection thresholds for phenyl ethyl alcohol using

serial dilutions in diVerent solvents. Chemical Senses 28 (1) 25–32. doi: 10.1093/chemse/28.1.25 | Ward, O. P., Ray, R. C. (2006) Microbial biotechnology in horticulture – an

overview. In Microbial Biotechnology in Horticulture Vol. 1; (R.C. Ray and O.P. Ward, eds.), in press, Science Publishers, Enfield, NH. |

10 | PARIPEX - INDIAN JOURNAL OF RESEARCH

You might also like

- Wine FollyDocument483 pagesWine Folly刘舒33% (3)

- Jarelin Huayta Practice N5 Too-Too-Much-Too-Many-Not-EnoughDocument2 pagesJarelin Huayta Practice N5 Too-Too-Much-Too-Many-Not-EnoughJarelin Huayta Puente de la VegaNo ratings yet

- (Cooking) Brew - Your.own. .150.classic - Clone.recipes. .2006Document84 pages(Cooking) Brew - Your.own. .150.classic - Clone.recipes. .2006Gaspar CurettiNo ratings yet

- 478 2011-CJFSDocument10 pages478 2011-CJFSRichardValenciaNo ratings yet

- Reaction Kinetics of Physico-Chemical Attributes in Coconut Inflorescence Sap During FermentationDocument9 pagesReaction Kinetics of Physico-Chemical Attributes in Coconut Inflorescence Sap During FermentationElena ContrerasNo ratings yet

- Evaluation of Set Yoghurt Quality Enhanced With Selected Indigenous FruitsDocument10 pagesEvaluation of Set Yoghurt Quality Enhanced With Selected Indigenous FruitsEditor IJTSRDNo ratings yet

- Comparative Evaluation of The Proximate Composition and Antioxidant Properties of Processed Products of Quince (Cydonia Oblonga Miller)Document6 pagesComparative Evaluation of The Proximate Composition and Antioxidant Properties of Processed Products of Quince (Cydonia Oblonga Miller)MayZi MayZiNo ratings yet

- Studies On Preparation of Custard Apple VinegarDocument6 pagesStudies On Preparation of Custard Apple VinegarIJAERS JOURNALNo ratings yet

- DEVELOPMENT AND QUALITY EVALUATION OF KIWI-APPLE in WordDocument4 pagesDEVELOPMENT AND QUALITY EVALUATION OF KIWI-APPLE in WordRanjan KarkiNo ratings yet

- NPR 8 (4) 374-379Document6 pagesNPR 8 (4) 374-379Kiều ChâuNo ratings yet

- Fermentasi Air KelapaDocument10 pagesFermentasi Air Kelapapebrian sahputraNo ratings yet

- Fed-Batch Alcoholic Fermentation of Palm Juice (Arenga Pinnata Merr) : Influence of The Feeding Rate On Yeast, Yield and ProductivityDocument5 pagesFed-Batch Alcoholic Fermentation of Palm Juice (Arenga Pinnata Merr) : Influence of The Feeding Rate On Yeast, Yield and ProductivityindriNo ratings yet

- Production and Characterization of Wine From MangoDocument7 pagesProduction and Characterization of Wine From MangoRichardValenciaNo ratings yet

- IOP Conf VinegarDocument9 pagesIOP Conf VinegarJuniawatiNo ratings yet

- Assessment of The Nutritional Profile of Variable Graded Levels of Julie Mango Fruit Juice Flavoured Yoghurt and Plain YoghurtDocument7 pagesAssessment of The Nutritional Profile of Variable Graded Levels of Julie Mango Fruit Juice Flavoured Yoghurt and Plain YoghurtInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- J Fbio 2020 100591Document40 pagesJ Fbio 2020 100591phamgiang29032002No ratings yet

- Akan 6Document5 pagesAkan 6siboyif881No ratings yet

- Pineapple PDFDocument7 pagesPineapple PDFDestia AyuNo ratings yet

- Buckwheat Flour Proteins Are Safe For Coeliac Patients: Hurdle Technology Preserve Fruit ChunksDocument0 pagesBuckwheat Flour Proteins Are Safe For Coeliac Patients: Hurdle Technology Preserve Fruit ChunksProf C.S.PurushothamanNo ratings yet

- Production of Banana Alcohol and UtilizaDocument5 pagesProduction of Banana Alcohol and UtilizaSambridhi DhakalNo ratings yet

- Study of Some Physicochemical and Functional Properties of Quinoa (Chenopodium Quinoa Willd) Protein IsolatesDocument6 pagesStudy of Some Physicochemical and Functional Properties of Quinoa (Chenopodium Quinoa Willd) Protein IsolatesHoracio GorosteguiNo ratings yet

- Process Standardization, Characterization and Storage Study of A Sweet Potato (Ipomoea Batatas L.) WineDocument8 pagesProcess Standardization, Characterization and Storage Study of A Sweet Potato (Ipomoea Batatas L.) WinePrasanna KumarNo ratings yet

- Quality Assessment of Water Melon (Citruluslanatus) Wine Produced Using Saccharomyces Cerevisiae Isolated From Palm WineDocument9 pagesQuality Assessment of Water Melon (Citruluslanatus) Wine Produced Using Saccharomyces Cerevisiae Isolated From Palm WineTường Vy Lê NguyễnNo ratings yet

- Antioxidant Property and Total PolyphenoDocument8 pagesAntioxidant Property and Total PolyphenoRyan RetortaNo ratings yet

- The Influence of Process Optimization On The Fermentation Profile of Mango Wine Prepared From The Apple Mango VarietyDocument8 pagesThe Influence of Process Optimization On The Fermentation Profile of Mango Wine Prepared From The Apple Mango VarietyMeng HeangNo ratings yet

- The Making of Pomegranate Wine Using Yeast Immobilized On SoDocument6 pagesThe Making of Pomegranate Wine Using Yeast Immobilized On SoNguyenThaiAnhNo ratings yet

- 6 Ijasrjun20196Document8 pages6 Ijasrjun20196TJPRC PublicationsNo ratings yet

- Production of Fermented Fruit Juice and Value Addition by Blending Medicinal PlantsDocument3 pagesProduction of Fermented Fruit Juice and Value Addition by Blending Medicinal Plantsirene abadNo ratings yet

- Original Article Elaboration of A Fruit Wine From Cocoa (Theobroma Cacao L.) PulpDocument11 pagesOriginal Article Elaboration of A Fruit Wine From Cocoa (Theobroma Cacao L.) PulpWilliam Rolando Miranda ZamoraNo ratings yet

- 1 1 17.1 PDFDocument4 pages1 1 17.1 PDFCamila CobosNo ratings yet

- Artikel 3 EngDocument8 pagesArtikel 3 EngAndri PratamaNo ratings yet

- Nutrition Vol10 No3 918-927Document10 pagesNutrition Vol10 No3 918-927Mustaqim AbubakarNo ratings yet

- Citric Acid Production by Koji Fermentat PDFDocument5 pagesCitric Acid Production by Koji Fermentat PDFtuti lestariantiNo ratings yet

- 4 MangopaperDocument5 pages4 MangopaperMunaza Binte ayubNo ratings yet

- 16archibonghezemba2015winefrommixedfruitarticle Wjpps 1438352725Document12 pages16archibonghezemba2015winefrommixedfruitarticle Wjpps 1438352725karen marie dela pasionNo ratings yet

- Optimization of Vinegar Production From Nipa (Nypa Fruticans Wurmb.) Sap Using Surface Culture Fermentation ProcessDocument8 pagesOptimization of Vinegar Production From Nipa (Nypa Fruticans Wurmb.) Sap Using Surface Culture Fermentation ProcessevanyllaNo ratings yet

- Kelompok 1 - JurnalDocument5 pagesKelompok 1 - JurnalreniNo ratings yet

- BBRAV11SplEditionP187 192Document6 pagesBBRAV11SplEditionP187 192Dava ErwinNo ratings yet

- Production of Bioethanol From Fruit Rinds by Saccharification and Fermentation PDFDocument4 pagesProduction of Bioethanol From Fruit Rinds by Saccharification and Fermentation PDFVon Russel SaringNo ratings yet

- Valorization of Pineapple Produced in Benin: Production and Evaluation of Wine Quality ParametersDocument11 pagesValorization of Pineapple Produced in Benin: Production and Evaluation of Wine Quality ParametersNghiaNguyenNo ratings yet

- Cultivo de PitayaDocument7 pagesCultivo de PitayaNando FranklinNo ratings yet

- Kombinasi Kalum Metabisulfat Dan Natrium Benzoat Pada Jus MulberiDocument5 pagesKombinasi Kalum Metabisulfat Dan Natrium Benzoat Pada Jus MulberiMaulidanty ParahitaNo ratings yet

- Lab Journal 520Document3 pagesLab Journal 520eimanfatima79No ratings yet

- Physicochemical Analysis of Jam Preparations From Watermelon WasteDocument4 pagesPhysicochemical Analysis of Jam Preparations From Watermelon WasteHamada AhmedNo ratings yet

- Production of Biofuel From Fruits and Vegetable WastesDocument5 pagesProduction of Biofuel From Fruits and Vegetable WasteslimyungchiNo ratings yet

- Use of Additives To Reduce Browning PDFDocument11 pagesUse of Additives To Reduce Browning PDFnhidinh97No ratings yet

- Production and Optimization of Citric Acid by Aspergillus Niger Using Fruit Pulp WasteDocument6 pagesProduction and Optimization of Citric Acid by Aspergillus Niger Using Fruit Pulp WasteYesenia YsabelNo ratings yet

- Phenolic Compounds and Carotenoids in Pumpkin Fruit and Related Traditional ProductsDocument5 pagesPhenolic Compounds and Carotenoids in Pumpkin Fruit and Related Traditional Productschaima rekikNo ratings yet

- BBRC28 016Document6 pagesBBRC28 016Cristina AgustinNo ratings yet

- Extraction of Saba Banana PeelDocument7 pagesExtraction of Saba Banana PeelRameg EtakNo ratings yet

- 25f3 PDFDocument9 pages25f3 PDFJäymär M. IlägänNo ratings yet

- Characterization of Pomegranate Juice and Whey Based Novel Beverage Fermented by KefirDocument8 pagesCharacterization of Pomegranate Juice and Whey Based Novel Beverage Fermented by KefirAzzabad LizarazuNo ratings yet

- ISFAS 2012-SukirahDocument4 pagesISFAS 2012-SukirahSukirah Abdul RahmanNo ratings yet

- Happiemaga2008 PDFDocument9 pagesHappiemaga2008 PDFGabriel FigueroaNo ratings yet

- Effect of Storage Temperature On Physicochemical and Sensory Evaluation of Kinnow Mandarin Juice Blends 2157 7110.1000361Document4 pagesEffect of Storage Temperature On Physicochemical and Sensory Evaluation of Kinnow Mandarin Juice Blends 2157 7110.1000361Asif MerajNo ratings yet

- Technology Development of "Gac" Fruit (Momordica Cochinchinensis) NectarDocument7 pagesTechnology Development of "Gac" Fruit (Momordica Cochinchinensis) NectarPham Thi Cam TuNo ratings yet

- Volume1 2006 3Document12 pagesVolume1 2006 3khearize.allagaNo ratings yet

- Isolation and Identification of Anaerobic Yeasts and Bacteria From Weasel Coffee For Cellulase and PectinaseDocument6 pagesIsolation and Identification of Anaerobic Yeasts and Bacteria From Weasel Coffee For Cellulase and PectinaseNgoc Hanh NguyenNo ratings yet

- Utilization of Mango Peels and Seed Kernels Powders As Sources of Phytochemicals in BiscuitDocument8 pagesUtilization of Mango Peels and Seed Kernels Powders As Sources of Phytochemicals in BiscuitbarenakedearthNo ratings yet

- Haile, 2019Document16 pagesHaile, 2019hasska028No ratings yet

- Pushpa Parihar, Et AlDocument11 pagesPushpa Parihar, Et AlSanju Chandu100% (1)

- Starter Cultures in Food ProductionFrom EverandStarter Cultures in Food ProductionBarbara SperanzaNo ratings yet

- GRN SIV BAR Milk Products Date: Today'SDocument7 pagesGRN SIV BAR Milk Products Date: Today'SStephen WillingtonNo ratings yet

- Bar and Beverage ReviewerDocument12 pagesBar and Beverage ReviewerGrazokryNo ratings yet

- Digital Menu Ib347423122022Document1 pageDigital Menu Ib347423122022pavli999No ratings yet

- Selling Skill TechniquesDocument29 pagesSelling Skill TechniquesMassa Putro100% (1)

- La Brisa NEW Drink Menu 2022Document10 pagesLa Brisa NEW Drink Menu 2022Z ONo ratings yet

- JAP189 Essay 8Document7 pagesJAP189 Essay 8Lutfi DimasNo ratings yet

- Common Man Night Shift Menu Sep23Document13 pagesCommon Man Night Shift Menu Sep23tanmabel16No ratings yet

- Black Books S1e5 ScriptDocument6 pagesBlack Books S1e5 Scriptslickguy191No ratings yet

- Gluten Free FoodsDocument14 pagesGluten Free FoodsDWOZ PUBG - Mobile100% (1)

- Muttis Drink ListDocument3 pagesMuttis Drink ListphgaoNo ratings yet

- F & B UC and ElementsDocument3 pagesF & B UC and ElementsRaes TaganileNo ratings yet

- BAV Christmas Catalogue 2020Document22 pagesBAV Christmas Catalogue 2020alexdrinkscraftsakeNo ratings yet

- AMC Corporate Gifts & HampersDocument15 pagesAMC Corporate Gifts & HampersnikoulisNo ratings yet

- New Text DocumentDocument2 pagesNew Text Documentszabomark00No ratings yet

- Solstice Shenanigans (v2) PDFDocument22 pagesSolstice Shenanigans (v2) PDFNo GunNo ratings yet

- 101 Most Popular CocktailsDocument37 pages101 Most Popular CocktailsUjjwol ShiwakotiNo ratings yet

- Certified Sommelier Exam Guide & What To ExpectDocument32 pagesCertified Sommelier Exam Guide & What To Expectvinaytiwarirkt29No ratings yet

- Alcohol and Alcohol-Related Problems in Caraka SamhitaDocument14 pagesAlcohol and Alcohol-Related Problems in Caraka SamhitaAshu SinghNo ratings yet

- PP Poultry Dishes 1 QuizDocument14 pagesPP Poultry Dishes 1 QuizVienice AllanaNo ratings yet

- The Irish ExpressionsDocument3 pagesThe Irish ExpressionsgiercejjenowskiNo ratings yet

- Carbonated Fermented Dairy Drink - Effect On Quality and Shelf LifeDocument7 pagesCarbonated Fermented Dairy Drink - Effect On Quality and Shelf LifeОскар ЛинаресNo ratings yet

- COLLIER - The-ChaserDocument3 pagesCOLLIER - The-ChaserJuan RizzoNo ratings yet

- Inventario 18-15-19Document12 pagesInventario 18-15-19auraespaillatNo ratings yet

- Frequency AdverbsDocument2 pagesFrequency AdverbsCarlos Díaz RomeroNo ratings yet

- "ARTOS From AP": Rangasthalam', A Telugu Movie Which Hit The Theatres in 2018 Reminded Us of Our FavouriteDocument4 pages"ARTOS From AP": Rangasthalam', A Telugu Movie Which Hit The Theatres in 2018 Reminded Us of Our FavouriteKiran KumarNo ratings yet

- General Accounting Principles Part 3Document9 pagesGeneral Accounting Principles Part 3AmitKumarNo ratings yet

- Ginger Ale Verses BeerDocument9 pagesGinger Ale Verses BeerSwami AbhayanandNo ratings yet