Professional Documents

Culture Documents

Process Conditions: Design Calculation of Throttling Device

Process Conditions: Design Calculation of Throttling Device

Uploaded by

Thineshraaj Naidu JayaramanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Conditions: Design Calculation of Throttling Device

Process Conditions: Design Calculation of Throttling Device

Uploaded by

Thineshraaj Naidu JayaramanCopyright:

Available Formats

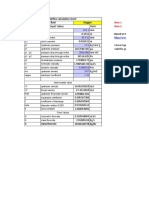

Design calculation of throttling device

Ordering unit:

Installation tag

Contract No: number:FE103 Installation method: Horizontal

Pressure measurement

Throttling part: Long method: Diameter

diameter nozzle distance pressure Fluid Name: Superheated steam

measurement

Supply content: Complete set Quantity: 1 set

Accessories: Stop valve, Condenser

The upstream side of throttling piece is a single 90. Elbow, two 90 ° elbows on

any plane (S > 30D)

Process conditions

Maximum flow:60000.00 kg/h Common flow:45000.00 kg/h Minimum flow:13500.00 kg/h

Working gauge pressure: Working temperature: Operating density:28.18642

9.80000 Mpa 540.00℃ kg/m3

Regional atmospheric Fluid viscosity:0.0306

pressure:1000 mbar The Conduit:6141.3X12.7 mm mPa.s

Isentropic index:1.27640 Compressibility factor:0.93408

Absolute wall roughness:0.075 mm

Pipe material: 12Cr1MoVG Linear expansion coefficient: 0.00001420 mm / mm℃

Throttle material: 304 Linear expansion coefficient: 0.00001820 mm / mm℃

Calculation results

Differential pressure upper

Scale flow:60000.00 kg/h limitΔPmax: 160000 Pa

Common differential

Maximum pressure loss:58751 Pa pressureΔPcom: 90000 Pa

Opening ratio β: Outflow coefficient C : Coefficient of expansion

0.681951 0.993945 ε:0.992702

Maximum Reynolds number: Common Reynolds Minimum Reynolds number:

5939235 number:4454426 1336328

Calculation error E: Discharge coefficient α:

0.000007% Flow uncertainty e:±2.09% 1.122746

Front straight pipe section L1:3.00m Rear straight pipe section L2:0.80m

Opening under working condition d: 79.622mm

Long axle shaft a:57.950 mm Short axle shaft b:18.513 mm

Opening of flow parts at 20 ℃ d20:78.875 ±0.041mm

Calculation formula:M=0.003998595*d^*ε*α*(ΔP*p) ^0.5 kg/h

Remarks: main steam flow

You might also like

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Swimming Pool Design 2Document30 pagesSwimming Pool Design 2olomizana100% (2)

- Process Conditions: Design Calculation of Throttling DeviceDocument4 pagesProcess Conditions: Design Calculation of Throttling DeviceThineshraaj Naidu JayaramanNo ratings yet

- Mtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsDocument4 pagesMtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsbaljeetjatNo ratings yet

- Orifice Calc - Vapor - Steam - GasesDocument2 pagesOrifice Calc - Vapor - Steam - GasesAsad KhanNo ratings yet

- Test Sheet: Customer References Johnson ReferencesDocument18 pagesTest Sheet: Customer References Johnson ReferencesVinay YadavNo ratings yet

- Performance Data CurveDocument57 pagesPerformance Data Curveedwin nolberto100% (1)

- Dual Fuel Genset - Heat Recovery-1-2Document2 pagesDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- Mtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsDocument4 pagesMtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsbaljeetjatNo ratings yet

- NPSH CalculationDocument3 pagesNPSH Calculationatul bansalNo ratings yet

- Gacc RX 020 1 21N Cfa7a UnnnDocument2 pagesGacc RX 020 1 21N Cfa7a Unnnachmad.yogaNo ratings yet

- Model: 3196 Size: 1.5X3-6 Group: Sti 60Hz RPM: 2453 Stages: 1Document10 pagesModel: 3196 Size: 1.5X3-6 Group: Sti 60Hz RPM: 2453 Stages: 1Weisong D. LeeNo ratings yet

- Gacc RX 031 1 1WN Dha4a UnnnDocument2 pagesGacc RX 031 1 1WN Dha4a Unnnachmad.yogaNo ratings yet

- Mtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsDocument4 pagesMtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsbaljeetjatNo ratings yet

- Inra-Doc-Air-Mc-002 Sumario Consumo AireDocument6 pagesInra-Doc-Air-Mc-002 Sumario Consumo AireGabriel Alvarez RojasNo ratings yet

- Gacc RX 031 1 1WN Fha7a UnnnDocument2 pagesGacc RX 031 1 1WN Fha7a Unnnachmad.yogaNo ratings yet

- Elmadaen Static PressureDocument40 pagesElmadaen Static PressureKarthy GanesanNo ratings yet

- Datasheet (1) GEA .2 SODocument1 pageDatasheet (1) GEA .2 SOHardik JaniNo ratings yet

- Bosch Afs Maf SensorDocument4 pagesBosch Afs Maf SensorAndo Tamkõrv100% (1)

- Air Comperssor Test Rig ReciprocatingDocument4 pagesAir Comperssor Test Rig ReciprocatingShashank pNo ratings yet

- Vent Sizing - SpreadsheetDocument2 pagesVent Sizing - SpreadsheetPradip ShindeNo ratings yet

- Datasheet Engine Driven PumpDocument1 pageDatasheet Engine Driven PumpPankajjain1972No ratings yet

- Curvas de Desempeño de Una Bomba Vertical Tipo TurbinaDocument1 pageCurvas de Desempeño de Una Bomba Vertical Tipo TurbinaGidel M. FloresNo ratings yet

- Curvas de Operacion Tag 2810-PU-032Document2 pagesCurvas de Operacion Tag 2810-PU-032JOSUE FERNANDO FERNANDEZNo ratings yet

- Gacc RX 031 1 1WN Dha4a UnnnDocument2 pagesGacc RX 031 1 1WN Dha4a Unnnachmad.yogaNo ratings yet

- Bomba GouldsDocument6 pagesBomba GouldsBryanMojalottMoroteNo ratings yet

- Rosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetDocument1 pageRosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetMamta DeshmukhNo ratings yet

- Motor 2.5 HP - ShakersDocument2 pagesMotor 2.5 HP - ShakersAlex SinissNo ratings yet

- Annexure-II: West Kuwait GC-01 01-FIT-5102 9/nov/18 Crude OilDocument3 pagesAnnexure-II: West Kuwait GC-01 01-FIT-5102 9/nov/18 Crude Oila.r.sarateNo ratings yet

- GP04 2PHE 1M3H 98-40-10 FD Bermo TrocadorDocument5 pagesGP04 2PHE 1M3H 98-40-10 FD Bermo TrocadorWanner MartinsNo ratings yet

- Performance Data SheetDocument1 pagePerformance Data SheetvindyakikNo ratings yet

- Fan FlaktwoodsDocument1 pageFan FlaktwoodsKaffelNo ratings yet

- Sulphuric Acid TransferDocument2 pagesSulphuric Acid Transfer511231103No ratings yet

- Mtu Engine Model 16 V 2000 G63 A. LT CIRCUIT (175 KW at 14 M /HR) Heat Exchanger: Gl-13Lx14 Duty Requirements LT Water Raw WaterDocument2 pagesMtu Engine Model 16 V 2000 G63 A. LT CIRCUIT (175 KW at 14 M /HR) Heat Exchanger: Gl-13Lx14 Duty Requirements LT Water Raw WaterbaljeetjatNo ratings yet

- Goulds - 3409curva CaracteristicaDocument2 pagesGoulds - 3409curva CaracteristicaPercy TorresNo ratings yet

- Pump Performance CurveDocument1 pagePump Performance CurveAshish Patel100% (2)

- Flow 450m3hr at 18 Meter HeadDocument1 pageFlow 450m3hr at 18 Meter HeadVINIT KUMAR SINGHNo ratings yet

- Pump Sizing Calculation SpreadsheetDocument26 pagesPump Sizing Calculation Spreadsheetsterling100% (1)

- Pitot Selection RefDocument2 pagesPitot Selection RefVinay ChhatrolaNo ratings yet

- Annubar Spec SheetDocument1 pageAnnubar Spec SheetmeledathNo ratings yet

- Calculos For Pre-Commission SECTION Number 6Document7 pagesCalculos For Pre-Commission SECTION Number 6ahmed.lassouedNo ratings yet

- Aerovent BLI 710 Datasheet - 17645Document1 pageAerovent BLI 710 Datasheet - 17645Dedi KartiwaNo ratings yet

- Model: 3700 Size: 6x8-16a Group: LA 60Hz RPM: 1780 Stages: 1Document1 pageModel: 3700 Size: 6x8-16a Group: LA 60Hz RPM: 1780 Stages: 1Gabrielito PachacamaNo ratings yet

- Pressure Drop CalculationsDocument4 pagesPressure Drop CalculationsOmprakaash Mokide100% (1)

- Gacc RX 050 2 2SN Jna7e UnnnDocument2 pagesGacc RX 050 2 2SN Jna7e UnnnR'n'R BatamNo ratings yet

- Rosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetDocument1 pageRosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetMamta DeshmukhNo ratings yet

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDocument4 pages1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- MC Fe-88115spiDocument1 pageMC Fe-88115spigallegos70No ratings yet

- Ga CurveDocument3 pagesGa Curvemano_gceNo ratings yet

- Scrubbing CirculationDocument2 pagesScrubbing Circulation511231103No ratings yet

- Evaporator (DX) : GACC RX 050.2/2SN/HNA7A.UNNNDocument2 pagesEvaporator (DX) : GACC RX 050.2/2SN/HNA7A.UNNNciprian ilieNo ratings yet

- Fan Efficiency CalculatorDocument109 pagesFan Efficiency CalculatorSantanu PachhalNo ratings yet

- 511-CP02 KPD 25-16QFDocument3 pages511-CP02 KPD 25-16QFNitin KurupNo ratings yet

- PHE - 4 Section For Ice Cream MixDocument9 pagesPHE - 4 Section For Ice Cream MixMuhammad JunaidNo ratings yet

- Gas Pipeline Hydraulic Analysis CalculationDocument10 pagesGas Pipeline Hydraulic Analysis Calculationbalakrishna100% (3)

- Performance Test On Double Stage Reciprocating Air CompressorDocument8 pagesPerformance Test On Double Stage Reciprocating Air Compressormohammed rashidNo ratings yet

- Orifice Calculation For Chlorine GasDocument2 pagesOrifice Calculation For Chlorine GastechkasambaNo ratings yet