Professional Documents

Culture Documents

MOS Template - Plastering Work

MOS Template - Plastering Work

Uploaded by

Anantha PadmanabhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOS Template - Plastering Work

MOS Template - Plastering Work

Uploaded by

Anantha PadmanabhanCopyright:

Available Formats

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 1

(This is a template for MS for Plastering Work. Please fill all the sections

highlighted in yellow with project specific data.)

METHOD STATEMENT FOR

PLASTERING WORK

DOCUMENT NO.: …………………..As per KCC/Project naming Standards

JOB NO. : ---------------

(Project Name)

(Location), KINGDOM OF SAUDI ARABIA

APPROVED FOR

CLIENT OWNER

Approved Approved

Approved w/ comments Approved w/ comments

Name Name

Signature Signature

Date Date

ISSUE STATUS

Rev. Date Description Prepared by Sign Approved Sign

(Name) (Name)

0 Approval

QA/QC Manager Site Manager

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 2

SECTION REV. PAGE

TITLE SECTION

NO. NO. NO.

1 SCOPE 0 3

2 REFERENCES 0 3

3 GENERAL 0 3

4 ORGANIZATION CHART 0 6

5 DUTIES & RESPONSIBILITIES 0 7

6 TOOLS & EQUIPMENT 0 8

7 WORK PROCEDURE 0 9

8 INSPECTION 0 15

9 SAFETY ACTION PLAN 0 15

10 ATTACHMENT 0 16

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 3

1 SCOPE

This method statement is made to enumerate the preparation and application of cement

plastering for masonry walls at Site Buildings as per the project specifications and also to

ensure safety procedures involved in the execution of the activity, according to the

requirements of Project name, Location.

2 REFERENCES

The latest project specification and the site safety procedures shall be used as references

and is part of this method statement in the execution of the work.

ASTM C150 -Standard Specification for Portland cement

ASTM C8 -Standard Specification for Aggregate for Job-Mixed

Portland cement based Mortars

ASTM C926 -Standard Specification for Application of Portland

Cement-Based Plaster

ASTM C270 -Standard Specification for Mortar for Unit Masonry

ASTM C25 -Test Methods for Chemical Analysis of Limestone

Quicklime and Hydrated lime

3 GENERAL

Internal and external plastering shall be applied to the walls as indicated on the building

finishing schedule. Where the false ceiling is provided, plastering of walls shall be extend

beyond the false ceiling level as required for the proper installation of the false ceiling.

Terminology:

3.1 Dash-bond coat

A thick wet mixture of Portland cement and water, with or without aggregate,

dashed onto the surface of a plaster base such as smooth monolithic concrete

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 4

or concrete block surfaces to improve the mechanical key for subsequent

plaster coats.

3.2 Admixture

A material other than water, aggregate, or basic cementitious material added

to the batch before or during job mixing.

3.3 Bond

It is the state of adhesion between plaster coats or between plaster and

plaster base.

3.4 Coat

Thickness of plaster applied in a single operation.

3.5 Base coat

All plaster applied before the application of the finish coat.

3.6 Brown coat

The brown coat is the coat directly beneath the finish coat.

3.7 Finish coat

The final layer of plaster applied over basecoat plaster.

3.8 Scratch coat

The first coat of plaster applied to a plaster base.

3.9 Curing

Curing is the act of processes of producing a moisture environment favorable

to cement hydration, resulting in the setting or hardening of the plaster.

3.10 Scoring (Scratching)

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 5

It is the grooving of the surface of an unset plaster coat to provide a key for a

subsequent coat.

3.11 Plaster

Portland cement based cementitious mixture.

3.12 Set

The chemical and physical change in plaster as it goes from a plastic,

workable state to a rigid state.

Materials:

3.13 Cement

Cement for plastering works shall be ordinary Portland cement in accordance

with ASTM C150.

3.14 Sand

Sand for cement mortar shall be sampled and used for plastering purpose in

accordance with ASTM C897. Aggregate failing to meet gradation limits in

specification ASTM C897 shall be used, provided the plaster made with this

sand has an acceptable demonstrated performance record in similar

construction and climatic conditions.

3.15 Lime

A hydrated lime that contains not more than 8% unhydrated oxides when

tested in accordance with ASTM C25.

3.16 Water

Water used in mixing, application, and finishing of plaster shall be clean, fresh,

suitable for domestic water consumption, and free of such amounts of mineral

or organic substances as would affect the set, the plaster, or any metal in the

system.

3.17 Beads and Stops

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 6

All Plastering accessories like beads, stop, lath and mesh shall be provided

from approved supplier by Client/Owner. Nails, Screws, Welded Fabric Mesh

and Washers shall be of galvanized steel.

4 ORGANIZATION CHART

SITE MANAGER

CONSTRUCTION

MANAGER

QA/QC MANAGER CIVIL/ BUILDING HSE MANAGER

SUPERINDENT

WORK PERMIT

CIVIL QA/QC SUPERVISOR COORDINATOR

SURVEYOR

CIVIL SUPERVISOR SAFETY SUPERVISOR

QA/QC INSPECTOR

FORMWORK CIVIL FOREMAN REBAR FOREMAN FABRICATION

FOREMAN FOREMAN

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 7

CARPENTARS / MASON / HELPERS STEEL FITTERS / WELDER / FITTER

HELPERS HELPERS

5 DUTIES AND RESPONSIBILITIES

5.1 Site Manager

Site Manager shall be responsible to provide his site teams with appropriate

resources to ensure that works are done in accordance with the project safety and

quality standards.

5.2 Construction Manager

He is the responsible for the multitude of tasks. He shall review the project activities

in depth and to manage the construction schedule in an effective and efficient

manner. He is the responsible person to lead the construction crew as per project

requirements.

5.3 Civil / Building Superintendent

Civil / Building Superintendent shall be responsible for the over-all direction,

monitoring coordination and control of all the activities related to the plastering

works. He shall be responsible to encourage the workforce for safe and productive

working culture. He shall be dealing with site supervisor teams for implementing work

in correct procedure at site.

5.4 Surveyor

He is the trained professional in understanding and interpreting drawings, data and

survey measurements. He is authorized to assess drawing plans with a view to

ensure that they are compliant with site regulations. He is also responsible to

prepare survey reports.

5.5 Civil Supervisor

The Civil Supervisor shall be directly involved in the supervision, planning and

execution of all activities. He shall be responsible for the preparation of work plan

prior to commencement of work. .

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 8

5.7 QA/QC Manager

The QA/QC Manager shall be responsible to ensure that all works are in accordance

with the approved drawings and specification requirements and as well as

implementation of quality control procedure. He is responsible to review / prepare

ITP and Method Statements.

5.8 QA/QC Supervisor / Inspector

The QA/QC Supervisor / Inspector shall be responsible for the necessary inspections

and testing to be carried during the activities.

5.9 Work Permit Coordinator

Work Permit Coordinator shall be the authorized person for all the work permit

related activities and he shall be the responsible channel for Client. He shall be the

responsible person for guiding and granting work permit for all site activities. He

should ensure that all safety precautions are followed and maintain at work. Any

deviation will mean temporary stoppage of work until all safety requirements are met.

5.10 Foreman

The Foreman shall be responsible in his own discipline for the direct execution of the

plastering activities according to the plan. He shall directly control and give

instruction to the working personnel. He shall also ensure that works are performed

with proper tools/equipment, PPE’s and good housekeeping around the working

area.

5.11 HSE Manager / Supervisor

HSE Manager / Supervisor shall review each activity based on JHA for the activity,

submitted along with work permit for approval prior to the work. He shall ensure that

safe working plan and work permits submitted to Client safety department must be

implemented and observed during the concerned activity.

6 TOOLS AND EQUIPMENT

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 9

All equipment and tools being mobilized on site will be certified and in good and running

condition. The following are the equipment and tools to be used.

Lifting Crane

Dump truck

Man lift

Trailer

Water Truck

Boom Lift

Pay loader

Bobcat

Fork lift

Hammer

Chisel

Marker

Fiber Brush

Steel Wire Brush

Aluminium or Wooden runner

Measuring Tape

Fixing Nails

Marking Thread

Hand Shovel

Drilling machine

Screwing Gun

Grinding machine

Mortar Mixer

Buckets

Plumb bob

Auto level

7 WORK PROCEDURE

7.1 Requirements for Bases to receive Portland Cement-based Plaster

7.1.1 Surfaces of solid bases to receive plaster, such as masonry walls

shall be straight and true within ¼ in. in 10 ft. (2.1 mm/m) and shall

be free of form oil or other elements.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 10

7.1.2 Solid surfaces shall have the suction (ability to absorb water) or

surface roughness, or both, to provide the bond required for the

plaster.

7.1.3 Smooth or nonabsorbent solid surfaces, such as cast-in-place or

precast concrete, shall be prepared to receive plaster through wire

brushing or chipping or a combination of both.

7.1.4 Where masonry surfaces vary in plane, plaster thickness required to

produce level surfaces shall not be required to be uniform.

7.1.5 Electrical items like boxes, conduits, sleeves etc. shall be embedded

on the wall surface prior to plastering work.

7.1.6 Plumbing pipes and accessories are also embedded on walls before

plastering works begin.

7.1.7 Similarly Frames for Doors and Windows are fixed on wall openings

and positioned respect to plastering.

7.1.8 Beads, Stops, Mesh and lath accessories are fixed with nail, washers

and screws on vulnerable wall surfaces and or where plaster needs

reinforcement.

7.1.9 Plumb check shall be done on the surface to identify its uniformity

throughout the wall area.

7.1.10 Tiny model levels (Guides) are spotted on the walls with respect to

final plaster finish thickness at approximately 1.5m distance on both

horizontal and vertical directions.

7.2 Measuring Box for Cement-based Plaster Mix

The Measuring box size for mixing Cement and Aggregates, in preparation of Plaster

for Solid bases or Masonry Units is calculated as per the following,

The Bulk Density of ordinary Portland cement = 1505 Kgs/M3.

The Ordinary Portland cement per bag = 50 Kgs.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 11

The Bulk Density of ordinary Portland cement per bag (50 / 1505 x 1) =

0.033M3.

The Steel or Wooden Box Size volume = 0.033M3.

The Size of the box {(√3 (0.033)} = 0.37M x 0.30M x 0.30M

7.3 Measuring Box for Cement-based Plaster Mix

Nominal thickness for exterior and interior plaster applications are given from the

following tables,

Nominal Plaster Thickness for Exterior Application

Dash Scratch Brown Finish

Base Total

Coat Coat Coat Coat

Masonry Unit

- 10mm 10mm 4mm 24mm

/Concrete

Nominal Plaster Thickness for Interior Application

Dash Scratch Brown Finish

Base Total

Coat Coat Coat Coat

MasonryUnit/Conc

- 7mm 7mm 4mm 18mm

rete

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 12

7.4 Plaster Proportions

Plaster proportions for various coat applications is given in the following table:

Plaster Proportion (By Volume)

Ordinary

Plaster Mix Lime Sand Water

P Portland Cement

Dash Coat 1 - 2 1

Scratch Coat 1 1 3 1

Brown Coat 1 1 3 1

Finish Coat 1 1 3 1

7.5 Mixing

7.5.1 All plaster shall be prepared in a mechanical mixer, using sufficient

water to produce a workable consistency and uniform color. Hand

mixing shall not be permitted.

7.5.2 Proper mixing is adopted by measuring the ingredients using box

volume container. Any other non-approved containers shall not be

used.

7.5.3 Admixtures shall be allowed in plaster mix for certain conditions, only

after prior approval from Client / Owner representatives.

7.5.4 After all ingredients are in the mixer; mix the plaster for 3 to 5

minutes.

7.5.5 Plaster mix that has stiffened shall be re-tempered by adding water

as frequently as needed to restore the required consistency.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 13

However, plaster not used within 11/2 hour from start of initial mixing

shall be discarded.

7.5.6 The mechanical mixer shall be cleaned whenever not in continuous

operation.

7.6 Plastering Application

7.6.1 Prior to application, the masonry units are wetted sufficiently to avoid

sudden loss of moisture.

7.6.2 Initially mortar mix for dash coat is prepared and applied on the solid base

surface and has to be moist cured for at least 24 hours. Trowel finishing

for this coat shall not be done.

7.6.3 The first (scratch coat) shall be applied with sufficient material and

pressure to ensure tight contact and complete coverage of the solid base,

to the nominal thickness.

7.6.4 As soon as the scratch coat becomes firm, the entire surface shall be

scored in one direction only. The vertical surfaces shall be scored

horizontally.

7.6.5 The second (brown) coat shall be applied same as the first coat, bringing

the surface to a true, even plane using wooden or aluminum runner. The

excessive mortar shall be leveled and the gap or void portions to be filled.

7.6.6 In order to provide more intimate contact and bond between coats and to

reduce rapid water loss, the second coat shall be applied as soon as the

first coat is sufficiently rigid to resist cracking, the pressures of the second

coat application, and the leveling process.

7.6.7 The second (brown) coat surface shall be uniformly floated uniformly to

provide a surface receptive to the application of the third (finish) coat.

7.6.8 Each coat shall be permitted to set before the next coat is applied.

7.6.9 The timing between coats shall vary with climatic conditions and types of

plaster base.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 14

7.6.10 The third (finish) coat shall be applied with sufficient material and

pressure to ensure tight contact with, and complete coverage of the base

coat and to the nominal thickness.

7.6.11 The use of excessive water during the application and finishing of finish-

coat plaster shall be avoided. Finish-coat plaster shall not be tempered.

7.6.12 Each plaster coat shall be applied to an entire wall or similar panel

without interruption to avoid cold joints and abrupt changes in the uniform

appearance of succeeding coats.

7.6.13 Final finish shall be regular, smooth and uniform and also based on the

desired thickness as per the approved construction drawing. An identical,

neat and consistent corner or edges finish to be achieved.

7.6.14 Raking of plastered walls of not more than 5mm is done for areas where

tiling work to be carried out.

7.6.15 Control joints on plaster surfaces are provided by 5mm groove on

specified locations as per latest approved drawings.

7.7 Curing

7.7.1 Moist curing is accomplished by applying a fine fog spray of water as

frequently as required, generally twice daily in the morning and evening.

7.7.2 Care shall be taken to avoid erosion damage to portland cement-based

plaster surfaces.

7.7.3 Curing of plastered walls shall be done for 7 days.

7.8 Safety Considerations

7.8.1 Proper scaffolding with enough working space shall be provided for

higher elevated plastering work.

7.8.2 Proper Housekeeping shall be maintained around the working area.

Waste mortar during plastering the walls shall be collected effectively by

paper bags or any other means and disposed immediately.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 15

7.8.3 All working personnel shall be provided with necessary Personal

Protective Equipments (PPE). Safety Harness to be included for higher

elevated working crew.

7.8.4 All the electrical equipments shall be cabled safely and in proper manner.

7.8.5 Good artificial lighting shall be provided for areas where natural lighting is

not sufficient.

7.8.6 During plaster works, protection shall be done for surrounded objects and

areas by covering with plastic sheets in order to avoid splashing or falling

of mortar.

8 INSPECTION

The QC Inspectors of Subcontractor, Client and the OWNER representatives shall carry out

the necessary tests and cement plastering works and generate the RFI maintain the record

as per the approved Inspection and Test Plan, Latest Drawings, International Standards,

Project Specification and this Method statement. All the tests shall be performed by an

authorized third party laboratory.

9 SAFETY ACTION PLAN

9.1 Subcontractor safety supervisor shall carry out the safety site inspections to ensure

that safety requirements laid out in the safe work plan are followed during and after

the plastering works. Safety Manager / Supervisor shall review the Safety Action

Plan and secure Work Permit if necessary prior to start of any activities.

9.2 Equipment, tools and materials inspection.

9.3 All equipment for plastering works shall have to be inspected by Subcontractor

Safety Manager / Supervisor prior to forwarding to Client safety department

inspection prior to use at site to ensure their safe worthiness at work.

9.4 Permit to work (PTW) document is properly mentioned with enough description and

shall be submitted to Client for approval before executing.

9.5 According to the nature of the work Job Hazard Analysis (JHA) shall be used and

filled everyday together with tool box meeting and shall be attached to the PTW and

be available in PTW Box.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 16

9.6 Enough working spaces will be provided and the enter/exit access. Proper

barricading and safety signboards, emergency equipment introduced. Designated

safety person shall monitor and act throughout the whole work activity.

9.7 During plastering procedure, first the area shall be under safety work area for

the whole duration of the activity. All the precautionary measures shall be

taken considering the probability of emergency. In hospitalization cases,

ambulance will be provided.

9.8 Emergency exit point, assembly area, emergency evacuation plan and emergency

numbers shall be posted on the boards at site.

10 ATTACHMENTS

SITE EMERGENCY CONTACT NUMBERS

Attachment – 1 (Page 1 of 1)

CLIENT Name

NAME DESIGNATION PHONE NUMBER

KIL JIN KANG & PARTNER CONST. CONT. CO. LTD.

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 17

NAME DESIGNATION PHONE NUMBER

Site Manager

Safety Manager

QA/QC Manager

Construction Superintend

Male Nurse

Attachment – 2 (Page 1 of 1)

EMERGENCY EVACUATION PROCEDURE

When The Alarm

Sounds

All Personnel Area Wardens Area Safety Officers

Vacate Area by

nearest emergency

Check Area under your Control Assembly

exit and move 90⁰ to

responsibility Area

path of wind

direction

Ensure Personnel

Do not Re-Enter

Evacuated to Designated Connection with Area

Existing Area until

Assembly Point and Turn Wardens

Safe Signal

off all Equipment

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

(Client Name – Logo)

ISO Certificate Reg. No.: 44 100 100 281 valid until: 2013-05-22

As per KCC/Project

Doc. No.

naming Standards

Method Statement

Project/Owner Logo Rev. 0

for Plastering Work Date

Page 18

Report HSE Manager

Assemble at the

Report the Area Situation for Rescue if

Designated Assembly

to the Manager Needed / Contact

Point

Client HSE

Await Further At Assembly Point,

Roll calls pass to

Instructions from undertake a roll call and

Safety Manager

Controller do the head count

Do not allow any Person

to re-enter

Kil Jin Kang & Partner Const. Cont. Co. Ltd.

P. O. Box 850, Jubail 31951 Tel: +96633611950/2257/2431 Fax: +96633622162

E-mail: info@kccsa.com website: www.kccsa.com

You might also like

- Method Statement For Kerb Stone InstallationDocument16 pagesMethod Statement For Kerb Stone InstallationAnantha Padmanabhan100% (1)

- Method Statement For Kerb Stone InstallationDocument16 pagesMethod Statement For Kerb Stone InstallationAnantha Padmanabhan100% (1)

- WMS - ARCHI - 003 - WMS For Brickwork and PlasteringDocument5 pagesWMS - ARCHI - 003 - WMS For Brickwork and PlasteringEcho100% (1)

- Method Statement For Metal Roof and Wall Cladding WorkDocument14 pagesMethod Statement For Metal Roof and Wall Cladding WorkAnantha PadmanabhanNo ratings yet

- Method Statement For Metal Roof and Wall Cladding WorkDocument14 pagesMethod Statement For Metal Roof and Wall Cladding WorkAnantha PadmanabhanNo ratings yet

- Method Statement For Construction - Method Statement - Non Suspended SlabDocument3 pagesMethod Statement For Construction - Method Statement - Non Suspended SlabKellyNo ratings yet

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDDocument5 pagesMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy6290% (1)

- Method Statement For Concreting WorksDocument1 pageMethod Statement For Concreting WorksEncik BadrulNo ratings yet

- MS Sikalastic-110 Flat Roof - 100826dannyDocument2 pagesMS Sikalastic-110 Flat Roof - 100826dannyAuYongTheanSengNo ratings yet

- BLS PDFDocument6 pagesBLS PDFAyesha JadoonNo ratings yet

- Method Statement For Painting WorkDocument13 pagesMethod Statement For Painting WorkAnantha PadmanabhanNo ratings yet

- Painting Work Method StatementDocument5 pagesPainting Work Method StatementMusthafa ShaikNo ratings yet

- MOS - Concrete Works 07.18 R-0Document9 pagesMOS - Concrete Works 07.18 R-0RABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNo ratings yet

- Work Method Statement - BOND IT & Elite 90Document3 pagesWork Method Statement - BOND IT & Elite 90Sathish Gowda0% (1)

- Method Statement of Installing I-BeamDocument1 pageMethod Statement of Installing I-BeamfaizbukhariNo ratings yet

- MOS-002B Door Frame, Door Leaf & IronmongeriesDocument6 pagesMOS-002B Door Frame, Door Leaf & IronmongeriesChezy629No ratings yet

- Method of Statement For Backfilling WorksDocument4 pagesMethod of Statement For Backfilling Worksaboodeissa97No ratings yet

- MOS of Installation Rise FloorDocument13 pagesMOS of Installation Rise FloorHussam WaleedNo ratings yet

- Work Method Statement For Fire Rated and Non-Fire Rated WallDocument14 pagesWork Method Statement For Fire Rated and Non-Fire Rated WallMohd Hafizi Azlan100% (1)

- Method Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامDocument20 pagesMethod Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامM.ZEKEBA0% (1)

- Method of Statement PartDocument3 pagesMethod of Statement PartAl Manar PetroleumNo ratings yet

- Method Statement For Tiles InstallationDocument4 pagesMethod Statement For Tiles InstallationVeronica De JesusNo ratings yet

- MOS For Epoxy PaintingDocument3 pagesMOS For Epoxy PaintingHussam WaleedNo ratings yet

- 11 - MS For Painting WorkDocument9 pages11 - MS For Painting Workgulzaman100% (1)

- JMS 36 - Roofing WorkDocument9 pagesJMS 36 - Roofing WorkNaditek BinaNo ratings yet

- Construction Method Statement Replacement of GutterDocument3 pagesConstruction Method Statement Replacement of GutterJomar BienesNo ratings yet

- MS For Windows - Louvres InstallationDocument9 pagesMS For Windows - Louvres InstallationGary LoNo ratings yet

- Mos For Gypsum PartitionsDocument8 pagesMos For Gypsum PartitionsCamlockNo ratings yet

- Painting Work MOS FCHSDocument4 pagesPainting Work MOS FCHSCamlockNo ratings yet

- Casting of RC Slab MosDocument2 pagesCasting of RC Slab MosEngr Badz de DiosNo ratings yet

- MOS (Installation of Ceramic Tile) REV2Document3 pagesMOS (Installation of Ceramic Tile) REV2Don Roseller DumayaNo ratings yet

- Fire Stop Work Installation & Application Method Statement: ScopeDocument22 pagesFire Stop Work Installation & Application Method Statement: ScopeWahid HusainNo ratings yet

- Lysaght Klip-Lok OptimaDocument12 pagesLysaght Klip-Lok OptimaZaid AzmiNo ratings yet

- Work Method Statement - WATER PROOFINGDocument3 pagesWork Method Statement - WATER PROOFINGSathish GowdaNo ratings yet

- Method Statement For Concrete WorkDocument6 pagesMethod Statement For Concrete WorktotA ahmedNo ratings yet

- SECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralDocument4 pagesSECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralJojolasNo ratings yet

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNo ratings yet

- Method of Statement (Concrete Repair)Document3 pagesMethod of Statement (Concrete Repair)Sa3id HassanNo ratings yet

- Method of Statement - Drainage WorksDocument6 pagesMethod of Statement - Drainage Worksainamin77No ratings yet

- Method Statement "Quickplast 399" Skim CoatDocument3 pagesMethod Statement "Quickplast 399" Skim CoatAdam TangNo ratings yet

- Water RecDocument9 pagesWater RecToyEn MEgatNo ratings yet

- TEC-031100G-MET-DoR-001a (Method Statement For The Erection and Dismantling of GFT Formwork)Document7 pagesTEC-031100G-MET-DoR-001a (Method Statement For The Erection and Dismantling of GFT Formwork)scriptd_ozd3nNo ratings yet

- Mathod Stetement. SafetyDocument17 pagesMathod Stetement. Safetymangeshshinde124No ratings yet

- Method Statement 09062023Document13 pagesMethod Statement 09062023JAMES neelNo ratings yet

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- Method Statement ConbextraGPDocument7 pagesMethod Statement ConbextraGPsinambeladavidNo ratings yet

- Method Statement FOR Acoustic Ceiling TilesDocument12 pagesMethod Statement FOR Acoustic Ceiling Tilesraks07010% (1)

- Repairing ConcreteDocument10 pagesRepairing ConcreteWan HabibNo ratings yet

- Polyseal 1PU: One Part Polyurethane Joint SealantDocument2 pagesPolyseal 1PU: One Part Polyurethane Joint SealantVaittianathan MahavapillaiNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- METHOD OF STATEMENT - ALKHOMRA PROJECT - MarbleDocument9 pagesMETHOD OF STATEMENT - ALKHOMRA PROJECT - Marbleahmed samirNo ratings yet

- MS Concrete Works - Method StatementDocument6 pagesMS Concrete Works - Method StatementmemekenyaNo ratings yet

- MS - MasterTop 135PGDocument4 pagesMS - MasterTop 135PGAzhar Shaikh100% (1)

- QCS 2010 Section 26 Part 3 Primers, Paints and CoatingsDocument4 pagesQCS 2010 Section 26 Part 3 Primers, Paints and Coatingsbryanpastor106No ratings yet

- Method Statement For Installation of Pre-Finished Engineering Flooring and SkirtingDocument7 pagesMethod Statement For Installation of Pre-Finished Engineering Flooring and SkirtingGary LoNo ratings yet

- Method Statement of Tiling Works: ContentDocument4 pagesMethod Statement of Tiling Works: ContentChezy629No ratings yet

- RC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutDocument3 pagesRC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutAnonymous ze9ag1No ratings yet

- Work Methodology For Clearing and Grubbing of Trees and ShrubsDocument2 pagesWork Methodology For Clearing and Grubbing of Trees and ShrubsNasser Issa Abu HalimehNo ratings yet

- MS For Form - WorksDocument8 pagesMS For Form - WorksImho Tep100% (1)

- Method Statements 06 - Drywall Partition WorksDocument7 pagesMethod Statements 06 - Drywall Partition WorksMathewNo ratings yet

- Renovations Method StatementDocument8 pagesRenovations Method StatementOfentse LedwabaNo ratings yet

- Pile Head BreakingDocument4 pagesPile Head BreakingHakan Bnbsyz0% (1)

- Epoxy Painting MethodDocument3 pagesEpoxy Painting MethodKaram MoatasemNo ratings yet

- Method Statement For Installation and Relocation of Isolation FenceDocument13 pagesMethod Statement For Installation and Relocation of Isolation FenceAnantha PadmanabhanNo ratings yet

- Unipro CatalogueDocument334 pagesUnipro CatalogueAnantha PadmanabhanNo ratings yet

- Method Statement For Painting WorkDocument13 pagesMethod Statement For Painting WorkAnantha PadmanabhanNo ratings yet

- Method Statement For Installation and Relocation of Isolation FenceDocument13 pagesMethod Statement For Installation and Relocation of Isolation FenceAnantha PadmanabhanNo ratings yet

- 25.MOS Template - Installation of HDPE LiningDocument14 pages25.MOS Template - Installation of HDPE LiningAnantha PadmanabhanNo ratings yet

- Rowad - Installation Procedure For HDPEDocument19 pagesRowad - Installation Procedure For HDPEAnantha Padmanabhan100% (1)

- Industrial HygineDocument33 pagesIndustrial HygineNiraj RanjanNo ratings yet

- BUSINESS PROPOSALManluyang and GroupDocument9 pagesBUSINESS PROPOSALManluyang and GroupElla Mae ManluyangNo ratings yet

- Demonizing Drugmakers: The Political Assault On The Pharmaceutical Industry, Cato Policy Analysis No. 475Document56 pagesDemonizing Drugmakers: The Political Assault On The Pharmaceutical Industry, Cato Policy Analysis No. 475Cato InstituteNo ratings yet

- (II) Misadventure Is Mischance, Accident or Disaster. It Is of Three TypesDocument3 pages(II) Misadventure Is Mischance, Accident or Disaster. It Is of Three TypesSandeep BansalNo ratings yet

- CobasDocument145 pagesCobasAugia Nur IftihatunnisaNo ratings yet

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNo ratings yet

- MASS 2021 10-v2Document121 pagesMASS 2021 10-v2Fidel MangoldNo ratings yet

- Ichi The KillerDocument7 pagesIchi The KillerShaul RechterNo ratings yet

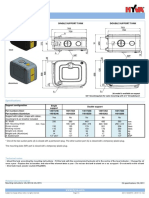

- Hyva Oil Tank: Single Support Tank Double Support TankDocument4 pagesHyva Oil Tank: Single Support Tank Double Support TankPutera Bumi NusantaraNo ratings yet

- 1.2 Safety & Rules in Biology LaboratoryDocument32 pages1.2 Safety & Rules in Biology LaboratoryasyuraNo ratings yet

- Industrial Combustion AnalyzerDocument2 pagesIndustrial Combustion AnalyzerjeffchengNo ratings yet

- Classified 2014 10 21 000000Document6 pagesClassified 2014 10 21 000000sasikalaNo ratings yet

- Reportable in The Supreme Court of India Criminal Appellate Jurisdiction Criminal Appeal NO. 615 of 2020 (Arising Out of SLP (CRL.) No.8260/2018)Document38 pagesReportable in The Supreme Court of India Criminal Appellate Jurisdiction Criminal Appeal NO. 615 of 2020 (Arising Out of SLP (CRL.) No.8260/2018)GunjeetNo ratings yet

- 7 - HandDocument30 pages7 - Handعاصم مروانNo ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- Historia Tartarorum EcclesiasticaDocument4 pagesHistoria Tartarorum EcclesiasticaVladimir SaricNo ratings yet

- Which of The Following Is NOT True About Dust?Document3 pagesWhich of The Following Is NOT True About Dust?lucel palaca100% (1)

- PCB Design Techniques To Reduce EMIDocument21 pagesPCB Design Techniques To Reduce EMIelfrichNo ratings yet

- Capgemini Excelity Payroll FAQDocument16 pagesCapgemini Excelity Payroll FAQAbhijitNo ratings yet

- Bar97specs Part2Document47 pagesBar97specs Part2N J Vargas SampayoNo ratings yet

- UKA Athletics Coach Induction Pack v2 Jan 2013Document36 pagesUKA Athletics Coach Induction Pack v2 Jan 2013gpitbullNo ratings yet

- UD150L-40E Ope M501-E053GDocument164 pagesUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- No Homework PolicyDocument2 pagesNo Homework PolicyKyla BetchaydaNo ratings yet

- AAADocument12 pagesAAAMisael CamposanoNo ratings yet

- Planned ParenthoodDocument2 pagesPlanned ParenthoodChylon BudagherNo ratings yet

- Solar Power For Beginners Basics Design and Installation of A Solar Panel System The Complete Guide For Your Off Grid HomeDocument96 pagesSolar Power For Beginners Basics Design and Installation of A Solar Panel System The Complete Guide For Your Off Grid HomeTek_nikkosNo ratings yet

- Enviline VLD ENDocument4 pagesEnviline VLD EN8b8m724mb9No ratings yet

- Offtake Oc035 Preparation Go No Go ChecklistDocument8 pagesOfftake Oc035 Preparation Go No Go ChecklistIhwan AsrulNo ratings yet

- Manual Usuario Smart LGDocument36 pagesManual Usuario Smart LGkarl CgcNo ratings yet