Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

286 viewsTDS - Sika Igolflex-160 QA PDF

TDS - Sika Igolflex-160 QA PDF

Uploaded by

Jamsheed Ap KadangodCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Risk Assessment For Polyurea Waterproofing WorksDocument11 pagesRisk Assessment For Polyurea Waterproofing WorksJamsheed Ap Kadangod100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MS - Sikacrete 114 QA PumpingDocument13 pagesMS - Sikacrete 114 QA PumpingJamsheed Ap Kadangod100% (1)

- Method Statement: Sikagrout®-214 QaDocument12 pagesMethod Statement: Sikagrout®-214 QaJamsheed Ap KadangodNo ratings yet

- Method Statement Floor and Speciality JointsDocument10 pagesMethod Statement Floor and Speciality JointsJamsheed Ap KadangodNo ratings yet

- Sikadur® - Combiflex® SG: Method Statement For Application ofDocument11 pagesSikadur® - Combiflex® SG: Method Statement For Application ofJamsheed Ap KadangodNo ratings yet

- Con Stru Ctio N: Sikacrete - Gunit 105Document3 pagesCon Stru Ctio N: Sikacrete - Gunit 105Jamsheed Ap KadangodNo ratings yet

- Dew Point Temperature (°C) : Relative Air Humidity (%)Document2 pagesDew Point Temperature (°C) : Relative Air Humidity (%)Jamsheed Ap Kadangod100% (1)

- Sika Crack Injection Method Statement v4 2021Document19 pagesSika Crack Injection Method Statement v4 2021Jamsheed Ap KadangodNo ratings yet

- Sika Igolflex-160 QADocument66 pagesSika Igolflex-160 QAJamsheed Ap KadangodNo ratings yet

- Method Statement - Sika Antisol QADocument6 pagesMethod Statement - Sika Antisol QAJamsheed Ap KadangodNo ratings yet

TDS - Sika Igolflex-160 QA PDF

TDS - Sika Igolflex-160 QA PDF

Uploaded by

Jamsheed Ap Kadangod0 ratings0% found this document useful (0 votes)

286 views2 pagesOriginal Title

TDS_Sika Igolflex-160 QA.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

286 views2 pagesTDS - Sika Igolflex-160 QA PDF

TDS - Sika Igolflex-160 QA PDF

Uploaded by

Jamsheed Ap KadangodCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

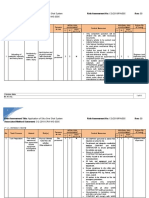

Provisional Product Data Sheet

Eaition: 08/2018

Identification no: QA

PHN:

Sika” igolfiex®160 QA

Sika® Igolflex®-160 QA

Rubberized Bituminous Waterproofing Emulsion

Product Sika” Igofiex®-160 QA, also known as Igasol” Emulsion BA-10, is a rubberizes

ti bituminous liquid emulsion with excellent adhesion which dries to a tough,

Description seamless, flexible, waterproof and vapour proof membrane for concrete structures.

Suitable for tropical and hot climatic conditions.

Uses "= Tanking and waterproofing of substructures to provide an impervious membrane

Vapour barter of cladded walls

"© Maintenance of many roof types including asphall-elt rofs, concrete, cement,

lightweight screeds, timber etc.

1 As an adhesive for bonding insulation boards, expanded polystyrene, cork tiles

at,

= Damp proof membrane for roofs and floor slabs

Efficient curing membrane to fresily laid concrete

Basements, retaining walls

Characteristics /

Advantages:

High rubber contont - 10%

Excellent adhesion to most building substrates

Reduced chloride penetration

‘Can be applied on damp substrates

Non sagging

Single component

Water based

Economical, easy to apply, reduces labour cost

‘Can be applied on vertical and horizontal areas

Impermeable to water

Elastic, seamless, joint free

Unaffected by high ambient temperature

Resistant to aggressive soils and contaminated ground water

Low odour, dries without generating strong vapour

Product Data

Chemical Base Blend of bitumen and rubber

‘Appearance /Golour Dark brown (liauid)

Black (dry)

Packaging 180 kg drums

Density ~ 1.03 kgil (25°C)

Solid content by weight ~35 % (10 9% rubber content)

‘Chemical Resistance Groundwater, salt solutions, sea water, mild detergents, mild acids and alkalis,

Contact Sika Technical Department for further information

Service Temperature -10 °C min. / +85 °C max.

@

Sia" goes" 12

Storage

Shelf Lite “12 months from date of production if stored properly

Storage Conditions ‘Sore in undamaged and unopened, orginal sealed packaging, n cool and dry

Conditions at temperatures between +5 °C and +35 °C. Protect from direct sunlight

and frost.

Application Information

‘Consumption (0.25 - 0.50 kgin™ per coat, apply 2-3 coats

‘This figure is theoretical and does not include for any additional material required

due to surface porosity, surface profile, variations in level and wastage ete

‘Ambient Air Temperature _+5 °C min, | +45 °C max

‘Substrate Temperature +5 "C min. +65 °C max.

Drying Time “Touch dry after ~1 h (#35 °C)

Waiting Time/ Minimum 4 h (#35 °C)

Overcoating

‘Applied Product Ready ~3 days (-25°C)

for Use

Substrate Preparation All surfaces must be sound, even, fee from dust, loose particles and any

contamination, May be applied to damp but not waterlogged surfaces,

Hot and very dry, porous concrete surfaces must be primed by diluting Sika®

Igolflex®-160 QA with clean water at 1 : 1 ratio (oy weight).

‘When used as protective coating ll pinholes, cavities, cracks etc. n the substrate

must be filed with a sutable Sika® repair mortar.

Mixing ‘Ska® Igollex®-160 GA must be sled well before use. Where a single dam is

Used for prolonged periods, occasional stiring during apalication is recommended.

Application Method / Ifa primer coat is applied, allow it to dry before applying subsequent coats.

Tools ‘Apply evenly and in one direction using a brush of rller. A two-coat application is

recommended to avoid possible pinnalos in the membrane. Each coat must be

allowed to dry before applying the next one.

Protect freshly applied product rom rain unl its fully cured.

‘leaning of Equipment Clean all equipment and tools with watorimmodiataly aftr uso.

Dampen tools before and occasionally during use to avid clogging and ease

application

Value Base ‘All echnical data stated in his Product Data Shoat aro based on laboratory tote

‘Actual measured data may vary due to circumstances beyond our contol

Local Restrictions Please note tat as a resul of specif focal regulations the performance of this

product may vary from country to country. Please consult the local Product Data

Sheet forthe exact description of the product uses.

Health and Safety Forinformaton and advice on the safe handing, storage and dsposal of chemical

products, users shall refer to the most recent Safety Data Sheet (SDS) containing

Information physical, ecological, toxicological and other safety-related data.

Legal Notes “The information, and, in particular, the recommendations relating to the application

and end-use of Sika products, are given in good fath based on Sika's currant

knowledge and experience of the products when properly store, handled and

applied under normal conditions in accordance with Sika's recommendations. In

practic, the differences in materials, substrates and actual site candlions are such

that no warrant in respect of merchantability or of fiess fora particular purpose,

ror any lablty sing out of ary legal lationship whatsoover, can be infertad

eithor from tis information, of from any written recommendations, of from any other

advice offered, The user of the product must test the products suitability forthe

intended application and purpose. Sika reserves the nght to change the properties

ofits products. The proprietary rights of third parties must be observed. Al orders

are accepted subject to our current terms of sale and dolivey, Users must always

refer tothe most recent issue ofthe local Product Data Sheet forthe product,

concomed, copes of which wil be supplied on request.

‘sha Geer LLC ‘lprosues are supped

Prone 4574 4016 3366 ‘toner an

@ Fae” Tapa tore 2370, ‘ervpatona Mea & sty

hepa shan. ‘Sandor 180 900

Pre owz0%8)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Risk Assessment For Polyurea Waterproofing WorksDocument11 pagesRisk Assessment For Polyurea Waterproofing WorksJamsheed Ap Kadangod100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MS - Sikacrete 114 QA PumpingDocument13 pagesMS - Sikacrete 114 QA PumpingJamsheed Ap Kadangod100% (1)

- Method Statement: Sikagrout®-214 QaDocument12 pagesMethod Statement: Sikagrout®-214 QaJamsheed Ap KadangodNo ratings yet

- Method Statement Floor and Speciality JointsDocument10 pagesMethod Statement Floor and Speciality JointsJamsheed Ap KadangodNo ratings yet

- Sikadur® - Combiflex® SG: Method Statement For Application ofDocument11 pagesSikadur® - Combiflex® SG: Method Statement For Application ofJamsheed Ap KadangodNo ratings yet

- Con Stru Ctio N: Sikacrete - Gunit 105Document3 pagesCon Stru Ctio N: Sikacrete - Gunit 105Jamsheed Ap KadangodNo ratings yet

- Dew Point Temperature (°C) : Relative Air Humidity (%)Document2 pagesDew Point Temperature (°C) : Relative Air Humidity (%)Jamsheed Ap Kadangod100% (1)

- Sika Crack Injection Method Statement v4 2021Document19 pagesSika Crack Injection Method Statement v4 2021Jamsheed Ap KadangodNo ratings yet

- Sika Igolflex-160 QADocument66 pagesSika Igolflex-160 QAJamsheed Ap KadangodNo ratings yet

- Method Statement - Sika Antisol QADocument6 pagesMethod Statement - Sika Antisol QAJamsheed Ap KadangodNo ratings yet