Professional Documents

Culture Documents

Adjustment of Mechanical Overload sx4 5-2018

Adjustment of Mechanical Overload sx4 5-2018

Uploaded by

Rafa EpromOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adjustment of Mechanical Overload sx4 5-2018

Adjustment of Mechanical Overload sx4 5-2018

Uploaded by

Rafa EpromCopyright:

Available Formats

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

PH: 937-328-5100

www.rmhoist.com

Adjustment of Mechanical Overload Device

WARNING: High voltage is present in the hoist control cabinet

and overload switch.

1. Turn adjustment screw for the mechanical limit switch counterclockwise until

it no longer engages micro-switch.

2. Lift test load 1-3 inches. (Use 110% rated capacity as a starting reference not to

exceed 125% of rated capacity)

3. Remove power to hoist.

4. On a low headroom or double girder hoist remove the hoist cover. On a

normal headroom hoist remove the access plate above the control

enclosure directly below the trolley side plate.

5. Using a continuity tester across terminals 53 and 54 in the hoist control box

(Continuity should be read), adjust the mechanical limit switch adjustment

screw until the micro-switch just “opens” causing an interruption in the circuit.

6. Remove the test equipment then apply the power to the hoist.

7. Test the hoist using the load referenced in step 2. The hoist should shut off

and not pick up the load. Note: If the hoist lifts the load, stop lifting and

repeat steps 2 through 7

8. Test the hoist with 100%. The hoist should be capable of lifting the load.

9. Repeat steps 2 through 8 until the hoist lifts 100% of capacity but will not lift

125%.

10. Seal Screw with thread locking compound after Overload Protection is set

properly.

11. Replace access covers.

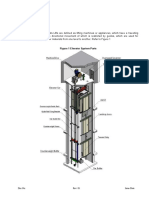

Mechanical Overload Protection Switch

1. Rope anchorage

2. Lever mechanism

3. Set of plate springs

4. Mechanical limit switch

5. Adjustment screw for mechanical limit switch

RISE ABOVE

You might also like

- Manual - Servicio Ingles - Haulotte h18 SDXDocument221 pagesManual - Servicio Ingles - Haulotte h18 SDXTesla Ec50% (4)

- Overhead Crane Load Test ProceduresDocument6 pagesOverhead Crane Load Test ProceduresMeritorious Khan100% (5)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Catalogo Pit Hog #1Document150 pagesCatalogo Pit Hog #1ANDRES0% (1)

- Report (Elevator)Document12 pagesReport (Elevator)Lee MinNo ratings yet

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocument38 pagesME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNo ratings yet

- Load Test ProcedureDocument5 pagesLoad Test ProcedureAlzaki Abdullah83% (6)

- Dumper ManualDocument10 pagesDumper Manual2692rimmi5902No ratings yet

- CK-500 Instruction Manual DownloadDocument16 pagesCK-500 Instruction Manual DownloadRonnie OoiNo ratings yet

- G150CNDocument11 pagesG150CNElois grimonNo ratings yet

- ErectionDocument16 pagesErectionÞÜšhpendra JAñgidNo ratings yet

- 1631617166934-EOT Maintenance PDFDocument16 pages1631617166934-EOT Maintenance PDFMohd Haidi100% (1)

- 开山印尼SMGP地热发电项目集装箱式箱变操作手册Document11 pages开山印尼SMGP地热发电项目集装箱式箱变操作手册Jessyka SsykaNo ratings yet

- Manual: Diversified Products, Inc. PowertraxDocument28 pagesManual: Diversified Products, Inc. PowertraxProyectos Trans roll, C.A. OficinaNo ratings yet

- 开山印尼SMGP地热发电项目集装箱式箱变操作手册 2Document11 pages开山印尼SMGP地热发电项目集装箱式箱变操作手册 2Jessyka SsykaNo ratings yet

- SOP - 6.6 KV Breaker OperationDocument4 pagesSOP - 6.6 KV Breaker OperationJitendra kumarNo ratings yet

- Manual: Diversified Products, Inc. PowertraxDocument24 pagesManual: Diversified Products, Inc. PowertraxProyectos Trans roll, C.A. OficinaNo ratings yet

- Hydraulic Hoist With Free FallDocument8 pagesHydraulic Hoist With Free Fallabelmonte_geotecniaNo ratings yet

- Load Bank Operating InstructionsDocument194 pagesLoad Bank Operating InstructionsJonathan Javier Ceballos Bonilla0% (1)

- Yale YJLHook - YJC680Document36 pagesYale YJLHook - YJC680Francisco Javier BurgosNo ratings yet

- KYN28-12 高压开关柜 操作培训 High Voltage Switchgear Operation TrainingDocument12 pagesKYN28-12 高压开关柜 操作培训 High Voltage Switchgear Operation TrainingJessyka SsykaNo ratings yet

- Safety Training Cranes and HoistsDocument89 pagesSafety Training Cranes and HoistsJose Antonio García Ruíz100% (3)

- Pollock Step Lift Users ManualDocument22 pagesPollock Step Lift Users ManualRomuald ZemlianskijNo ratings yet

- Instruction For OperationDocument16 pagesInstruction For OperationAanantharaj LourdesamyNo ratings yet

- MU PHENIX LD75 LD100 Rev1Document19 pagesMU PHENIX LD75 LD100 Rev1soporte.widaggNo ratings yet

- Electric Overhead Traveling Crane Erection and Maintenance PDFDocument10 pagesElectric Overhead Traveling Crane Erection and Maintenance PDFSalman KhanNo ratings yet

- E & M of E.O.T.Document10 pagesE & M of E.O.T.bisweswar100% (1)

- Jlc680 ManDocument36 pagesJlc680 ManGabrielMéndezGrimaldoNo ratings yet

- Lock Out Tag-Out Tank Hydrotesting: Petrol Steel Company LimitedDocument24 pagesLock Out Tag-Out Tank Hydrotesting: Petrol Steel Company Limitedmohammed harrisNo ratings yet

- Industrial Door - Operating Manual Insert Address HereDocument12 pagesIndustrial Door - Operating Manual Insert Address HereAbiodun Ilori0% (1)

- Crane Operators Manual Rev 8-1-14Document14 pagesCrane Operators Manual Rev 8-1-14Dante WilliamsNo ratings yet

- Chevrolet Colorado T-Case TSDocument5 pagesChevrolet Colorado T-Case TSzdwkxgnjd7No ratings yet

- Users Manual Phenix Technologies Inc.: PPD September 19, 2007Document31 pagesUsers Manual Phenix Technologies Inc.: PPD September 19, 2007Edinson Cardenas AlikhanNo ratings yet

- 475-20 Users ManualDocument26 pages475-20 Users ManualMilton HernandezNo ratings yet

- Jarring IntroductionDocument8 pagesJarring IntroductionRafael NavasNo ratings yet

- Alikraft Elevator - O&m ManualDocument28 pagesAlikraft Elevator - O&m Manualamarsingh choudharyNo ratings yet

- Manual TirforDocument2 pagesManual TirforWilmer SaldañaNo ratings yet

- 475-20 DC Dielectric Test Set - Version 5.0Document31 pages475-20 DC Dielectric Test Set - Version 5.0davidramirezmNo ratings yet

- Stored Energy Controlling ProcedureDocument2 pagesStored Energy Controlling ProcedureDananja BuddhikaNo ratings yet

- Elevator Test Method Rev. 1 (Dood)Document12 pagesElevator Test Method Rev. 1 (Dood)ThomasNo ratings yet

- Oil Test Kit Instruction Manual & Test CertificateDocument5 pagesOil Test Kit Instruction Manual & Test Certificateraju289No ratings yet

- 2 1105693707Document61 pages2 1105693707a_salehiNo ratings yet

- Cranes InspectionDocument2 pagesCranes InspectionMahmoud AbdallahNo ratings yet

- Agitador Orbital Belly Button Ref Bbuaav1sDocument8 pagesAgitador Orbital Belly Button Ref Bbuaav1sjuan cometaNo ratings yet

- ATDocument16 pagesATjganguy2004No ratings yet

- Overhead Crane FamiliarisationDocument16 pagesOverhead Crane Familiarisationmohamed fahsNo ratings yet

- 2 Post Lifter - ManualDocument24 pages2 Post Lifter - ManualRyan EncomiendaNo ratings yet

- 924G 924Gz Wheel Loader RBB00001-UP (MACHINE) POWERED BY 3056E Engine (SEBP3526 - 79) - Sistemas y Componentes ElectricoDocument5 pages924G 924Gz Wheel Loader RBB00001-UP (MACHINE) POWERED BY 3056E Engine (SEBP3526 - 79) - Sistemas y Componentes Electricoubaldo caraballoNo ratings yet

- Faac 400 ManDocument24 pagesFaac 400 ManJuanNo ratings yet

- 101NDXFGLUUU1Document2 pages101NDXFGLUUU1John OigbochieNo ratings yet

- Phenix 4120-10 2.3Document27 pagesPhenix 4120-10 2.3Trần Danh VũNo ratings yet

- Crane MaintenanceDocument7 pagesCrane Maintenancemichol2014No ratings yet

- PolipastoDocument32 pagesPolipastoHaro A FranciscoNo ratings yet

- MU PHENIX PM6 Rev1Document21 pagesMU PHENIX PM6 Rev1soporte.widaggNo ratings yet

- Two Man Self Powered Cradle - Emergency Procedure (Manual Cradle Descent)Document6 pagesTwo Man Self Powered Cradle - Emergency Procedure (Manual Cradle Descent)Francis BautistaNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Check Weigher: Revolutionizing Quality Control with Computer VisionFrom EverandCheck Weigher: Revolutionizing Quality Control with Computer VisionNo ratings yet