Professional Documents

Culture Documents

Dimension Specification: Hyundai Heavy Industries

Dimension Specification: Hyundai Heavy Industries

Uploaded by

Александр ОлейникOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimension Specification: Hyundai Heavy Industries

Dimension Specification: Hyundai Heavy Industries

Uploaded by

Александр ОлейникCopyright:

Available Formats

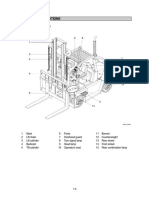

Dimension Specification

Identification

1.1 Manufacturer HYUNDAI

1.2 Manufacturer's type designation 15BT-9 18BT-9 20BT-9

1.3 Drive : electric (battery or mains), diesel, petrol, fuel gas, manual Electric Electric Electric

1.4 Type of operation : hand, pedestrian, standing, seated, order-picker Seated Seated Seated Electric Counterbalance Trucks

1.5 Load capacity / rated load Q kg 1,500 1,800 2,000

1.6 Load center distance c mm 500 500 500

1.8 Load distance, center of front axle to fork x mm 360 360 365

1.9 Wheelbase y mm 1335 1,420 1,420

Weights hyundai heavy industries

2. 1 Service weight kg 3,125 3,365 3,500

2. 2 Axle loading, loaded front / rear kg 4,127 / 498 4,600 / 565 4,900 / 600

2. 3 Axle loading , unloaded front / rear kg 1,661 / 1,464 1,710 / 1,655 1,684 / 1,816

Wheels, Chassis

3. 1 Tires : solid rubber(V), superelastic(SE), pneumatic(P), polyurethane(PE) SE SE SE

h4

3. 2 Tires size, front(Φ x width) 18 x 7-8 200 / 50-10 200 / 50-10

3. 3 Tires size, rear(Φx width ) 15 x 4.5-8 15 x 4.5-8 15 x 4.5-8

h3

3. 5 Wheels, number front rear(x = driven wheels) 2 x /2 2 x /2 2 x /2

h5

3. 6 Track width, front mm 895 905 905

h1

3. 7 Track width, rear mm 170 170 170

c Basic Dimensions

h7

4.1 Mast / fork carriage tilt forward / backward degrees 5/7 5/7 5/7

h4

4.2 Lowered mast height h1 mm 1,970 1,979 1,979

h2

h10

4.3 Free lift height h2 mm 35 35 40

m2

4.4 Lift height h3 mm 3,300 3,300 3,300

m1

S

h3

l x y

l2 4.5 Extended mast height h4 mm 4,020 4,020 4,020

h5

h1

l1

4.7 Overhead guard (cab) height h5 mm 2,065 2,065 2,065

4.8 Seat height / Standing height h7 mm 927 927 927

c

4.12 Coupling height h10 mm 410 410 410

h7

4.19 Overall length l1 mm 2,785 2,875 2,910

h2

4.20 Length to face of forks l2 mm 1,885 1,975 2,010

h10

Wa

m2

4.21 Overall width b1 mm 1,074 1,105 1,105

m1

S

l x y 4.22 Fork dimensions l / e / s mm 900 x 100 x 35 900 x 100 x 35 900 x 100 x 40

l2

l1

4.23 Fork carriage ISO 2328, class / type A, B 2A 2A 2A

4.24 Fork - carriage width b3 mm 980 980 980

e

4.31 Ground clearance, loaded, under mast m1 mm 85 94 94

b3

b1

4.32 Ground clearance, centre of wheelbase m2 mm 90 90 100

4.33 Aisle width for pallets 1,000 x 1,200 crossways Ast mm 3,226 3,316 3,351

4.34 Aisle width for pallets 800 x 1,200 lengthways Ast mm 3,350 3,440 3,475

Wa

4.35 Turning radius Wa mm 1,540 1,630 1,660

Performance Data

5.1 Travel speed, loaded/ unloaded km/h 16 / 17 16 / 17 16 / 17

Ast

e

5.2 Lift speed, loaded/ unloaded mm/s 410 / 600 410 / 600 410 / 600

b3

b1

5.3 Lowering speed, loaded/unloaded mm/s 500 / 450 500 / 450 500 / 450

5.6 Max. drawbar pull, loaded/ unloaded S2 5min N 15,102 / 14,759 15,190 / 14,710 14,367 / 14,043

5.8 Max. gradient performance, loaded S2 5min % 29.5 27.5 24.5

5.10 Service brake Hydraulic Hydraulic Hydraulic

E - Motor

6.1 Dirve motor rating S2 60min kW 4.7x2 4.7x2 4.7x2

Ast

6.2 Lift motor rating at S3 20%(S2 10min) kW 14.0 14.0 14.0

6.4 Battery voltage, nominal capacity K5 V/Ah 48 / 510 48 / 585 48 / 585

6.5 Battery weight (Min.) kg 710 835 835

Battery compartment dimensions l/w/h mm 983 / 553 / 636 983 / 638 / 636 983 / 638 / 636

Other Details

8.1 Type of drive control AC AC AC

PLEASE CONTACT

Head Office (Sales Office)

14th Fl., Hyundai Bldg. 75, Yulgok-ro, Jongno-gu, Seoul 110-796, Korea

TEL (82) (2) 746-4609, 4753 / FAX (82) (2) 746-7444, 7445

Americas Operation : Hyundai Construction Equipment Americas, Inc.

6100 ATLANTIC BOULEVARD NORCROSS GA 30071 U.S.A

TEL (1) 847-678-823-7802 / FAX (1) 847-678-823-7778

Europe Operation : Hyundai Heavy Industries Europe N.V.

VOSSENDAAL 11, 2440 GEEL, BELGIUM

TEL (32) 14-56-2200 / FAX (32) 14-59-3405 www.hyundai-ce.com 2013. 10 Rev. 0

Your satisfaction is Compact forklift with proven AC technology

our priority!

• Maximum performance

• Comfortable operating room

• Battery side loading system

Hyundai introduces a new line of 9-series battery forklift trucks. • Curve control system

The newly designed 3 wheel counterbalance trucks provide every operator • Fingertip controlled mini levers available (optional)

comfortable driving, increased productivity and easy maintenance. • Weight indicator (optional)

• Safety system that prevents over loading (optional)

Some of the photos may include optional equipment.

02 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 03

High Efficiency & Efficient, smooth running and compact design

provide you with enhanced performance and

Optimal Performance highest productivity.

More efficient operating control levers (Optional)

Electronic directional control and secondary horn are

mounted to the hydraulic lift lever for quick and Curve control

precise maneuvering. Curve Control limits travel speed based

on turning radius, reducing speed for a

smooth, precise turning operation for

the driver.

Limit the

Driving Speed speed

Designed for compact aisle width and turning radius

The combination of 3-wheel design and dual drive motors

offer central pivot turning.

Finger tip control levers (Optional) Some of the photos may include optional equipment. Some of the photos may include optional equipment. This allows the driver to work in very confined spaces.

The finger tip control lever allows more precise control and fatigue-free working.

The ergonomically designed armrest can be adjusted up, down, forward and backward

for various operator’s body type.

Max. Gradeability (loaded) Max. Travel Speed (unloaded)

Model % Model km / h

15BT-9 29.5 15BT-9 17

18BT-9 27.5 18BT-9 17

20BT-9 24.5 20BT-9 17

Advanced drive and lift performance with Auto fork leveling system (Optional) Anti roll back system, travel speed and gradeability

proven durability and low maintenance In order to improve productivity the auto fork Anti Roll-back system offers protection against the machine

The enclosed drive and pump motor with AC technology combine power, leveling system will automatically stop the tilt rolling back on a ramp in combination with exceptional ramp

high maintenance intervals and excellent durability. movement when the mast is in a straight start capabilities.

The brushless AC motors offer improved efficiency and reduction maintenance cost. position.

04 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 05

Advanced Safety

The safely designed driver's space makes

your operating more comfortable.

Fork safety features

When the forks are being lowered, a down-control valve

maintains the controlled speed. The down-safety valve

prevents forks from dropping down in case of sudden

damage of hydraulic line.

OPSS(Operator Presence Sensing System)

When the operator is not in the seat all mast and drive

Some of the photos may include optional equipment.

Excellent visibility for safe operation movements are impossible.

Optimized lift cylinder arrangement provides operator with wider visibility. Lift Lock Tilt Lock Drive Lock

The panoramic mirror expands the driver’s view when backing up.

Some of the photos may include optional equipment.

Strong overhead guard Safety lamps & rear reflectors

Exceeding CEE and ANSI regulations, the overhead guard offers LED combination lights and halogen headlights offer the driver visibility in all circumstances.

great protection combined with excellent all around visibility. Rear reflectors mounted on the counterweight enhance safety for the driver and the application.

06 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 07

Optimised Ergonomics & An ideal arrangement of components

ensures easy access and convenience for

Fast and Easy Maintenance maintenance.

180O

Spacious operator cabin Some of the photos may include optional equipment.

Easy battery replacement Some of the photos may include optional equipment.

The BT is designed as a small, compact design, yet the operator compartment has The battery compartment is equipped with a side battery removal

ample room for virtually any operator. assembly for easy removal and replacement.

Optimized pedal position Advanced LCD Monitor

and floor mat The LCD color monitor with 3.5 inch graphic smart display allows

The position of accelerator and the operator to easily and efficiently control the machine.

throttle have been optimized The monitor provides information about speed & accelerator lever,

through human engineering. steer angle & travel direction, battery discharge indicator,

hour meter & working mode. The optional load indicator displays

the load weight in the monitor. The operator can select various

performance modes to meet all working conditions.

It is available multi-languages (maximum 11) for operator.

H (High) mode N (Normal) mode E (Economic) mode

Turtle mode (maintain 7 km/h travel speed when lifting)

Brake oil reservoir with level sensor

Low entrance height Adjustable steering wheel Grammer seat (Optional) The enhanced brake oil reservoir, located in the upper left

In order to get in and out of To achieve a comfortable drive An easily adjustable suspension seat, dash is equipped with an electronic level sensor and easily

the cabin in an easy and safe position, the angle of the steering based on a human engineering visible through the monitor.

way the height of the entrance column can easily be adjusted design, provides greater comfort

step is only 400mm high. through a lever on the right-hand reducing operator fatigue.

side of the steering column.

08 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 09

New 9 Series

Mast Specification (15/18BT-9) Load Capacity

Maximum

Fork Height

Overall Height

(Lowered)

Free Lift Height (mm)

Tilt Angle (deg)

Load Capacity

without side shift at

Load Capacity with

side shift at

Truck Weight

(Unloaded)

15BT-9 18BT-9 20BT-9

Mast Type Fwd / Bwd

(mm) (mm) With Load Backrest Without Load Backrest (500mm LC)(kg) (500mm LC)(kg) (kg)

15/18BT-9 15/18BT-9 15/18BT-9 15/18BT-9 15/18BT-9 15BT-9 18BT-9 15BT-9 18BT-9 15BT-9 18BT-9

V250 2,525 1,720 35 35 5/7 1,500 1,800 1,440 1,730 2,953 3,239

V270 2,725 1,820 35 35 5/7 1,500 1,800 1,440 1,730 2,966 3,252

V300 3,025 1,970 35 35 5/7 1,500 1,800 1,440 1,730 2,985 3,271

* V330 3,325 2,120 35 35 5/7 1,500 1,800 1,440 1,730 3,006 3,292

2- Stage V350 3,525 2,220 35 35 5/7 1,500 1,800 1,440 1,730 3,019 3,305

Limited

V370 3,725 2,320 35 35 5/7 1,500 1,800 1,440 1,730 3,031 3,317

free lift

V400 4,025 2,470 35 35 5/7 1,450 1,750 1,400 1,680 3,056 3,342

V450 4,525 2,820 35 35 5/5 1,400 1,700 1,400 1,640 3,123 3,409

V500 5,025 3,070 35 35 5/5 1,350 1,600 1,340 1,540 3,157 3,443

V550 5,525 3,320 35 35 5/5 1,300 1,550 1,250 1,500 3,177 3,463

2- Stage VF300 3,025 1,970 972 1,460 5/5 1,500 1,800 1,440 1,730 3,024 3,310

full VF330 3,325 2,120 1,122 1,610 5/5 1,500 1,800 1,440 1,730 3,045 3,331

free lift VF350 3,525 2,220 1,222 1,710 5/5 1,500 1,800 1,440 1,730 3,061 3,347

TF/TS370 3,735 1,770 772 1,260 5/5 1,475 1,750 1,420 1,680 3,101 3,387

TF/TS400 4,035 1,870 872 1,360 5/5 1,450 1,700 1,390 1,630 3,121 3,407

TF/TS430 4,335 1,970 972 1,460 5/5 1,400 1,650 1,340 1,590 3,141 3,427

TF/TS450 4,535 2,070 1,072 1,560 5/5 1,375 1,625 1,320 1,560 3,160 3,446

3 - Stage TF/TS470 4,735 2,120 1,122 1,610 5/5 1,350 1,600 1,300 1,530 3,171 3,457

full

free lift TF/TS500 5,035 2,220 1,222 1,710 5/5 1,300 1,550 1,250 1,490 3,191 3,477

TF/TS550 5,535 2,420 1,422 1,910 5/5 1,250 1,450 1,200 1,390 3,230 3,516

TF/TS600 6,035 2,620 1,622 2,110 5/5 1,175 1,175 1,130 1,130 3,294 3,580

TF/TS650

TF/TS700

6,535

7,035

2,820

3,020

1,822

2,022

2,310

2,510

5/5

5/5

900

650

1,050

800

850

610

1,010

760

3,338 3,624

3,663

Various Attachments

3,377

Side Shift Hinged Fork Hinged Bucket Rotating Fork Push Pull Rotating Roll Clamp Load Stabilizer

Mast Specification (20BT-9)

Maximum Overall Height Free Lift Height (mm) Load Capacity Load Capacity with Truck Weight

Tilt Angle (deg)

Fork Height (Lowered) without side shift at side shift at (Unloaded)

Mast Type Fwd / Bwd

(mm) (mm) With Load Backrest Without Load Backrest (500mm LC)(kg) (500mm LC)(kg) (kg)

20BT-9 20BT-9 20BT-9 20BT-9 20BT-9 20BT-9 20BT-9 20BT-9

Carton Clamp Pallet Invert Drum Clamp Bale Clamp Load Extender Fork Positioner

V250 2,530 1,729 40 40 5/7 2,000 1,920 3,418

V270 2,730 1,829 40 40 5/7 2,000 1,920 3,431

V300 3,030 1,979 40 40 5/7 2,000 1,920 3,450

* V330 3,330 2,129 40 40 5/7 2,000 1,920 3,471

2- Stage V350 3,530 2,229 40 40 5/7 2,000 1,920 3,484

Limited

V370 3,730 2,329 40 40 5/7 2,000 1,920 3,496

free lift

V400 4,030 2,479 40 40 5/7 1,950 1,880 3,521

V450 4,530 2,829 40 40 5/5 1,850 1,780 3,588

V500 5,030 3,079 40 40 5/5 1,800 1,730 3,622

V550 5,530 3,329 40 40 5/5 1,700 1,640 3,642

2- Stage VF300 3,030 1,979 986 1,474 5/5 2,000 1,920 3,489

full VF330 3,330 2,129 1,136 1,624 5/5 2,000 1,920 3,510

free lift VF350 3,530 2,229 1,236 1,725 5/5 2,000 1,920 3,526

Optional Items

TF/TS370 3,740 1,779 786 1,274 5/5 1,950 1,880 3,566 . Fork (mm) 15 / 18BT-9 : 35X100X750, 850, 900(STD), 1050, 1200, 1350, 1500 . M.C.V : 2-Spool (STD), 3-Spool, 4-Spool

TF/TS400 4,040 1,879 886 1,374 5/5 1,900 1,830 3,586 . Auto Fork Leveling

20BT-9 : 40X100X900(STD), 950, 1000, 1050, 1150, 1200, 1350, 1500, 1600

TF/TS430 4,340 1,979 986 1,474 5/5 1,850 1,790 3,606

. Overshoe (mm) : 1300 / 1500 / 1700 . Beacon Lamp

TF/TS450 4,540 2,079 1,086 1,574 5/5 1,825 1,770 3,625

3 - Stage TF/TS470

. Integral Sideshift . Load Indicator

4,740 2,129 1,136 1,624 5/5 1,800 1,740 3,636

full . Tire : SOLID (STD) / Non-marking / Cushion tire / . Work Lamp

free lift TF/TS500 5,040 2,229 1,236 1,724 5/5 1,750 1,690 3,656

. OPSS : Mast

TF/TS550 5,540 2,429 1,436 1,924 5/5 1,700 1,640 3,695

Wide tire [15BT-9 : Front tire (200 / 50-10), 18/20BT-9 : Rear tire (15X5.5-9 ) ]

. Seat : Grammer . UL : ES, EE

TF/TS600 6,040 2,629 1,636 2,124 5/5 1,500 1,500 3,759

. Finger Tip Control . Cabin

TF/TS650 6,540 2,829 1,836 2,324 5/5 1,300 1,250 3,803

. Cold Storage

TF/TS700 7,040 3,029 2,036 2,524 5/5 1,050 1,010 3,842

※ TS-Mast : Wide Visible 3-Stage Full Free Lift Mast with 2 Free Lift Cylinders. * Standard

10 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 11

You might also like

- Hyster G005 Parts ManualDocument492 pagesHyster G005 Parts Manualcalexico01No ratings yet

- Manual Operare Valtra T180-t190 PDFDocument230 pagesManual Operare Valtra T180-t190 PDFramiro0001No ratings yet

- MDKDP DR DV Parts ManualDocument94 pagesMDKDP DR DV Parts ManualDave TrolianNo ratings yet

- Parts Book Generator Diesel Engine DA1146, D1146T, PO86TI - ENGLISHDocument61 pagesParts Book Generator Diesel Engine DA1146, D1146T, PO86TI - ENGLISHracso92% (12)

- HLX5 Drifter Failure Guide (Rev3)Document57 pagesHLX5 Drifter Failure Guide (Rev3)Leo67% (3)

- Important Information: Section 1A - SpecificationsDocument20 pagesImportant Information: Section 1A - SpecificationsGuillermo Calderon GarciaNo ratings yet

- Esaote S.P.A. Technos Family Service Manual 8310055000 Rev. A 2003Document19 pagesEsaote S.P.A. Technos Family Service Manual 8310055000 Rev. A 2003SamNo ratings yet

- 004.7 - VCE150 Session 7 Cabin LiftDocument24 pages004.7 - VCE150 Session 7 Cabin LiftMahmoud Elpop ElsalhNo ratings yet

- JPX SBRO 004 E 1 BrochureDocument2 pagesJPX SBRO 004 E 1 BrochureHydro Energy GroupNo ratings yet

- Manual AC-M1 (Rev1)Document62 pagesManual AC-M1 (Rev1)HushanjiNo ratings yet

- 20D/25D/30D/33D-7: Dimension SpecificationDocument7 pages20D/25D/30D/33D-7: Dimension SpecificationАлександр ОлейникNo ratings yet

- FangLing Shape Cutting Control System Operation and Installation Manual PDFDocument147 pagesFangLing Shape Cutting Control System Operation and Installation Manual PDFRashedul HasanNo ratings yet

- 03-2 N Series Hydraulic Section PDFDocument115 pages03-2 N Series Hydraulic Section PDFusuario29000100% (3)

- BT CargoDocument4 pagesBT CargoAlmacen HuskyNo ratings yet

- FB 20 NTKDocument21 pagesFB 20 NTKAnderson BriedaNo ratings yet

- h40 500 45 500 50 500 50 600evo en (Ed2) PDFDocument2 pagesh40 500 45 500 50 500 50 600evo en (Ed2) PDFAdmir BašićNo ratings yet

- YALE A284 MPR080VG LIFT TRUCK Service Repair Manual PDFDocument10 pagesYALE A284 MPR080VG LIFT TRUCK Service Repair Manual PDFsekfsekmdddeNo ratings yet

- Kalmar DCE90-180 Diesel Specs 18 TON'Document12 pagesKalmar DCE90-180 Diesel Specs 18 TON'Raul0% (1)

- Illustrated Parts Breakdown Manual Forward Reach Forklift Model XR1267 (Tier III)Document402 pagesIllustrated Parts Breakdown Manual Forward Reach Forklift Model XR1267 (Tier III)Jeff LaitinenNo ratings yet

- Heavy Lift Trucks 20 - 30 Tonnes: Technical Information Kalmar Dcd200-300, DieselDocument12 pagesHeavy Lift Trucks 20 - 30 Tonnes: Technical Information Kalmar Dcd200-300, Dieselbatuhany90No ratings yet

- Classic: Model HTA (3,000 LB To 6,000 LB) Drawbar Pull (13.3 KN To 26.7 KN)Document2 pagesClassic: Model HTA (3,000 LB To 6,000 LB) Drawbar Pull (13.3 KN To 26.7 KN)kilofome05No ratings yet

- Technical Brochure - DCF370-520 - EN PDFDocument9 pagesTechnical Brochure - DCF370-520 - EN PDFAndres Cardenas Moya100% (1)

- H - 01 - ST D214 C236 H008 General Overview en Rev4Document83 pagesH - 01 - ST D214 C236 H008 General Overview en Rev4fabioNo ratings yet

- CROWN FC 4000 Series Brouchure SpecificationsDocument6 pagesCROWN FC 4000 Series Brouchure SpecificationsLuis Alberto Rivas Garcia0% (1)

- Empty Container Handlers: 6000 - 7000 KG at 1220 MM H6XM-12EC3 / H7XM-12EC4Document5 pagesEmpty Container Handlers: 6000 - 7000 KG at 1220 MM H6XM-12EC3 / H7XM-12EC4Wolf LordNo ratings yet

- Parts Catalog: Models 50, 51, 60 Models 20 (812) Attachment AccessoriesDocument779 pagesParts Catalog: Models 50, 51, 60 Models 20 (812) Attachment AccessoriesRubén MuñozNo ratings yet

- Wet Brakes - NMHG Hyster H4Document18 pagesWet Brakes - NMHG Hyster H4KUATE JEAN CALVINNo ratings yet

- Reachstacker Intermodal Handlers Reachstacker Container HandlersDocument7 pagesReachstacker Intermodal Handlers Reachstacker Container HandlersWolf LordNo ratings yet

- Hyunday ForkliftDocument6 pagesHyunday ForkliftIrham M AFNo ratings yet

- k21 Gen InfoDocument28 pagesk21 Gen InfoArtur MeierNo ratings yet

- GPS WheelsDocument48 pagesGPS WheelsYang GomezNo ratings yet

- Installation & Ops Manual - Smart Start M and D Models 7-2009Document24 pagesInstallation & Ops Manual - Smart Start M and D Models 7-2009Yang GomezNo ratings yet

- 12ESH Electric Stacker Operation Manual Service ManualDocument45 pages12ESH Electric Stacker Operation Manual Service Manualmehdi100% (1)

- Drive Axle and Differential Assembly Repair (Wet Brake - NMHG)Document66 pagesDrive Axle and Differential Assembly Repair (Wet Brake - NMHG)KUATE JEAN CALVINNo ratings yet

- 1F 5 SERIES BrochureDocument4 pages1F 5 SERIES Brochureomni_partsNo ratings yet

- Electric C4000 Service Training Pack PDFDocument28 pagesElectric C4000 Service Training Pack PDFduongpnNo ratings yet

- Kalmar DCG90-180 Lift Trucks 9 - 18 Tonnes: Technical Information, Stage IIIB/Tier 4iDocument7 pagesKalmar DCG90-180 Lift Trucks 9 - 18 Tonnes: Technical Information, Stage IIIB/Tier 4iJuan Amanqui GarciaNo ratings yet

- 7fbest 10Document16 pages7fbest 10luis tocoraNo ratings yet

- 504164-003 X-32 sn53095-53100 C.PSDocument102 pages504164-003 X-32 sn53095-53100 C.PSSergio RecabarrenNo ratings yet

- Ficha Técnica LWE130Document8 pagesFicha Técnica LWE130brunoneroniNo ratings yet

- N20 КрокодилDocument335 pagesN20 КрокодилИсмаилNo ratings yet

- Forklift Fc5200 Spec GBDocument10 pagesForklift Fc5200 Spec GBwish me100% (1)

- RP2.0-RP3.0 (B448) : 1514231 ©2011 Hyster Company 01/2011Document122 pagesRP2.0-RP3.0 (B448) : 1514231 ©2011 Hyster Company 01/2011André TarginoNo ratings yet

- The Atlet Truck RangeDocument2 pagesThe Atlet Truck RangeXb Z100% (1)

- General Information: HandsetDocument17 pagesGeneral Information: HandsetChristian BedoyaNo ratings yet

- Installation Instructions: CascadeDocument4 pagesInstallation Instructions: CascadeSARAMQRNo ratings yet

- Tdce01 04GBDocument217 pagesTdce01 04GBALEX FLORIDO CORREANo ratings yet

- Vista Mast RepairDocument28 pagesVista Mast RepairTan JaiNo ratings yet

- Subaru Legacy Owners Manual 2007Document442 pagesSubaru Legacy Owners Manual 2007Peter IlievNo ratings yet

- Four-Wheel Electric Counterbalanced Lift Trucks J2.00-3.20XMDocument7 pagesFour-Wheel Electric Counterbalanced Lift Trucks J2.00-3.20XMSonny Cotty100% (1)

- Capacities and Specifications GDP25MXDocument14 pagesCapacities and Specifications GDP25MXvicmart3030No ratings yet

- MX T6 MX T8 MX T10 MX T12 MX T15 MX T16: User Manual Please Read Carefully Before Using MX LoaderDocument32 pagesMX T6 MX T8 MX T10 MX T12 MX T15 MX T16: User Manual Please Read Carefully Before Using MX LoaderAlin Ioan TirnovanNo ratings yet

- Hyster C176 Service ManualDocument21 pagesHyster C176 Service ManualBruno Ferreira Silva0% (1)

- Ep16nt PDFDocument4 pagesEp16nt PDFBa MamadouNo ratings yet

- 060378en - General Reachstacker Forklift - SCANIA ENGINE DC13 (74A AND 76A)Document11 pages060378en - General Reachstacker Forklift - SCANIA ENGINE DC13 (74A AND 76A)MohamedSalahNo ratings yet

- Master Drive Unit - Mpb040-E (B827)Document14 pagesMaster Drive Unit - Mpb040-E (B827)Juan Esteban AgudeloNo ratings yet

- Operating Instructions: Linde Fork Lift TruckDocument96 pagesOperating Instructions: Linde Fork Lift TruckVictorNo ratings yet

- C3000GT PM en 09Document127 pagesC3000GT PM en 09ForktechNo ratings yet

- BYD Forklift ECB40!45!50 Cutsheet Rev9-20-A DigitalDocument3 pagesBYD Forklift ECB40!45!50 Cutsheet Rev9-20-A DigitalEiSerVasquezNo ratings yet

- Manual de Servicio Montacargas MitsubishI Modelo ESR23N2 36 2Document46 pagesManual de Servicio Montacargas MitsubishI Modelo ESR23N2 36 2Ulises Raul JimenezNo ratings yet

- Capacities and SpecificationsDocument12 pagesCapacities and SpecificationsSandy RiveraNo ratings yet

- Service Manual Beta 2LTR Impco Engine ManualDocument485 pagesService Manual Beta 2LTR Impco Engine ManualDan Delfino100% (1)

- Service Manual: Chassis, Mast & Options EP16NT EP18NT EP20NTDocument7 pagesService Manual: Chassis, Mast & Options EP16NT EP18NT EP20NTIvaylo PetkovNo ratings yet

- C3000-C5000 Electric Circuit PLC GM LPG Tier 4 (22.05.16)Document3 pagesC3000-C5000 Electric Circuit PLC GM LPG Tier 4 (22.05.16)David CraigNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- Dimension Specification: IdentificationDocument7 pagesDimension Specification: IdentificationАлександр ОлейникNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesAdven Tius Surya SurbaktiNo ratings yet

- 15D/18D/20DA-7E: Dimension SpecificationDocument6 pages15D/18D/20DA-7E: Dimension SpecificationАлександр ОлейникNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- 40TA15PA+rev0 출력Document2 pages40TA15PA+rev0 출력Александр ОлейникNo ratings yet

- Dimension Specification: IdentificationDocument5 pagesDimension Specification: IdentificationАлександр ОлейникNo ratings yet

- Electric Towing / Platform Trucks: Photo May Include Optional EquipmentDocument4 pagesElectric Towing / Platform Trucks: Photo May Include Optional EquipmentАлександр ОлейникNo ratings yet

- Forklift Trucks: Environmental - FriendlyDocument12 pagesForklift Trucks: Environmental - FriendlyАлександр ОлейникNo ratings yet

- 35/40/45D-9S, 50D-9SA Tier 3 Sales Guide: Diesel Engine Fork Lift TrucksDocument84 pages35/40/45D-9S, 50D-9SA Tier 3 Sales Guide: Diesel Engine Fork Lift TrucksАлександр ОлейникNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- Dimension Specification: IdentificationDocument7 pagesDimension Specification: IdentificationАлександр Олейник0% (1)

- 20D/25D/30D/33D-7: Dimension SpecificationDocument7 pages20D/25D/30D/33D-7: Dimension SpecificationАлександр ОлейникNo ratings yet

- 15D/18D/20DA-7E: Dimension SpecificationDocument6 pages15D/18D/20DA-7E: Dimension SpecificationАлександр ОлейникNo ratings yet

- 35/40/45DS-7E 50DA-7E: Diesel Forklift TrucksDocument12 pages35/40/45DS-7E 50DA-7E: Diesel Forklift TrucksАлександр ОлейникNo ratings yet

- 100D/120D/135D/160D-7: Optional ItemsDocument7 pages100D/120D/135D/160D-7: Optional ItemsАлександр ОлейникNo ratings yet

- Dimension Specification: IdentificationDocument7 pagesDimension Specification: IdentificationАлександр ОлейникNo ratings yet

- Please Contact: Some of The Photos May Include Optional EquipmentDocument7 pagesPlease Contact: Some of The Photos May Include Optional EquipmentАлександр ОлейникNo ratings yet

- Group 2 Specifications: 1. Major ComponentsDocument8 pagesGroup 2 Specifications: 1. Major ComponentsАлександр ОлейникNo ratings yet

- Unit IDocument25 pagesUnit IRamarao BNo ratings yet

- AIRCOOLAIR U.E. - IOM - MIL 122E-0613 06-201 Lennox 3 PDFDocument28 pagesAIRCOOLAIR U.E. - IOM - MIL 122E-0613 06-201 Lennox 3 PDFveerapen clydeNo ratings yet

- Ares Veloce BT A500 and A1000 - Instruction ManualDocument21 pagesAres Veloce BT A500 and A1000 - Instruction ManualAustral SecuriityNo ratings yet

- Manual Skoda Octavia 1,9 50kWDocument78 pagesManual Skoda Octavia 1,9 50kWCornea Horatiu SebastianNo ratings yet

- Wet Chemical Pre E PresentationDocument310 pagesWet Chemical Pre E PresentationEdwardAlexanderGarciaNo ratings yet

- Anchor Bolt Holes StructuralSteelDetailerDocument1 pageAnchor Bolt Holes StructuralSteelDetailercivil27No ratings yet

- Techspec RS27 RS35 enDocument2 pagesTechspec RS27 RS35 enpesumasinadNo ratings yet

- 6702 WallboxesDocument2 pages6702 WallboxesRaviNo ratings yet

- Cpe 2019 8862391Document6 pagesCpe 2019 8862391abhishek mNo ratings yet

- MLT630Rev 09-04 PDFDocument650 pagesMLT630Rev 09-04 PDFЛеонид Лазар0% (1)

- Pump A10VO DFR PrincipleDocument25 pagesPump A10VO DFR Principlemaintenance 2kpb100% (1)

- Manual Progr BrakeDocument4 pagesManual Progr BrakeGerchu GTNo ratings yet

- Technical Exam 5QDocument11 pagesTechnical Exam 5QEugeneNo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorDocument3 pages303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorCARLOS LIMADANo ratings yet

- Belt Conveyor Troubleshooting: HGRS MASTER - MaintenanceDocument7 pagesBelt Conveyor Troubleshooting: HGRS MASTER - MaintenanceJerry HukyNo ratings yet

- 60393748C (GB) Iveco PDFDocument176 pages60393748C (GB) Iveco PDFCesar ZarateNo ratings yet

- Zero Cross90003138ADocument11 pagesZero Cross90003138AJeremiasPereiraNo ratings yet

- 2005 Workshop Manual - S1-UNAE01B - 4Document218 pages2005 Workshop Manual - S1-UNAE01B - 4HS it50% (4)

- Rescue Technology Catalogue PDFDocument140 pagesRescue Technology Catalogue PDFHerlan A Buon CuoreNo ratings yet

- Material List - 2421Document9 pagesMaterial List - 2421ETHANNo ratings yet

- UPS Weekly Check ListDocument5 pagesUPS Weekly Check Listabid azizNo ratings yet

- .1st Batch of P&IDs Consolidated For MCPPDocument26 pages.1st Batch of P&IDs Consolidated For MCPPbaqerhassanNo ratings yet