Professional Documents

Culture Documents

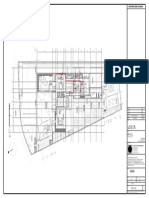

Fuel Storage Tank Details: (Sub-Con. Logo) Shang Residences at Wack-Wack Fuel System Diagram

Fuel Storage Tank Details: (Sub-Con. Logo) Shang Residences at Wack-Wack Fuel System Diagram

Uploaded by

Sherwin MagnoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Storage Tank Details: (Sub-Con. Logo) Shang Residences at Wack-Wack Fuel System Diagram

Fuel Storage Tank Details: (Sub-Con. Logo) Shang Residences at Wack-Wack Fuel System Diagram

Uploaded by

Sherwin MagnoCopyright:

Available Formats

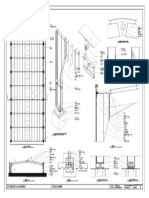

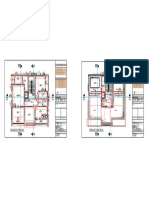

12mmØ BENDED

ROUND BAR PADLOCK

(HANDLE)

12mmØ ROUND BENDED

ROUND BAR (HANDLE)

RUBBER GASKET

1

2"Ø FABRICATED 1

PADLOCK HOLE 2"Ø FABRICATED HINGE

HINGE

MANHOLE OPENING

COVER 8mm THICK

10mm THICK FLAT BAR

FUEL STORAGE TANK SUPPORT

MANHOLE DETAIL

SCALE NTS

10mm THICK RUBBER PAD

by others

CONCRETE SADDLE

by others

FILL CABINET

FRONT VIEW WITH COVER CONTENT PILOT LIGHT

100mmØ

FILL VALVE

EMPTY BUZZER

FILL LINE CABINET

8mm THICK

END PLATE

FUEL STORAGE TANK DETAILS

DIAMETER 2400 mm

LENGTH 6400 mm

CAPACITY 28950 LITERS

MATERIAL 5mm THICK MS PLATE

TOP VIEW FINISH

600mmØ MANHOLE RED EPOXY PRIMER AND

WITH 7.5mm THICK BOLTED FINISH W/ EPOXY PAINT

COVER

50mmØ SPARE 50mmØ OVERFLOW

75mmØ VENT LINE NOTES:

100mmØ FUEL FILL LINE 1. TANK SHALL BE MADE SINGLE WALL ONLY USING COMMERCIAL GRADE

50mmØ PROVISION FOR 5.0mm THICK BODY SHELL AND 8.0mm END PLATE.

SOUNDING LINE 2. TANK SHALL PAINTED WITH RED OXIDE PRIMER

AND FINISH-PAINTED WITH EPOXY GRAY ENAMEL PAINT.

65mmØ PUMP SUCTION PIPE

3. LEAK TESTING OF TANK SHALL BE DONE BY USING AIR PRESSURE ONLY

FUEL STORAGE TANK 16mmØ ROUND BAR W/ 5.0 PSI OTHER METHOD OF TESTING NOT INCLUDED.

28950 LITERS FABRICATED LADDER 4. ANY CIVIL WORKS SHALL BE BY

INSIDE THE TANK OTHERS.

5. ANY CIVIL WORKS SHALL BE BY OTHERS.

CONCRETE SADDLE

by others

FLOOR LINE

(BY OTHERS) FYI:

- FOR FUEL STORAGE TANK CAPACITY PLEASE SEE

ATTACHED BOQ AND PROJECT SPECIFIC

REQUIREMENT FOR YOUR REFERENCE.

SIDE VIEW

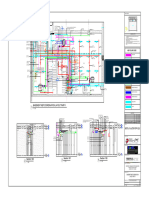

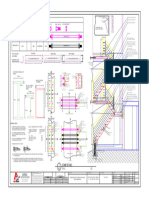

EQUALIZING LINE

50mmØ

OVERFLOW OVERFLOW MANHOLE 600mmØ MANHOLE 600mmØ

50mmØ 50mmØ COMPLETE WITH COVER, COMPLETE WITH COVER,

FUEL OIL BOLTS AND NUTS BOLTS AND NUTS

CONTAINMENT

3600x3300x600mm

by others

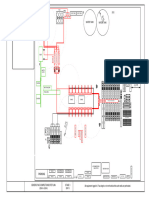

SUPPLY FROM STORAGE TANK SUPPLY FROM STORAGE TANK

50mmØ 50mmØ AIR VENT

50mmØ

FUEL DAYTANK SCHEDULE

SPARE SPARE

DIAMETER 1100 mm

FUEL OIL RETURN FUEL OIL RETURN

GENSET TO FDT GENSET TO FDT LENGTH 3000 mm

25mmØ 25mmØ TRANSFER PUMP SPECIFICATION

0°

0°

SIGHT GLASS

CAPACITY 2851 LITERS

12

1

12

2"with WIREMESS GUARD

1 END PLATE END PLATE 1

MANHOLE 600mmØ MANHOLE 600mmØ 2"Ø ROUND BAR 6mm THICK 6mm THICK 2"Ø ROUND BAR MATERIAL 4mm THICK MS PLATE

COMPLETE WITH COVER, COMPLETE WITH COVER, FDT LADDER FDT LADDER

BOLTS AND NUTS BOLTS AND NUTS FINISH RED EPOXY PRIMER AND

EQUALIZING LINE

50mmØ FINISH W/ EPOXY PAINT

HI - LO FLOAT HI - LO FLOAT FUEL OIL SUPPLY FROM

SWITCH 38mmØ SWITCH 38mmØ DAY TANK TO GENSET Fuel Daytank Capacity Computation:

25mmØ

Generator Fuel Consumption = 283.04 liters/hr @ 100% load

SPARE SPARE

Fuel Daytank Capacity requirement for 8.0 hours = (283.04liters/hr)(8.0hrs)

AIR VENT AIR VENT FUEL OIL =2264.32 liters

50mmØ 50mmØ CONTAINMENT

by others Actual Fuel DayTank Capacity = Tank1 + Tank2

DOME TYPE =2851Liters + 2851Liters

FLOOR DRAIN =5702liters

CONCRETE SLAB

by others

Fuel Containment Capacity Computation:

FUEL OIL SUPPLY FROM FUEL OIL SUPPLY FROM

DAY TANK TO GENSET DAY TANK TO GENSET =3300mmx3600mmx600mm

25mmØ 25mmØ =7.128m ³/7128Liters

* 4mm MS plate standard in the philippines (used in all our projects)

NOTES:

MANHOLE 600mmØ MANHOLE 600mmØ MANHOLE 600mmØ 1. TANK SHALL BE MADE SINGLE WALL ONLY USING COMMERCIAL GRADE

COMPLETE WITH COVER, COMPLETE WITH COVER, COMPLETE WITH COVER, 4.0mm THICK BODY SHELL AND 6.0mm END PLATE.

BOLTS AND NUTS SUPPLY FROM BOLTS AND NUTS BOLTS AND NUTS

FUEL STORAGE TANK

2. TANK SHALL PAINTED WITH RED OXIDE PRIMER

FUEL OIL RETURN

HI - LO FLOAT GENSET TO FDT TO FUEL DAY TANK AND FINISH-PAINTED WITH EPOXY GRAY ENAMEL PAINT.

50mmØ SUPPLY FROM

SWITCH 38mmØ 25mmØ

FUEL STORAGE TANK 3. LEAK TESTING OF TANK SHALL BE DONE BY USING AIR PRESSURE ONLY

TO FUEL DAY TANK AT 5.0PSI OTHER METHOD OF TESTING NOT INCLUDED.

AIR VENT 50mmØ 4. ANY CIVIL WORKS SHALL BE BY

50mmØ SPARE SPARE

OTHERS.

5. ANY CIVIL WORKS SHALL BE BY OTHERS.

OVERFLOW OVERFLOW

50mmØ 50mmØ

FDT TO FST

SIGHT GLASS BODY SHELL

0°

0°

1

2" with WIREMESS GUARD 4mm THICK 6mm THICK DOUBLER

12

12

END PLATE END PLATE

1 1 6mm THICK 1 WELDED ON TANK SHELL

2"Ø ROUND BAR 2"Ø ROUND BAR 6mm THICK 2"Ø ROUND BAR

FDT LADDER FDT LADDER FDT LADDER

EQUALIZING LINE

50mmØ

EQUALIZING LINE 2"X1/4"-THICKNESS

50mmØ ANGLE BAR

TANK SUPPORT

FUEL OIL FUEL OIL

CONTAINMENT CONTAINMENT

by others by others

CONCRETE SLAB CONCRETE SLAB

SCALE: NTS

PROJECT MANAGER: DRAWN BY: SRM

SHEET CONTENTS: PROJECT TITLE: OWNER: PROFESSIONAL MECHANICAL ENGINEER: SHEET NO:

DATE: JUNE 11, 2018

(SUB-CON. LOGO) FUEL SYSTEM SHANG RESIDENCES AT WACK-WACK 1/1

CHECKED BY:

DIAGRAM

DATE: LOCATION: #575 WACK-WACK ROAD, BRGY. WACK-WACK, GREENHILLS, SAN JUAN CITY, MM

You might also like

- 9272 Additional Problems PDFDocument20 pages9272 Additional Problems PDFGOONo ratings yet

- Ts Eamcet 2015 Last RankDocument34 pagesTs Eamcet 2015 Last RankARZeeshan100% (1)

- Chapter 09 Embedded Firmware Design and DevelopmentDocument63 pagesChapter 09 Embedded Firmware Design and DevelopmentAbhishek73% (15)

- Plate 1 Portal FrmaesDocument1 pagePlate 1 Portal FrmaesMAHAK GUPTANo ratings yet

- Dimensi sprinkler-PLANSDocument1 pageDimensi sprinkler-PLANSPT. Rona Jaya InternusaNo ratings yet

- 8 - 4 Emd Comb Water and DrainageDocument3 pages8 - 4 Emd Comb Water and DrainageAcar Hakan BayramoğluNo ratings yet

- 18.detail Standard Fire FightingDocument1 page18.detail Standard Fire FightingMuhammad ArifNo ratings yet

- Landscape PlanDocument1 pageLandscape PlancoNo ratings yet

- New IPCamDocument1 pageNew IPCamChandra KiranaNo ratings yet

- Robinson Pagadian - Bended Roof 9Document1 pageRobinson Pagadian - Bended Roof 9Cesar DuriasNo ratings yet

- DJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1Document1 pageDJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1info.infinitytechnicalNo ratings yet

- r2 Revised Ceiling Layout 25.09.2023Document1 pager2 Revised Ceiling Layout 25.09.2023blackshark0809No ratings yet

- 4.bifold Doors DetailsDocument1 page4.bifold Doors DetailsarsilanNo ratings yet

- Construction Drawing: Boundary Line Boundary Line Boundary LineDocument1 pageConstruction Drawing: Boundary Line Boundary Line Boundary LinerajavelNo ratings yet

- AemaxDocument1 pageAemaxRonalyn Lago R.C.ENo ratings yet

- NTS DWG El GR 20116Document1 pageNTS DWG El GR 20116janNo ratings yet

- Completed DrawingDocument1 pageCompleted DrawingUmesgNo ratings yet

- Plate 1 - Aluminium DoorsDocument1 pagePlate 1 - Aluminium DoorsGokulNo ratings yet

- S3 Sample Working DrawingDocument1 pageS3 Sample Working DrawingjasonNo ratings yet

- Progress Report (16-12-23)Document1 pageProgress Report (16-12-23)Wijaya GultomNo ratings yet

- Fire Exit: Notes: Date 4.6.19Document1 pageFire Exit: Notes: Date 4.6.19vinaysettyNo ratings yet

- 10-5-2023 - Banquet Hall..Document1 page10-5-2023 - Banquet Hall..ds18.albertcastroNo ratings yet

- Central Engineering Consultancy Bureau Schematic Diagram ofDocument1 pageCentral Engineering Consultancy Bureau Schematic Diagram ofChandima Tharaka HerathNo ratings yet

- A904 - Parking DetailsDocument1 pageA904 - Parking DetailsØwięs MØhãmmedNo ratings yet

- xs1 122 2 A11yDocument1 pagexs1 122 2 A11yProfessor PuppiesNo ratings yet

- SBWR Tma-Brasilia Arc 20221229Document1 pageSBWR Tma-Brasilia Arc 20221229Daniel CiprianoNo ratings yet

- Detail of Septic VaultDocument1 pageDetail of Septic Vaultのれ はぼぇんNo ratings yet

- COMPLETED DRAWING Rev-1Document1 pageCOMPLETED DRAWING Rev-1UmesgNo ratings yet

- COMPLETED DRAWING NewDocument1 pageCOMPLETED DRAWING NewUmesgNo ratings yet

- Ring Detail A 2L#8@100C/C B 2L#8@150C/C: Top Plan (AT +0.5 FROM NGL)Document1 pageRing Detail A 2L#8@100C/C B 2L#8@150C/C: Top Plan (AT +0.5 FROM NGL)Prem SutharNo ratings yet

- ST 2.0 Schedule of Beam, Column, Footing, Slab and Cutting Bar DetailDocument1 pageST 2.0 Schedule of Beam, Column, Footing, Slab and Cutting Bar DetailKate WilleignNo ratings yet

- G+2 NewDocument1 pageG+2 New39 - Deep MandokarNo ratings yet

- CASE 9040B ServmanDocument1,096 pagesCASE 9040B Servmanthebrowns5165No ratings yet

- L - Ar-100.1part PlansDocument1 pageL - Ar-100.1part PlansAslam YaseenNo ratings yet

- Stair Case DetailsDocument1 pageStair Case DetailsSOUNDARYA CHOTHENo ratings yet

- AOS WHITEFIELD-07.03.2022 - Electrical-PLANDocument1 pageAOS WHITEFIELD-07.03.2022 - Electrical-PLANMr. AliNo ratings yet

- Airbus A318-111 Avianca Marterair PDFDocument4 pagesAirbus A318-111 Avianca Marterair PDFAmogelang RakaleNo ratings yet

- Cabana StructuralDocument1 pageCabana StructuralAlsean Soriano DetubioNo ratings yet

- Proposed Serene Court KitchenDocument1 pageProposed Serene Court KitchenkevinalumasaNo ratings yet

- Basement WallDocument1 pageBasement WallSOUNDARYA CHOTHENo ratings yet

- Plot Plan Wellpad E - SUPERIMPOSE RIG (E31P, E56P) (WI)Document1 pagePlot Plan Wellpad E - SUPERIMPOSE RIG (E31P, E56P) (WI)Xiang JintaoNo ratings yet

- Final Floor PlanDocument1 pageFinal Floor Plansafwanmohammad52No ratings yet

- FP-02 Site Dev't PlanDocument1 pageFP-02 Site Dev't PlanBerlin Andrew SionNo ratings yet

- Electrical Drawings For Boy DormitoryDocument5 pagesElectrical Drawings For Boy Dormitorynkurunzizaapollinaire202No ratings yet

- Rig2-Ee-100 - 103-Ee-100Document1 pageRig2-Ee-100 - 103-Ee-100Shamim ImtiazNo ratings yet

- Big Nose: Georges Craioveanu Radu Zaharia Vectorized by Ionut Bornoiu Engine Size .40 - .46 Model NameDocument1 pageBig Nose: Georges Craioveanu Radu Zaharia Vectorized by Ionut Bornoiu Engine Size .40 - .46 Model NameStefan IonutNo ratings yet

- Ultimate NAC V1.0 - FullDocument1 pageUltimate NAC V1.0 - FullAlexandre OuteiroNo ratings yet

- Bautista - A4Document1 pageBautista - A4Wilfredo MinaNo ratings yet

- Sheet Title: Part Plan of Toilet: Working DrawingDocument1 pageSheet Title: Part Plan of Toilet: Working DrawingAditiNo ratings yet

- 302-KG - Nirup - Residence 2bed - Type 2 - 2BRS - DD - King Room Bathroom-303Document1 page302-KG - Nirup - Residence 2bed - Type 2 - 2BRS - DD - King Room Bathroom-303hari alfandiNo ratings yet

- Formworks: Wall Footing 1 DetailDocument1 pageFormworks: Wall Footing 1 DetailAndre Joseph OrtizNo ratings yet

- Road Ouside Plant To Ipc Port Road Ouside Plant To Ipc PortDocument1 pageRoad Ouside Plant To Ipc Port Road Ouside Plant To Ipc PortAllif ArrozynNo ratings yet

- LA501 - Site Details Rev.1Document1 pageLA501 - Site Details Rev.1Amogh SwamyNo ratings yet

- IRP 20 Generic Site Plan Example Stages 1 8Document8 pagesIRP 20 Generic Site Plan Example Stages 1 8Ralf JonesNo ratings yet

- KkcitymapDocument1 pageKkcitymapAbu Bakar Hj PunimanNo ratings yet

- Lake PointDocument26 pagesLake Pointmanglicmotabigail11No ratings yet

- Lufthansa A319Document3 pagesLufthansa A319sarita kumariNo ratings yet

- Elevation D'-D': SCALE 1: 20Document1 pageElevation D'-D': SCALE 1: 20Silvia PratiwiNo ratings yet

- Farm House Layout PlanDocument1 pageFarm House Layout PlanshNo ratings yet

- Plumbing Plan 1Document1 pagePlumbing Plan 1Dialyn San Jose MangcoyNo ratings yet

- Vacuum Cleaner Hose-Durability and Reliability (All-Plastic Hose)Document6 pagesVacuum Cleaner Hose-Durability and Reliability (All-Plastic Hose)ROHITNo ratings yet

- TMEC Basic WorkflowDocument1 pageTMEC Basic WorkflowChuah Lu ShengNo ratings yet

- Hydroboration OxidationDocument7 pagesHydroboration OxidationAlexNo ratings yet

- Brochure Twinwall Sheets enDocument13 pagesBrochure Twinwall Sheets enkdpmansiNo ratings yet

- Eco Friendly Road Dust CleanerDocument5 pagesEco Friendly Road Dust CleanerrassNo ratings yet

- KBL Fire Catalogue PDFDocument31 pagesKBL Fire Catalogue PDFmoinulsaqibNo ratings yet

- Img 20190925 0001 PDFDocument4 pagesImg 20190925 0001 PDFChristina PerezNo ratings yet

- SQTimetableDocument248 pagesSQTimetableSarunNo ratings yet

- Ansii Nomenclature TableDocument2 pagesAnsii Nomenclature TableNaveed IrshadNo ratings yet

- Prografixx Ersatzteil Katalog 2022Document230 pagesPrografixx Ersatzteil Katalog 2022Tech IndoNo ratings yet

- Connections 5.5 Small Deployment Part 1 - Core AppsDocument90 pagesConnections 5.5 Small Deployment Part 1 - Core Appsmachg5573No ratings yet

- L&T Yaskawa AC DrivesDocument20 pagesL&T Yaskawa AC Drivesjunfa0% (1)

- Visual Guide For Terminating Gigaflex Modules T568-A: (In Pictures)Document25 pagesVisual Guide For Terminating Gigaflex Modules T568-A: (In Pictures)pyzaczekNo ratings yet

- SelectedDocument3 pagesSelectedRhett SilvaNo ratings yet

- 4Q2223 Correl 2 RCD 2 PM June 22Document25 pages4Q2223 Correl 2 RCD 2 PM June 22Ronnie BalcitaNo ratings yet

- Generator Maintenance - Common Generator Problems and How To Prevent ThemDocument3 pagesGenerator Maintenance - Common Generator Problems and How To Prevent ThemAditya Shiva AppallaNo ratings yet

- AMP Tecnam P2002-JF Ed3 Rev0Document56 pagesAMP Tecnam P2002-JF Ed3 Rev0Александр ЛукинNo ratings yet

- Assignment and BOQ 16-04-19Document80 pagesAssignment and BOQ 16-04-19Taure YambeNo ratings yet

- AP030 Project Team Learning PlanDocument11 pagesAP030 Project Team Learning PlanRam ParepalliNo ratings yet

- Ropex Cirus A4 ENDocument6 pagesRopex Cirus A4 ENRainNo ratings yet

- Cutler-Hammer: Learning Module 2: Fundamentals of ElectricityDocument39 pagesCutler-Hammer: Learning Module 2: Fundamentals of ElectricityobeNo ratings yet

- Bma OVC International Sugar Journal 2012 enDocument2 pagesBma OVC International Sugar Journal 2012 enErick CubasNo ratings yet

- Suspension System in AutomobilesDocument27 pagesSuspension System in AutomobilesJainul PatelNo ratings yet

- Circuit Breaker Types and Applications - C&S ElectricDocument6 pagesCircuit Breaker Types and Applications - C&S ElectricDeus KatureebeNo ratings yet

- 4 Bar Mechanism PDFDocument3 pages4 Bar Mechanism PDFSagar Dutt MathurNo ratings yet

- Principle of Compiler Question and AnswerDocument2 pagesPrinciple of Compiler Question and AnswerSyafiqa RoslanNo ratings yet

- Chapter 1 Activated CarbonDocument2 pagesChapter 1 Activated Carbonjscott123No ratings yet