Professional Documents

Culture Documents

Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast Alloy

Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast Alloy

Uploaded by

evelynCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASTM B733 Electroless Nickel PlatingDocument13 pagesASTM B733 Electroless Nickel PlatingManan Vadher100% (1)

- Articulo 319Document4 pagesArticulo 319evelynNo ratings yet

- E3-11 Preparation of Metallographic Specimens PDFDocument12 pagesE3-11 Preparation of Metallographic Specimens PDFevelyn50% (2)

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDocument5 pagesPen Rchive Oulouse Rchive Uverte : O A T A O OataoevelynNo ratings yet

- 28 Pezda Effect of t6 1s 2013Document4 pages28 Pezda Effect of t6 1s 2013evelynNo ratings yet

- Effect of Hardness Test On Precipitation Hardening Aluminium Alloy 6061-T6Document11 pagesEffect of Hardness Test On Precipitation Hardening Aluminium Alloy 6061-T6evelynNo ratings yet

- Fabco 115Document2 pagesFabco 115jimmy_wdNo ratings yet

- Draft Handbook On Welding TechniquesDocument77 pagesDraft Handbook On Welding Techniquessssf-doboj100% (2)

- Sae J404-2000 PDFDocument5 pagesSae J404-2000 PDF2601220150379No ratings yet

- 13480-2 2017 EN-MaterialsDocument83 pages13480-2 2017 EN-MaterialsPaulo VidasinhaNo ratings yet

- Unibar 7Document18 pagesUnibar 7marutb99No ratings yet

- BVL Dau Han NgoaiDocument1 pageBVL Dau Han NgoaiHanLe DuyNo ratings yet

- 410 Stainless Steel Wire UNS S41000 WireDocument4 pages410 Stainless Steel Wire UNS S41000 WireFarid Naim Bojanini PerezNo ratings yet

- 43 Fallo en Alabe de Turbina de GasDocument13 pages43 Fallo en Alabe de Turbina de GasJuanpe HdezNo ratings yet

- Lamina Tech - Catálogo 2017-2018 PDFDocument342 pagesLamina Tech - Catálogo 2017-2018 PDFGilberto Garcia100% (2)

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- Argañaraz 2011 Electrochimica-Acta 1Document6 pagesArgañaraz 2011 Electrochimica-Acta 1momenziNo ratings yet

- Mechanical Behavior of Aluminum Metal Matrix Composite Reinforcement With Graphene Nano FillersDocument11 pagesMechanical Behavior of Aluminum Metal Matrix Composite Reinforcement With Graphene Nano FillersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- STOH FailuresDocument6 pagesSTOH FailuresWilson MillanNo ratings yet

- ASTM A516-70 Plate As Rolled - Pressure Vessel Grade SteelDocument2 pagesASTM A516-70 Plate As Rolled - Pressure Vessel Grade SteelHidden TruthNo ratings yet

- Material Metallurgy - Descriptive TypesDocument53 pagesMaterial Metallurgy - Descriptive TypesSushant GhurupNo ratings yet

- Alloy 6201 Product Specification Rev.0Document3 pagesAlloy 6201 Product Specification Rev.0serkan temelNo ratings yet

- The Structure of The AtomDocument28 pagesThe Structure of The AtomAnonymous dh6DITNo ratings yet

- Elkem 13 Compacted Graphite IronDocument2 pagesElkem 13 Compacted Graphite Ironmarcotulio123No ratings yet

- Api 578-Mock 1 - KeyDocument28 pagesApi 578-Mock 1 - KeysheikmoinNo ratings yet

- ForgingDocument35 pagesForgingGopalakrishnan KuppuswamyNo ratings yet

- Attachment 8 - STN 00 Z20 V SP 0002 - A01 - ENDocument18 pagesAttachment 8 - STN 00 Z20 V SP 0002 - A01 - ENrameshqcNo ratings yet

- partPG PDFDocument75 pagespartPG PDFJatin SomaiyaNo ratings yet

- Types of Butterfly Valves (API 609) - ProjectmaterialsDocument19 pagesTypes of Butterfly Valves (API 609) - Projectmaterialssornapudi.pradeep1991No ratings yet

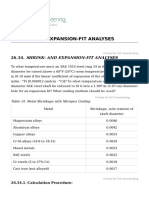

- Shrink - and Expansion-Fit AnalysesDocument3 pagesShrink - and Expansion-Fit AnalysesScribdUser11235No ratings yet

- Manual ELECTRODOS LINCOLNDocument48 pagesManual ELECTRODOS LINCOLNLeyniz York Arias LlanosNo ratings yet

- Metals and Non MetalsDocument10 pagesMetals and Non MetalsKaran MahajanNo ratings yet

- Spec # Specification Title - 01/2016 Amendments Document Status Revision SourceDocument10 pagesSpec # Specification Title - 01/2016 Amendments Document Status Revision SourceTony C.No ratings yet

- DIS Ductile Iron Quality Assurance GuideDocument117 pagesDIS Ductile Iron Quality Assurance GuidesushilrajageNo ratings yet

- 9.57405-Eng - Plating Std.Document20 pages9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)

Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast Alloy

Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast Alloy

Uploaded by

evelynOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast Alloy

Tillová (2012) - Solution Treatment Effect On Microstructure and Mechanical Properties of Automotive Cast Alloy

Uploaded by

evelynCopyright:

Available Formats

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License.

To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/ or send a letter to Creative

Commons, 444 Castro Street, Suite 900, Mountain View, California, 94041, USA.

E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical 39

This copy of the article was downloaded from http://www.mateng.sk , online version of Materials Engineering - Materiálové inžinierstvo (MEMI)

properties of automotive cast alloy

journal, ISSN 1335-0803 (print version), ISSN 1338-6174 (online version). Online version of the journal is supported by www.websupport.sk .

SOLUTION TREATMENT EFFECT ON

MICROSTRUCTURE AND MECHANICAL

PROPERTIES OF AUTOMOTIVE CAST ALLOY

Eva Tillová1,*, Mária Chalupová1

1

Department of Materials Engineering, Faculty of Mechanical Engineering, University of Žilina, Univerzitná 1,

010 26 Žilina, Slovak Republic.

*

corresponding author: Tel.: 00421-41-513 6007, Fax: 00421-41-565 2940, e-mail: eva.tillova@fstroj.uniza.sk

Resume Article info

The contribution describes influence of the heat treatment (solution

treatment at temperature 545°C and 565°C with different holding time 2, Article history:

4, 8, 16 and 32 hours; than water quenching at 40°C and natural aging at Received 21 July 2011

room temperature during 24 hours) on mechanical properties (tensile Accepted 12 December 2011

strength and Brinell hardness) and microstructure of the secondary Online 6 February 2012

AlSi12Cu1Fe automotive cast alloy. Mechanical properties were

measured in line with EN ISO. A combination of different analytical Keywords:

techniques (light microscopy, scanning electron microscopy (SEM)) were AlSi12Cu1Fe;

therefore been used for study of microstructure. Solution treatment led to Solution treatment;

changes in microstructure includes the spheroidization and coarsening of Mechanical properties;

eutectic silicon. The dissolution of precipitates and the precipitation of Microstructure

finer hardening phase further increase the hardness and tensile strength of

the alloy. Optimal solution treatment (545°C/4 hours) most improves

mechanical properties and there mechanical properties are comparable

with mechanical properties of primary AlSi12Cu1Fe alloy. Solution

treatment at 565 °C caused testing samples distortion, local melting

process and is not applicable for this secondary alloy with 12.5 % Si. ISSN 1335-0803 (print version)

Available online: http://fstroj.uniza.sk/journal-mi/PDF/2012/07-2012.pdf ISSN 1338-6174 (online version)

1. Introduction means that efficient aluminium recycling is

The use of aluminium components in the profitable.

automotive industry has increased considerably Among aluminium alloys, aluminium-

during the past ten years due to their lightweight silicon (Al-Si) alloys are known for their good

and reduced fuel energy consumption advantages. castability and mechanical properties. The

Another advantage, which is equally important addition of Mg, Cu, and Zn makes the alloys

from an environmental point of view, is the fact heat-treatable [2-3], providing the means to

that aluminium components may be recycled at enhance their properties with the use of

relatively low energy costs. Secondary aluminium appropriate heat treatments. The mechanical

produced from recycled Al-metal requires only properties of an Al-Si cast alloy are mainly

about 2.8 kWh/kg of metal produced. Primary determined by its cast structure and the

aluminium production is highly energy-intensive microstructural characteristics such as the grain

and requires about 45 kWh/kg of Al-metal size, dendrite arm spacing (DAS), the size,

produced. Please note, however, that the metal's shape and distribution of the eutectic silicon

melting point (approx. 660 °C) is so low that re- particles, as well as the morphologies and

melting requires only about five per cent of the amounts of present intermetallic phases [2-7].

original energy input and creates only about 5 % These parameters are completely changed after

as much CO2 as by primary production [1]. This heat treatment, which, in turn, influences the

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

40 E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical

properties of automotive cast alloy

resultant mechanical properties [2-3, 8-12].

The present study is a part of larger research

project, which was conducted to investigate and to

provide a better understanding of secondary

(recycled) cast alloys after heat treatment. Present

work is focused on study of the effect of solution

heat treatment parameters on mechanical

properties and on microstructure (changes in Fig. 1. Experimental castings

morphology of eutectic Si and intermetallic

phases) of AlSi12Cu1Fe cast alloy. In the The sand casting produced from primary

automotive industry this recycled alloy is used in AlSi12Cu1Fe cast alloy achieves high values for

the form of various motor mounts or pistons, tensile strength (Rm = 240 MPa), offset 0.2 %

cylinder blocks and so on. yield stress (Rp0.2 = 140 MPa), however the low

ductility limits (1 - 3 %) and Brinell hardness

70 HB.

2. Experimental part

Experimental samples (standard tensile

As an experimental material was used

test specimens) were treated with T4 heat

secondary (recycled) eutectic AlSi12Cu1Fe cast

treatment - solution treatment for 2, 4, 8, 16 or

alloy (in the form of 12.5 kg ingots). The chemical

32 hours at two temperatures (545 °C and

composition is presented in the table 1. The alloy

565 °C); water quenching at 40 °C and natural

was molten into the sand form. Sand casting is the

simplest and most widely used casting method. A aging for 24 hours at room temperature. After

pattern, of the final casting (Fig. 1), was formed heat treatment were samples subjected for

from metal. The melting temperature was mechanical test. For as cast state, each solution

maintained at 760 °C ± 5 °C. Melting was before temperature and each aging time, a minimum of

casting refined with salt AlCu4B6. The melt was five specimens were tested.

not modified or grain refined. The chemical Metallographic samples were prepared

analysis of AlSi12Cu1Fe cast alloy was carried from selected tensile specimens (after testing)

out using arc spark spectroscopy. and the microstructures were examined by

optical and electron microscopy (SEM).

AlSi12Cu1Fe as eutectic cast alloy has very

Samples were prepared by standards

good castability, lower corrosion resistance and is

metallographic procedures (mounting in

suitable for high temperature applications

bakelite, wet ground, DP polished with diamond

(dynamic exposed casts, where are not so high

pastes, finally polished with commercial fine

requirements on mechanical properties) - it means

silica slurry (STRUERS OP-U) and etched by

to 250 °C. Such high silicon contents assure the

Dix-Keller. Some samples were also deep-

dimensional stability of the casting upon heating

etched for 15-30 s in HCl solution in order to

e.g. for new Audi V6 and V8 cylinder block.

reveal the three-dimensional morphology of the

eutectic silicon [4]. The specimen preparation

Table 1 procedure for deep-etching consists of

Chemical composition of AlSi12Cu1Fe cast alloy dissolving the aluminium matrix in a reagent

that will not attack the eutectic components.

Mass concentration of the element, %

The residuals of the etching products should

Si Mg Cu Fe Mn Zn Ni Ti be removed by intensive rinsing in alcohol.

The preliminary preparation of the specimen is not

12.5 0.347 0.85 0.70 0.245 0.43 0.044 0.024

necessary, but removing the superficial

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical 41

properties of automotive cast alloy

deformed or contaminated layer can shorten the temperature. Local melting gives notches at the

process. surface, greater tendency to sagging, and more

oxidation during the heat treatment. The

Standard tensile test specimens with 6 mm

dangerous temperatures for local melting are the

diameter were measured in line STN EN 10002-1

eutectic points of the Al-systems (e.g. pure Al-Si

at room temperature. Hardness measurement was

with Fe: 578 °C [13-14]; Al-Si with Cu and Fe:

preformed by a Brinell hardness tester with a load

525 °C [15]). Slow heating may remove

of 62.5 kp (1 kp = 9.807 N), 2.5 mm diameter ball

eutectics and even out concentration gradients,

and a dwell time of 15 s. The Brinell hardness

thereby allowing heat treatment up to the

value at each state was obtained by an average of

equilibrium solidus temperature of the alloy.

at least six measurements.

This temperature can in principle be found in the

phase diagram. Solution heat treatment time

3. Results depends on microstructure, section thickness,

Heat treatment of Al-Si cast alloys is to and furnace loading and can vary from less than

some extent optional. High pressure die cast a minute to 20 hours. Generally, the soak times

components tend to contain air-filled pores which for castings are longer than for wrought products

expand during heat treatment, and are not heat- due to coarser microstructures.

treatable due to blistering, etc. Sand-cast or Although the morphology, the amount

permanent mould cast components are more and the distribution of the precipitates during

amenable to heat treatments. For experimental aging process significantly influence the

work was used T4 heat treatment consists of: mechanical properties, an appropriate solution

solution treatment for two different treatment is a prerequisite for obtaining

temperatures 545 °C and 565 °C, that is desirable aging effect. From this point of view,

necessary to produce a solid solution; the solution heat treatment is critical in

determining the final microstructure and

rapid water quenching (40 °C) to retain the

mechanical properties of the alloys. Thus, it is

maximum concentration of hardening

very important to investigate the effects of

constituent in solid solution;

solution heat treatment on the alloys, before

natural ageing (24 hours at room temperature) moving on to aging issues.

to obtain the desired mechanical properties in

Influence of solution treatment on

the casting.

mechanical properties for experimental alloy is

Solution heat treatment causes: shows on Fig. 2 and Fig. 4.

homogenization of as-cast structure; rounds

250

(spheroidization) of the Si-particles, and thus

tensile strength - Rm [MPa]

240

particularly improves the ductility; dissolves or 230

transforms primary Mg- and Cu-intermetallic 220

phases like Mg2Si, -AlMgFeSi, Al2Cu and 210

200

AlCuMgSi provided that the temperature is high; 190

545 °C

improves the potential for age hardening of Mg- 180 565 °C

170

and Cu-bearing Al-Si alloys, especially if the as cast state

160

temperature is high and the cooling is fast and 150

removes internal stress, which can make it 140

0 4 8 12 16 20 24 28 32 36

difficult to stay within the dimensional tolerances.

solution treatment time [hours]

The heat treatment temperature should be Fig. 2. Influence of solution treatment

high, but referable below the local melting on tensile strength

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

42 E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical

properties of automotive cast alloy

After solution heat treatment at optimal 545 °C the hardness values are continuously

solution (545 °C) temperature, tensile strength and decrease as resulted from the coarsening of

hardness are remarkably improved, compared to eutectic silicon, increasing of interparticle

the corresponding as-cast condition. spacing and dissolution of the Al2Cu phase.

After prolonged solution treatment time up to

Fig. 2 shows the results of tensile strength

4 hours at 565 °C, it is clearly that the hardness

measurements. The as cast samples have

values are strong decreasing probably due to

a strength value approximately 200 MPa. For

local melting process of the alloy.

2 hours the solution treatment strength value

immediately increases. The increase of strength

values is significant chiefly for holding times 115 545 °C

110

maximal 4 hours. Highest tensile strength was 565 °C

HBS 2,5 / 62,5 / 15

105

approximately 245 MPa. By holding time 8 hours as cast state

100

begins decreasing of strength values and relates 95

probably to gradual coarsening of eutectic Si by 90

the holding time longer as 4 hours. 85

80

75

70

0 4 8 12 16 20 24 28 32 36

solution treatment time [hours]

Fig. 4. Influence of solution treatment

Fig. 3. Testing samples distortions (565 °C/32 hours) on Brinell hardness

With increase in solution temperature more

The mechanical properties of cast

than 545 °C tensile strength strong decreases.

component are determined largely by the shape

Probably by reason that the temperature 565 °C is

and distribution of Si particles in the matrix.

nearly at eutectic point comes to decline of

Optimum tensile, impact and fatigue properties

mechanical properties values from the reason of

[16] are obtained with small, spherical and

significant local melting process. Solution

evenly distributed particles.

treatment at 565 °C / 32 hours led to massive

testing samples distortion (Fig. 3) invoking by Structure of experimental eutectic

alloy melting and tensile strength values could not AlSi12Cu1Fe cast alloy consists of eutectic

correct measured. This suggests that, to enhance (dark grey Si-particles in light grey α-phase) and

the tensile strength, of this recycled eutectic alloy intermetallic phases (Fig. 5). The formation of

with 12.5 % Si, by increasing of solution Fe- and Cu-rich intermetallic phases should

temperature more than 545 °C does not seem correspond to successive reaction during

possible. solidification [17-18]. Si is the major alloying

Fig. 4 shows the evolution of Brinell element in heat-treatable cast Al-Si-Cu alloys,

hardness value. Results of hardness are and Si particles represent a large volume

comparable with results of tensile strength. The fraction of the eutectic alloy’s microstructure.

untreated (as cast samples) have hardness value The presence a minimum primary Si

approximately 83 HBS. For 2 hours the solution particles was observed too (Fig. 6). Numbers of

treatment, independently from temperature of hard coarse primary Si particles in the

solution treatment, hardness value immediately microstructure of eutectic Al-Si cast alloy are

increases. The maximum was observed after 4 undesirable. Primary Si particles certainly

hours at 545 °C (approximately 108 HBS). increase locally the wear resistance of the alloy,

However, up to 8 hours solution treatment at but unfortunately Si is brittle and is easy to

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical 43

properties of automotive cast alloy

crack exposing the soft Al matrix to extreme wear scratch pattern are in form needles (Fig. 5).

resulting catastrophic for the automotive For 2 hours the solution treatment were

components. noted that the Si-platelets were fragmentized

into smaller platelets with spherical edges (on

scratch pattern round particles and round

3 needles (Fig. 7a)). The spheroidized process

dominated after 4 hours. The smaller Si particles

were spheroidized to rounded shape (Fig. 7b).

Up to 8 hours solution treatment the

spheroidized particles gradually grew larger

1

(coarsening) (Fig. 7c, d). After solution

treatment we can observed, that the primary Si

4

particles rounded and reduced their size (refines)

2

10 μm - Fig. 7a.

Fig. 5. Microstructure of AlSi12Cu1Fe alloy Fe-phases precipitate first of all as

(1-eutectic Si, 2-α-phase, 3-Fe-phase, 4-Cu-phase) skeleton-like phase that are form by Fe, Si along

etch. Dix-Keller with Mn [4, 17-21]. This Al15(FeMn)3Si2 phase

has a compact skeleton-like morphology, which

does not initiate cracks in the cast material to the

1 same extent as the needle-like phase Al5FeSi

(Fig. 5). The effect of solution treatment on the

Fe-rich Al15(FeMn)3Si2 phase for solution

treatment is documented on Fig. 7 (marked with

) too. In untreated state is Al15(FeMn)3Si2

2

phases in compact skeleton-like form (Fig. 5).

Solution treatment of this skeleton-like phase

tends to fragmentation, spheroidization and

segmentation (Fig. 7a, 7b and 7c). Solution

treatment reduces its area rather than change the

morphology.

Fig. 6. Morphology of eutectic (1) and primary (2) Presence of Cu improves the strength of

silicon (as cast state), etch. HCl, SEM the aluminium alloy through the formation of Cu

based precipitate during heat treatment.

The effect of solution treatment on The Cu-rich intermetallic phase is formed

morphology of eutectic Si is demonstrated in with Al during solidification according to the

Fig. 6 and Fig. 7. The changes of eutectic Si reaction: L → (Al + Al2Cu + β-Al5FeSi + Si) at

morphology observed after heat treatments are 525 °C. This reaction relates to the start of

documented for temperature 545 °C. Experimental Al2Cu precipitation towards the end of

material was not modified and so eutectic Si solidifications and consequently may be

particles without heat treatment (untreated as cast nucleated on other interdendritic particles (Si,

state) are in form platelets (Fig. 6) [4], which on Fe-rich phases).

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

44 E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical

properties of automotive cast alloy

10 μm

10 μm

10 μm

10 μm

etch. Dix-Keller

25 μm 25 μm 25 μm 25 μm

etch. HCl, SEM

a) 2 hours b) 4 hours c) 16 hours d) 32 hours

Fig. 7. Effect of solution treatment at 545 °C on morphology of eutectic Si, Fe-rich () and Cu-rich (- - - -)

intermetallic phases, etch. Dix-Keller

Effect of solution treatment on particles also strengthen the alloy. Smaller and

morphology of Al2Cu correlated with works more uniformly distributed particles have

[6-7, 22-23]. In samples without heat treatment a stronger effect. The fragmentation of Si

(untreated as cast state) is Al2Cu phase observed particles reduces the particle size and increases

in form of compact oval troops. After solution the particle number and thus strengthens the

treatment these phase disintegrated into very fine alloy. The fragmentation of the eutectic Si

smaller segments (marked in Fig. 7 with - - - -) takes place mostly at the early stage of

and the amount of Al2Cu phase during heat solution treatment (Fig. 7a), and so, the

treatment decreases (Figures 7a, 7b and 7c). This strengthening effect caused by the morphology

phase is gradually dissolved into the surrounding variation of Si particles occurs mostly in that

α-matrix with an increase of solution treatment time. Most strengthening effects from Al2Cu

time. precipitation, crystal distortion, and Si particle

The alloy strengthening is mainly a result fragmentation occur at short solution treatment

of the formation of Al2Cu precipitates. time (2 - 4 hours), and thus, the alloy’s

The dissolution leaves vacancies and creates strength increases rapidly during this period.

distortions in the Al matrix crystals. In a short Because the dissolution of Si is complete at

time, the atoms will not have enough time to short solution treatment time, a longer solution

rearrange to fill and correct these vacancies and treatment time does not add more vacancies

distortions, and these vacancies and distortions and/or distortions.

act as nuclei and facilitate the formation of large Instead, the earlier formed vacancies

amount of fine Al2Cu particle precipitates and and distortions are reduced and smoothened

thus strengthen the alloy. The eutectic Si and become less and less active as nuclei,

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical 45

properties of automotive cast alloy

resulting in fewer Al2Cu precipitates and cast alloy (Rm = 240 MPa; 70 HB). Further

slowing the increase in strength. The reduction increases solution time (above 4 hours),

in vacancies and distortion itself also reduces the leads to gradual coarsening of eutectic Si

strengthening effect. and the mechanical properties continuously

drop get to. The primary Si particles

Thereafter (i. e., after 4 hours), the

rounded and reduced their size (refines).

strength variation will be determined mainly by

changes in Si particle size and morphology. Si Al2Cu phases during solution treatment are

fragmentation still may be occurring, but slowly, fragmented, dissolved and redistributed

and at the same time, Si particles are within α-matrix. Skeleton - like

spheroidized and coarsened. In that time, the Al15(FeMn)3Si2 phases are fragmented,

strengthening effect caused by Si fragmentation dissolved a spheroidized.

is counteracted by the weakening effects of

Solution treatment at 565 °C caused testing

coarsening and spheroidization, resulting in

samples distortion, local melting process

small variations in strength. Generally, solution

and is not applicable for this secondary

treatment homogenizes the microstructure by

alloy with 12.5 % Si.

dissolving the as cast Al2Cu precipitates as well

as intermetallics (such as Fe-rich compounds in

aluminium), it reduces segregation, and Acknowledgements

spheroidizes intermetallics, and inclusions, This work has been supported by

which all improve mechanical properties. Scientific Grant Agency of Ministry of Education

of Slovak republic and Slovak Academy of

Sciences, No1/0841/11, No220-009ŽU-4/2010

4. Conclusions and bilateral project SK-PL-0049-09. Thanks

In the present study, the effects of are also given to Anna Macúchová for

metallographic samples preparation.

temperature and holding time on solution heat

treatment of secondary eutectic AlSi12Cu1Fe

cast alloy for automotive applications in the light References

of metallographic parameters of silicon particles [1] Subodh K. Das, John. A. S. Green: JOM 62 2

and mechanical properties (tensile strength and (2010) 27-31.

Brinell hardness) was investigated. From an [2] M. A. Moustafa, F. H. Samuel, H. W. Doty: J.

Mater. Sci. 38 (2003) 4507-4522.

analysis of the results, the following conclusions

[3] M. A. Moustafa, F. H. Samuel, H. W. Doty: J.

can be drawn: Mater. Sci. 38 (2003) 4523-4534.

It has, so far, been shown that the mechanical [4] E. Tillová, M. Chalupová: Štruktúrna analýza

zliatin Al-Si (Structure analysis of Al-Si cast

properties are highly influenced by the alloys), EDIS, Žilina 2009 (in Slovak).

microstructure of the material, by the coarse [5] A. M. Samuel, F. H. Samuel, H. W. Doty: J.

silicon plates or the small hardening Al2Cu Mater. Sci. 31 (1996) 5529-5539.

precipitates. Consequently, the mechanical [6] E. Tillová, M. Panušková: Mater. Eng. –

properties can be related to the duration of Mater. inž. 14 (2) (2007) 73-76.

the solution heat treatment. [7] E. Tillová, M. Chalupová: Mettalurgija /

METABK 47 (3) (2008) 133-137.

Optimal condition of heat solution treatment [8] Jerry H. Sokolowski et al.: J. Mater. Process.

(545 °C/4 hours) most improves mechanical Tech. 109 (2001) 174-180.

properties thanks to spheroidization of [9] M. Panušková, E. Tillová, M. Chalupová:

eutectic Si to rounded shape and the values of Strength Mater. 1 (2008) 109-112.

tensile strength (245 MPa) or Brinell [10] H. R. Ammar et al.: Mater. Des. 30 (2009)

1014-1025.

hardness (cca 108 HB) are comparable with [11] M. Abdulwahab: Aust. J. Basic & Appl.

mechanical properties heat treated primary Sci 2(4) (2008) 839-843.

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

46 E. Tillová, M. Chalupová: Solution treatment effect on microstructure and mechanical

properties of automotive cast alloy

[12] M. Abdulwahab, U. Shehu, K. A. Bello: J. Appl. [18] R. Maniara, L. A. Dobrzański, M. Krupiński,

Sci. Res. 3 (9) (2007) 823-827. J. H. Sokołowski: Arch. of Foundry Eng. 7 (2)

[13] R. Pastirčák, D. Bolibruchová, A. Sládek: Teória (2007) 119-124.

zlievania (Theory of Casting), GEORG, Žilina, [19] J. A. Taylor: In: Proc. of 35th Australian

2009, (in Slovak). Foundry Institute National Conference,

[14] Š. Michna a kol.: Aluminium Materials and Adelaide, South Australiam 2004, pp. 148-157.

Technologies form A to Z, ADIN, Prešov, 2007. [20] S. Seifeddine, S. Johansson, I. Svensson:

[15] L. Hurtalová, E. Tillová: J. Mach. Manufact. Mater Sci Eng A 490 (2008) 385-390.

XLIX (E3-E5) (2009) 6-13. [21] K. Labisz, M. Krupiński, L. A. Dobrzański: J.

[16] E. Tillová, M. Chalupová, T. Podrábský: Mater. Achieve. Mater. Manufacturing Eng. 37 (2)

Eng. – Mater. Inž. 15(4) (2008) 11-17. (2009) 309-316.

[22] F. H. Samuel: J. Mater. Sci. 33 (1998) 2283-

[17] M. Krupiński, K. Labisz, L. A. Dobrzański: J.

Achieve. Mater. Manufacturing Eng. 34 (1) 2297.

(2009) 47-54. [23] R. Li: AFS Transaction 26 (1996) 777-783.

Materials Engineering - Materiálové inžinierstvo 19 (2012) 39-46

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASTM B733 Electroless Nickel PlatingDocument13 pagesASTM B733 Electroless Nickel PlatingManan Vadher100% (1)

- Articulo 319Document4 pagesArticulo 319evelynNo ratings yet

- E3-11 Preparation of Metallographic Specimens PDFDocument12 pagesE3-11 Preparation of Metallographic Specimens PDFevelyn50% (2)

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDocument5 pagesPen Rchive Oulouse Rchive Uverte : O A T A O OataoevelynNo ratings yet

- 28 Pezda Effect of t6 1s 2013Document4 pages28 Pezda Effect of t6 1s 2013evelynNo ratings yet

- Effect of Hardness Test On Precipitation Hardening Aluminium Alloy 6061-T6Document11 pagesEffect of Hardness Test On Precipitation Hardening Aluminium Alloy 6061-T6evelynNo ratings yet

- Fabco 115Document2 pagesFabco 115jimmy_wdNo ratings yet

- Draft Handbook On Welding TechniquesDocument77 pagesDraft Handbook On Welding Techniquessssf-doboj100% (2)

- Sae J404-2000 PDFDocument5 pagesSae J404-2000 PDF2601220150379No ratings yet

- 13480-2 2017 EN-MaterialsDocument83 pages13480-2 2017 EN-MaterialsPaulo VidasinhaNo ratings yet

- Unibar 7Document18 pagesUnibar 7marutb99No ratings yet

- BVL Dau Han NgoaiDocument1 pageBVL Dau Han NgoaiHanLe DuyNo ratings yet

- 410 Stainless Steel Wire UNS S41000 WireDocument4 pages410 Stainless Steel Wire UNS S41000 WireFarid Naim Bojanini PerezNo ratings yet

- 43 Fallo en Alabe de Turbina de GasDocument13 pages43 Fallo en Alabe de Turbina de GasJuanpe HdezNo ratings yet

- Lamina Tech - Catálogo 2017-2018 PDFDocument342 pagesLamina Tech - Catálogo 2017-2018 PDFGilberto Garcia100% (2)

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- Argañaraz 2011 Electrochimica-Acta 1Document6 pagesArgañaraz 2011 Electrochimica-Acta 1momenziNo ratings yet

- Mechanical Behavior of Aluminum Metal Matrix Composite Reinforcement With Graphene Nano FillersDocument11 pagesMechanical Behavior of Aluminum Metal Matrix Composite Reinforcement With Graphene Nano FillersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- STOH FailuresDocument6 pagesSTOH FailuresWilson MillanNo ratings yet

- ASTM A516-70 Plate As Rolled - Pressure Vessel Grade SteelDocument2 pagesASTM A516-70 Plate As Rolled - Pressure Vessel Grade SteelHidden TruthNo ratings yet

- Material Metallurgy - Descriptive TypesDocument53 pagesMaterial Metallurgy - Descriptive TypesSushant GhurupNo ratings yet

- Alloy 6201 Product Specification Rev.0Document3 pagesAlloy 6201 Product Specification Rev.0serkan temelNo ratings yet

- The Structure of The AtomDocument28 pagesThe Structure of The AtomAnonymous dh6DITNo ratings yet

- Elkem 13 Compacted Graphite IronDocument2 pagesElkem 13 Compacted Graphite Ironmarcotulio123No ratings yet

- Api 578-Mock 1 - KeyDocument28 pagesApi 578-Mock 1 - KeysheikmoinNo ratings yet

- ForgingDocument35 pagesForgingGopalakrishnan KuppuswamyNo ratings yet

- Attachment 8 - STN 00 Z20 V SP 0002 - A01 - ENDocument18 pagesAttachment 8 - STN 00 Z20 V SP 0002 - A01 - ENrameshqcNo ratings yet

- partPG PDFDocument75 pagespartPG PDFJatin SomaiyaNo ratings yet

- Types of Butterfly Valves (API 609) - ProjectmaterialsDocument19 pagesTypes of Butterfly Valves (API 609) - Projectmaterialssornapudi.pradeep1991No ratings yet

- Shrink - and Expansion-Fit AnalysesDocument3 pagesShrink - and Expansion-Fit AnalysesScribdUser11235No ratings yet

- Manual ELECTRODOS LINCOLNDocument48 pagesManual ELECTRODOS LINCOLNLeyniz York Arias LlanosNo ratings yet

- Metals and Non MetalsDocument10 pagesMetals and Non MetalsKaran MahajanNo ratings yet

- Spec # Specification Title - 01/2016 Amendments Document Status Revision SourceDocument10 pagesSpec # Specification Title - 01/2016 Amendments Document Status Revision SourceTony C.No ratings yet

- DIS Ductile Iron Quality Assurance GuideDocument117 pagesDIS Ductile Iron Quality Assurance GuidesushilrajageNo ratings yet

- 9.57405-Eng - Plating Std.Document20 pages9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)