Professional Documents

Culture Documents

Circular Absorptive Attenuators: Dimensions Type Sac

Circular Absorptive Attenuators: Dimensions Type Sac

Uploaded by

constantin.iacomi3837Copyright:

Available Formats

You might also like

- Oil Water Separator DrawingDocument1 pageOil Water Separator DrawingHazem Esam100% (1)

- Module-3.-RECREATION (Laro NG Lahi) 1Document7 pagesModule-3.-RECREATION (Laro NG Lahi) 1Michael Estela Jr.No ratings yet

- Silo 100 Ton Cement PDFDocument1 pageSilo 100 Ton Cement PDFMahmoud Taher El Khorzaty100% (3)

- Stylep 1 PDFDocument4 pagesStylep 1 PDF1dsmark27088No ratings yet

- Top Sectional Plan ViewDocument1 pageTop Sectional Plan ViewMan ChupingNo ratings yet

- 5-2 AC 101 - GrilleDocument3 pages5-2 AC 101 - GrilleGopi nathNo ratings yet

- 2l Ugr CompleteDocument5 pages2l Ugr CompletesinghNo ratings yet

- BPDL As-2Document16 pagesBPDL As-2chandra mouliNo ratings yet

- ITO Floor Plans Catalogue - Lunchrooms 12.04.2017Document8 pagesITO Floor Plans Catalogue - Lunchrooms 12.04.2017instanttransportableofficesNo ratings yet

- Sample Slope Protection DetailDocument1 pageSample Slope Protection DetailChub BokingoNo ratings yet

- 2 Whitgift Street Croydon NpsDocument35 pages2 Whitgift Street Croydon NpsravNo ratings yet

- Technical Data Sheet: DescriptionDocument2 pagesTechnical Data Sheet: DescriptionDhouha AbbassiNo ratings yet

- 9 ISTIQ Acoustic LouversDocument2 pages9 ISTIQ Acoustic LouversRichard OonNo ratings yet

- Elevation Section - A: Opening ScheduleDocument1 pageElevation Section - A: Opening Schedulechandra mouliNo ratings yet

- Water Fountain - R1Document1 pageWater Fountain - R1Arkhitekton engineeringNo ratings yet

- Plan 1-ModelDocument1 pagePlan 1-Modelchandra mouliNo ratings yet

- Astralloy 600 Pipe: A 600 BHN Abrasion Resistant PipeDocument4 pagesAstralloy 600 Pipe: A 600 BHN Abrasion Resistant Pipesarsan nedumkuzhiNo ratings yet

- RX 3100Document2 pagesRX 3100rakhikishore143No ratings yet

- RX 3100Document2 pagesRX 3100rakhikishore143No ratings yet

- DWG of 75 KL OHT, Kanhargaon - 1Document1 pageDWG of 75 KL OHT, Kanhargaon - 1Rajendra MittalNo ratings yet

- Peerless Pump Brochures and Flyers - 8196Document2 pagesPeerless Pump Brochures and Flyers - 8196Gaudencio Rodriguez RomeroNo ratings yet

- Riwaq New ColorsDocument6 pagesRiwaq New ColorsMahmoud SayedNo ratings yet

- Arch Detales 4Document1 pageArch Detales 4Joseph JayakanthanNo ratings yet

- 15a.SLAB 1Document1 page15a.SLAB 1khuekhuphaweNo ratings yet

- Section A - A, Scale 1:100: All Dimension Are in MilimeterDocument1 pageSection A - A, Scale 1:100: All Dimension Are in MilimetergadielNo ratings yet

- Thorlux HI19721 Hi-Style-Led 24WDocument3 pagesThorlux HI19721 Hi-Style-Led 24WravNo ratings yet

- Halton DamperDocument8 pagesHalton Dampermarcel cocanNo ratings yet

- BND Group Limited8Document1 pageBND Group Limited8Nana BarimaNo ratings yet

- ATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeDocument4 pagesATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeWK Sinn100% (1)

- Data Bumax PerformanceDocument4 pagesData Bumax PerformanceMurali ShanNo ratings yet

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel WorksheetAFTAB SAEEDNo ratings yet

- HD Plus Double Bowl Sinks On Legs: Range CompositionDocument8 pagesHD Plus Double Bowl Sinks On Legs: Range CompositionahmvvsjaonbNo ratings yet

- Reinforcement Calculation of Abutment (2) : A B A BDocument12 pagesReinforcement Calculation of Abutment (2) : A B A Bshashi rajhansNo ratings yet

- Floor PlansDocument1 pageFloor PlansSantosh AryalNo ratings yet

- HRC752 802 902 1002 (C) Spec Sheet 50 60Document2 pagesHRC752 802 902 1002 (C) Spec Sheet 50 60FREDDY YAJAMINNo ratings yet

- OMS_DS_TruxianDocument1 pageOMS_DS_Truxiancsvignesh89No ratings yet

- Serie 602Document4 pagesSerie 602Jmanuel AvalosNo ratings yet

- Untitled 4Document1 pageUntitled 4chinsy83No ratings yet

- Description: Standard Density and ThicknessDocument2 pagesDescription: Standard Density and Thicknessarash khajeimNo ratings yet

- Intake Head WallDocument1 pageIntake Head Wallalfad maulaNo ratings yet

- 2 Burners Gas Boiling Tops: Range CompositionDocument2 pages2 Burners Gas Boiling Tops: Range CompositionAnuta CosminNo ratings yet

- KS MDDocument2 pagesKS MDJaza PmzaNo ratings yet

- KLIP-LOK 700 SpecsDocument8 pagesKLIP-LOK 700 Specsmontree SupaphobNo ratings yet

- Revised Low Cost 11 New District - Structural Semi Detached FNDDocument1 pageRevised Low Cost 11 New District - Structural Semi Detached FNDElirehema MunuoNo ratings yet

- Dimension & Drawing For Bio DigesterDocument1 pageDimension & Drawing For Bio DigesterVishal shuklaNo ratings yet

- Hy Andritz Split Case Pump en DataDocument8 pagesHy Andritz Split Case Pump en Datazhigang ding100% (1)

- HQ & H SeriesDocument2 pagesHQ & H SerieselshadNo ratings yet

- Foundation Anchoring DetailsDocument1 pageFoundation Anchoring DetailsskangralkarNo ratings yet

- Multileaf Data VCDDocument4 pagesMultileaf Data VCDalexa_liviaNo ratings yet

- Groutbag Data Sheet - GM Series 2008Document1 pageGroutbag Data Sheet - GM Series 2008sandysrNo ratings yet

- String Quartet - Violin IDocument4 pagesString Quartet - Violin IMartin NardoNo ratings yet

- AFL Series Led Flood Light CatalogDocument8 pagesAFL Series Led Flood Light Catalogpraween worachumpaNo ratings yet

- Slag Silo 40 MT Capacity Increase For Bihiya PlantDocument1 pageSlag Silo 40 MT Capacity Increase For Bihiya PlantShafeek AhamedNo ratings yet

- Body Repair - LT1Document1 pageBody Repair - LT1Dwiki Ananda PutraNo ratings yet

- Seawater Filters 2 FLTR Purple EngineeringDocument3 pagesSeawater Filters 2 FLTR Purple EngineeringFLTR PURPLE E.No ratings yet

- 5-3 AC 440 - Linear Bar GrillDocument1 page5-3 AC 440 - Linear Bar GrillGopi nathNo ratings yet

- Elevation: Rib Type Color Roofing Ga. 24 X 8ft of Approved ColorDocument1 pageElevation: Rib Type Color Roofing Ga. 24 X 8ft of Approved ColorJayson FernandezNo ratings yet

- PD1852 Datasheet 310114Document1 pagePD1852 Datasheet 310114Emilio Pérez SabariegoNo ratings yet

- 20 GNA 0363 - Datasheet - Peerless Pump Brochures and Flyers - AE - v8Document2 pages20 GNA 0363 - Datasheet - Peerless Pump Brochures and Flyers - AE - v8Anderson BaziaNo ratings yet

- CoverTechnology Ionization ENGDocument12 pagesCoverTechnology Ionization ENGconstantin.iacomi3837No ratings yet

- Jonix DUCT EN Web 03 2020Document8 pagesJonix DUCT EN Web 03 2020constantin.iacomi3837No ratings yet

- Extended Warranty Protocol Pressure enDocument8 pagesExtended Warranty Protocol Pressure enconstantin.iacomi3837No ratings yet

- Mounting Systems For Solar Technologie: Dummy OverviewDocument8 pagesMounting Systems For Solar Technologie: Dummy Overviewconstantin.iacomi3837No ratings yet

- JONIX 2021 - 360 - EN (RGB-web)Document2 pagesJONIX 2021 - 360 - EN (RGB-web)constantin.iacomi3837No ratings yet

- Slotted Hood Sketch For Fab Shop FabricationDocument1 pageSlotted Hood Sketch For Fab Shop Fabricationconstantin.iacomi3837No ratings yet

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, Incconstantin.iacomi3837No ratings yet

- Extended Warranty Protocol Flow enDocument8 pagesExtended Warranty Protocol Flow enconstantin.iacomi3837No ratings yet

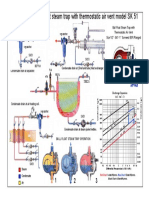

- Application For SK-51Document1 pageApplication For SK-51constantin.iacomi3837No ratings yet

- Batching Units - Pumps Series Akl - TPZ: Instructions ManualDocument19 pagesBatching Units - Pumps Series Akl - TPZ: Instructions Manualconstantin.iacomi3837No ratings yet

- Validation Plan For Hvac: (Heating, Ventilation and Air Conditioning)Document51 pagesValidation Plan For Hvac: (Heating, Ventilation and Air Conditioning)constantin.iacomi3837100% (1)

- Exhaustare in AtmosferaDocument1 pageExhaustare in Atmosferaconstantin.iacomi3837No ratings yet

- Design, Installation and Maintenance Instructions: Maxair Ducted Fan Coil SystemsDocument53 pagesDesign, Installation and Maintenance Instructions: Maxair Ducted Fan Coil Systemsconstantin.iacomi3837No ratings yet

- Sa Racord DN 560 Pe Canal CircularDocument3 pagesSa Racord DN 560 Pe Canal Circularconstantin.iacomi3837No ratings yet

- VAL Team Adca: Condensate Drain Valves CDV 32Document2 pagesVAL Team Adca: Condensate Drain Valves CDV 32constantin.iacomi3837No ratings yet

- Six-Way Zone Valves: Usage Point Usage Point Usage Point Usage PointDocument8 pagesSix-Way Zone Valves: Usage Point Usage Point Usage Point Usage Pointconstantin.iacomi3837No ratings yet

- Ashrae Pocket Guide For Air ConditioningDocument448 pagesAshrae Pocket Guide For Air Conditioningconstantin.iacomi3837100% (2)

- CR24 2 2 enDocument32 pagesCR24 2 2 enconstantin.iacomi3837No ratings yet

- Thermostatic Steam Trap (Air Vent) : Size 3/8"-1/2" Screwed BSPDocument1 pageThermostatic Steam Trap (Air Vent) : Size 3/8"-1/2" Screwed BSPconstantin.iacomi3837No ratings yet

- Etansare Filete SteamsealDocument2 pagesEtansare Filete Steamsealconstantin.iacomi3837No ratings yet

- Purestat Engineered Technologies, Inc: The Quality Choice in Clean Room CertificationDocument27 pagesPurestat Engineered Technologies, Inc: The Quality Choice in Clean Room Certificationconstantin.iacomi3837No ratings yet

- Condensate Drain Valves CDV 32: DescriptionDocument4 pagesCondensate Drain Valves CDV 32: Descriptionconstantin.iacomi3837No ratings yet

- Series EC Fan VAV Terminal Boxes: Type SFTBDocument14 pagesSeries EC Fan VAV Terminal Boxes: Type SFTBconstantin.iacomi3837No ratings yet

- Capac 560Document1 pageCapac 560constantin.iacomi3837No ratings yet

- Specifications: WG40 WG75 WG100 WG175 Performance Model NumberDocument1 pageSpecifications: WG40 WG75 WG100 WG175 Performance Model Numberconstantin.iacomi3837No ratings yet

- Magnum Series: Key FeaturesDocument1 pageMagnum Series: Key Featuresconstantin.iacomi3837No ratings yet

- Algebra and Geometry: Hung-Hsi WuDocument417 pagesAlgebra and Geometry: Hung-Hsi WuBob Cross100% (1)

- Specifications For Lightning & Earthing Protection SystemDocument9 pagesSpecifications For Lightning & Earthing Protection SystemMuhammad Ibad Alam100% (1)

- Spur GearDocument3 pagesSpur Gearigualdi53No ratings yet

- Academic Burnout and Student Engagement: A Moderated Mediation Model of Internal Locus of Control and LonelinessDocument21 pagesAcademic Burnout and Student Engagement: A Moderated Mediation Model of Internal Locus of Control and LonelinessHimanshu ShuklaNo ratings yet

- Media Studies Notes-Class: Co-Owner of A Lonely Heart and DR Who: An Unearthly ChildDocument3 pagesMedia Studies Notes-Class: Co-Owner of A Lonely Heart and DR Who: An Unearthly ChildAksharaNo ratings yet

- EthernetDocument37 pagesEthernetUrvarshi GhoshNo ratings yet

- Article Review Guideline - New Global Vision College - Addis AbabaDocument2 pagesArticle Review Guideline - New Global Vision College - Addis AbabaMan TK80% (5)

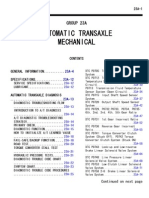

- GR00002600 23a PDFDocument180 pagesGR00002600 23a PDFStephen JordanNo ratings yet

- CsPbI3 XRDCDocument5 pagesCsPbI3 XRDCVinicius RochaNo ratings yet

- First CryDocument4 pagesFirst CrysamikshaNo ratings yet

- Performance Comparison of Sequential Quick Sort and Parallel Quick Sort AlgorithmsDocument9 pagesPerformance Comparison of Sequential Quick Sort and Parallel Quick Sort AlgorithmsWidya UtamiNo ratings yet

- FiberCable 2 V8 56 Oct20Document288 pagesFiberCable 2 V8 56 Oct20Ronald N Meza CNo ratings yet

- White - Paper-Bad Mad RobotsDocument19 pagesWhite - Paper-Bad Mad RobotsLexNo ratings yet

- Laptop Dell (1Th) : MSI Laptop Gaming-Design Laptop HP (2Th) Vaio Avita (2Th)Document1 pageLaptop Dell (1Th) : MSI Laptop Gaming-Design Laptop HP (2Th) Vaio Avita (2Th)Rizal Yoga PrasetyaNo ratings yet

- 10985C 03Document19 pages10985C 03Rene SaletrosNo ratings yet

- The Basics of Oracle ArchitectureDocument5 pagesThe Basics of Oracle Architecturebhuvan_boseNo ratings yet

- Remedial CT-1 21MAB101TDocument2 pagesRemedial CT-1 21MAB101Ttd4520No ratings yet

- NI 0133 (English)Document112 pagesNI 0133 (English)Cebrac ItatibaNo ratings yet

- NordicDLZ - HZXKE - Product PresentationDocument22 pagesNordicDLZ - HZXKE - Product PresentationВасилий ВасильченкоNo ratings yet

- English: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDocument25 pagesEnglish: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDorothy Yen Escalaña0% (1)

- Info Iec61000-4-30 (Ed1.0) en DDocument7 pagesInfo Iec61000-4-30 (Ed1.0) en DHARMET UP3 PEMATANGSIANTARNo ratings yet

- Bridge Over River Brahmaputra Between Dhubri and PhulbariDocument8 pagesBridge Over River Brahmaputra Between Dhubri and PhulbariANKUR GHOSHNo ratings yet

- Ge 12 - SyllabusDocument8 pagesGe 12 - SyllabusJie LimNo ratings yet

- The Lang 20W Class-A Mosfet AmplifierDocument7 pagesThe Lang 20W Class-A Mosfet AmplifiermoisesNo ratings yet

- Fettweis 1986Document60 pagesFettweis 1986Alex Arm.No ratings yet

- DQ 1 Week 8Document6 pagesDQ 1 Week 8LeeginaNo ratings yet

- Career Development ProjectDocument12 pagesCareer Development Projectapi-281199790No ratings yet

- Parts Catalog: 25 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

- Mil STD 1691 - 2011Document1,462 pagesMil STD 1691 - 2011mogatorNo ratings yet

Circular Absorptive Attenuators: Dimensions Type Sac

Circular Absorptive Attenuators: Dimensions Type Sac

Uploaded by

constantin.iacomi3837Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circular Absorptive Attenuators: Dimensions Type Sac

Circular Absorptive Attenuators: Dimensions Type Sac

Uploaded by

constantin.iacomi3837Copyright:

Available Formats

CIRCULAR ACOUSTICS AS.

Bankveien 7, 1383 Asker, Norway

Office : +47 66 77 73 70, E-mail: acoustics@acoustics.no

ABSORPTIVE ATTENUATORS

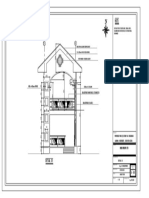

TYPE SAC2 DIMENSIONS A B L L1 L2

300

100 300 600 L+100 50

Application 900

Circular Sound Attenuators are used in ventilation systems and are specifically designed to reduce 1200

Flange type 300

duct born noise. Concerning noise sources such as axial fans, compressors, generators or any other Side view 125 325 600 L+100 50

900

type, these attenuators are highly recommended to reduce the generated noise. The attenuators can L1=overall lenght 1200

be made in different materials and as a flange or spigot type, making it accessible for installation in a Front view 300

L 160 360 600 L+100 50

variety of situations and are recommended for use in corrosive conditions as industrial and offshore L2 L2 900

1200

atmospheres. The SAC2 – 100 type is used as both primary and secondary attenuator, and can be 300

• • •

200 400 600 L+100 50

made in large dimensions. Special consideration is given to the design of all units which are to be 900

used in environments of high humidity, pollution or high temperatures. The design is optimized to • • 1200

300

attain a maximum insertion loss with a minimum pressure drop and may be used for pressures up to • • 250 450 600 L+100 50

B

A

900

20 bar.

• • 1200

300

• • • 315 515 600 L+100 50

Materials and dimensions 900

1200

The attenuator is normally constructed in stainless steel, and the standard sizes are shown in the 600

brochure, but all attenuators are individually designed according to the customers' requirements and 400 600 900 L+100 50

1200

non-standard sizes can be delivered upon request. Acoustical centerpods can be incorporated in the 1500

600

design for improved noise reduction performance where the pod's diameter can be adjusted for 500 700 900 L+100 50

optimal reduction. Spigot type 1200

1500

600

Noise data 630 830 900 L+100 50

Front view Side view 1200

The insulation material used consists of non-toxic and non-combustible mineral wool, and is firmly L

1500

900

covered by polyester or glass fibre cloth and a perforated plate to prevent fibre migration from the 800 1000 1200 L+100 50

1500

wool. For the circular sound attenuators the noise data is based on: 2000

900

1000 1250 1500 L+200 100

Ÿ ISO 7235- “Acoustic measurement procedure for ducted silencers – insertion loss, flow noise and 2000

B

A

2500

total pressure loss.” 1500

1250 1500 2000 L+200 100

2500

The sound reduction achieved by a sound attenuator is heavily dependent on the sound field inside a 3000

1500

duct, and is limited by the duct arrangement. This is why measurements on site will often vary from 1500 1800 2000 L+300 150

2500

laboratory measurements, because the attenuator on site will be affected by factors as flanking 3500

noise, background noise, vibration etc. In order to get the best possible result, please contact 2000

1700 2000 2500 L+300 150

Acoustics for accurate noise calculations for your particular need. For more information on self- 3000

4000

generated noise for the circular sound attenuator, please contact Acoustics. 2000

2500 L+300 150

3500

4500

SPECIFICATIONS

Attenuator Area Pressure Self gen Nominal Acoustic Connection Material

type code drop code noise code dia (A) lenght (L)

SAC2

To be specified

To be specified

A or B

100-1900

300-4500

Flange (F)

Spigot (S) }

To be specified

Example: SAC 2 - 1561B - Ø800 X 900L - F - AISI316L/3mm

CURVES AND TABLES

-5 EXAMPLE

Type Nominal Area Pressure Self. Static insertion losses dB, ref. 2 x 10 Pa

Airflow: 21.000 m 3/h - 5,83m 3/s

dimensions code drop gen.

Selected type: SAC2 -1561B - Ø800 X 900L mm

mm code noise Octave band centre frequency, Hz

Dia Length code

Diagram 2 - Pressure drop code: 61.

A L 63 125 250 500 1K 2K 4K 8K

Read: 37 Pa

SAC2 100 300 1 11 A 4 8 11 22 28 30 31 22

600 1 29 A 6 11 18 34 36 43 43 28 Diagram 3 - Self generated noise code: B

900 1 57 A 7 13 22 42 44 50 49 33

1200 1 86 A 8 14 25 48 50 50 50 40 Read: SWLtot = 72 dB

125 300 2 8 A 3 6 9 18 23 24 25 20

600 2 21 A 5 10 16 28 31 36 39 25

900 2 43 A 6 12 20 36 38 45 45 30

Frequency correction - table 1

1200 2 65 A 6 13 23 45 47 50 50 35 63 125 250 500 1K 2K 4K 8K

160 300 3 6 A 2 3 7 12 17 19 16 16

600 3 16 A 4 7 13 23 27 31 28 22 70 64 62 60 56 52 47 42

900 3 32 A 4 11 17 32 34 38 34 27

1200 3 48 A 5 12 22 40 42 46 42 28

200 300 4 4 A 2 3 7 9 15 18 15 12

600 4 12 A 3 6 12 21 23 25 19 17 SELF GENERATED NOISE

900 4 24 A 3 9 16 30 31 31 25 19

1200 4 36 A 3 11 21 36 38 37 34 24 - FREQUENCY CORRECTION

250 300 5 3 A 1 2 4 8 9 10 7 6

600 5 9 A 2 4 9 16 19 18 15 14

900 5 18 A 2 7 14 24 28 23 19 16 SWLfrequency = SWL tot + CF

1200 5 27 A 4 10 20 33 34 26 24 20

250 300 4 75 B 1 3 8 13 18 16 13 9

600 4 98 B 2 6 17 27 34 32 30 27

900 4 150 B 2 9 21 33 41 39 36 33 CORRECTION FACTORS CF

1200 4 201 B 5 12 25 42 50 48 45 37

315 300 7 3 A 1 2 3 7 7 9 5 4

ADD dB TABLE 1

600 7 7 A 2 4 8 14 15 14 11 8

900 7 13 A 2 6 13 20 22 18 14 11 FREQUENCY CORRECTION

1200 7 20 A 4 8 18 30 30 23 18 14

315 300 6 62 B 1 3 5 11 16 13 11 8 Self Centre band frequency, Hz ref 10-12 Watt

600 6 100 B 2 5 16 22 27 29 25 22 gen.

900 6 151 B 2 7 21 31 35 37 33 31 noise 63 125 250 500 1K 2K 4K 8K

1200 6 204 B 5 12 24 39 48 50 39 38 code

400 600 9 5 A 1 3 6 12 11 9 7 5

900 9 10 A 2 5 11 18 17 14 12 9 A -1 -9 -19 -26 -29 -34 -41 -42

1200 9 A 2 6 14 23 21 19 16 12

B -2 -8 -10 -12 -16 -20 -25 -30

1500 9 21 A 3 8 16 28 25 25 22 16

400 600 8 99 B 1 4 11 20 22 19 15 13

900 8 145 B 2 5 15 24 29 28 22 20 Note! Pressure drop values are based on

1200 8 180 B 3 7 20 29 34 37 30 26 air density 1,2 kg/m3 and temperature

1500 8 216 B 3 8 24 33 39 45 39 35

500 600 11 3 A 1 3 6 10 8 6 5 3 20C o. Duct connection

900 11 7 A 2 4 10 14 12 9 8 6

1200 11 11 A 2 6 13 17 16 12 11 8

1500 11 15 A 3 7 14 19 18 16 14 11

500 600 10 87 B 1 3 8 15 20 17 10 9

900 10 113 B 2 4 10 18 25 26 17 14

1200 10 139 B 3 6 16 21 30 37 25 18

1500 10 166 B 3 7 21 24 34 46 32 22

630 600 14 3 A 1 2 6 8 9 9 7 5

900 14 5 A 2 3 9 11 13 11 9 7

1200 14 8 A 2 5 12 14 16 15 14 9

1500 14 11 A 3 6 15 16 20 19 16 13

630 600 12 67 B 1 3 10 15 18 20 9 7

900 12 85 B 2 4 12 20 24 25 14 11

16

1200 12 101 B 2 4 13 23 29 28 16 13

1500 12 116 B 2 5 16 24 31 30 19 15

800 900 18 4 A 2 3 8 10 8 7 6 3

1200 18 6 A 2 3 10 13 10 9 8 5

1500 18 8 A 2 4 11 14 12 11 9 7

2000 18 12 A 3 5 13 16 15 13 11 9

800 900 15 61 B 2 3 9 16 20 16 11 9

1200 15 68 B 2 4 13 19 25 21 14 11

1500 15 76 B 2 5 16 22 30 26 18 16

2000 15 88 B 3 7 18 26 37 33 23 21

1000 900 23 3 A 1 2 7 9 8 7 4 2

1500 23 6 A 3 4 10 12 12 11 7 5

2000 23 9 A 4 5 12 15 14 13 10 7

2500 23 12 A 5 6 15 19 17 15 13 9

1000 900 18 63 B 2 3 11 18 21 18 13 11

1500 18 74 B 2 5 16 24 30 23 18 16

2000 18 82 B 3 7 19 28 36 26 23 20

2500 18 91 B 4 9 21 31 41 30 29 24

1250 1500 23 78 B 2 4 14 21 26 21 14 13

2000 23 85 B 3 6 17 23 30 26 16 15

2500 23 91 B 5 7 19 25 33 30 19 16

3000 23 97 B 6 9 21 27 35 33 21 18

1500 1500 30 74 B 3 6 15 21 27 14 9 8

2000 30 80 B 3 7 17 27 34 17 11 10

2500 30 86 B 4 7 18 30 37 18 11 10

3500 30 98 B 5 12 21 39 46 23 15 12

1700 2000 35 72 B 3 6 15 22 27 13 9 8

2500 35 77 B 3 7 18 26 31 15 9 8

3000 35 82 B 4 8 19 30 35 17 10 9

4000 35 94 B 6 16 26 39 44 24 17 12

1900 2000 38 66 B 3 6 14 18 21 11 7 6

2500 38 72 B 3 7 18 22 26 13 7 7

3500 38 82 B 5 12 25 31 35 19 11 9

4500 38 93 B 7 16 31 37 41 23 15 11

You might also like

- Oil Water Separator DrawingDocument1 pageOil Water Separator DrawingHazem Esam100% (1)

- Module-3.-RECREATION (Laro NG Lahi) 1Document7 pagesModule-3.-RECREATION (Laro NG Lahi) 1Michael Estela Jr.No ratings yet

- Silo 100 Ton Cement PDFDocument1 pageSilo 100 Ton Cement PDFMahmoud Taher El Khorzaty100% (3)

- Stylep 1 PDFDocument4 pagesStylep 1 PDF1dsmark27088No ratings yet

- Top Sectional Plan ViewDocument1 pageTop Sectional Plan ViewMan ChupingNo ratings yet

- 5-2 AC 101 - GrilleDocument3 pages5-2 AC 101 - GrilleGopi nathNo ratings yet

- 2l Ugr CompleteDocument5 pages2l Ugr CompletesinghNo ratings yet

- BPDL As-2Document16 pagesBPDL As-2chandra mouliNo ratings yet

- ITO Floor Plans Catalogue - Lunchrooms 12.04.2017Document8 pagesITO Floor Plans Catalogue - Lunchrooms 12.04.2017instanttransportableofficesNo ratings yet

- Sample Slope Protection DetailDocument1 pageSample Slope Protection DetailChub BokingoNo ratings yet

- 2 Whitgift Street Croydon NpsDocument35 pages2 Whitgift Street Croydon NpsravNo ratings yet

- Technical Data Sheet: DescriptionDocument2 pagesTechnical Data Sheet: DescriptionDhouha AbbassiNo ratings yet

- 9 ISTIQ Acoustic LouversDocument2 pages9 ISTIQ Acoustic LouversRichard OonNo ratings yet

- Elevation Section - A: Opening ScheduleDocument1 pageElevation Section - A: Opening Schedulechandra mouliNo ratings yet

- Water Fountain - R1Document1 pageWater Fountain - R1Arkhitekton engineeringNo ratings yet

- Plan 1-ModelDocument1 pagePlan 1-Modelchandra mouliNo ratings yet

- Astralloy 600 Pipe: A 600 BHN Abrasion Resistant PipeDocument4 pagesAstralloy 600 Pipe: A 600 BHN Abrasion Resistant Pipesarsan nedumkuzhiNo ratings yet

- RX 3100Document2 pagesRX 3100rakhikishore143No ratings yet

- RX 3100Document2 pagesRX 3100rakhikishore143No ratings yet

- DWG of 75 KL OHT, Kanhargaon - 1Document1 pageDWG of 75 KL OHT, Kanhargaon - 1Rajendra MittalNo ratings yet

- Peerless Pump Brochures and Flyers - 8196Document2 pagesPeerless Pump Brochures and Flyers - 8196Gaudencio Rodriguez RomeroNo ratings yet

- Riwaq New ColorsDocument6 pagesRiwaq New ColorsMahmoud SayedNo ratings yet

- Arch Detales 4Document1 pageArch Detales 4Joseph JayakanthanNo ratings yet

- 15a.SLAB 1Document1 page15a.SLAB 1khuekhuphaweNo ratings yet

- Section A - A, Scale 1:100: All Dimension Are in MilimeterDocument1 pageSection A - A, Scale 1:100: All Dimension Are in MilimetergadielNo ratings yet

- Thorlux HI19721 Hi-Style-Led 24WDocument3 pagesThorlux HI19721 Hi-Style-Led 24WravNo ratings yet

- Halton DamperDocument8 pagesHalton Dampermarcel cocanNo ratings yet

- BND Group Limited8Document1 pageBND Group Limited8Nana BarimaNo ratings yet

- ATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeDocument4 pagesATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeWK Sinn100% (1)

- Data Bumax PerformanceDocument4 pagesData Bumax PerformanceMurali ShanNo ratings yet

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel WorksheetAFTAB SAEEDNo ratings yet

- HD Plus Double Bowl Sinks On Legs: Range CompositionDocument8 pagesHD Plus Double Bowl Sinks On Legs: Range CompositionahmvvsjaonbNo ratings yet

- Reinforcement Calculation of Abutment (2) : A B A BDocument12 pagesReinforcement Calculation of Abutment (2) : A B A Bshashi rajhansNo ratings yet

- Floor PlansDocument1 pageFloor PlansSantosh AryalNo ratings yet

- HRC752 802 902 1002 (C) Spec Sheet 50 60Document2 pagesHRC752 802 902 1002 (C) Spec Sheet 50 60FREDDY YAJAMINNo ratings yet

- OMS_DS_TruxianDocument1 pageOMS_DS_Truxiancsvignesh89No ratings yet

- Serie 602Document4 pagesSerie 602Jmanuel AvalosNo ratings yet

- Untitled 4Document1 pageUntitled 4chinsy83No ratings yet

- Description: Standard Density and ThicknessDocument2 pagesDescription: Standard Density and Thicknessarash khajeimNo ratings yet

- Intake Head WallDocument1 pageIntake Head Wallalfad maulaNo ratings yet

- 2 Burners Gas Boiling Tops: Range CompositionDocument2 pages2 Burners Gas Boiling Tops: Range CompositionAnuta CosminNo ratings yet

- KS MDDocument2 pagesKS MDJaza PmzaNo ratings yet

- KLIP-LOK 700 SpecsDocument8 pagesKLIP-LOK 700 Specsmontree SupaphobNo ratings yet

- Revised Low Cost 11 New District - Structural Semi Detached FNDDocument1 pageRevised Low Cost 11 New District - Structural Semi Detached FNDElirehema MunuoNo ratings yet

- Dimension & Drawing For Bio DigesterDocument1 pageDimension & Drawing For Bio DigesterVishal shuklaNo ratings yet

- Hy Andritz Split Case Pump en DataDocument8 pagesHy Andritz Split Case Pump en Datazhigang ding100% (1)

- HQ & H SeriesDocument2 pagesHQ & H SerieselshadNo ratings yet

- Foundation Anchoring DetailsDocument1 pageFoundation Anchoring DetailsskangralkarNo ratings yet

- Multileaf Data VCDDocument4 pagesMultileaf Data VCDalexa_liviaNo ratings yet

- Groutbag Data Sheet - GM Series 2008Document1 pageGroutbag Data Sheet - GM Series 2008sandysrNo ratings yet

- String Quartet - Violin IDocument4 pagesString Quartet - Violin IMartin NardoNo ratings yet

- AFL Series Led Flood Light CatalogDocument8 pagesAFL Series Led Flood Light Catalogpraween worachumpaNo ratings yet

- Slag Silo 40 MT Capacity Increase For Bihiya PlantDocument1 pageSlag Silo 40 MT Capacity Increase For Bihiya PlantShafeek AhamedNo ratings yet

- Body Repair - LT1Document1 pageBody Repair - LT1Dwiki Ananda PutraNo ratings yet

- Seawater Filters 2 FLTR Purple EngineeringDocument3 pagesSeawater Filters 2 FLTR Purple EngineeringFLTR PURPLE E.No ratings yet

- 5-3 AC 440 - Linear Bar GrillDocument1 page5-3 AC 440 - Linear Bar GrillGopi nathNo ratings yet

- Elevation: Rib Type Color Roofing Ga. 24 X 8ft of Approved ColorDocument1 pageElevation: Rib Type Color Roofing Ga. 24 X 8ft of Approved ColorJayson FernandezNo ratings yet

- PD1852 Datasheet 310114Document1 pagePD1852 Datasheet 310114Emilio Pérez SabariegoNo ratings yet

- 20 GNA 0363 - Datasheet - Peerless Pump Brochures and Flyers - AE - v8Document2 pages20 GNA 0363 - Datasheet - Peerless Pump Brochures and Flyers - AE - v8Anderson BaziaNo ratings yet

- CoverTechnology Ionization ENGDocument12 pagesCoverTechnology Ionization ENGconstantin.iacomi3837No ratings yet

- Jonix DUCT EN Web 03 2020Document8 pagesJonix DUCT EN Web 03 2020constantin.iacomi3837No ratings yet

- Extended Warranty Protocol Pressure enDocument8 pagesExtended Warranty Protocol Pressure enconstantin.iacomi3837No ratings yet

- Mounting Systems For Solar Technologie: Dummy OverviewDocument8 pagesMounting Systems For Solar Technologie: Dummy Overviewconstantin.iacomi3837No ratings yet

- JONIX 2021 - 360 - EN (RGB-web)Document2 pagesJONIX 2021 - 360 - EN (RGB-web)constantin.iacomi3837No ratings yet

- Slotted Hood Sketch For Fab Shop FabricationDocument1 pageSlotted Hood Sketch For Fab Shop Fabricationconstantin.iacomi3837No ratings yet

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, Incconstantin.iacomi3837No ratings yet

- Extended Warranty Protocol Flow enDocument8 pagesExtended Warranty Protocol Flow enconstantin.iacomi3837No ratings yet

- Application For SK-51Document1 pageApplication For SK-51constantin.iacomi3837No ratings yet

- Batching Units - Pumps Series Akl - TPZ: Instructions ManualDocument19 pagesBatching Units - Pumps Series Akl - TPZ: Instructions Manualconstantin.iacomi3837No ratings yet

- Validation Plan For Hvac: (Heating, Ventilation and Air Conditioning)Document51 pagesValidation Plan For Hvac: (Heating, Ventilation and Air Conditioning)constantin.iacomi3837100% (1)

- Exhaustare in AtmosferaDocument1 pageExhaustare in Atmosferaconstantin.iacomi3837No ratings yet

- Design, Installation and Maintenance Instructions: Maxair Ducted Fan Coil SystemsDocument53 pagesDesign, Installation and Maintenance Instructions: Maxair Ducted Fan Coil Systemsconstantin.iacomi3837No ratings yet

- Sa Racord DN 560 Pe Canal CircularDocument3 pagesSa Racord DN 560 Pe Canal Circularconstantin.iacomi3837No ratings yet

- VAL Team Adca: Condensate Drain Valves CDV 32Document2 pagesVAL Team Adca: Condensate Drain Valves CDV 32constantin.iacomi3837No ratings yet

- Six-Way Zone Valves: Usage Point Usage Point Usage Point Usage PointDocument8 pagesSix-Way Zone Valves: Usage Point Usage Point Usage Point Usage Pointconstantin.iacomi3837No ratings yet

- Ashrae Pocket Guide For Air ConditioningDocument448 pagesAshrae Pocket Guide For Air Conditioningconstantin.iacomi3837100% (2)

- CR24 2 2 enDocument32 pagesCR24 2 2 enconstantin.iacomi3837No ratings yet

- Thermostatic Steam Trap (Air Vent) : Size 3/8"-1/2" Screwed BSPDocument1 pageThermostatic Steam Trap (Air Vent) : Size 3/8"-1/2" Screwed BSPconstantin.iacomi3837No ratings yet

- Etansare Filete SteamsealDocument2 pagesEtansare Filete Steamsealconstantin.iacomi3837No ratings yet

- Purestat Engineered Technologies, Inc: The Quality Choice in Clean Room CertificationDocument27 pagesPurestat Engineered Technologies, Inc: The Quality Choice in Clean Room Certificationconstantin.iacomi3837No ratings yet

- Condensate Drain Valves CDV 32: DescriptionDocument4 pagesCondensate Drain Valves CDV 32: Descriptionconstantin.iacomi3837No ratings yet

- Series EC Fan VAV Terminal Boxes: Type SFTBDocument14 pagesSeries EC Fan VAV Terminal Boxes: Type SFTBconstantin.iacomi3837No ratings yet

- Capac 560Document1 pageCapac 560constantin.iacomi3837No ratings yet

- Specifications: WG40 WG75 WG100 WG175 Performance Model NumberDocument1 pageSpecifications: WG40 WG75 WG100 WG175 Performance Model Numberconstantin.iacomi3837No ratings yet

- Magnum Series: Key FeaturesDocument1 pageMagnum Series: Key Featuresconstantin.iacomi3837No ratings yet

- Algebra and Geometry: Hung-Hsi WuDocument417 pagesAlgebra and Geometry: Hung-Hsi WuBob Cross100% (1)

- Specifications For Lightning & Earthing Protection SystemDocument9 pagesSpecifications For Lightning & Earthing Protection SystemMuhammad Ibad Alam100% (1)

- Spur GearDocument3 pagesSpur Gearigualdi53No ratings yet

- Academic Burnout and Student Engagement: A Moderated Mediation Model of Internal Locus of Control and LonelinessDocument21 pagesAcademic Burnout and Student Engagement: A Moderated Mediation Model of Internal Locus of Control and LonelinessHimanshu ShuklaNo ratings yet

- Media Studies Notes-Class: Co-Owner of A Lonely Heart and DR Who: An Unearthly ChildDocument3 pagesMedia Studies Notes-Class: Co-Owner of A Lonely Heart and DR Who: An Unearthly ChildAksharaNo ratings yet

- EthernetDocument37 pagesEthernetUrvarshi GhoshNo ratings yet

- Article Review Guideline - New Global Vision College - Addis AbabaDocument2 pagesArticle Review Guideline - New Global Vision College - Addis AbabaMan TK80% (5)

- GR00002600 23a PDFDocument180 pagesGR00002600 23a PDFStephen JordanNo ratings yet

- CsPbI3 XRDCDocument5 pagesCsPbI3 XRDCVinicius RochaNo ratings yet

- First CryDocument4 pagesFirst CrysamikshaNo ratings yet

- Performance Comparison of Sequential Quick Sort and Parallel Quick Sort AlgorithmsDocument9 pagesPerformance Comparison of Sequential Quick Sort and Parallel Quick Sort AlgorithmsWidya UtamiNo ratings yet

- FiberCable 2 V8 56 Oct20Document288 pagesFiberCable 2 V8 56 Oct20Ronald N Meza CNo ratings yet

- White - Paper-Bad Mad RobotsDocument19 pagesWhite - Paper-Bad Mad RobotsLexNo ratings yet

- Laptop Dell (1Th) : MSI Laptop Gaming-Design Laptop HP (2Th) Vaio Avita (2Th)Document1 pageLaptop Dell (1Th) : MSI Laptop Gaming-Design Laptop HP (2Th) Vaio Avita (2Th)Rizal Yoga PrasetyaNo ratings yet

- 10985C 03Document19 pages10985C 03Rene SaletrosNo ratings yet

- The Basics of Oracle ArchitectureDocument5 pagesThe Basics of Oracle Architecturebhuvan_boseNo ratings yet

- Remedial CT-1 21MAB101TDocument2 pagesRemedial CT-1 21MAB101Ttd4520No ratings yet

- NI 0133 (English)Document112 pagesNI 0133 (English)Cebrac ItatibaNo ratings yet

- NordicDLZ - HZXKE - Product PresentationDocument22 pagesNordicDLZ - HZXKE - Product PresentationВасилий ВасильченкоNo ratings yet

- English: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDocument25 pagesEnglish: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDorothy Yen Escalaña0% (1)

- Info Iec61000-4-30 (Ed1.0) en DDocument7 pagesInfo Iec61000-4-30 (Ed1.0) en DHARMET UP3 PEMATANGSIANTARNo ratings yet

- Bridge Over River Brahmaputra Between Dhubri and PhulbariDocument8 pagesBridge Over River Brahmaputra Between Dhubri and PhulbariANKUR GHOSHNo ratings yet

- Ge 12 - SyllabusDocument8 pagesGe 12 - SyllabusJie LimNo ratings yet

- The Lang 20W Class-A Mosfet AmplifierDocument7 pagesThe Lang 20W Class-A Mosfet AmplifiermoisesNo ratings yet

- Fettweis 1986Document60 pagesFettweis 1986Alex Arm.No ratings yet

- DQ 1 Week 8Document6 pagesDQ 1 Week 8LeeginaNo ratings yet

- Career Development ProjectDocument12 pagesCareer Development Projectapi-281199790No ratings yet

- Parts Catalog: 25 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

- Mil STD 1691 - 2011Document1,462 pagesMil STD 1691 - 2011mogatorNo ratings yet