Professional Documents

Culture Documents

Central Sterile Supply Department - Need of The Hour.: Review Article

Central Sterile Supply Department - Need of The Hour.: Review Article

Uploaded by

Hemant VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Central Sterile Supply Department - Need of The Hour.: Review Article

Central Sterile Supply Department - Need of The Hour.: Review Article

Uploaded by

Hemant VermaCopyright:

Available Formats

REVIEW ARTICLE J Pub Health Med Res 2013;1(2):58-62

Central Sterile Supply Department –

Need Of The Hour.

1 2

Asima Banu , Subhas G.T. ,

1

Associate professor, Dept. of Microbiology, Bowring and Lady Curzon Hospitals, Bangalore Medical College and Research Institute

2

Professor, Department of Neurology, Bangalore Medical College and Research Institute, Bangalore

Abstract: Central Sterile Supply Department(CSSD) is a service unit in a hospital that processes, issues, and

controls the sterile stores supply to all departments of the hospital. The essentials of this department are correct

design, appropriate equipments, skillful operators and a unidirectional work flow. The CSSD should have four

zones – 1) The unclean and washing area, 2) The assembly and packing area, 3) The sterilization area and 4) The

sterile area. Each of these has equipments in place in order to perform specific functions towards sterilization of

articles for immediate use in patient care. All The hospitals should establish an adequate CSSD set-up and adopt

strict quality control processes with the latest technology to mitigate hospital acquired infections.

Key words: Central Sterile Supply Department, Hospital Acquired Infections, Sterilization.

Introduction : their knowledge and experience. The committee is

Central sterile supply department( CSSD) is a service unit required to meet monthly even during the running of a

fully functional CSSD in order to discuss new procedures

in a hospital that processes, issues, and controls the sterile

stores supply to all departments of the hospital. It can be or alternations to existing procedures in the light of new

defined as that service, with in the hospital, catering for knowledge and breakthroughs.

the sterile supplies to all departments , both to specialized

The objectives of the department are:

units as well as general wards and OPDs(Bhattacharjee l To provide sterilized material from a central

definition). The last few years have witnessed an department where sterilizing practice is conducted

increasing interest in organizing sterilization1. The under conditions, which are controlled, thereby

purpose of such a CSSD is to provide all the departments contributing to a reduction in the incidence of

of a hospital with guaranteed sterile equipment ready and hospital infection.

available for immediate use in patient care – a step l To take some of the work of the Nursing staff so that

towards the prevention of hospital acquired they can devote more time to their patients.

infections(HAI)2. l To avoid duplication of costly equipment's, which

Ideally, CSSD is an independent department with may be infrequently used.

facilities to receive, clean, pack, disinfect, sterilizes, store

l To maintain record of effectiveness of cleaning,

and distribute instruments as per well-delineated disinfection and sterilization process.

protocols. The essentials of this department are correct l To monitor and enforce controls necessary to

design, appropriate equipments, skilful operators and prevent cross infection according to infection

2

proper work flow The history of CSSD starts in 1928 control policy.

when American College Of Surgeons introduced the l To maintain an inventory of supplies and equipment.

word CSSD.In1955 the Cambridge Military Hospital l To stay updated regarding developments in the field

established Regular CSSD in United Kingdom. In India, in the interest of efficiency, economy, accuracy and

Safdarjang Hospital New Delhi, established the first provision of better patient care.

CSSD in 1965.

l To provide a safe environment for the patients and

The planning of a CSSD has to be steered by committee staff.

including representatives of departments of

Designing of a CSSD:

administration, infection control, anaesthesia,

microbiology, nursing and housekeeping drawing upon The workload in a CSSD varies from hospital to hospital.

The size and location usually depends on the number of

Address Correspondence to : the hospitals the CSSD will serve as well as the number of

Dr. Asima Banu beds and the future expansion of the hospital. However 6

Associate professor, Dept. of Microbiology, to 10 square feet per bed is recommended as an area of

Bowring and Lady Curzon Hospitals,

Bangalore Medical College and Research Institute, Bangalore requirement for the CSSD. It should be located as close as

E-mail : asima.banu@gmail.com

58

Asima Banu, et al, Central Sterile supply Department – Need of the hour.

possible to the major user areas such as Operation Sterilisation: It renders materials sterile for quality

theatres, Accidents and Emergency department and patient care. It is achieved by steam sterilizers working at

wards. specified cycles of temperature and duration to attain

The CSSD layout should be designed for a unidirectional adequate sterility assurance level (SAL). Advantage of

flow. The CSSD should have four zones for a smooth steam sterilizers are rapid heating & penetration of

work flow. loads,destruction of all forms of microbial life and no

residual toxicity.Different types of Autolaving machines

1. The unclean and washing area

that can be used are

2. The assembly and packing area

1. Downward Displacement

3. The sterilization area

2. Vacuum Assisted.

4. The sterile area

3. Pulsed Steam Dilution .

The Layout The capacity of the sterilizer is based on the load and the

1. Entrance lobby number of cycles per day. The load is calculated by

2. Reception and Cleaning room estimating litres to each procedure and converting it into a

3. Glove room standard unit i.e st.u(1 st.u = 54L). This value is then

divided by the number of cycles that will be run per day to

4. Work room (Preparation and assembling of packs)

obtain a value of st.u/cycle. The capacity of the sterilizer

5. Sterilisation room is then selected based on the value obtained. It is better to

6. Sterile store room have 2 sterilizers in case of breakdowns.(Fig-4)

7. Nurses/Managers room Additionally an ethylene oxide sterilizer can be included

8. Staff changing room in a separate compartment of this area in order to sterilize

heat sensitive instruments.(Fig-5)

Workflow in the CSSD

Storage: The function includes storage of sterilized

Receipt: The material that is to be sterilized coming from

materials where space is also provided for storing

various departments arrives in the reception area using

distribution trolleys. Sterile store maintains inventory of

stainless steel trolleys via a dedicated elevator.

all types of sterile packs. At the end of the path of the

Cleaning: This function means cleaning of the used treated material a computer terminal should be provided

equipments/materials, rubber and plastic goods either in order to manage delivery of materials and transport

manually or by machines eg., washer-disinfector, documentation.(Fig-6)

ultrasonic cleaner, jet glove washing machines and

Issue and Distribution: The function entails issue of the

dryers.(Fig-1) This function may also include cleaning of

sterilized packages, dressings, linen, instruments and

the delivery trolleys..The common items handled by the 3,4

disposables to various departments of the hospitals .

CSSD stores are syringes and needles, Procedure sets

which includes Lumbar puncture, Sternal puncture, Process of sterilization:

venesection, paracentesis. aspiration, catheterization, The items to be sterilized at the Central Sterile Supply

tracheotomy, suturing, dressing, biopsy, incision & Department are washed (with detergent or chemical as

drainage, aortography cardiac resuscitation, gloves, I.V. applicable), sorted in the washing area. linen from wards

Fluids, treatment Trays, O.T Instruments, O.T. Linen, and OT are to be sent directly to the laundry for cleaning.

infusion Fluids for Renal Dialysis and at times linen from The laundry washed linen are to be received , packed and

wards etc. forwarded to the CSSD for sterilization.

Assembly and Packing: It includes checking of glass The CSSD technicians or trained nurses shall receive the

items for breakages, needles and instruments for unsterile packs, inspect them to check the status of the

sharpness and breakages, assembling of the equipment item (torn, punctured, cracked etc) and place them at the

after washing and drying, making appropriate sets for use unsterile packs storing platform. Entry must be made in

by various departments and packaging along with sealing CSSD receipts register including date, time, type of

either manually or using a machine before sterilization. instruments in the pack, ward, its source, procedure used

Adequate documentation and labeling of each pack for, and case infected or not, name and signature of person

should be done and records should be maintained.(Fig 2 handing over, and name and signature of person receiving

& 3) it.

J Pub Health Med Res 2013;1(2):58-62 59

Asima Banu, et al, Central Sterile supply Department – Need of the hour.

FLOW PROCESS IN CSSD

WARDS/DEPTS BULK STORES

DIRTY RECEIPT CLEAN RECEIPT COTTON & GAUZE

DISASSEMBLY

INSTRUMENT GLOVES RUBBERWARE

WASHING AREAS

ASSEMBLY

INSPECTION

PRE - STERILE STORAGE

STERILISATION STERILE STORAGE

DISTRIBUTION

The autoclave indicator is pasted in the packs by the vendor of the respective CSSD equipments. All details in

CSSD technician and the packs are taken to the main these regard are maintained by the Maintenance

sterilizing area where the sterilizing units are placed .The Department of the hospital.

CSSD technician places the unsterile packs under All equipments used in the department are to be

appropriate temperature and pressure specifications in appropriately calibrated at periodic intervals to ascertain

the sterilizing units. The temperature, pressure whether they are performing at the expected level and a

specifications and accordingly the temperature period are record of the same is documented in the department as

0

for Normal Sterilization, temperature of 121 C at 15 lb well as with the concerned case workers working in the

0

for 20 minutes, and for Rapid Sterilization , 140 C at 20 administration.

lb for 15 minutes. At the end of the sterilization the packs Indent for setting up an ideal CSSD:

are removed from the sterilizing units, the autoclave 1. Washer disinfector with accessories - The washer

indicators are checked to confirm adequate sterilization should perform pre-rinsing, cleaning, post-rinsing,

of the packs, and incase the sterilization is not adequate thermal disinfection, final rinsing and drying phases.

the process is to be repeated. A material is pronounced Validated programs are secured by access code.

sterile if it achieves 99.99% kill of bacterial spores. Packs Detergents and rinse agents should be automatically

which are adequately sterilized are stored in the sterile dispensed during the cycle.

storage area. If the sterile packs are torn, if it has been

2. Steam Sterilizers - The sterilizer should meet the

opened, they are wet, etc, and then the whole process is to

relevant standards. The chamber and doors should be

be repeated again.

made of solid, high quality 316L Stainless steel. The

In case the packs which are sterilized in the CSSD and chamber should be jacketed to ensure the temperature

issued to the departments remains un utilized in the uniformity in chamber. The chamber floor is slightly

respective user departments for a period of 72 hours , the sloped towards an internal drain to facilitate drainage. A

same are returned to the CSSD department for re- stainless steel mesh strainer should be provided to protect

sterilization. Registers to be maintained in the CSSD are the drain port from blockage by debris. The chamber is

CSSD receipt register, CSSD issue Register, Equipment mounted on a stainless steel framework with height

Maintenance Record register and Equipment Calibration adjustable feet.

Register.

The internal surface should be electro-chemically treated

Maintenance of the equipments are to be done as per the for high quality smooth finish to facilitate cleaning. The

annual maintenance contract (AMC) entered into with the

J Pub Health Med Res 2013;1(2):58-62 60

Asima Banu, et al, Central Sterile supply Department – Need of the hour.

resultant surface should be polished to less than 0.8 μm documentation system. The ergonomically design

fineness to protect against corrosion. The internal corners should be tilted forward for increased user convenience

should be rounded off to facilitate efficient cleaning. and space saving installation.

The sterilizer jacket and door should be completely 5. Inspection tables, lamps, cleaning equipment, interior

insulated with mineral rock wool to keep the autoclave water treatment facilities

cool on the outside. The insulation should be completely 6. Table top sterilizer with accessories - Table Top

encased in a rigid removable sheet housing. The jacket Sterilizers should be equipped with B-process as per

should be made of 316L quality stainless steel. The latest international standards

chamber should have a warranty for 10 years. The

7. Ethylene Oxide Sterilizer (optional)- Ethylene oxide

sterilizer should have inbuilt steam generator of adequate

sterilizer is defined as equipment which uses ethylene

capacity. It should be mounted under the sterilizer

oxide as a biocide to destroy bacteria, viruses, fungi and

chamber & should be made of 316 quality stainless steel.

other unwanted organisms. Ethylene oxide is used in

The steam generator should have insulation of thick

sterilization of items that are heat and moisture sensitive.

chloride free mineral rock wool with rigid aluminum

The ETO gas sterilizer should be fully automatic type for

sheet housing. It should have a built in thermostat,

sterilization of heat sensitive goods such as anesthetic

pressure safety valve & water level glass gauge

tubing and endoscopes.

inspection device visible from service area. The heating

element, not less than 36KW should also be made of 8. Documentation labeller

stainless steel. It should also have the automatic blow 9. Process challenge devices

down valve & degassing system for feed water to steam 10. Water treatment plant

generator. To make the sterilization process faster the

capacity of the heating element should not be less than 36 11. All necessary furniture required for the facility

KW. An alarming rate of hospital acquired infections (HAI) in

3. Ultrasonic cleaner (optional) - The units should be a Indian hospitals has highlighted the importance of CSSD.

compact free-standing bench model, with a built-in tank Despite all measures and advancements in technology,

manufactured from high-quality (316) stainless steel and hospital acquired infections remain a challenge in

a solid-state generator that sends ultrasonic (approx healthcare scenario today. The hospitals are required to

42,000 cycles per second) impulses through wash water establish an adequate CSSD set-up and adopt strict

containing detergent and electrical heating; quality control processes with the latest technology to

microprocessor controlled display with memory time and mitigate hospital acquired infections. Hence the concept

temperature functions. The electrical energy should be of infection control by FLORENCE NIGHTINGALE

transformed into sound waves by transducers, fixed to the who said"No Stronger Condemnation of any hospital or

bottom of the tank. The tank should be made of solid ward could be pronounced than the simple fact that

stainless steel (316). zymotic disease has originated in it or that such disease

attack other patients than those brought-in with ''. stands

The ultrasonic cleaner should have a display and control

true for generations of healthcare to come.

which could be easily seen and placed above any liquid

for safety and reliability. It should have digital read out Acknowledgement :

timer and temperature setting (up to +69° C (temperature We are thankful to Medovation Products, Bangalore for

adjustable from 20 to 69 °C) monitoring.- their valuable technical inputs.

4. Heat Sealing Machine - Rotary heat sealers should References :

provide validated sealing of sterilization bags and clear- 1. Welch JD. The Organization of Central Supply Departments. J Clin Path.

1961; 14: 69-75

view pouches (paper/plastic laminate). These through

2. Allison VD. Hospital Central Sterile Supply Depts.. BMJ. 1960: 772-778

feed-type sealers should be microprocessor-controlled 3. Gardner JF and Peel MM. Introduction to Sterilization, Disinfection and

for highest capacity and ease of operation. The rotary heat Infection control, Second Edition. Melbourne, Churchill Livingstone.

sealer should give documentation of process parameters 1991

via an integrated printer and could be integrated with 4. Ayeliffe GAJ et al Control of Hospital Infection: A Practical Handbook.

Third Edition. London, Chapman Hall. 1992.

J Pub Health Med Res 2013;1(2):58-62 61

Asima Banu, et al, Central Sterile supply Department – Need of the hour.

Fig 1- The washing and disinfection area with fully automatic Fig 3-Linen inspection and storage room.

washer disinfector.

Fig 2-Packing and assembly area- Clean Area Fig 4- Steriisation Area having two fully automatic steam sterilisers

Fig 5- ETO Steriliser and Flash sterilisers. Fig 6- Sterile area with storage racks.

How to Cite this article :

Banu A, Subhas GT. Central Sterile supply Department – Need of the hour. J Pub Health Med Res, 2013;1(2):58-62

Funding: Declared none

Conflict of interest: Declared none

J Pub Health Med Res 2013;1(2):58-62 62

You might also like

- 1000 Prometric MCQ Solved 2Document351 pages1000 Prometric MCQ Solved 2chronos653490% (108)

- Natural Vitiligo Treatment System PDF - Ebook Free Download Michael DawsonDocument11 pagesNatural Vitiligo Treatment System PDF - Ebook Free Download Michael Dawsonkopi kaneNo ratings yet

- Central Sterile Supply DepartmentDocument23 pagesCentral Sterile Supply DepartmentXee Jay86% (7)

- 93 - Operating Room ProtocolDocument25 pages93 - Operating Room ProtocolFelix Kwenandar100% (1)

- Principles of DrapingDocument2 pagesPrinciples of DrapingSanny RamosNo ratings yet

- CSSD Policy1Document58 pagesCSSD Policy1Namdev Suryawanshi100% (1)

- An Ambiguous Journey To The City The Village and Other Odd Ruins of The Self in The Indian Imagination PDFDocument82 pagesAn Ambiguous Journey To The City The Village and Other Odd Ruins of The Self in The Indian Imagination PDFakshidraj100% (1)

- Clinical Practice Guidelines Burns Physiotherapy and Occupational TherapyDocument34 pagesClinical Practice Guidelines Burns Physiotherapy and Occupational Therapyfauziafahmi95100% (2)

- CSSD PPT FinalDocument16 pagesCSSD PPT FinalnikhilNo ratings yet

- Dr. Kasim Khot Mrs. Preeti JadhavDocument13 pagesDr. Kasim Khot Mrs. Preeti JadhavAbhi JeetNo ratings yet

- Central Sterile Supply DepartmentDocument24 pagesCentral Sterile Supply DepartmentVikas DhyaniNo ratings yet

- CSSD PresentationDocument23 pagesCSSD PresentationNirali Sheth91% (22)

- OrganisationDocument46 pagesOrganisationShreyas Walvekar100% (1)

- Handbook for Cssd Technicians: Understanding the Basics - Second EditionFrom EverandHandbook for Cssd Technicians: Understanding the Basics - Second EditionNo ratings yet

- CSSDDocument25 pagesCSSDbalachanderNo ratings yet

- Infection Control in CSSDDocument44 pagesInfection Control in CSSDAzira Afzan100% (1)

- CSSDDocument90 pagesCSSDNikhil MohananNo ratings yet

- Autoclave GuideDocument48 pagesAutoclave GuideIman 111No ratings yet

- CSSD - Sep 1st 2016 Final 3 in 1-1Document16 pagesCSSD - Sep 1st 2016 Final 3 in 1-1SundaraBharathiNo ratings yet

- Central Sterile Supply DepartmentDocument5 pagesCentral Sterile Supply Departmentssbansod100% (3)

- CSSDDocument18 pagesCSSDMehak KapoorNo ratings yet

- CSSD Performance Quality Analysis at A Super Speciality HospitalDocument29 pagesCSSD Performance Quality Analysis at A Super Speciality HospitalD. GandhirajNo ratings yet

- CSSDDocument4 pagesCSSDjerimiah_manzon100% (1)

- Module 2 Managing Medical Records - Learner Module - Nov.13Document135 pagesModule 2 Managing Medical Records - Learner Module - Nov.13Tex Zgreat100% (1)

- CISDocument4 pagesCISjerimiah_manzonNo ratings yet

- CSSD Guidelines 2021 Version I GDIPCDocument66 pagesCSSD Guidelines 2021 Version I GDIPCJyoti100% (1)

- Concepts of Infection Prevention and ControlDocument21 pagesConcepts of Infection Prevention and Controllisalov100% (2)

- Poorvi CSSD PROJECTDocument45 pagesPoorvi CSSD PROJECTPiaNo ratings yet

- Hospital Infection Control Manual AIIMS Raipur2019Document202 pagesHospital Infection Control Manual AIIMS Raipur2019Anjely SNo ratings yet

- Aseptic TechniqueDocument9 pagesAseptic Techniquebethh_6No ratings yet

- Operation Theater Policies and Procedures ManualDocument33 pagesOperation Theater Policies and Procedures Manualakinrav50% (2)

- Medical RecordsDocument17 pagesMedical Recordspdamodar2007No ratings yet

- NARCOTIC&CONTROLLEDDocument56 pagesNARCOTIC&CONTROLLEDMelai Rodriguez IbardalozaNo ratings yet

- Specimen Collection Handling TransportationDocument12 pagesSpecimen Collection Handling TransportationDewa LanggengNo ratings yet

- CSSD Safety PDFDocument4 pagesCSSD Safety PDFhhato2100% (3)

- CSSD Manual-1 PDFDocument47 pagesCSSD Manual-1 PDFTarun BhattacharjeeNo ratings yet

- CSSD RCRD KeepingDocument4 pagesCSSD RCRD KeepingsattichenNo ratings yet

- Operation Theatre ManagementDocument20 pagesOperation Theatre ManagementSalinder Kaur Dhaliwal0% (1)

- CSSD FunctonalityDocument5 pagesCSSD Functonalitya_kiytNo ratings yet

- HIC Manual (2015-2016) PDFDocument161 pagesHIC Manual (2015-2016) PDFparth_desi100% (1)

- Fumigation in Operation TheatresDocument22 pagesFumigation in Operation TheatresUtkarsh RaiNo ratings yet

- CSSDDocument43 pagesCSSDMohd SalahuddinNo ratings yet

- CSSDDocument8 pagesCSSDniraj_sdNo ratings yet

- Audits in Infection ControlDocument26 pagesAudits in Infection ControlshaheenasifsamnaniNo ratings yet

- Central Service Technical Manual: Seventh EditionDocument103 pagesCentral Service Technical Manual: Seventh EditionFarhan Ali100% (2)

- CSSD Central Sterile Supply DepartmentDocument35 pagesCSSD Central Sterile Supply DepartmentAnsari Shariq0% (1)

- MRDDocument17 pagesMRDPrasoon BanerjeeNo ratings yet

- Endoscopy UnitDocument77 pagesEndoscopy Unitmonir6150% (2)

- 2 CSSDDocument24 pages2 CSSDSunija Selvam100% (4)

- Final HICC Manual AIIMSDocument35 pagesFinal HICC Manual AIIMSNaMakNo ratings yet

- Material ManagementDocument11 pagesMaterial ManagementBhoomika Pandey100% (1)

- 8 Decontamination Disinfection SterilizationDocument8 pages8 Decontamination Disinfection SterilizationJay VillasotoNo ratings yet

- 2.quality Assurance in NursingDocument7 pages2.quality Assurance in NursingNancy SamuelNo ratings yet

- Lesson 122Document4 pagesLesson 122jerimiah_manzonNo ratings yet

- Notes On Infection PreventionDocument9 pagesNotes On Infection PreventionDipti PunjalNo ratings yet

- Intraoperative NotesDocument22 pagesIntraoperative NotesIsabel AranconNo ratings yet

- MRDDocument32 pagesMRDDishantt GandhiNo ratings yet

- Operating Room Orientation Manual Goals &Document4 pagesOperating Room Orientation Manual Goals &bhuselleNo ratings yet

- Standard Operating Procedure For CSSDDocument10 pagesStandard Operating Procedure For CSSDsreejths96% (25)

- CSSDDocument32 pagesCSSDRAHUL100% (1)

- Lesson 124Document5 pagesLesson 124jerimiah_manzonNo ratings yet

- Structure of CSSD For WebsiteDocument6 pagesStructure of CSSD For WebsiteTatavarti AnandNo ratings yet

- CSSD ManagementDocument5 pagesCSSD ManagementShafqat UllahNo ratings yet

- Bollywood and HousingDocument13 pagesBollywood and HousingakshidrajNo ratings yet

- Menu Bar RendersDocument19 pagesMenu Bar RendersakshidrajNo ratings yet

- Akshid Rajendran B110077AR 4/8/2014 F 10000: E-Receipt For State Bank Collect PaymentDocument1 pageAkshid Rajendran B110077AR 4/8/2014 F 10000: E-Receipt For State Bank Collect PaymentakshidrajNo ratings yet

- Model Exam For Nurse 2016E.CDocument19 pagesModel Exam For Nurse 2016E.Ctemesgen AsmamawNo ratings yet

- Green Tea For Fat Burn - F45 ChallengeDocument5 pagesGreen Tea For Fat Burn - F45 ChallengeMegan KelleyNo ratings yet

- Ope-101-Human Anatomy-ModuleDocument37 pagesOpe-101-Human Anatomy-ModuleAlbert MartinezNo ratings yet

- PhysioEx Exercise 5Document21 pagesPhysioEx Exercise 5Sinisa Ristic100% (1)

- Asphaltene Inh MSDSDocument11 pagesAsphaltene Inh MSDSfructoraNo ratings yet

- Disorders of Thought and SpeechDocument50 pagesDisorders of Thought and SpeechTilarupa BhattaraiNo ratings yet

- What Is Family Health Assessment?Document5 pagesWhat Is Family Health Assessment?James PajarilloNo ratings yet

- Memmory Shit 1 2 1Document3 pagesMemmory Shit 1 2 1Cristian Radu100% (1)

- Class 12 Investigatory Project by Heymang AgarwalDocument30 pagesClass 12 Investigatory Project by Heymang AgarwalHEYMANG AGARWALNo ratings yet

- Surgery Cwu ExampleDocument12 pagesSurgery Cwu ExampleDiyana ZatyNo ratings yet

- Nursing Care Plan UlcerDocument2 pagesNursing Care Plan Ulcerxrampley2100% (2)

- 15 The Cell Cycle-S PDFDocument6 pages15 The Cell Cycle-S PDFAml Aml0% (1)

- Nurture Your Dreams: Phylum ProtozoaDocument5 pagesNurture Your Dreams: Phylum ProtozoaNaduku EridadNo ratings yet

- Newborn WorksheetDocument4 pagesNewborn Worksheetcandice lavigneNo ratings yet

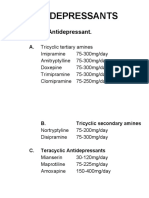

- Antidepressants: I. Cyclic AntidepressantDocument17 pagesAntidepressants: I. Cyclic AntidepressantVaibhav KrishnaNo ratings yet

- Cardio Pulmonary Resuscitation and End of Life CareDocument21 pagesCardio Pulmonary Resuscitation and End of Life CareSundaraBharathi100% (1)

- Cause of Lower Limb Edema and Hypoproteinemia DiagDocument2 pagesCause of Lower Limb Edema and Hypoproteinemia DiagVictoria HNo ratings yet

- Fundus Camera PDFDocument8 pagesFundus Camera PDFDhivya SekarNo ratings yet

- Continuum Spinal Cord AnatomyDocument25 pagesContinuum Spinal Cord AnatomyslojnotakNo ratings yet

- R3X5 Part A 2013 PDFDocument7 pagesR3X5 Part A 2013 PDFTuấnNo ratings yet

- BP3T GuideDocument17 pagesBP3T Guidejorge jonesNo ratings yet

- CHAP 5 Quest For HealthDocument42 pagesCHAP 5 Quest For HealthRajkishor YadavNo ratings yet

- Fruit Chapter 5Document33 pagesFruit Chapter 5wabdushukurNo ratings yet

- Benzing-2021-Insights Into Glomerular FiltrationDocument10 pagesBenzing-2021-Insights Into Glomerular FiltrationNguyen LequyenNo ratings yet

- Community Health Nursing Notes - Epidemiology, Health Policy, DisasterDocument16 pagesCommunity Health Nursing Notes - Epidemiology, Health Policy, DisasterKristen Ruehman100% (1)

- Lecture 4 Biliary TreeDocument31 pagesLecture 4 Biliary TreeattooNo ratings yet

- What Is OpsonizationDocument56 pagesWhat Is OpsonizationrekhaNo ratings yet