Professional Documents

Culture Documents

Tension - Test (ASTM A 615M) - Report

Tension - Test (ASTM A 615M) - Report

Uploaded by

Nadira Pervin0 ratings0% found this document useful (0 votes)

34 views3 pagesThe document summarizes the results of tension tests performed on mild steel bars according to ASTM A615M standards. Three steel bars with a nominal diameter of 20mm were tested in each of three separate tests conducted on different dates in 2017 and 2018. The tests measured properties including actual diameter, weight, yield load, yield strength, ultimate load, ultimate strength, elongation and reported values in comparison to the minimum ASTM requirements. In each test, the yield and ultimate strengths and elongations of the steel bars were found to meet or exceed the ASTM grade 60 specifications.

Original Description:

Original Title

Tension_Test[ASTM A 615M]_Report

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the results of tension tests performed on mild steel bars according to ASTM A615M standards. Three steel bars with a nominal diameter of 20mm were tested in each of three separate tests conducted on different dates in 2017 and 2018. The tests measured properties including actual diameter, weight, yield load, yield strength, ultimate load, ultimate strength, elongation and reported values in comparison to the minimum ASTM requirements. In each test, the yield and ultimate strengths and elongations of the steel bars were found to meet or exceed the ASTM grade 60 specifications.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

34 views3 pagesTension - Test (ASTM A 615M) - Report

Tension - Test (ASTM A 615M) - Report

Uploaded by

Nadira PervinThe document summarizes the results of tension tests performed on mild steel bars according to ASTM A615M standards. Three steel bars with a nominal diameter of 20mm were tested in each of three separate tests conducted on different dates in 2017 and 2018. The tests measured properties including actual diameter, weight, yield load, yield strength, ultimate load, ultimate strength, elongation and reported values in comparison to the minimum ASTM requirements. In each test, the yield and ultimate strengths and elongations of the steel bars were found to meet or exceed the ASTM grade 60 specifications.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 3

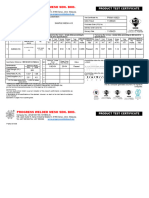

STRUCTURAL MECHANICS LABORATORY

TENSION TEST OF DEFORMED MILD STEEL BARS [ASTM A 615M]

NSU Ref No. : NSU/CEE/SM/2017/11001 Date Received : April 11, 2017

Sent By : Abul Kalam Azad, Project Manager Date Tested : April 12, 2017

Harbour Developments and Constructions Ltd.

House#08, Road#10, Sector#06, Uttara, Dhaka-1230.

Ref. Letter :

Project :

Sl. Frog Nominal Actual Actual Average Yield or Proof Yield or Average Ultimate Ultimate Average TS/YS Elongation Average

No. Mark Dia Dia Unit Actual Unit Load Proof Yield or Proof Load Strength Ultimate (%) Elongation

Weight Weight Strength Strength Strength (Gauge (%)

(YS) (TS) length= (G. length=

203.2 mm) 203.2 mm)

mm mm kg/m kg/m kN MPa MPa kN MPa MPa

1 None 20 17.94 1.98 134.0 530 540 181.5 720 720 6.33

2 None 20 17.89 1.97 1.975 135.3 540 (78,300 psi) 179.4 715 (104,400 psi) 1.33 6.53 6.43

3 - - - - - - - - -

Minimum Standard Requirements (ASTM A615/A 615M -96a)

ASTM A615 ASTM A 615M ASTM A615/A 615M

Yield Ultimate Yield Ultimate

Grade Grade Minimum Elongation in 8" (203.2mm) GL, (%)

Strength Strength Strength Strength

psi (kg/sq.cm ) psi (kg/sq.cm ) MPa (kg/sq.cm) MPa (kg/sq.cm) 10 mm 13,16,19mm 22, 25 mm 29,32,36mm

40 40000 (2810) 70000 (4910) 300 300 (3050) 500 (5090) 11 12 - -

60 60000 (4210) 90000 (6310) 420 420 (4275) 620 (6295) 9 9 8 7

75 75000 (5255) 100000 (7015) 520 520 (5275) 690 (7010) - 7* 7 6

*For 19 mm bar only.

Samples were received in unsealed condition

Test Performed by: Test Supervised by: Countersigned by:

Syed Abid Hassan, Md. Saidur Rahman Chowdhury, Dr. Mohammad Nazmul Islam,

Asst. Officer (Lab), Dept. of CEE. Lab Officer, Dept. of CEE. Professor, Dept. of CEE.

Important Notes:Samples are supplied to us have been tested in our laboratory.NSU does not have any responsibility as to the representative character of the samples required to be tested. It is

recommended that samples are sent in a secure and sealed cover/packet/container under signature of the competent authority. In order to avoid fraudulent fabrication of test results, it is recommended

that all test reports are collected by duly authorized person, and not by the contractor/supplier.

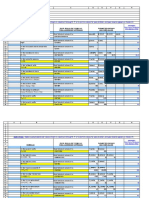

STRUCTURAL MECHANICS LABORATORY

TENSION TEST OF DEFORMED MILD STEEL BARS [ASTM A 615M]

NSU Ref No. : NSU/CEE/SM/2017/11002 Date Received : April 27, 2017

Sent By : Abul Kalam Azad, Project Manager Date Tested : April 27, 2017

Harbour Developments and Constructions Ltd.

House#08, Road#10, Sector#06, Uttara, Dhaka-1230.

Ref. Letter :

Project : Construction of 6 classroom-NAC/SAC

Sl. Frog Nominal Actual Actual Average Yield or Proof Yield or Average Ultimate Ultimate Average TS/YS Elongation Average

No. Mark Dia Dia Unit Actual Unit Load Proof Yield or Proof Load Strength Ultimate (%) Elongation

Weight Weight Strength Strength Strength (Gauge (%)

(YS) (TS) length= (G. length=

203.2 mm) 203.2 mm)

mm mm kg/m kg/m kN MPa MPa kN MPa MPa

1 None 20 17.70 1.93 156.3 635 176.6 715 3.58

2 None 20 17.84 1.96 1.951 128.2 515 167.4 670 - 2.00 2.99

3 None 20 17.82 1.96 129.0 515 178.5 715 3.39

Minimum Standard Requirements (ASTM A615/A 615M -96a)

ASTM A615 ASTM A 615M ASTM A615/A 615M

Yield Ultimate Yield Ultimate

Grade Grade Minimum Elongation in 8" (203.2mm) GL, (%)

Strength Strength Strength Strength

psi (kg/sq.cm ) psi (kg/sq.cm ) MPa (kg/sq.cm) MPa (kg/sq.cm) 10 mm 13,16,19mm 22, 25 mm 29,32,36mm

40 40000 (2810) 70000 (4910) 300 300 (3050) 500 (5090) 11 12 - -

60 60000 (4210) 90000 (6310) 420 420 (4275) 620 (6295) 9 9 8 7

75 75000 (5255) 100000 (7015) 520 520 (5275) 690 (7010) - 7* 7 6

*For 19 mm bar only.

Samples were received in unsealed condition

Test Performed by: Test Supervised by: Countersigned by:

Syed Abid Hassan, Md. Saidur Rahman Chowdhury, Dr. Mohammad Nazmul Islam,

Asst. Officer (Lab), Dept. of CEE. Lab Officer, Dept. of CEE. Professor, Dept. of CEE.

Important Notes:Samples are supplied to us have been tested in our laboratory.NSU does not have any responsibility as to the representative character of the samples required to be tested. It is

recommended that samples are sent in a secure and sealed cover/packet/container under signature of the competent authority. In order to avoid fraudulent fabrication of test results, it is recommended

that all test reports are collected by duly authorized person, and not by the contractor/supplier.

STRUCTURAL ENGINEERING LABORATORY

TENSION TEST OF DEFORMED MILD STEEL BARS [ASTM A 615M]

NSU Ref No. : NSU/CEE/SM/2018/11003 Date Received : June 11, 2018

Sent By : Mahbubur Rahman Date Tested : June 11, 2018

Asst. Civil Engineer

North South University

Ref. Letter :

Project : NSU rooftop extension NAC/SAC

Sl. Frog Nominal Actual Actual Average Yield or Proof Yield or Average Ultimate Ultimate Average TS/YS Elongation Average

No. Mark Dia Dia Unit Actual Unit Load Proof Yield or Proof Load Strength Ultimate (%) Elongation

Weight Weight Strength Strength Strength (Gauge (%)

(YS) (TS) length= (G. length=

203.2 mm) 203.2 mm)

mm mm kg/m kg/m kN MPa MPa kN MPa MPa

1 None - 22.57 3.14 35.1 90 267 665 0.98

2 None - 22.86 3.22 3.22 135.3 330 - 212.8 520 - - 4.17 -

3 None - 23.14 3.30 167.6 400 247.6 590 1.95

Minimum Standard Requirements (ASTM A615/A 615M -96a)

ASTM A615 ASTM A 615M ASTM A615/A 615M

Yield Ultimate Yield Ultimate

Grade Grade Minimum Elongation in 8" (203.2mm) GL, (%)

Strength Strength Strength Strength

psi (kg/sq.cm ) psi (kg/sq.cm ) MPa (kg/sq.cm) MPa (kg/sq.cm) 10 mm 13,16,19mm 22, 25 mm 29,32,36mm

40 40000 (2810) 70000 (4910) 300 300 (3050) 500 (5090) 11 12 - -

60 60000 (4210) 90000 (6310) 420 420 (4275) 620 (6295) 9 9 8 7

75 75000 (5255) 100000 (7015) 520 520 (5275) 690 (7010) - 7* 7 6

*For 19 mm bar only.

Samples were received in unsealed condition

Test Performed by: Test Supervised by: Countersigned by:

Syed Abid Hassan, Md. Saidur Rahman Chowdhury, Dr. Mohammad Nazmul Islam,

Asst. Officer (Lab), Dept. of CEE. Lab Officer, Dept. of CEE. Professor, Dept. of CEE.

Important Notes:Samples are supplied to us have been tested in our laboratory.NSU does not have any responsibility as to the representative character of the samples required to be tested. It is

recommended that samples are sent in a secure and sealed cover/packet/container under signature of the competent authority. In order to avoid fraudulent fabrication of test results, it is recommended

that all test reports are collected by duly authorized person, and not by the contractor/supplier.

You might also like

- Technical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaDocument2 pagesTechnical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaG Nurhidayat ANo ratings yet

- CA Foundation Account Scanner by Nahta CoachingDocument521 pagesCA Foundation Account Scanner by Nahta CoachingSuneeta Srivastava50% (8)

- VSL Tech Data PDFDocument29 pagesVSL Tech Data PDFhythamNo ratings yet

- Case Digests For FinalsDocument40 pagesCase Digests For FinalsJayson YuzonNo ratings yet

- ASTM D 1075 Effect of Water On Strength of Compacted BitumenDocument2 pagesASTM D 1075 Effect of Water On Strength of Compacted BitumenRajesh Kumar100% (3)

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNo ratings yet

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- GFRP RebarsDocument16 pagesGFRP Rebarsrajbir1001No ratings yet

- Josh Munsayac - 10 TestingRebar - 1 29 24Document8 pagesJosh Munsayac - 10 TestingRebar - 1 29 24Adam MirandaNo ratings yet

- Mechanical Properties:: Properties of Acrylic SheetDocument2 pagesMechanical Properties:: Properties of Acrylic SheetIrshim GNNo ratings yet

- CompressiveStrength (ASTM-C39) Test ReportDocument21 pagesCompressiveStrength (ASTM-C39) Test ReportNadira PervinNo ratings yet

- Engineering Materials: Important NotesDocument1 pageEngineering Materials: Important NotesMiftahul IslamNo ratings yet

- Con Rep 3Document8 pagesCon Rep 3Marcus SanNo ratings yet

- 14mm Gr60Document1 page14mm Gr60alshaya steelNo ratings yet

- Trailing Chasis Axle R1Document62 pagesTrailing Chasis Axle R1Waris La Joi WakatobiNo ratings yet

- 330HWSADocument1 page330HWSAAhmed MorsyNo ratings yet

- Ce 14444 Lab7Document5 pagesCe 14444 Lab7Owen Francis Arles MaongatNo ratings yet

- Group 2 DataDocument4 pagesGroup 2 DataHind AwadNo ratings yet

- Reinforcing SteelDocument39 pagesReinforcing SteelGage Floyd Bitayo100% (1)

- For Solid Concrete Interlocking Paving UnitsDocument7 pagesFor Solid Concrete Interlocking Paving UnitsomerNo ratings yet

- Fiberglass Rods PropertiesDocument5 pagesFiberglass Rods PropertiesJohn WycliffeNo ratings yet

- Technical Data Sheet: 1. Table of Belt SizeDocument1 pageTechnical Data Sheet: 1. Table of Belt SizeVicky ImmanuelNo ratings yet

- Department of Structural Engineering: M B M Engineering CollegeDocument4 pagesDepartment of Structural Engineering: M B M Engineering CollegeAjayvidyanand SharmaNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- Strands Area and Their Specifications PDFDocument2 pagesStrands Area and Their Specifications PDFLamin AungNo ratings yet

- TDS 140N - TipicosDocument2 pagesTDS 140N - TipicosCris AranzNo ratings yet

- Cross-Section and Material Optimization of An Automotive Chassis Using FEADocument13 pagesCross-Section and Material Optimization of An Automotive Chassis Using FEABhimsen ShresthaNo ratings yet

- Flakiness Index TestDocument20 pagesFlakiness Index TestanasameranaNo ratings yet

- ASTM A333 GR.6 Seamless Low Temperature Pipes PDFDocument7 pagesASTM A333 GR.6 Seamless Low Temperature Pipes PDFraditya putraNo ratings yet

- Mirafi-500X PDSDocument1 pageMirafi-500X PDSLarry Wayne Sumpter, JrNo ratings yet

- Mirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueDocument2 pagesMirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueLuis Angel Criollo DivertidoNo ratings yet

- 10mm Gr60Document1 page10mm Gr60alshaya steelNo ratings yet

- 20210607钢筋(Janjira)Document9 pages20210607钢筋(Janjira)bojun liNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- Physical PropertiesDocument16 pagesPhysical PropertiesRahul GoyalNo ratings yet

- Appendix Field Manual For Concrete AnchoringDocument3 pagesAppendix Field Manual For Concrete AnchoringZed BaladrafNo ratings yet

- A10 TestDocument2 pagesA10 TestmohdaminhussainiNo ratings yet

- MTC الاتفاق 25ملىDocument1 pageMTC الاتفاق 25ملىbwd51523No ratings yet

- Basil Chandrakanta 741 - 28 DaysDocument1 pageBasil Chandrakanta 741 - 28 Days2cmtrcNo ratings yet

- Material Testing Laboratory: Military Engineer Services (Mes)Document1 pageMaterial Testing Laboratory: Military Engineer Services (Mes)Abdus SalamNo ratings yet

- Group 3 - Tensile TestDocument25 pagesGroup 3 - Tensile TestKimi AzmanNo ratings yet

- Aa - U ChannelsDocument3 pagesAa - U ChannelsFiorella Margarita Mechato LaraNo ratings yet

- MBM Lab ReportDocument11 pagesMBM Lab ReportPavan Kalyan PNo ratings yet

- Annexure-10 Dropper SpecificationDocument1 pageAnnexure-10 Dropper SpecificationAnkit AgarwalNo ratings yet

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- Certif Calidad GeomallaDocument1 pageCertif Calidad GeomallaDanni HerediaNo ratings yet

- Basil Chandrakanta 742 - 28 DaysDocument1 pageBasil Chandrakanta 742 - 28 Days2cmtrcNo ratings yet

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Structural Engineering Division: SubjectDocument18 pagesStructural Engineering Division: Subjecthaidarullah0060116No ratings yet

- Gradation Work Sheet Form - 9.5mmDocument4 pagesGradation Work Sheet Form - 9.5mmlab copriNo ratings yet

- Design Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthDocument9 pagesDesign Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthMarc Joshua MACATANGAYNo ratings yet

- Compressive Strength Test of Concrete Cylinders Specimen: CP06/RIW/190828/CVL/SWY/02630Document1 pageCompressive Strength Test of Concrete Cylinders Specimen: CP06/RIW/190828/CVL/SWY/02630Shoyeeb AhmedNo ratings yet

- CMT QuizDocument3 pagesCMT QuizCHARLES LEJANONo ratings yet

- Ningbo Brightfast Co.,Ltd: Certificate of Quality En10204 3.1Document1 pageNingbo Brightfast Co.,Ltd: Certificate of Quality En10204 3.1amicikicikNo ratings yet

- Abrasion Test (LA)Document2 pagesAbrasion Test (LA)ratoooooja24No ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- Ball Cover TensileDocument1 pageBall Cover Tensileshalinda Anup RitigahapolaNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Strength of Materials-Ii Experiment 3 "To Perform Tension Test On Mild Steel Bars and Determine Principal Stresses Using Analytical Method"Document13 pagesStrength of Materials-Ii Experiment 3 "To Perform Tension Test On Mild Steel Bars and Determine Principal Stresses Using Analytical Method"Fahim AnwerNo ratings yet

- Water Tank Size and Capacity Calculator.Document3 pagesWater Tank Size and Capacity Calculator.Nadira Pervin100% (1)

- Crack Width Calculation For ColumnDocument3 pagesCrack Width Calculation For ColumnNadira PervinNo ratings yet

- CompressiveStrength (ASTM-C39) Test ReportDocument21 pagesCompressiveStrength (ASTM-C39) Test ReportNadira PervinNo ratings yet

- Oncrete Aboratory: Test Results of Blended Hydraulic (Portland Composite) CementDocument2 pagesOncrete Aboratory: Test Results of Blended Hydraulic (Portland Composite) CementNadira PervinNo ratings yet

- 2 Trial Mix Measuring RecordDocument4 pages2 Trial Mix Measuring RecordNadira PervinNo ratings yet

- Summary of CAMCE Trial MixDocument1 pageSummary of CAMCE Trial MixNadira PervinNo ratings yet

- 3 Days Cylinder Test (1!10!2019)Document1 page3 Days Cylinder Test (1!10!2019)Nadira PervinNo ratings yet

- Steel Building Manufacturers Association of BangladeshDocument1 pageSteel Building Manufacturers Association of BangladeshNadira PervinNo ratings yet

- Excel Automated FormulasDocument37 pagesExcel Automated FormulasNadira PervinNo ratings yet

- GF - rt23m Tower Boq. (G.F)Document42 pagesGF - rt23m Tower Boq. (G.F)Nadira PervinNo ratings yet

- Site ID: KHU - X0990 BOQ Summry For Consultant CheckDocument3 pagesSite ID: KHU - X0990 BOQ Summry For Consultant CheckNadira PervinNo ratings yet

- Formet GF - RT 27 M Tower Boq. (G.F)Document36 pagesFormet GF - RT 27 M Tower Boq. (G.F)Nadira PervinNo ratings yet

- Mix Design and Pie Chart RepresentationDocument27 pagesMix Design and Pie Chart RepresentationNadira PervinNo ratings yet

- BOQ - EGB BoilerDocument4 pagesBOQ - EGB BoilerNadira PervinNo ratings yet

- Sloped Footing With PedestalDocument11 pagesSloped Footing With PedestalNadira PervinNo ratings yet

- NAZRUL - CV ChuadangaDocument2 pagesNAZRUL - CV ChuadangaNadira PervinNo ratings yet

- Read Me (How To Install)Document1 pageRead Me (How To Install)Nadira PervinNo ratings yet

- Continuous North Edge Continuous East Edge Continuous South Edge Continuous West EdgeDocument1 pageContinuous North Edge Continuous East Edge Continuous South Edge Continuous West EdgeNadira PervinNo ratings yet

- Plastering Work ChecklistDocument1 pagePlastering Work ChecklistNadira PervinNo ratings yet

- Beam CalculatorDocument12 pagesBeam CalculatorNadira PervinNo ratings yet

- IBM Public Cloud Platform - Amigo2021Document24 pagesIBM Public Cloud Platform - Amigo2021Thai PhamNo ratings yet

- Interpol Global ComplexDocument174 pagesInterpol Global ComplexJayce Teo Wei WenNo ratings yet

- What You See Is Not What You Get: A Man-in-the-Middle Attack Applied To Video ChannelsDocument20 pagesWhat You See Is Not What You Get: A Man-in-the-Middle Attack Applied To Video ChannelsAlessandro VisintinNo ratings yet

- Royalton Hotel Dubai Hotel VoucherDocument1 pageRoyalton Hotel Dubai Hotel VoucherGabriel OmoluruNo ratings yet

- AA Soal Bedah SKL 2019 Ke 2Document4 pagesAA Soal Bedah SKL 2019 Ke 2fitrihidayatiNo ratings yet

- Narrative 1Document6 pagesNarrative 1Babiejoy Beltran AceloNo ratings yet

- Amit Varma NoticeDocument3 pagesAmit Varma NoticeparbatarvindNo ratings yet

- Sefer YetzirahDocument12 pagesSefer YetzirahChild of EnochNo ratings yet

- Voucher Tur DubaiDocument2 pagesVoucher Tur Dubaimaria caragopNo ratings yet

- Link Reit Part 2 PDFDocument97 pagesLink Reit Part 2 PDFDnukumNo ratings yet

- Sintesis de Las Tres Montanas - Es.enDocument12 pagesSintesis de Las Tres Montanas - Es.enMungai123No ratings yet

- 34 Chap - Module 5 - Direct MarketingDocument7 pages34 Chap - Module 5 - Direct MarketingraisehellNo ratings yet

- Thomas Hobbes: Alarcon, Maria Teresa LDocument3 pagesThomas Hobbes: Alarcon, Maria Teresa LNievesAlarcon100% (1)

- Tese - Cristiana AlmeidaDocument257 pagesTese - Cristiana AlmeidaDeia AlmeidaNo ratings yet

- Renewable Energy Mir 20200330 Web PDFDocument31 pagesRenewable Energy Mir 20200330 Web PDFJuan Carlos CastroNo ratings yet

- Mahatma Gandhi BiographyDocument5 pagesMahatma Gandhi BiographyGian LuceroNo ratings yet

- Endocrine of The Pancreas: Eman Alyaseen 20181081Document8 pagesEndocrine of The Pancreas: Eman Alyaseen 20181081ÂmoOł ÀhmdNo ratings yet

- 2 - Dividing Income Among Partners - ExamplesDocument4 pages2 - Dividing Income Among Partners - ExamplesJohnNo ratings yet

- Flight TicketDocument3 pagesFlight TicketAkshay KanyanNo ratings yet

- Arihant Adita Srs Faridabad Nandanvan Greens: Submitted by Eshna Singh Ishika Agarwal Leena Soni Nidhi Jain Rishi VijayDocument108 pagesArihant Adita Srs Faridabad Nandanvan Greens: Submitted by Eshna Singh Ishika Agarwal Leena Soni Nidhi Jain Rishi VijayLeenaNo ratings yet

- Essays On Contemporary Issues in AfricanDocument19 pagesEssays On Contemporary Issues in AfricanDickson Omukuba JuniorNo ratings yet

- Arens14e ch20 PPTDocument30 pagesArens14e ch20 PPTkabirakhan2007No ratings yet

- The Global Impact of COVIDDocument4 pagesThe Global Impact of COVIDmuddasirNo ratings yet

- Concrete Quality Control PlanDocument5 pagesConcrete Quality Control PlanKripasindhu SamantaNo ratings yet

- Magic Quadrant For 5G Network Infrastructure For Communications Service ProvidersDocument19 pagesMagic Quadrant For 5G Network Infrastructure For Communications Service ProvidersRazman Rashid100% (1)

- Trust Deed FormatDocument17 pagesTrust Deed Formatcpjamalu0% (1)

- 2023 Aerial Incursions: UAP Recovery Operation Caught On CameraDocument6 pages2023 Aerial Incursions: UAP Recovery Operation Caught On CameraMemoryHoldNo ratings yet