Professional Documents

Culture Documents

AlTiN Spiral End Mill For Steel Speed Chart v3

AlTiN Spiral End Mill For Steel Speed Chart v3

Uploaded by

Calvin DeSarioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AlTiN Spiral End Mill For Steel Speed Chart v3

AlTiN Spiral End Mill For Steel Speed Chart v3

Uploaded by

Calvin DeSarioCopyright:

Available Formats

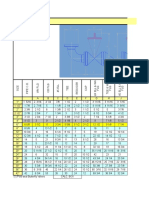

INDUSTRIAL

2, 3 & 4 Flute Solid Carbide CNC AlTiN Coated Spiral Router Bits / End Mills For Steel & Stainless Steel

Surface Feet

Per Minute

Material (SFM) Feed Rate: Inches Per Minute (IPM)

1/16" - 1/8" (3mm) 3/16" (4mm) 1/4" (6mm) 5/16" 3/8" 1/2" Tool Reference #’s Dia.

2 Flute

2 Flute 3 Flute 4 Flute 2 Flute 3 Flute 4 Flute 2 Flute 3 Flute 4 Flute 2 Flute 3 Flute 4 Flute 2 Flute 3 Flute 4 Flute 2 Flute 3 Flute 4 Flute 51461 1/8"

12,200 RPM* 8,200 RPM* 6,100 RPM* 5,000 RPM* 4,100 RPM* 3,100 RPM* 51463 3/16"

51465 1/4"

Steel: Low Carbon 400" 29" 43" 58" 32" 48" 64" 28" 43" 56" 30" 45" 60" 32" 48" 64" 29" 43" 58"

51466 1/4"

7,600 RPM* 5,100 RPM* 3,800 RPM* 3,100 RPM* 2,500 RPM* 1,900 RPM* 51467 3/8"

Steel: Medium Carbon 250" 18" 27" 36" 20" 30" 40" 18" 27" 36" 18" 27" 36" 19" 28" 38" 19" 28" 38" 51468 1/2"

51673 1/16"

6,100 RPM* 4,100 RPM* 3,100 RPM* 2,500 RPM* 2,000 RPM* 1,500 RPM* 51674 1/8"

Tool Steel: Hardened 200" 4" 6" 8" 4" 6" 8" 4" 6" 8" 4" 6" 8" 4" 6" 8" 4" 6" 8" 51675 3/16"

51676 1/4"

10,700 RPM* 7,100 RPM* 5,300 RPM* 4,300 RPM* 3,600 RPM* 2,600 RPM*

51677 3/8"

Stainless Steel: 350" 18" 27" 36" 20" 30" 40" 18" 27" 36" 18" 27" 36" 19" 28" 38" 19" 28" 38" 3 Flute

301, 303, 410 51460 1/8"

51462 3/16"

6,700 RPM* 4,100 RPM* 3,400 RPM* 2,700 RPM* 2,200 RPM* 1,700 RPM* 51464 1/4"

Stainless Steel: 220" 18" 27" 36" 20" 30" 40" 18" 27" 36" 18" 27" 36" 19" 28" 38" 19" 28" 38" 51610 3mm

51612 4mm

304, 316, 17-4 PH

51614 6mm

5,300 RPM* 4,700 RPM* 2,700 RPM* 2,100 RPM* 1,800 RPM* 1,300 RPM* 4 Flute

Titanium Alloys 175" 18" 27" 36" 20" 30" 40" 18" 27" 36" 18" 27" 36" 19" 28" 38" 19" 28" 38" 51602 1/8"

51604 1/4"

10,700 RPM* 7,100 RPM* 5,300 RPM* 4,300 RPM* 3,600 RPM* 2,600 RPM*

Cast Iron: Gray CG 350" 18" 27" 36" 20" 30" 40" 18" 27" 36" 18" 27" 36" 19" 28" 38" 19" 28" 38"

7,600 RPM* 5,100 RPM* 3,800 RPM* 3,100 RPM* 2,500 RPM* 1,900 RPM*

Cast Iron: Ductile 250" 18" 27" 36" 20" 30" 40" 18" 27" 36" 18" 27" 36" 19" 28" 38" 19" 28" 38"

*RPM: Revolutions Per Minute

Simple Machining Calculations:

To find RPM: (SFM x 3.82) / diameter of tool

To find SFM: 0.262 x diameter of tool x RPM

To find Feed Rate IPM: RPM x # of flutes x chip load

To find Chip Load: Feed Rate IPM / (RPM x # of Flutes)

Depth of Cut: 1 x D Use recommended feed rate

2 x D Reduce feed rate by 25%

3 x D Reduce feed rate by 50%

Disclaimer: It is important to understand that these values are only recommendations. © Copyright Amana Tool® All Rights Reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Npti BooksDocument3 pagesNpti BooksYogendra88% (8)

- Cooling Tower PracticalDocument17 pagesCooling Tower PracticalRichardt LootsNo ratings yet

- The ArmatronDocument20 pagesThe ArmatronCar Jav EspNo ratings yet

- The Influence of The Overlap Ratio On Transmission Error in Parallel Axis GearsDocument8 pagesThe Influence of The Overlap Ratio On Transmission Error in Parallel Axis GearsMurugan Jeyaselvan JaiNo ratings yet

- SF7 XCM Da PDFDocument1 pageSF7 XCM Da PDFPéter KovátsNo ratings yet

- Nov Dec 2018 Som Question Paper SPPUDocument6 pagesNov Dec 2018 Som Question Paper SPPUaniket wadheNo ratings yet

- Engine Control Fuel SystemDocument154 pagesEngine Control Fuel Systemdothicamvan101No ratings yet

- The Allen Engine-Charles T. PorterDocument3 pagesThe Allen Engine-Charles T. PorterLuis VizcaínoNo ratings yet

- Theory of Indeterminate StructuresDocument6 pagesTheory of Indeterminate StructuresRimon GawandeNo ratings yet

- Tender Coconut Extracting MachineDocument17 pagesTender Coconut Extracting MachineMANJUNATHA K H100% (2)

- VWP Installation and Operation ManualDocument14 pagesVWP Installation and Operation ManualDenzil StephensonNo ratings yet

- GAPL-HVAC People UKDocument20 pagesGAPL-HVAC People UKrandeep ravishNo ratings yet

- Solar Air Conditioning (1) Physics Seminar TopicsDocument5 pagesSolar Air Conditioning (1) Physics Seminar TopicsMichael Asmith UniqueNo ratings yet

- 01 10 0001 enDocument4 pages01 10 0001 enFernando SabinoNo ratings yet

- HEAT & THERMODYNAMICS (WWW - Crackjee.xyz)Document210 pagesHEAT & THERMODYNAMICS (WWW - Crackjee.xyz)Ajay Adithya100% (1)

- Heat Transfer in Bioreactor: Manam Walait Lecturer FLS, UCP LahoreDocument8 pagesHeat Transfer in Bioreactor: Manam Walait Lecturer FLS, UCP LahoreJawadNo ratings yet

- Unit 2 Welding III HazDocument9 pagesUnit 2 Welding III HazHada NanuNo ratings yet

- Pipe FittingsDocument273 pagesPipe FittingsRyan Goh Chuang HongNo ratings yet

- Lag Rang Ian Dynamic Formulation of A Four-Bar MechanismDocument7 pagesLag Rang Ian Dynamic Formulation of A Four-Bar MechanismpradeepkumaruvNo ratings yet

- Pharmaceutical Engineering: Gpat Online ClassesDocument49 pagesPharmaceutical Engineering: Gpat Online ClassesWadih Al-amriyNo ratings yet

- Wiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinDocument4 pagesWiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinAnonymous yjK3peI7No ratings yet

- Gaseous Oxygen SystemsDocument30 pagesGaseous Oxygen SystemsJacob Philip100% (1)

- Sundyne Prospekt Int Geared PDFDocument16 pagesSundyne Prospekt Int Geared PDFrohituchaniNo ratings yet

- Tchart PDFDocument3 pagesTchart PDFferdyak1No ratings yet

- BroombastickDocument3 pagesBroombastickAllen SornitNo ratings yet

- 6001b Failure QTR July-Sept PP 64-66Document3 pages6001b Failure QTR July-Sept PP 64-66Hernan Giraut100% (2)

- 2005 Bookmatter SurfaceWavesInGeomechanicsDire PDFDocument8 pages2005 Bookmatter SurfaceWavesInGeomechanicsDire PDFJulioPNo ratings yet

- Major Risks in Ammonia PlantsDocument17 pagesMajor Risks in Ammonia PlantsrobertionNo ratings yet

- Cyclic1D UserManualDocument28 pagesCyclic1D UserManualABDELILAH ERRAHALINo ratings yet