Professional Documents

Culture Documents

Kem Microconcrete - N

Kem Microconcrete - N

Uploaded by

Irfan BiradarCopyright:

Available Formats

You might also like

- Manpower & Material Requirements of Civil Works.Document20 pagesManpower & Material Requirements of Civil Works.Bhavanishankar ShettyNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- Polybit Polycrete LW (Major Crack Repair)Document2 pagesPolybit Polycrete LW (Major Crack Repair)Mebepure GazeNo ratings yet

- CIKOcrete Micro HSDocument3 pagesCIKOcrete Micro HSMuhammathu Anver AbdullahNo ratings yet

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- Cikocrete Micro: Technical DataDocument3 pagesCikocrete Micro: Technical DataMuhammathu Anver AbdullahNo ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- TDS Conbextra 621 Saudi ArabiaDocument4 pagesTDS Conbextra 621 Saudi ArabiaMichael MazoNo ratings yet

- TDS Fosroc Nitocote CM210 India3Document4 pagesTDS Fosroc Nitocote CM210 India3reshmitapallaNo ratings yet

- TDS Renderoc UW India3Document3 pagesTDS Renderoc UW India3ARCHANA GUPTANo ratings yet

- Polycrete ST: Polymer Modified High Strength Cementitious Repair MortarDocument2 pagesPolycrete ST: Polymer Modified High Strength Cementitious Repair Mortarmohamed ragabNo ratings yet

- Strongcoat 400 - TDSDocument4 pagesStrongcoat 400 - TDSOsama Abu ShalthamNo ratings yet

- Nitokit Surface SealantDocument4 pagesNitokit Surface SealanttalatzahoorNo ratings yet

- Weberrep 360 FFR-KSA 01Document2 pagesWeberrep 360 FFR-KSA 01moizm53No ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Cempatch SDocument2 pagesCempatch Sjerry6670100% (1)

- TDS Nitocote CM210 BFL3Document4 pagesTDS Nitocote CM210 BFL3ryan wachiraNo ratings yet

- Tec 301 (Lebanon) : Non Shrink Structural GroutDocument2 pagesTec 301 (Lebanon) : Non Shrink Structural GroutRajuNSanaboinaNo ratings yet

- 6 2 3 6 3 Polybond Ac PDFDocument2 pages6 2 3 6 3 Polybond Ac PDFHtun ZarniNo ratings yet

- Fosroc Nitocote CM210: Elastomeric Cementitious CoatingDocument4 pagesFosroc Nitocote CM210: Elastomeric Cementitious Coatingade fauziNo ratings yet

- RCT-ConGuard CTEDocument2 pagesRCT-ConGuard CTEfahadNo ratings yet

- TDS Renderoc RG IndiaDocument3 pagesTDS Renderoc RG IndiaBijaya RaulaNo ratings yet

- Cempatch S: DescriptionDocument4 pagesCempatch S: DescriptionMohamed RusfanNo ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Cempatch FL90 (23.02.2021)Document2 pagesCempatch FL90 (23.02.2021)Mohamed RusfanNo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Nitocote CM210Document91 pagesNitocote CM210Gavriel NgNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Conbextra UW: Constructive SolutionsDocument4 pagesConbextra UW: Constructive SolutionstalatzahoorNo ratings yet

- Sikadur 752Document2 pagesSikadur 752Budhi KurniawanNo ratings yet

- DR - Fixit Pidigrout 10 MDocument3 pagesDR - Fixit Pidigrout 10 MBijaya RaulaNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- Cera MicroconcreteDocument2 pagesCera MicroconcreteSindhe SwethaNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Sikalastic®-1K: Product Data SheetDocument4 pagesSikalastic®-1K: Product Data SheetKhin Sandi KoNo ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Masterflow 622: Heavy Duty Epoxy Resin Chocking GroutDocument2 pagesMasterflow 622: Heavy Duty Epoxy Resin Chocking GroutAndri AjaNo ratings yet

- Masterkure CC 1315 WB TdsDocument3 pagesMasterkure CC 1315 WB TdsRavi SinghNo ratings yet

- 1-Nitocote CM210Document4 pages1-Nitocote CM210Ahmed I. GhallabNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- CIKOproof 2KDocument2 pagesCIKOproof 2Kelieraffoul98No ratings yet

- Fosroc Nitocote CM210: Uses Standards ComplianceDocument4 pagesFosroc Nitocote CM210: Uses Standards ComplianceSaif SNo ratings yet

- Webercote Protect PE - 0Document2 pagesWebercote Protect PE - 0Mohammed Tabraiz HussainNo ratings yet

- Cera Bond EPDocument2 pagesCera Bond EPrajeshdas.vidvattaNo ratings yet

- Alccofine 1108 KR TDS V2Document3 pagesAlccofine 1108 KR TDS V2Siddhesh Kamat MhamaiNo ratings yet

- Polytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingDocument2 pagesPolytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingVaittianathan MahavapillaiNo ratings yet

- Contite WS2 015 Jul10Document2 pagesContite WS2 015 Jul10chriscivil12No ratings yet

- 1104 CC Civil Brochure UKDocument4 pages1104 CC Civil Brochure UKwillcrawfordNo ratings yet

- RCT-ConGrout EP GPDocument2 pagesRCT-ConGrout EP GPfahadNo ratings yet

- Setseal B - TDSDocument4 pagesSetseal B - TDShussam jumah100% (1)

- DR - Fixit Micro ConcreteDocument3 pagesDR - Fixit Micro ConcreteKiran KumarNo ratings yet

- Mat in Arch 0159Document32 pagesMat in Arch 0159tec.mostafakmNo ratings yet

- Monoseal: DescriptionDocument2 pagesMonoseal: Descriptionosama mohNo ratings yet

- Nitocote CM210.3.018Document4 pagesNitocote CM210.3.018Shahin ShajahanNo ratings yet

- Nitomortar SDocument4 pagesNitomortar SMansoor AliNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Setseal B: DescriptionDocument4 pagesSetseal B: DescriptionRAKESH REDDYNo ratings yet

- ArmGrout M 65 Ver 7Document3 pagesArmGrout M 65 Ver 7beemasundarNo ratings yet

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioNo ratings yet

- STGDocument13 pagesSTGTan Nguyen HuuNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenDocument3 pagesPressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenMytzy Godoy TapiaNo ratings yet

- Diaphragm WallsDocument8 pagesDiaphragm WallsKathirgamanathan SivanathanNo ratings yet

- Exxon™ Bromobutyl 2211: RubberDocument2 pagesExxon™ Bromobutyl 2211: RubberMaram YasserNo ratings yet

- Mozam Jahi DocumentaryDocument50 pagesMozam Jahi DocumentaryFasi Rahman AbrarNo ratings yet

- Estimate For Toll Plaza 16112015Document1 pageEstimate For Toll Plaza 16112015ParamitaDanaNo ratings yet

- High Carbon Wire RodDocument9 pagesHigh Carbon Wire Rodninganray6316100% (1)

- Antipolo Del Norte, Lipa City: SubjectDocument3 pagesAntipolo Del Norte, Lipa City: SubjectRamled RerrefNo ratings yet

- G.I TUBE Technical GuidesDocument3 pagesG.I TUBE Technical GuidesmariaNo ratings yet

- Thermal Sizing of A S&T ExchangerDocument67 pagesThermal Sizing of A S&T Exchangerraja raniNo ratings yet

- LAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016Document9 pagesLAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016faezahjalalNo ratings yet

- Piping Codes & Standard and Cross ReferrenceDocument12 pagesPiping Codes & Standard and Cross ReferrencesmaluqNo ratings yet

- HW Cot SpecsDocument1 pageHW Cot SpecsRonal PaniaguaNo ratings yet

- Universal Air Tool Oil SpecDocument1 pageUniversal Air Tool Oil SpecAbd Alkarim MohamedNo ratings yet

- BS en 1057 Tube Sizes - Crane Copper TubeDocument2 pagesBS en 1057 Tube Sizes - Crane Copper TubeΣπίθας ΣπιθαμήNo ratings yet

- Construction Project Manager or Quality Control Manager or QA/QCDocument3 pagesConstruction Project Manager or Quality Control Manager or QA/QCapi-77462936No ratings yet

- Corrosion Science: H.F. Jackson, C. San Marchi, D.K. Balch, B.P. SomerdayDocument12 pagesCorrosion Science: H.F. Jackson, C. San Marchi, D.K. Balch, B.P. SomerdayDida KhalingNo ratings yet

- Elestomeric BearingsDocument152 pagesElestomeric BearingsvaibhavNo ratings yet

- CRD - c55 (1) Within Batch Uniformity FRSH ConcreteDocument6 pagesCRD - c55 (1) Within Batch Uniformity FRSH ConcreteKothiyal MukeshNo ratings yet

- Appendix 2: Geomembrane Test MethodsDocument5 pagesAppendix 2: Geomembrane Test MethodsliviuNo ratings yet

- Lecture 1Document17 pagesLecture 1Kaaviyan ThirunyanamNo ratings yet

- Fatigue, Endurance Limit and Its Approximate Estimation, DesignDocument9 pagesFatigue, Endurance Limit and Its Approximate Estimation, DesignMelese AschalewNo ratings yet

- Fire SprinklerDocument30 pagesFire SprinklerNil DG50% (2)

- Medicion de Flujo de Solidos Por ImpactoDocument47 pagesMedicion de Flujo de Solidos Por ImpactogfautopackNo ratings yet

- Anual Estimate 19-20 (17-18 SSR)Document16 pagesAnual Estimate 19-20 (17-18 SSR)k v rajeshNo ratings yet

- SBR Horizon BROCHUREDocument8 pagesSBR Horizon BROCHUREGokulakrishnan SelvarajanNo ratings yet

- Revit MEPDocument3 pagesRevit MEPSeenivasan GovindarajNo ratings yet

- C595Document7 pagesC595JoSueMeJiaNo ratings yet

- ICB Boiler Book PDFDocument28 pagesICB Boiler Book PDFfauzi endraNo ratings yet

Kem Microconcrete - N

Kem Microconcrete - N

Uploaded by

Irfan BiradarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kem Microconcrete - N

Kem Microconcrete - N

Uploaded by

Irfan BiradarCopyright:

Available Formats

Chloride Content: Nil

KEM MICROCONCRETE - N

High Strength Microconcrete Depth of Carbonation: Nil

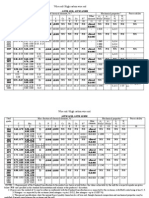

Ref: CR/CI - 04-2020 Compressive strength: At 0.14 - 0.16 w/p ratio @

0

30 C ASTM C 109

Description

Age Compressive Strength

KEM MICROCONCRETE-N is a general purpose (days) Mpa

nonshrink,cementitious, flowable, high strength 1 20

mortar for repairs with high strength precision 3 30

concrete. It is free flowing and suited for thickness 7 40

up to 40 mm to 100 mm. It is apt for various 28 65

structural strengthening measures such as

encasement build-ups, jacketing, etc. Wet Density: BS 1881 - 2250 kg/m3

0

Uses Flexural Strength: @28 days 25 C 10 N/mm2

General repair and renovation of decayed, Setting Time: BS 4550 at 200 C and 0.14 - 0.16

defective or damaged concrete structures like water to powder ratio (flowable consistency)

beams, columns, walls, and honey combed

concrete where access is required and Initial set: 6 hours 00 minutes

compaction is not available.

Final set: 8 hours 15 minutes

Jacketing of RCC columns, strengthening of

vertical members. Alkali content: The presence of non-alkali reactive

aggregates ensures its resistance to future

Advantages expansive reactions and deterioration.

Can be pumped or poured into restricted Bond Strength: The typical shear bond strength

locations. when tested as per BS-6319 at water powder ratio

of 0.14 - 0.16 at 200 C without any bonding agent

Flowable mortar eliminates honey

is 68 N/mm2 at 28 days.

Combination.

Develops high initial and ultimate final Expansion characteristics: An initial expansion of

strength. about 1 % when measured according to ASTM C

827 overcomes plastic settlement in the unset

Gaseous expansion system compensates for material. Expansion in the hardened state when

shrinking and settles in the plastic state. measured according to ASTM C 1090-88

compensates for drying shrinkage. Pressure to

Excellent resistance to moisture Ingress. restrain plastic

2

Can be applied at 100mm thick at one stroke. Expansion: Approximately 0.004 N/mm .

Self compacting with guaranteed Standards

Performance.

KEM MICROCONCRETE - N is tested using the

Easy to use by adding water on site. relevant sections of :

ASTM C -1107 Grade C

Contains no chloride hence there is no BS - 1881

BS - 4550

reinforcement corrosion.

CRDC - 821 - 82 A

BS - 6319

Typical Properties

Nature : Cementitious grey powder

Direction for use Technical Service

Expose the sound base of defective concrete Chembond has established itself in various fields

surfaces. For better adhesion, roughen the on the basis of its dependable technical service.

prepared surface. For this purpose, we maintain a well equipped

laboratory for research & quality assurance of all

Several hours in advance, water the surface well. products. Our experienced personnel are always

Excess water should be removed before on call and would always be available for product

application of fresh concrete. The formwork demonstrations and product performance

should include drainage outlets for pre-soaking monitoring.

and allow for air venting.

Safety Precautions

There should be access points to pour or pump in KEM MICROCONCRETE - N is a cementitious

KEM MICROCONCRETE - N. alkaline product. Care should be taken to avoid

contact with eyes, skin, mouth and food stuff. Any

Mix KEM MICROCONCRETE - N in a concrete mixer splashes on the human body must be washed with

to get a homogenous mix and pour into the plenty of water.

formwork.

Allow it to cure for 24 hours.

Yield

Approx 13.0 liter / 25 kg bag, actual yield depends

on the consistency required and the site

requirement.

Packaging

25 kg in moisture-resistant bags

Storage and Shelf life

6 months from manufacture in original unopened

bags if stored in dry conditions.

Chembond Chemicals Limited Limitation of Liability:

Chembond Centre, EL-71, MIDC, This information is based on our current level of

Mahape, Navi Mumbai, India 400 710. knowledge. It is given in a good faith but it is not

Tel.: +91 22 39213 000,Fax: +91 22 3921 3100,. intended to guarantee any particular properties. The

website: www.chembondindia.com, users must satisfy themselves that there are no

e-mail: enquiries.conschem@chembondindia.com circumstances requiring additional information or

precautions or he verification of details given herein.

You might also like

- Manpower & Material Requirements of Civil Works.Document20 pagesManpower & Material Requirements of Civil Works.Bhavanishankar ShettyNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- Polybit Polycrete LW (Major Crack Repair)Document2 pagesPolybit Polycrete LW (Major Crack Repair)Mebepure GazeNo ratings yet

- CIKOcrete Micro HSDocument3 pagesCIKOcrete Micro HSMuhammathu Anver AbdullahNo ratings yet

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- Cikocrete Micro: Technical DataDocument3 pagesCikocrete Micro: Technical DataMuhammathu Anver AbdullahNo ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- TDS Conbextra 621 Saudi ArabiaDocument4 pagesTDS Conbextra 621 Saudi ArabiaMichael MazoNo ratings yet

- TDS Fosroc Nitocote CM210 India3Document4 pagesTDS Fosroc Nitocote CM210 India3reshmitapallaNo ratings yet

- TDS Renderoc UW India3Document3 pagesTDS Renderoc UW India3ARCHANA GUPTANo ratings yet

- Polycrete ST: Polymer Modified High Strength Cementitious Repair MortarDocument2 pagesPolycrete ST: Polymer Modified High Strength Cementitious Repair Mortarmohamed ragabNo ratings yet

- Strongcoat 400 - TDSDocument4 pagesStrongcoat 400 - TDSOsama Abu ShalthamNo ratings yet

- Nitokit Surface SealantDocument4 pagesNitokit Surface SealanttalatzahoorNo ratings yet

- Weberrep 360 FFR-KSA 01Document2 pagesWeberrep 360 FFR-KSA 01moizm53No ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Cempatch SDocument2 pagesCempatch Sjerry6670100% (1)

- TDS Nitocote CM210 BFL3Document4 pagesTDS Nitocote CM210 BFL3ryan wachiraNo ratings yet

- Tec 301 (Lebanon) : Non Shrink Structural GroutDocument2 pagesTec 301 (Lebanon) : Non Shrink Structural GroutRajuNSanaboinaNo ratings yet

- 6 2 3 6 3 Polybond Ac PDFDocument2 pages6 2 3 6 3 Polybond Ac PDFHtun ZarniNo ratings yet

- Fosroc Nitocote CM210: Elastomeric Cementitious CoatingDocument4 pagesFosroc Nitocote CM210: Elastomeric Cementitious Coatingade fauziNo ratings yet

- RCT-ConGuard CTEDocument2 pagesRCT-ConGuard CTEfahadNo ratings yet

- TDS Renderoc RG IndiaDocument3 pagesTDS Renderoc RG IndiaBijaya RaulaNo ratings yet

- Cempatch S: DescriptionDocument4 pagesCempatch S: DescriptionMohamed RusfanNo ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Cempatch FL90 (23.02.2021)Document2 pagesCempatch FL90 (23.02.2021)Mohamed RusfanNo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Nitocote CM210Document91 pagesNitocote CM210Gavriel NgNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Conbextra UW: Constructive SolutionsDocument4 pagesConbextra UW: Constructive SolutionstalatzahoorNo ratings yet

- Sikadur 752Document2 pagesSikadur 752Budhi KurniawanNo ratings yet

- DR - Fixit Pidigrout 10 MDocument3 pagesDR - Fixit Pidigrout 10 MBijaya RaulaNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- Cera MicroconcreteDocument2 pagesCera MicroconcreteSindhe SwethaNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Sikalastic®-1K: Product Data SheetDocument4 pagesSikalastic®-1K: Product Data SheetKhin Sandi KoNo ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Masterflow 622: Heavy Duty Epoxy Resin Chocking GroutDocument2 pagesMasterflow 622: Heavy Duty Epoxy Resin Chocking GroutAndri AjaNo ratings yet

- Masterkure CC 1315 WB TdsDocument3 pagesMasterkure CC 1315 WB TdsRavi SinghNo ratings yet

- 1-Nitocote CM210Document4 pages1-Nitocote CM210Ahmed I. GhallabNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- CIKOproof 2KDocument2 pagesCIKOproof 2Kelieraffoul98No ratings yet

- Fosroc Nitocote CM210: Uses Standards ComplianceDocument4 pagesFosroc Nitocote CM210: Uses Standards ComplianceSaif SNo ratings yet

- Webercote Protect PE - 0Document2 pagesWebercote Protect PE - 0Mohammed Tabraiz HussainNo ratings yet

- Cera Bond EPDocument2 pagesCera Bond EPrajeshdas.vidvattaNo ratings yet

- Alccofine 1108 KR TDS V2Document3 pagesAlccofine 1108 KR TDS V2Siddhesh Kamat MhamaiNo ratings yet

- Polytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingDocument2 pagesPolytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingVaittianathan MahavapillaiNo ratings yet

- Contite WS2 015 Jul10Document2 pagesContite WS2 015 Jul10chriscivil12No ratings yet

- 1104 CC Civil Brochure UKDocument4 pages1104 CC Civil Brochure UKwillcrawfordNo ratings yet

- RCT-ConGrout EP GPDocument2 pagesRCT-ConGrout EP GPfahadNo ratings yet

- Setseal B - TDSDocument4 pagesSetseal B - TDShussam jumah100% (1)

- DR - Fixit Micro ConcreteDocument3 pagesDR - Fixit Micro ConcreteKiran KumarNo ratings yet

- Mat in Arch 0159Document32 pagesMat in Arch 0159tec.mostafakmNo ratings yet

- Monoseal: DescriptionDocument2 pagesMonoseal: Descriptionosama mohNo ratings yet

- Nitocote CM210.3.018Document4 pagesNitocote CM210.3.018Shahin ShajahanNo ratings yet

- Nitomortar SDocument4 pagesNitomortar SMansoor AliNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Setseal B: DescriptionDocument4 pagesSetseal B: DescriptionRAKESH REDDYNo ratings yet

- ArmGrout M 65 Ver 7Document3 pagesArmGrout M 65 Ver 7beemasundarNo ratings yet

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioNo ratings yet

- STGDocument13 pagesSTGTan Nguyen HuuNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenDocument3 pagesPressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenMytzy Godoy TapiaNo ratings yet

- Diaphragm WallsDocument8 pagesDiaphragm WallsKathirgamanathan SivanathanNo ratings yet

- Exxon™ Bromobutyl 2211: RubberDocument2 pagesExxon™ Bromobutyl 2211: RubberMaram YasserNo ratings yet

- Mozam Jahi DocumentaryDocument50 pagesMozam Jahi DocumentaryFasi Rahman AbrarNo ratings yet

- Estimate For Toll Plaza 16112015Document1 pageEstimate For Toll Plaza 16112015ParamitaDanaNo ratings yet

- High Carbon Wire RodDocument9 pagesHigh Carbon Wire Rodninganray6316100% (1)

- Antipolo Del Norte, Lipa City: SubjectDocument3 pagesAntipolo Del Norte, Lipa City: SubjectRamled RerrefNo ratings yet

- G.I TUBE Technical GuidesDocument3 pagesG.I TUBE Technical GuidesmariaNo ratings yet

- Thermal Sizing of A S&T ExchangerDocument67 pagesThermal Sizing of A S&T Exchangerraja raniNo ratings yet

- LAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016Document9 pagesLAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016faezahjalalNo ratings yet

- Piping Codes & Standard and Cross ReferrenceDocument12 pagesPiping Codes & Standard and Cross ReferrencesmaluqNo ratings yet

- HW Cot SpecsDocument1 pageHW Cot SpecsRonal PaniaguaNo ratings yet

- Universal Air Tool Oil SpecDocument1 pageUniversal Air Tool Oil SpecAbd Alkarim MohamedNo ratings yet

- BS en 1057 Tube Sizes - Crane Copper TubeDocument2 pagesBS en 1057 Tube Sizes - Crane Copper TubeΣπίθας ΣπιθαμήNo ratings yet

- Construction Project Manager or Quality Control Manager or QA/QCDocument3 pagesConstruction Project Manager or Quality Control Manager or QA/QCapi-77462936No ratings yet

- Corrosion Science: H.F. Jackson, C. San Marchi, D.K. Balch, B.P. SomerdayDocument12 pagesCorrosion Science: H.F. Jackson, C. San Marchi, D.K. Balch, B.P. SomerdayDida KhalingNo ratings yet

- Elestomeric BearingsDocument152 pagesElestomeric BearingsvaibhavNo ratings yet

- CRD - c55 (1) Within Batch Uniformity FRSH ConcreteDocument6 pagesCRD - c55 (1) Within Batch Uniformity FRSH ConcreteKothiyal MukeshNo ratings yet

- Appendix 2: Geomembrane Test MethodsDocument5 pagesAppendix 2: Geomembrane Test MethodsliviuNo ratings yet

- Lecture 1Document17 pagesLecture 1Kaaviyan ThirunyanamNo ratings yet

- Fatigue, Endurance Limit and Its Approximate Estimation, DesignDocument9 pagesFatigue, Endurance Limit and Its Approximate Estimation, DesignMelese AschalewNo ratings yet

- Fire SprinklerDocument30 pagesFire SprinklerNil DG50% (2)

- Medicion de Flujo de Solidos Por ImpactoDocument47 pagesMedicion de Flujo de Solidos Por ImpactogfautopackNo ratings yet

- Anual Estimate 19-20 (17-18 SSR)Document16 pagesAnual Estimate 19-20 (17-18 SSR)k v rajeshNo ratings yet

- SBR Horizon BROCHUREDocument8 pagesSBR Horizon BROCHUREGokulakrishnan SelvarajanNo ratings yet

- Revit MEPDocument3 pagesRevit MEPSeenivasan GovindarajNo ratings yet

- C595Document7 pagesC595JoSueMeJiaNo ratings yet

- ICB Boiler Book PDFDocument28 pagesICB Boiler Book PDFfauzi endraNo ratings yet