Professional Documents

Culture Documents

Otivation: Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

Otivation: Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

Uploaded by

Mitsui Solar LabCopyright:

Available Formats

You might also like

- Donald A. Neumann-Kinesiology of The Musculoskeletal System PDFDocument607 pagesDonald A. Neumann-Kinesiology of The Musculoskeletal System PDFSekar Ciptaningrum97% (97)

- Squeezed by Alissa Quart "Why Our Families Can't Afford America"Document6 pagesSqueezed by Alissa Quart "Why Our Families Can't Afford America"Zahra AfikahNo ratings yet

- MPI Painting CodeDocument28 pagesMPI Painting CodeGhayas JawedNo ratings yet

- SPAJ140C Terminal DiagramDocument1 pageSPAJ140C Terminal DiagramKunjan DalwadiNo ratings yet

- Forward Bias CurrentDocument21 pagesForward Bias CurrentCristhian MP DtNo ratings yet

- MAT263 NotessDocument2 pagesMAT263 NotessAN NUR INSYIRAH AZRINNo ratings yet

- Chapter 10Document1 pageChapter 10halharbi0568No ratings yet

- SITE-DEV-PLANDocument1 pageSITE-DEV-PLANSecond Floor ConstructionNo ratings yet

- Title: Dual Hot Air Soldering Station 898D: Alex BaruthDocument1 pageTitle: Dual Hot Air Soldering Station 898D: Alex BaruthJaricsa Bernaola100% (1)

- Ball Rollers (For Upward Facing) : Milled Stainless SteelDocument1 pageBall Rollers (For Upward Facing) : Milled Stainless SteelLộcLộcNo ratings yet

- 40 Hilux (Cont. Next Page) : Power Source Ect (2Tr-Fe)Document2 pages40 Hilux (Cont. Next Page) : Power Source Ect (2Tr-Fe)boirxNo ratings yet

- Schematic rs501Document1 pageSchematic rs501dareka darezouNo ratings yet

- AB - DT INLET & OUTLET ROCKBOLTS & SHOTCRETE PLAN-Layout1Document1 pageAB - DT INLET & OUTLET ROCKBOLTS & SHOTCRETE PLAN-Layout1haroldwilsonfranciscoNo ratings yet

- N 1 (A), N10 (B)Document1 pageN 1 (A), N10 (B)Julius ThomasNo ratings yet

- 06 Fire Alarm Layout Plan-Fire AlarmDocument1 page06 Fire Alarm Layout Plan-Fire AlarmPhúc Đinh TấnNo ratings yet

- Structure of Bridge. No. 3Document1 pageStructure of Bridge. No. 3Ravpreet SinghNo ratings yet

- Hitachi-350 CircuitDocument6 pagesHitachi-350 CircuittserenbatbaatNo ratings yet

- E PlanDocument1 pageE PlanSheila Mary CamuloNo ratings yet

- Swastik Infra Marihaan Site Plan, March-Model - PDF RohitDocument1 pageSwastik Infra Marihaan Site Plan, March-Model - PDF RohitvindhyaashirwadNo ratings yet

- E01 - Modifikasi sf6Document7 pagesE01 - Modifikasi sf6Carvin AgriantoNo ratings yet

- 20 Hilux (Cont. Next Page) : Taillight (RHD)Document6 pages20 Hilux (Cont. Next Page) : Taillight (RHD)BASILIO JARA HUERTANo ratings yet

- AUDITORIUM - zone02-GA MARKUPS& REINF-2 - 117Document1 pageAUDITORIUM - zone02-GA MARKUPS& REINF-2 - 117Omer HayatNo ratings yet

- Scanning - Balayage - Ablenkung - Barrido - Scansione: BL002 BL002Document1 pageScanning - Balayage - Ablenkung - Barrido - Scansione: BL002 BL002Fernando OrtizNo ratings yet

- Hexagon Socket Set Screws, Flat Type Hexagon BoltsDocument1 pageHexagon Socket Set Screws, Flat Type Hexagon BoltsVarun VaruNo ratings yet

- 22 Toyota Fortuner: Power Source Rear Differential LockDocument1 page22 Toyota Fortuner: Power Source Rear Differential Lockalexander pintoNo ratings yet

- Igbt 30F125Document15 pagesIgbt 30F125Efren CisnerosNo ratings yet

- Shop DWG - 02Document1 pageShop DWG - 02AVP PAFCDO ProjectNo ratings yet

- Discrete Igbts: SemiconductorDocument16 pagesDiscrete Igbts: Semiconductormoacir carlos guandaliniNo ratings yet

- Front Air ConditionerDocument2 pagesFront Air Conditionertuan anh nguyễnNo ratings yet

- Ficha Tecnica Autohormigonera Dieci L3500Document2 pagesFicha Tecnica Autohormigonera Dieci L3500REINALDO ANTONIO NAVARRO BLANCONo ratings yet

- 19 Hilux (Cont. Next Page) : Taillight (LHD)Document6 pages19 Hilux (Cont. Next Page) : Taillight (LHD)BASILIO JARA HUERTANo ratings yet

- Girder Layout & LengthDocument1 pageGirder Layout & LengthMrinal KayalNo ratings yet

- Csifinal 5Document1 pageCsifinal 5michaelberliantNo ratings yet

- Analysis 01Document2 pagesAnalysis 0165011119No ratings yet

- Pelco Developer Network (PDN) : Pelco API Web Services Supported On Pelco ProductsDocument2 pagesPelco Developer Network (PDN) : Pelco API Web Services Supported On Pelco ProductsFranklin AlvaradoNo ratings yet

- Computer Vision 2Document30 pagesComputer Vision 2lcnblzr3877No ratings yet

- 2Document1 page2dimas wahyuNo ratings yet

- Math 2Document1 pageMath 2assal2007faisalNo ratings yet

- Canada Carte DétailléeDocument1 pageCanada Carte DétailléePasymal Pas Si MalNo ratings yet

- Previa/Tarago (Ewd445F) 175Document1 pagePrevia/Tarago (Ewd445F) 175tokkobarokkoNo ratings yet

- 714 - Om4000Document2 pages714 - Om4000Edson LemosNo ratings yet

- Tantrasco: PROJECT - 220kV-M/C Monopoles Summary SheetDocument1 pageTantrasco: PROJECT - 220kV-M/C Monopoles Summary SheetMOHAMMAD ZUEF - SKIPPER LIMITEDNo ratings yet

- Tail LightDocument2 pagesTail Lighttuan anh nguyễnNo ratings yet

- Technics Sea2000 Power Amplifier Service ManualDocument27 pagesTechnics Sea2000 Power Amplifier Service ManualAlexander RodriguezNo ratings yet

- A B C D E F G H J: Jumeirah VillageDocument1 pageA B C D E F G H J: Jumeirah VillageMUBASHIRNo ratings yet

- Selection of Ball Screws 2 - MISUMIDocument1 pageSelection of Ball Screws 2 - MISUMIDuong NguyenNo ratings yet

- Psu SchematicsDocument1 pagePsu SchematicsJerry LeeNo ratings yet

- Scheme Legends: L&T Electrical & AutomationDocument1 pageScheme Legends: L&T Electrical & AutomationSivachandran RNo ratings yet

- Tabela de IgbtsDocument16 pagesTabela de IgbtsEdmilson Mendes PimentelNo ratings yet

- Summary of Lecture 1: "Let There Be Light"Document32 pagesSummary of Lecture 1: "Let There Be Light"Chandramouleeswaran SarmaNo ratings yet

- CML (103) - Major 2Document39 pagesCML (103) - Major 2usfeklvxnjrdgsjfseNo ratings yet

- Multiport Conversions Between S, Z, Y, H, ABCD, and T ParametersDocument1 pageMultiport Conversions Between S, Z, Y, H, ABCD, and T ParametersOscar Niño BernalNo ratings yet

- ASDADocument1 pageASDAKristine ChavezNo ratings yet

- 9852 1404 01a Driving M2 C, L1 C, L2 CDocument2 pages9852 1404 01a Driving M2 C, L1 C, L2 CGustavo A. Utreras FariasNo ratings yet

- Auma Terminal ManualDocument2 pagesAuma Terminal ManualPunesh PaulNo ratings yet

- Almana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Document4 pagesAlmana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Jet ArcaNo ratings yet

- Carvin 8 BusDocument1 pageCarvin 8 BusRobby AhyanaNo ratings yet

- Traigulation NW Final 11082021Document1 pageTraigulation NW Final 11082021Sreedhar PoluNo ratings yet

- Overall EWD Vehicle Interior Illumination (RHD)Document6 pagesOverall EWD Vehicle Interior Illumination (RHD)gabrielzinho43No ratings yet

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Taillight (RHD)Document6 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Taillight (RHD)gabrielzinho43No ratings yet

- Powered Mixer Tables de Mixage Á Amplification de Puissance Aktiv-MischpultDocument21 pagesPowered Mixer Tables de Mixage Á Amplification de Puissance Aktiv-MischpultJun AballeNo ratings yet

- Powered MixageDocument21 pagesPowered MixageFodil DouazNo ratings yet

- Kiambu CidpDocument342 pagesKiambu CidpCharles ZihiNo ratings yet

- T N M M T N M M: HE EW Essies Anual HE EW Essies AnualDocument8 pagesT N M M T N M M: HE EW Essies Anual HE EW Essies AnualMunna100% (1)

- Barcode v1Document31 pagesBarcode v1Desinta OctavianiNo ratings yet

- PSP Assignment1Document25 pagesPSP Assignment1B BasitNo ratings yet

- Mbarang 10102022Document3 pagesMbarang 10102022zeta chenkNo ratings yet

- Bence Bays Resume July 2015Document2 pagesBence Bays Resume July 2015api-292242662No ratings yet

- The History of The Big Bang TheoryDocument6 pagesThe History of The Big Bang Theorymay ann dimaanoNo ratings yet

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- Promotion Letter ShwetaDocument2 pagesPromotion Letter ShwetayogeshNo ratings yet

- BIOLOGY HOTS Questions Class 12thDocument68 pagesBIOLOGY HOTS Questions Class 12thAkshatha Nayak50% (2)

- Emilio Aguinaldo College: School of NursingDocument2 pagesEmilio Aguinaldo College: School of NursingAwani ONo ratings yet

- Laboratory Information Management System: Prepared By: Mariela C. Ronquillo, RMTDocument33 pagesLaboratory Information Management System: Prepared By: Mariela C. Ronquillo, RMTRonel RonquilloNo ratings yet

- Common Problems and Actions Taken in The Philippine Education SystemDocument3 pagesCommon Problems and Actions Taken in The Philippine Education SystemDoods Galdo88% (16)

- Manual Spray GunDocument6 pagesManual Spray GunSyazwan KhairulNo ratings yet

- Discard ManagementDocument9 pagesDiscard ManagementDevvrath SinghNo ratings yet

- Emotional IntelligenceDocument43 pagesEmotional IntelligenceMelody ShekharNo ratings yet

- SPE 13932 Wettability Part2 AndersonDocument17 pagesSPE 13932 Wettability Part2 AndersonSergio EduardoNo ratings yet

- Parent Medical CoverageDocument9 pagesParent Medical CoveragecampeonNo ratings yet

- Mina NEGRA HUANUSHA 2 ParteDocument23 pagesMina NEGRA HUANUSHA 2 ParteRoberto VillegasNo ratings yet

- Chicken BellagioDocument4 pagesChicken BellagioJagr MaddoxNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- A Study On Occupational Hazards in Die Casting IndustriesDocument8 pagesA Study On Occupational Hazards in Die Casting IndustriesManik LakshmanNo ratings yet

- Vikas BhagwanDocument13 pagesVikas BhagwanhappysinNo ratings yet

- BRS TestDocument2 pagesBRS TestMuhammad Ibrahim KhanNo ratings yet

- Pro 3 Mplusdevipplus 07Document6 pagesPro 3 Mplusdevipplus 07daylavianNo ratings yet

- 793-P-1C Relay Data SheetDocument6 pages793-P-1C Relay Data SheetsendmebooksNo ratings yet

- Astm C 592Document9 pagesAstm C 592hoseinNo ratings yet

Otivation: Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

Otivation: Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

Uploaded by

Mitsui Solar LabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Otivation: Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

Otivation: Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

Uploaded by

Mitsui Solar LabCopyright:

Available Formats

Innovation

for a Better Life

LIFETIME WARRANTY TEST METHOD CONSIDERING POTENTIAL

INDUCED DEGRADATION RECOVERY BEHAVIOR

Kyung Chan Kang, Byong Su Kim, Sang Hwan Park, Sung Ho Chang

LG Electronics, 168, Suchul-daero, Gumi-si 730-903, Korea, Tel : +82-54-469-0407, E-mail : kcpv.kang@lge.com

Motivation

To verify no PID Effect on particular N-type module with illumination

To figure out the recovery characteristic after PID occurred on PV modules

To suggest the test method considering recovery characteristics

LG NeON® model PID Characterization

(A) Electrochemical Corrosion (B) Polarization Effect

Na+ Capacitor-Like

ARC

Light

(+) (+) (+) (+) (+) (+) NeON®n-Type

LG NeON n-Type metal (+) (+)

(+) (+) (+) (+) (+)(+)(+)(+) (+) (+)

p-type emitter

Na+ ARC

Na ions

Na ionscan’t

can’tbebe

moving

moving (-) (-) (-) (-) (-) (-) (-) (-)

Junction Field e- (-)(-) (-)(-)

n-type bulk p-type emitter

ARC

Junction Field Junction Field Junction Field

emitter

n-type bulk

Na+

Junction Field

bulk ARC

Conventional p-Type Dark

Dark : - Polarization

Polarization – Reversible PID

(Reversible)

Na+

(-) (-) Na+ (-) (-) Conventional p-Type

LightLight

: No –Polarization effect

Na+ n-type emitter Ion Migration – Irreversible PID - Weaken

Na+

Ion Migration – Irreversible PID

- Weakenp-n junction

p-n field field

junction No Polarization effect

- Na ions form shunting channel - Increase recombination in emitter

Junction Field - Na ions form shunting channel - Increase recombination in emitter

- Cumulated Charges for Polarization

p-type bulk - Cumulated Charges for Polarization

The + ion cannot shunt LG n-type NeON® cells, which have a p-type emitter on Although LG n-type NeON® cells do show the power degradation under normal

its top surface, as opposed to the n-type emitter that most p-type modules have PID Test condition, they naturally prevent the charge from building up while

on their top surfaces. As a result, Electrochemical Corrosion cannot be found on under irradiance, eliminating any effects from polarization.

LG n-type NeON® modules.

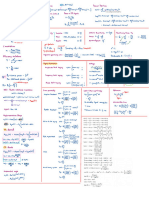

Test set-up & Results

Step 1 : PID Test acc. to IEC TC 62804 ed. 1 Step 3 : PID- / With Light Source Step 4 : Leakage Current Monitor

Step 2 : PID- / Light-Recovery Sequence

Recovery Sequence : 10 sequences

1st : Under lighting 5 hours (20°C/50 % rh.),

- During the light phase, the power of the module will be monitored.

2nd : After then, without lighting 3 hours (40°C/90% rh.)

3rd : IV measurement Chamber

60℃/85%RH

M03 Light / Dark

Isc Voc Imp Vmp Pmax FF eff DC Power

[A] [V] [A] [V] [W] [%] [%] Supply

Initial Measurement 9.93 40.64 9.32 33.11 308.68 76.49 18.82 1000V

PID Test 96 hours at -1000 V

After 96 hrs PID Test 9.76 40.14 9.16 32.34 296.24 75.59 18.06

Deviation to initial [%] -1.70 -1.20 -1.80 -2.30 -4.00 -1.20 -4.00 R V

Recovery Procedure at -1000 V

After Recovery 9.99 40.64 9.34 33.00 308.26 75.91 18.80 Figure : PID test with light source

Deviation to initial [%] 0.60 0.00 0.20 -0.30 -0.10 -0.80 -0.10

M07

M04 Isc Voc Imp Vmp Pmax FF eff

Isc Voc Imp Vmp Pmax FF eff [A] [V] [A] [V] [W] [%] [%]

Initial Measurement 10.07 40.52 9.56 32.76 313.24 76.76 19.10

[A] [V] [A] [V] [W] [%] [%]

PID Test 96 hours at -1000 V

Initial Measurement 9.99 40.66 9.36 33.00 308.80 76.06 18.83

with light (200W/m2) Figure : Schematic of leakage current measurement system

PID Test 96 hours at -1000 V

After 96 hrs PID Test 10.09 40.43 9.65 32.46 313.30 76.76 19.10

After 96 hrs PID Test 9.87 40.39 9.24 32.64 301.73 75.70 18.40

Deviation to initial [%] 0.21 -0.21 0.94 -0.92 0.02 0.00 0.00

Deviation to initial [%] -1.20 -0.70 -1.20 -1.10 -2.30 -0.50 -2.30

M08 Leakage Current During PID test

Recovery Procedure at -1000 V Isc Voc Imp Vmp Pmax FF eff

After Recovery 10.00 40.70 9.38 33.05 310.00 76.20 18.90 [A] [V] [A] [V] [W] [%] [%]

Deviation to initial [%] 0.10 0.10 0.20 0.20 0.40 0.20 0.40 Initial Measurement 10.07 40.48 9.57 32.75 313.26 76.86 19.10

PID Test 96 hours at -1000 V

Measurement Uncertainty [%] ± 1.9 ± 0.6 ± 2.2 ± 1.2 ± 2.1 ± 1.6 ± 2.2 with light (1,000W/m2)

After 96 hrs PID Test 10.04 40.41 9.48 32.85 311.36 76.76 19.00

Table : Performance measurement at STC, PID test with -1000 V Deviation to initial [%] -0.33 -0.16 -0.92 0.30 -0.61 -0.13 -0.53

Table : Performance measurement at STC, PID test with -1000 V with light source

25℃ 60℃/85%

Light

60℃/85% Stay section

Dark

Time

Figure : Leakage current comparison (light / dark)

Before PID test After PID test (-1000V) After recovery Before PID test After PID test (-1000V) Before PID test After PID test (-1000V) Examining the leakage current during PID test, a

Figure : Electroluminescence images of module M03, M04 Figure : Electroluminescence images of module M07, M08

current profile of the dark state’s module similar to

+1000V : not occurred PID 0.2 / 1 sun : not occurred PID that of a capacitor is observed, on the other hand a

- 1000V : slightly occurred power drop, however low irradiance : verified no polarization effect current of the light state’s module is not observed.

found recovery after additional sequence. with light.

Conclusions

The behavior described above shows clearly that the modules recover fast when exposed to light and that a simulated day-night sequence, as applied

in the scope of this study, does not lead to a continuous decrease in power. And we confirmed that ‘Polarization Effect’ does not show in light state

according to cell type, result from the measurement of leakage current, EL and module power after test. The test result indicates that the PID effect will

be equalized in the field to the largest extent. The modules show different results depend on cell types, it requires new lifetime warranty test method

considering potential induced degradation recovery behavior.

You might also like

- Donald A. Neumann-Kinesiology of The Musculoskeletal System PDFDocument607 pagesDonald A. Neumann-Kinesiology of The Musculoskeletal System PDFSekar Ciptaningrum97% (97)

- Squeezed by Alissa Quart "Why Our Families Can't Afford America"Document6 pagesSqueezed by Alissa Quart "Why Our Families Can't Afford America"Zahra AfikahNo ratings yet

- MPI Painting CodeDocument28 pagesMPI Painting CodeGhayas JawedNo ratings yet

- SPAJ140C Terminal DiagramDocument1 pageSPAJ140C Terminal DiagramKunjan DalwadiNo ratings yet

- Forward Bias CurrentDocument21 pagesForward Bias CurrentCristhian MP DtNo ratings yet

- MAT263 NotessDocument2 pagesMAT263 NotessAN NUR INSYIRAH AZRINNo ratings yet

- Chapter 10Document1 pageChapter 10halharbi0568No ratings yet

- SITE-DEV-PLANDocument1 pageSITE-DEV-PLANSecond Floor ConstructionNo ratings yet

- Title: Dual Hot Air Soldering Station 898D: Alex BaruthDocument1 pageTitle: Dual Hot Air Soldering Station 898D: Alex BaruthJaricsa Bernaola100% (1)

- Ball Rollers (For Upward Facing) : Milled Stainless SteelDocument1 pageBall Rollers (For Upward Facing) : Milled Stainless SteelLộcLộcNo ratings yet

- 40 Hilux (Cont. Next Page) : Power Source Ect (2Tr-Fe)Document2 pages40 Hilux (Cont. Next Page) : Power Source Ect (2Tr-Fe)boirxNo ratings yet

- Schematic rs501Document1 pageSchematic rs501dareka darezouNo ratings yet

- AB - DT INLET & OUTLET ROCKBOLTS & SHOTCRETE PLAN-Layout1Document1 pageAB - DT INLET & OUTLET ROCKBOLTS & SHOTCRETE PLAN-Layout1haroldwilsonfranciscoNo ratings yet

- N 1 (A), N10 (B)Document1 pageN 1 (A), N10 (B)Julius ThomasNo ratings yet

- 06 Fire Alarm Layout Plan-Fire AlarmDocument1 page06 Fire Alarm Layout Plan-Fire AlarmPhúc Đinh TấnNo ratings yet

- Structure of Bridge. No. 3Document1 pageStructure of Bridge. No. 3Ravpreet SinghNo ratings yet

- Hitachi-350 CircuitDocument6 pagesHitachi-350 CircuittserenbatbaatNo ratings yet

- E PlanDocument1 pageE PlanSheila Mary CamuloNo ratings yet

- Swastik Infra Marihaan Site Plan, March-Model - PDF RohitDocument1 pageSwastik Infra Marihaan Site Plan, March-Model - PDF RohitvindhyaashirwadNo ratings yet

- E01 - Modifikasi sf6Document7 pagesE01 - Modifikasi sf6Carvin AgriantoNo ratings yet

- 20 Hilux (Cont. Next Page) : Taillight (RHD)Document6 pages20 Hilux (Cont. Next Page) : Taillight (RHD)BASILIO JARA HUERTANo ratings yet

- AUDITORIUM - zone02-GA MARKUPS& REINF-2 - 117Document1 pageAUDITORIUM - zone02-GA MARKUPS& REINF-2 - 117Omer HayatNo ratings yet

- Scanning - Balayage - Ablenkung - Barrido - Scansione: BL002 BL002Document1 pageScanning - Balayage - Ablenkung - Barrido - Scansione: BL002 BL002Fernando OrtizNo ratings yet

- Hexagon Socket Set Screws, Flat Type Hexagon BoltsDocument1 pageHexagon Socket Set Screws, Flat Type Hexagon BoltsVarun VaruNo ratings yet

- 22 Toyota Fortuner: Power Source Rear Differential LockDocument1 page22 Toyota Fortuner: Power Source Rear Differential Lockalexander pintoNo ratings yet

- Igbt 30F125Document15 pagesIgbt 30F125Efren CisnerosNo ratings yet

- Shop DWG - 02Document1 pageShop DWG - 02AVP PAFCDO ProjectNo ratings yet

- Discrete Igbts: SemiconductorDocument16 pagesDiscrete Igbts: Semiconductormoacir carlos guandaliniNo ratings yet

- Front Air ConditionerDocument2 pagesFront Air Conditionertuan anh nguyễnNo ratings yet

- Ficha Tecnica Autohormigonera Dieci L3500Document2 pagesFicha Tecnica Autohormigonera Dieci L3500REINALDO ANTONIO NAVARRO BLANCONo ratings yet

- 19 Hilux (Cont. Next Page) : Taillight (LHD)Document6 pages19 Hilux (Cont. Next Page) : Taillight (LHD)BASILIO JARA HUERTANo ratings yet

- Girder Layout & LengthDocument1 pageGirder Layout & LengthMrinal KayalNo ratings yet

- Csifinal 5Document1 pageCsifinal 5michaelberliantNo ratings yet

- Analysis 01Document2 pagesAnalysis 0165011119No ratings yet

- Pelco Developer Network (PDN) : Pelco API Web Services Supported On Pelco ProductsDocument2 pagesPelco Developer Network (PDN) : Pelco API Web Services Supported On Pelco ProductsFranklin AlvaradoNo ratings yet

- Computer Vision 2Document30 pagesComputer Vision 2lcnblzr3877No ratings yet

- 2Document1 page2dimas wahyuNo ratings yet

- Math 2Document1 pageMath 2assal2007faisalNo ratings yet

- Canada Carte DétailléeDocument1 pageCanada Carte DétailléePasymal Pas Si MalNo ratings yet

- Previa/Tarago (Ewd445F) 175Document1 pagePrevia/Tarago (Ewd445F) 175tokkobarokkoNo ratings yet

- 714 - Om4000Document2 pages714 - Om4000Edson LemosNo ratings yet

- Tantrasco: PROJECT - 220kV-M/C Monopoles Summary SheetDocument1 pageTantrasco: PROJECT - 220kV-M/C Monopoles Summary SheetMOHAMMAD ZUEF - SKIPPER LIMITEDNo ratings yet

- Tail LightDocument2 pagesTail Lighttuan anh nguyễnNo ratings yet

- Technics Sea2000 Power Amplifier Service ManualDocument27 pagesTechnics Sea2000 Power Amplifier Service ManualAlexander RodriguezNo ratings yet

- A B C D E F G H J: Jumeirah VillageDocument1 pageA B C D E F G H J: Jumeirah VillageMUBASHIRNo ratings yet

- Selection of Ball Screws 2 - MISUMIDocument1 pageSelection of Ball Screws 2 - MISUMIDuong NguyenNo ratings yet

- Psu SchematicsDocument1 pagePsu SchematicsJerry LeeNo ratings yet

- Scheme Legends: L&T Electrical & AutomationDocument1 pageScheme Legends: L&T Electrical & AutomationSivachandran RNo ratings yet

- Tabela de IgbtsDocument16 pagesTabela de IgbtsEdmilson Mendes PimentelNo ratings yet

- Summary of Lecture 1: "Let There Be Light"Document32 pagesSummary of Lecture 1: "Let There Be Light"Chandramouleeswaran SarmaNo ratings yet

- CML (103) - Major 2Document39 pagesCML (103) - Major 2usfeklvxnjrdgsjfseNo ratings yet

- Multiport Conversions Between S, Z, Y, H, ABCD, and T ParametersDocument1 pageMultiport Conversions Between S, Z, Y, H, ABCD, and T ParametersOscar Niño BernalNo ratings yet

- ASDADocument1 pageASDAKristine ChavezNo ratings yet

- 9852 1404 01a Driving M2 C, L1 C, L2 CDocument2 pages9852 1404 01a Driving M2 C, L1 C, L2 CGustavo A. Utreras FariasNo ratings yet

- Auma Terminal ManualDocument2 pagesAuma Terminal ManualPunesh PaulNo ratings yet

- Almana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Document4 pagesAlmana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Jet ArcaNo ratings yet

- Carvin 8 BusDocument1 pageCarvin 8 BusRobby AhyanaNo ratings yet

- Traigulation NW Final 11082021Document1 pageTraigulation NW Final 11082021Sreedhar PoluNo ratings yet

- Overall EWD Vehicle Interior Illumination (RHD)Document6 pagesOverall EWD Vehicle Interior Illumination (RHD)gabrielzinho43No ratings yet

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Taillight (RHD)Document6 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Taillight (RHD)gabrielzinho43No ratings yet

- Powered Mixer Tables de Mixage Á Amplification de Puissance Aktiv-MischpultDocument21 pagesPowered Mixer Tables de Mixage Á Amplification de Puissance Aktiv-MischpultJun AballeNo ratings yet

- Powered MixageDocument21 pagesPowered MixageFodil DouazNo ratings yet

- Kiambu CidpDocument342 pagesKiambu CidpCharles ZihiNo ratings yet

- T N M M T N M M: HE EW Essies Anual HE EW Essies AnualDocument8 pagesT N M M T N M M: HE EW Essies Anual HE EW Essies AnualMunna100% (1)

- Barcode v1Document31 pagesBarcode v1Desinta OctavianiNo ratings yet

- PSP Assignment1Document25 pagesPSP Assignment1B BasitNo ratings yet

- Mbarang 10102022Document3 pagesMbarang 10102022zeta chenkNo ratings yet

- Bence Bays Resume July 2015Document2 pagesBence Bays Resume July 2015api-292242662No ratings yet

- The History of The Big Bang TheoryDocument6 pagesThe History of The Big Bang Theorymay ann dimaanoNo ratings yet

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- Promotion Letter ShwetaDocument2 pagesPromotion Letter ShwetayogeshNo ratings yet

- BIOLOGY HOTS Questions Class 12thDocument68 pagesBIOLOGY HOTS Questions Class 12thAkshatha Nayak50% (2)

- Emilio Aguinaldo College: School of NursingDocument2 pagesEmilio Aguinaldo College: School of NursingAwani ONo ratings yet

- Laboratory Information Management System: Prepared By: Mariela C. Ronquillo, RMTDocument33 pagesLaboratory Information Management System: Prepared By: Mariela C. Ronquillo, RMTRonel RonquilloNo ratings yet

- Common Problems and Actions Taken in The Philippine Education SystemDocument3 pagesCommon Problems and Actions Taken in The Philippine Education SystemDoods Galdo88% (16)

- Manual Spray GunDocument6 pagesManual Spray GunSyazwan KhairulNo ratings yet

- Discard ManagementDocument9 pagesDiscard ManagementDevvrath SinghNo ratings yet

- Emotional IntelligenceDocument43 pagesEmotional IntelligenceMelody ShekharNo ratings yet

- SPE 13932 Wettability Part2 AndersonDocument17 pagesSPE 13932 Wettability Part2 AndersonSergio EduardoNo ratings yet

- Parent Medical CoverageDocument9 pagesParent Medical CoveragecampeonNo ratings yet

- Mina NEGRA HUANUSHA 2 ParteDocument23 pagesMina NEGRA HUANUSHA 2 ParteRoberto VillegasNo ratings yet

- Chicken BellagioDocument4 pagesChicken BellagioJagr MaddoxNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- A Study On Occupational Hazards in Die Casting IndustriesDocument8 pagesA Study On Occupational Hazards in Die Casting IndustriesManik LakshmanNo ratings yet

- Vikas BhagwanDocument13 pagesVikas BhagwanhappysinNo ratings yet

- BRS TestDocument2 pagesBRS TestMuhammad Ibrahim KhanNo ratings yet

- Pro 3 Mplusdevipplus 07Document6 pagesPro 3 Mplusdevipplus 07daylavianNo ratings yet

- 793-P-1C Relay Data SheetDocument6 pages793-P-1C Relay Data SheetsendmebooksNo ratings yet

- Astm C 592Document9 pagesAstm C 592hoseinNo ratings yet