Professional Documents

Culture Documents

Field Installation, Inspection & Test Plan

Field Installation, Inspection & Test Plan

Uploaded by

Saiful Ahda100%(1)100% found this document useful (1 vote)

70 views2 pagesThis document outlines the field installation, inspection, and test plan for the civil and structural works of the CCPP Jawa 1 500 kV switching station project. It details the inspection levels and acceptance criteria for tasks like drainage works, ditch excavation, road works, and concrete pavement construction. The plan specifies that subcontractors and GE will execute the works, while the client/owner will review documentation and approve the works. Inspections will be conducted by subcontractors with monitoring by GE and approval by the client to ensure all construction complies with specifications, drawings, and quality standards.

Original Description:

Original Title

Rfi Aspal Excel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the field installation, inspection, and test plan for the civil and structural works of the CCPP Jawa 1 500 kV switching station project. It details the inspection levels and acceptance criteria for tasks like drainage works, ditch excavation, road works, and concrete pavement construction. The plan specifies that subcontractors and GE will execute the works, while the client/owner will review documentation and approve the works. Inspections will be conducted by subcontractors with monitoring by GE and approval by the client to ensure all construction complies with specifications, drawings, and quality standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

70 views2 pagesField Installation, Inspection & Test Plan

Field Installation, Inspection & Test Plan

Uploaded by

Saiful AhdaThis document outlines the field installation, inspection, and test plan for the civil and structural works of the CCPP Jawa 1 500 kV switching station project. It details the inspection levels and acceptance criteria for tasks like drainage works, ditch excavation, road works, and concrete pavement construction. The plan specifies that subcontractors and GE will execute the works, while the client/owner will review documentation and approve the works. Inspections will be conducted by subcontractors with monitoring by GE and approval by the client to ensure all construction complies with specifications, drawings, and quality standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

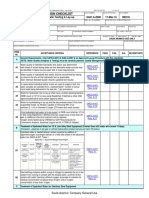

FIELD INSTALLATION, INSPECTION & TEST PLAN

Dicipline CIVIL AND STRUCTURE LEGEND

: Hold Point H : Document Review R GE Electric

: General

Project Title : CCPP JAWA 1 - 500 kV SWITCHING STATION : Execution E : Approval A CO / Owner

: Client

Client Name : JAWA 1 POWER : Monitoring M

Issued Date : 22.May.2019 : Witness W

Revison :2

INSPECTION LEVEL

No DESCRIPTION REFERENCE DOCUMENT FREQUENCY VERIFIED DOCUMENT ACCEPTANCE CRITERIA

SUBCONT. GE CO

4 DRAINAGE/DITCH

4,1 Procedure

a. General Earth Work Technical Specification PI038-CBT-500-ITS-8015-CW-S7050 Comply with spec. & proc. E R R&A

b. Drainage Work Procedure PI038-CBT-500-ITS-9008-CW-S7050 Comply with spec. & proc. E R R&A

4,2 Open Ditch

a. Excavation PI038-ASD-QC1-003 Comply with spec. & DWG. E M R

b. Form work, rebar installation and concreting PI038-ASD-QC1-011 Comply with spec. & DWG. E M W

Technical Specification, PI038-ASD-QC1-012

Every Locations

c. Straightness, elevation, width and side slope of ditch Drainage Work Procedure PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

d. Backfill and compacted PI038-ASD-QC1-004 Comply with spec. & DWG. E M R

PI038-ASD-QC1-005

4,3 Pre-cast Ditch

a. Material receiving Inspection (Manufacturer Compressive Manufacturer Data Sheet and Approved MAR (Material

Strength Test, Bending Test, Rebar Test (yield, tension, Every Delivery PI038-ASD-QC1-001 E R&A R

Testing Report Approval Request)

chemical composition))

b. Excavation PI038-ASD-QC1-003 E M R

c. Straightness, elevation, width and side slope of ditch PI038-ASD-QC1-002 E M W

Work Procedure Every Locations Comply with spec. & DWG.

PI038-ASD-QC1-004

d. Backfill and compacted E M R

PI038-ASD-QC1-002

4,4 Subsoil Drainage/French Drain

Material Control & Receiving Every Delivery Approved MAR (Material

a. Material receiving Inspection PI038-ASD-QC1-001 E R&A R

Document Approval Request)

b. Excavation PI038-ASD-QC1-003 E M R

c. Straightness, elevation, width and graveling PI038-ASD-QC1-002 E M R

Work Procedure Every Locations

d. Backfill and compacted PI038-ASD-QC1-004 E M R

PI038-ASD-QC1-005

5 ROAD

5,1 Procedure

a. General Earth Work PI038-CBT-500-ITS-8015-CW-S7050 Comply with spec. & proc. E R R&A

Technical Specification

b. Road Work Procedure PI038-CBT-500-ITS-8010-TD-S7050 Comply with spec. & proc. E R R&A

5,2 Concrete Pavement (Rigid Pavement)

a. Sub-Grade for pavement

Technical Specification; SNI Sample from quarry prior to

1. Material Inspection PI038-ASD-QC1-000 Comply with spec. E R&A R

6388-2015 delivery

2. Excavation Approved Drawing, PI038-ASD-QC1-003 Comply with spec. & DWG. E M R

100%

3. Surface finishing, slope, thickness and elevation PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

Field/Laboratory Test; SNI 1738-

2 Comply with spec. & DWG.

4. Compaction Test 2011 Every 500m PI038-ASD-QC1-006 E M W

Min Value 6%

b. Sub-Base

Technical Specification; SNI Sample from quarry prior to

1. Material Inspection PI038-ASD-QC1-019 Comply with spec. E R&A R

6388-2015 delivery

2. Surface finishing, slope, thickness and elevation Approved Drawing 100% PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

Field/Laboratory Test; SNI 1738- Comply with spec.

3. Compaction Test (CBR Test) Every 500m2 PI038-ASD-QC1-021 E M W

2011 Min Thk 20cm, CBR > 40%

c Concrete Pavement (Concrete Work)

1. Form Work rebar installation and concreting Approved Drawing, General PI038-ASD-QC1-011 Comply with spec. & DWG. E M R

100% PI038-ASD-QC1-012

Road Construction Procedure

2. Surface finishing, slope, thickness and elevation PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

5,3 Asphalt Pavement (Flexible Pavement)

a. Sub-Grade

Technical Specification; SNI Sample from quarry prior to

1. Material Inspection PI038-ASD-QC1-004 Comply with spec. E R&A R

6388-2015 delivery

2. Excavation Approved Drawing, PI038-ASD-QC1-003 Comply with spec. & DWG. E M R

100%

3. Surface finishing, slope, thickness and elevation PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

Field/Laboratory Test; SNI 1738-

2 Comply with spec. & DWG.

4. Compaction Test (CBR Test) 2011 Every 500m PI038-ASD-QC1-021 E M W

Min Value 6%

b. Sub-Base

Technical Specification; SNI Sample from quarry prior to

1. Material Inspection PI038-ASD-QC1-019 Comply with spec. E R&A R

6388-2015 delivery

2. Surface finishing, slope, thickness and elevation Approved Drawing 100% PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

Field/Laboratory Test; SNI 1738- 2 Comply with spec.

3. Compaction Test (CBR Test) Every 500m PI038-ASD-QC1-021 E M W

2011 Min Thk 20cm, CBR > 40%

c. Base Coarse

Technical Specification; SNI Sample from quarry prior to

1. Material Inspection PI038-ASD-QC1-019 Comply with spec. E R&A R

6388-2015 delivery

2. Surface finishing, slope, thickness and elevation Approved Drawing 100% PI038-ASD-QC1-002 Comply with spec. & DWG. E M R

Field/Laboratory Test; SNI 1738- 2 Comply with spec.

3. Compaction Test (CBR Test) Every 500m PI038-ASD-QC1-021 E M W

2011 Min Thk 10cm, CBR > 90%

d. Asphalt Work

1. Material Inspection Laboratorium Test Report Every Sample PI038-ASD-QC1-000 Comply with spec. E R&A R

2. Mixing proportion and temperature of materials, trial, Job Mix Design PI038-ASD-QC1-000 Comply with spec. E M R

lab test Once every trial

3 Prime Coat or Tack Coat Job Mix Design PI038-ASD-QC1-000 Comply with spec. E M R

4. Location, elevation, cross sectional slope, width, Approved Drawing, Site Core

100% PI038-ASD-QC1-002 Comply with spec. & DWG. E M W

thickness and flatness Test; SNI 6894-2001

You might also like

- TABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedDocument3 pagesTABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedKennedy VasconezNo ratings yet

- ITP For Panel - Rev 1Document4 pagesITP For Panel - Rev 1wawanNo ratings yet

- Service & Operating Manual: 1 1/2" Elima-Matic BoltedDocument21 pagesService & Operating Manual: 1 1/2" Elima-Matic BoltedArdi 4791No ratings yet

- MEP Site Construction FlowchartDocument5 pagesMEP Site Construction FlowchartAlaa AnwerNo ratings yet

- Section 017700 - Closeout ProceduresDocument5 pagesSection 017700 - Closeout ProceduresChase GietterNo ratings yet

- Pump Commissioning Checklist - SafetyCultureDocument3 pagesPump Commissioning Checklist - SafetyCultureMaxmore KarumamupiyoNo ratings yet

- Method Statement Coal TipplerDocument10 pagesMethod Statement Coal TipplerSunil T V SuniNo ratings yet

- BEF PV Commissioning ChecklistDocument4 pagesBEF PV Commissioning ChecklistBronoz GrypenNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacNo ratings yet

- MD1-0-T-030-05-00397-A - ITP For STGDocument25 pagesMD1-0-T-030-05-00397-A - ITP For STGTran KhuynhNo ratings yet

- SATIP-P-104-02 Rev 7 FinalDocument3 pagesSATIP-P-104-02 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Mechanical Completion CertificateDocument1 pageMechanical Completion CertificateJoanrenis SaranyaNo ratings yet

- Work Environment Measurement MemorandumDocument3 pagesWork Environment Measurement MemorandumDaniel Reyes100% (1)

- Dudaura Bridge ContractDocument3 pagesDudaura Bridge ContractkesharinareshNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- NCR Action PlanDocument5 pagesNCR Action PlandasNo ratings yet

- Lighting and Control Systems CommissioningDocument1 pageLighting and Control Systems CommissioningBruno CelisNo ratings yet

- Fire Stopping Mechanical and ElectricalDocument7 pagesFire Stopping Mechanical and Electricaljack.simpson.changNo ratings yet

- ITP For Flow MeterDocument4 pagesITP For Flow MeterSayee KrishnanNo ratings yet

- MS-Underground Utility DetectionDocument14 pagesMS-Underground Utility Detection刘俊逸liujunyirenNo ratings yet

- SATIP-P-104-07 Rev 7 FinalDocument4 pagesSATIP-P-104-07 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 PlumbDocument1 pageSaudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 Plumbbiplabpal2009No ratings yet

- MS Boiler & CalorifierDocument14 pagesMS Boiler & CalorifierSanto ENo ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument26 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- MZ-000-CCX-HS-PRO-00011 Control of Hazardous Energy Procedure Rev 0Document63 pagesMZ-000-CCX-HS-PRO-00011 Control of Hazardous Energy Procedure Rev 0Abílio Júnior MubaiNo ratings yet

- Pre Energization Test ProceduresDocument6 pagesPre Energization Test Proceduressani priadiNo ratings yet

- Request For Inspection (Rfi) : Project TitleDocument3 pagesRequest For Inspection (Rfi) : Project TitleehteshamNo ratings yet

- 002-PDS-CON-008 Method Statement For Material Handling ManualDocument11 pages002-PDS-CON-008 Method Statement For Material Handling ManualMalik ZamanNo ratings yet

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- SATIP-P-104-05 Rev 7 FinalDocument6 pagesSATIP-P-104-05 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- METHOD STATEMENT For Kalzip InstallationDocument2 pagesMETHOD STATEMENT For Kalzip Installationmd_rehan_2100% (1)

- Index Final Data BookDocument2 pagesIndex Final Data Booksajadsadeghi123100% (1)

- HIRAC CraneDocument2 pagesHIRAC CranetaufikNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Hose Test Method StatementDocument6 pagesHose Test Method StatementRavi ValiyaNo ratings yet

- Division 15 Mechanical IBS HVACDocument164 pagesDivision 15 Mechanical IBS HVACmasahinNo ratings yet

- LEED V4 Sustainable Materials Questionnaire - Exit 10 Al Hamra Development 10.03.2024Document3 pagesLEED V4 Sustainable Materials Questionnaire - Exit 10 Al Hamra Development 10.03.2024IB KNo ratings yet

- QAQCDocument142 pagesQAQCRuhul AmeenNo ratings yet

- Audit Notification - EmersonDocument2 pagesAudit Notification - Emersonnisha_khanNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Combustion Gas TurbinesDocument1 pageSaudi Aramco Pre-Commissioning Form: Combustion Gas TurbinessuparnaNo ratings yet

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDocument3 pagesSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkNo ratings yet

- Earth Moving Equipment ChekclistDocument2 pagesEarth Moving Equipment ChekclistBakri Bin SapilahNo ratings yet

- HVAC Specs - ComplianceDocument32 pagesHVAC Specs - ComplianceArchanaShenoyNo ratings yet

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocument1 pageAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairNo ratings yet

- 014 Commissioning Weekly Report Template PDFDocument21 pages014 Commissioning Weekly Report Template PDFali ahmadNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- 007 - WMS of K2 PasteDocument6 pages007 - WMS of K2 Pastealla malikNo ratings yet

- Boiler Comm SequenceDocument30 pagesBoiler Comm SequenceDian PriengadiNo ratings yet

- Pneumatic TestDocument6 pagesPneumatic TestShrichand G. BathvNo ratings yet

- Method Statement For Installaation of Hydronic Piping With SpecialitiesDocument37 pagesMethod Statement For Installaation of Hydronic Piping With SpecialitiesanwarNo ratings yet

- Cata Exhaust FansDocument40 pagesCata Exhaust FansPrak BaNo ratings yet

- Method Statement For HVACDocument6 pagesMethod Statement For HVACJoyanta DebNo ratings yet

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- Method Statement For Panel InstallationDocument8 pagesMethod Statement For Panel InstallationveksNo ratings yet

- 004 Material Inspection Request MepDocument1 page004 Material Inspection Request MepAbdalrhman KararNo ratings yet

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNo ratings yet

- SAIC-A-2008 - Verify Test Medium For Hydrostatic Testing & Lay-UpDocument3 pagesSAIC-A-2008 - Verify Test Medium For Hydrostatic Testing & Lay-UpwalidNo ratings yet

- HDPE Pipe Safety SheetDocument4 pagesHDPE Pipe Safety SheetHemant ChauhanNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- Toledo Power Company: Terms of ReferenceDocument8 pagesToledo Power Company: Terms of Referencejet toledo100% (1)

- ITP-QP-07 Seamless Line Pipe - Bevel Rev.00 - 1Document4 pagesITP-QP-07 Seamless Line Pipe - Bevel Rev.00 - 1aansetya175No ratings yet

- 03 Gambar Posisi PipaDocument5 pages03 Gambar Posisi PipaSaiful AhdaNo ratings yet

- Plumbing Inspection ReportDocument1 pagePlumbing Inspection ReportSaiful AhdaNo ratings yet

- Nilai Tanda Tangan Orang Tua: Copy Right SMK Mulia Medan Dedi Zulkifli S.Kom@2020Document2 pagesNilai Tanda Tangan Orang Tua: Copy Right SMK Mulia Medan Dedi Zulkifli S.Kom@2020Saiful AhdaNo ratings yet

- Please Write The Sentences of Simple Past Tense BelowDocument1 pagePlease Write The Sentences of Simple Past Tense BelowSaiful AhdaNo ratings yet

- Hollo-Bolt by Lindapter 960Document8 pagesHollo-Bolt by Lindapter 960Anonymous a5jwqF7tUNo ratings yet

- Chemistry Investigatory Project 2018-19: Setting of CementDocument18 pagesChemistry Investigatory Project 2018-19: Setting of CementOm Prakash GadgeNo ratings yet

- Razon Heat Proofing - White Water ProoferDocument2 pagesRazon Heat Proofing - White Water ProoferjustinNo ratings yet

- Slip On Flange RTJ GasketDocument2 pagesSlip On Flange RTJ GasketEDAC RFCLNo ratings yet

- Proiect Constructii Civile 2Document45 pagesProiect Constructii Civile 2Lazurca Augustin100% (1)

- Durbar Floor Plate (Corus) .Document12 pagesDurbar Floor Plate (Corus) .Stuart GoodswenNo ratings yet

- Concrete Products Plant ProposalDocument8 pagesConcrete Products Plant ProposalFady AntonNo ratings yet

- Astm b221mDocument14 pagesAstm b221mrandi777770% (1)

- 04 Steam TrapsDocument8 pages04 Steam TrapsJoshua Balaram RaoNo ratings yet

- Road Building MaterialsDocument8 pagesRoad Building MaterialsKalim AhmadNo ratings yet

- Diaphragm Walls, Cut-Off Walls and Slurry Walls: Implenia Spezialtiefbau GMBHDocument9 pagesDiaphragm Walls, Cut-Off Walls and Slurry Walls: Implenia Spezialtiefbau GMBHNemanja BralovicNo ratings yet

- MasterRehobuild 850 TDSDocument2 pagesMasterRehobuild 850 TDSAlec AbrahamNo ratings yet

- Poly V PulleysDocument12 pagesPoly V Pulleyskevin YachaNo ratings yet

- Specification Ig and Packing MaterialDocument8 pagesSpecification Ig and Packing MaterialVåïbhäv ÇhåühåñNo ratings yet

- Glass Fibre Reinforced Plastic (GRP) Panel Type Door Shutters For Internal Use - SpecificationDocument19 pagesGlass Fibre Reinforced Plastic (GRP) Panel Type Door Shutters For Internal Use - SpecificationAnuradhaPatraNo ratings yet

- Tarkett Norma Centra BrochureDocument6 pagesTarkett Norma Centra Brochuresay itNo ratings yet

- Specification Sheet: West-Com Part WYP Paige Part 32WYPWESTDocument2 pagesSpecification Sheet: West-Com Part WYP Paige Part 32WYPWESTAnonymous XYAPaxjbYNo ratings yet

- Sikadur 42 Vle PlusDocument4 pagesSikadur 42 Vle PlusMohammed AwfNo ratings yet

- DasdDocument2 pagesDasdAnonymous lApm6PsfNo ratings yet

- Concrete Curing Method of StatementDocument3 pagesConcrete Curing Method of Statement张亮No ratings yet

- Conduit Bushings For Rigid Metal Conduit and IMC: Applications Features Material/Finish Certifications and CompliancesDocument1 pageConduit Bushings For Rigid Metal Conduit and IMC: Applications Features Material/Finish Certifications and CompliancesJosé TimanáNo ratings yet

- Secondary Paint Process Qualification FormDocument13 pagesSecondary Paint Process Qualification FormRajwinder SinghNo ratings yet

- Chapter 9 Plumbing CodeDocument15 pagesChapter 9 Plumbing CodeHansel Tayong100% (1)

- MATERIAL STUDY and AUROVILLE CASE STUDYDocument18 pagesMATERIAL STUDY and AUROVILLE CASE STUDYMinni ImmanuelNo ratings yet

- H2 Parker PDFDocument44 pagesH2 Parker PDFAlejandro GilNo ratings yet

- STI SP001 - SP031 Repairs 5th Edition GuidelinesDocument33 pagesSTI SP001 - SP031 Repairs 5th Edition GuidelinesJade Geronimo80% (5)

- Stainless Steel Pipe SCHDocument5 pagesStainless Steel Pipe SCHmahaveenNo ratings yet

- Surface Box On Field or Verges Surface Box On Paved Roads Plan ViewDocument1 pageSurface Box On Field or Verges Surface Box On Paved Roads Plan ViewAbdelmoneimNo ratings yet