Professional Documents

Culture Documents

Linear Bush Series Slide Unit Series Shaft Unit Series: Natec Corporation Ltd. Japan

Linear Bush Series Slide Unit Series Shaft Unit Series: Natec Corporation Ltd. Japan

Uploaded by

Loc HuynhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linear Bush Series Slide Unit Series Shaft Unit Series: Natec Corporation Ltd. Japan

Linear Bush Series Slide Unit Series Shaft Unit Series: Natec Corporation Ltd. Japan

Uploaded by

Loc HuynhCopyright:

Available Formats

Linear Bush Series

Slide Unit Series

Shaft Unit Series

www.natec-corporation.com

Regional Distributor

NATEC CORPORATION LTD. JAPAN

Japan

INDEX

TECHNICAL INFORMATION 1

LINEAR BUSH SERIES

KH 9

LM 10

LME 12

LMB 14

LM L 16

LME L 17

LMF/LMK/LMH 18

LMEF/LMEK 20

LMF L/LMK L/LMH L 22

LMEF L/LMEK L 24

LMFC/LMKC 26

LMEFC/LMEKC 27

SLIDE UNIT SERIES

SC S 28

SC 28

SC L 28

SME 29

SMY 29

SH 30

SH L 30

SLIDE SHAFT

SFP 31

SFPT 32

SHAFT SUPPORT SERIES

SA 33

SK 34

SHF 35

DIMENSIONS OF ASSEMBLE 36

BALL BUSHING COMPARISON LIST 37

Japan Japan

TECHNICAL INFORMATION TECHNICAL INFORMATION

Fig.1 Hardness Factor

1.0

Load Rating 0.9

Hardness Factor f

Hardness Factor (fH) 0.8

Basic Dynamic Load Rating (C) Basic Static Load Rating (Co) 0.7

The shaft must be sufficiently hardened when a linear

This term is arrived at based on an evaluation of a This term defines a static load such that, at the 0.6

contacting position where the maximurn stress is bushing is used. lf not properly hardened, permissible

number of identical linear systems individually run 0.5

exercised, the sum of the permanent deformation load is lowered and the life of the bushing will be

in the same conditions, if 90% of them can run with 0.4

of the rolling elements and that of the rolling plane is shortened.

the load (with a constant value in a constant 0.3

0.0001 time of the diameter of the rolling elements. 0.2

direction) for adistance of 50 km without damage

caused by rolling fatigue. This is the basis of the 0.1

Table 1.Stactic Safety Factors

rating. 60 50 40 30 20 10

Allowable Static Moment (M) Condition of use Low limit of fs Raceway Hardness HRC

This term defines the allowable limit value of static When the shaft has less deflection

and shock 1to2

moment load,with reference to the amount of

When elastic deformation should Temperature Coefficient (fT) Fig.1 Hardness Factor

permanent deformation similar to that used for be considered with respect to If the temperature of the linear system exceeds 100

evaluation of basic rated load (Co).

Temperature Coefficient f

pinch load 2to4 hardness of the linear system and the shaft lowers to

Static Safety Factor (fs) 1.0

When the equipment is subject to decrease the permissible load compared to that of the

This factor is used based on the application vibration and impacts 3to5 0.9

linear system used at room temperature. As a result,

condition as shown in Table 1. 0.8

the abnormal temperature rise shortens the rating life.

0.7

0.6

Rating Life

0.5

Rating Life of the Linear System Consideration and influence of vibration impact loads 100 150 200 250

As long as the linear system reciprocates while and distribution of load should be taken into account Temperature of Linear System

being loaded,continuous stress acts on the linear when designing a linear motion system . it is difficult

system to cause flaking on the rolling bobies and to calculate the actual load . The rating life is also

planes because of material fatigue. The travelling affected by the operating temperature. In these Table 2 Contact Coefficient

conditions, the expression (1) is arranged as follows: Contact Coeffcient (fc)

distance of linear system until the fist flaking

Generally two or more linear bushings are used on

occurs is called the life of the systems of the same H. r . c c Number of linear

For ball type:L=( f f f p ) .50

3

fw

one shaft. Thus, the load on each linear sysem differs systems per shaft Contact coefficient fc

dimensions, structure,material,heat treatment and

depending on each processing accuracy. Because the

processing method, when used in the same condi- 1 1.00

L:Rating life (km) fh:Hardness factor (See Fig.1) linear bushings are not loaded equally, the number

tions,This variation is brought about from the essential C:Basic dynamic load rating (N) 2 0.81

of linear bushings per shaft changes the permissible

variations in the material fatigue itself. The rating life fT:Temperatuer coefficient (See Fig.2) P:Load (N)

3 0.72

fC:Contact coefficient (See Table 2) load of the system.

defined bellow is used as an index for the life expec- fw:Load coefficient (See Table 3) 4 0.66

tancy of the linear system. 5 0.61

Rating Life (L) The rating life in hours can be calculated by obtaining

Rating life is the total travelling distance that 90% the travelling distance per unit time. The rating life in

hours can be obtained from the following expression

of a group of systems of the same size can reach

when the stroke length and the number of strokes

without causing any flaking when they operate under are constant: Table 3 Load Coefficient

the same conditions.

Load Coefficient (fw)

L . 10 Opearating Conditions

3

Lh= . . When calculating the load on the linear system, it is

fw

The rating life can be obtained from the following 2 s n1 60

necessary to accurately obtain object weight, inertial Operation at low speed(15 m/min.

equation with the basic dynamic load rating and the Lh:Rating life in hours (hr) Or less) without impulsive shock 1.0 to 1.5

es:Stroke length (m) force based on motion speed, moment load, and each from outside

load on the linear system: L:Rating life (km)

transition as time passes. However, it is difficult to

n1:No.of strofes per minute (cpm)

Operation at intermediate speed

calculate those valuse accurately because reciprocating (60 m/min. Or less) without 1.5 to 2.0

For ball type:L=( C ).50

3

p (1)

motion involves the repetition of start and stop as well impulsive shock

as vibration and impact. A more practical approach is Operation at high speed

L:rating life (km) C:Basic dynamic load rating (N)

to obtain the load coefficient by taking the actual (over 60 m/min.) With 2.0 to 3.5

P:Load (N) impulsive shock from outside

operatingconditions into account.

01 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 02

Japan Japan

TECHNICAL INFORMATION TECHNICAL INFORMATION

Structure and Features

The KOLMB linear bushing consists of an outer cylinder, 1.High Precision and Rigidity

Frictional Resistance ball retainer, balls and two end rings. The ball retainer The KOLMB linear bushing is produced from a solid

which holds the balls in the recirculating tuucks in held steelouter cylinder and incorporates an industrial stre-

inside the outer cylinder by end rings. ngth resin retainer.

The static frictional resistance of the weight. The sealing resistance of one linear system

Those parts are assembled to optimize their required

2.Ease of Assembly

linear system is so low as to be only slightly is about 2000 to 500 gf. The coefficient of friction

The standard type of KOLMB linear bushing can be

different from the kinetic frictional resistance, depends on the load weight. Moment load. And pre- functions.

loaded from any direction. Precision control is Possible

enabling smooth linear movement from low to load.Table 6 shows the coefficient of kinetic friction The outer cylinder is maintained sufficient hardness using only the shaft supporter, and the mounting

high speeds. in general, the frictional resistance of each type of linear system which has been installed

by heat treatment, therefore if ensures the bushings surface can be machined easily.

is expressed by the following equation. and lubricated properly and applied with normalload

projected travel life and satisfactory duravbility. 3.Ease of Replacement

(P/C=0.2)

F= W+f The ball retainer is made from steel or synthetics resin. KOLMB linear bushings of each type are completely

interchangeable because of their standardized

The steel retainer has high rigidity, obtained by heat

F:Frictional resistance :Coefficient of friction dimensions and strict precision control. Replacement

W:Load weight f:Sealing resistance Table 5 Coefficient of Linear System Friction (u) treat meant.

because of wear or damage is therefore easy and

The synthetics resin retainer can reduce running noise. accurate.

The frictional resistance of each KOLMB linear Linear System Coefficient of

Type Models Friction (u) The user can select the optimum type for meeting the 4.Veriety of Types

system depends on the model, load weight,

user's service conditions. KOLMB offers a full line of linear bushing: the stan-

speed, and lubricant. The sealing resistance Linear Bushing LM, LME, LMB 0.002 to 0.003 dard, integral single-retainer closed types. The user

depends on the lip interference and lubricant,

regardless of the load. can choose from among these according to the

application requirements to be met.

Ambient Model Denominate Method

LINEAR BUSHING

Working Temperature Table 6 Ambient Working Temperature

N LM F 20 L UU OP

The ambient working temperature range for each Ambient

Linear System

KOLMB linear system depends on the model. Models Working

Type NO ENTRY - STANDARD TYPE

Temperature

Consult KOLMB on use outide the recommended

N- NICKEL PLATED

temperature range. Linear Bushing LM, LME, LMB -20to80 NO ENTRY - STANDARD TYPE

M- ANTI CORROSIM

AJ - CLEARANCE ADJUSTMENT

Temperature conversion equation Linear Bushing LM-A, LME-A, LMB-A -20to110 TYPE

5

C= 9

(F-32)

OP - OPEN TYPE

5

LM - ASIA SERIES

F= 32+ 9 C

LME - EUROPE SERIES

Lubrication and LMB - ENGLISH SYSTEM SERIES NO ENTRY - NO SEAL

Dust Prevention U - SEAL ON ONE SIDE

UU - SEAL ON BOTH SIDES

Using KOLMB linear systems without lubrication increases

NO ENTRY-STANDARD TYPE

the abrasion of the rolling elements, shortening the life

span, The KOLMB linear systems therefore require appro- F-FOUND FLANGE TYPE

priate lubrication. For lubrication KOLMB recommends NO ENTRY - STANDARD TYPE

K-SQUARE FLANGE TYPE

turbine oil conforming to ISO Standards G32 to G68 or S - SHORTEN TYPE

lithium base soap grease NO.2. Some KOLMB linear H-TWO SIDE CUT FLANGE TYPE

systems are sealed to block dust out and seal lubrication. L - LENGTHEN TYPE

FC-CENTERED ROUND FLANGE TYPE

If used in a harsh or corrosive environment, however,

apply a protective cover to the part involving linear motion. KC-CENTERED SQUARE LANGE

HC-CENTERED TWO SIDE CUT FLANGE INSCRIBED CIRCLE DIAMETER

Note: NICKEL PLATED ON SURFACE OF THE BEARING IS AVAILABLE ON REQUEST,

ADD PREFIX WITH ' N ' , EXAMPLE : NLMF 20 UU

03 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 04

Japan Japan

TECHNICAL INFORMATION TECHNICAL INFORMATION

SLIDE UNIT

Relation between ball

circuits and load rating

The KOLMB linear bushing includes ball circuits that The value in the dimension table indicates the load

are spaced equally and circumferentially. The load rating when the load is placed on top of one ball

SC 20 L UU rating varies according to the loaded position on the circuit. if the KOLMB linear bushing is used with two

circumference. ball circuits loaded uniformly, the load rating will be

greater, The following table shows the values by the

Table 1 number of ball circuits in such cases:

Number

NO ENTRY - NO SEAL of rows

SC - LM SERIES SLIDE BLOCK Row 3 4 5 6 8

U - SEAL ON ONE SIDE position

load ratio

SME - LM SERIES OPEN SLIDE BLOCK UU - SEAL ON BOTH SIDES

Q1 Q1 Q1 Q1 Q1

Row position

NO ENTRY - STANDARD TYPE

P1 P1 P1 P1

P0 P0 P0 P0 P1 P0 P1

Q 0 =P0 Q 1 =P0 Q 1 = 1.106 P0 Q 1 = 1.354 P0 Q 1 = 1.841 P0

SHAFT DIAMETER L - LENGTHEN TYPE

Q0 Q1 Q1 Q1 Q1

Row position

Tolerance P1 P1

P0 P0

P0 P0 P0 P0 P0 P0 P0 P0

Note that precision of inscribed circle diameters and outside diameters for the clearance adjustable type ( -AJ)

Q 0 =P0 Q 0 =1.414 P0 Q 0 = 1.618 P0 Q 0 = 1.732 P0 Q 0 = 2.052 P0

and the open type ( -OP) indicates the value obtained before the corresponding type is subjected to cutting

process.

Load ratio Q 0 Q 1 =1 Q 0 Q 1 =1.414 Q 0 Q 1 =1.463 Q 0 Q 1 =1.280 Q 0 Q 1 =1.115

Load Rating and Sample Calculations

Life Expectancy 1.Obtaining the rated life L and lifespan Lh of the KOLMB

linear bushing used in the following conditions:

2.Selecting the linear bushing type satisfying the

following conditions:

The life (L) of a linear bushing can be obtained Linear bushing: LM20 Number of linear bushing used: 4

The lifespan (Ln) of a linear bushing in hours can be

from the following equation with the basic dynamic Stroke length: 50mm Stroke length: lm

obtained by calculating the travelling distance per

load rating and the load applied to the busha: Number of strokes per minute: 50cpm Traveling speed: 10m/min

unit time.

Load per bush: 490N Number of strokes per minute: 5cpm

The lifespan can be obtained from the following

The basic dynamic load rating of the linear bushing is Lifespan: 10,000hr

. . T r. . C c cc equation if the stroke length and the number of

:L=(f f f f f f pp) ).50 882N from the dimension table. From equation(1),

3

L=(

HH

50 (1) Totalload: 980N

fWfw strokes are constant:

therefore, the rated life L is obtained as follows: From equation(2), the travelling distance within

3 the lifespan is obtained as follows:

L 10

L:Rated life (km) fH:Hardness factor (See page5) Lh= ( ( (2)

2 s n1 60

H. T. C c L=2X sXn1X60XLh=6 000km

C:Basic dynamic load rating (N) fT:Temperature coefficient (See page5) L=( f f f p ) 50 FH=fT=fC=fW=1.0

fW

P:Working load (N) fc:Contact coefficient (See page5) Lh:Lifespan s:Stroke length (m)

=( 882

490

)x50=292km From equation(1), the basic dynamic load rating is

fw:Load coefficient L:Rated life (km) n:Number of strokes per minute (cpm) obtained as follows:

From equation(2), the lifespan Lh is obtained as follows: 3

L fW

C= 50 ( fH fT fC ) p =1492N

Assume the following with a pair of shafts each with

two linear bushings:

L x 10 292 x 10

Lh= = =973hr

2xesxnlx60 2x0.05x50x60 fc=0.81,fw=fT=fH=1

As a result, Lm30 is selected from the dimension table as

the KOLMB linear bushing type satisfying the value of C

05 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 06

Japan Japan

TECHNICAL INFORMATION TECHNICAL INFORMATION

Fig.1

Clearance and Fit Mounting

When a standard-type KOLMB linear bushing is used The outside cylinder cylinder, to affect its precision When inserting the linear bush into the housing, do not

with a shaft, inadequate clearance, adjustment may and life. therefore, the appropriate clearance between hit the linear bush on the side ring holding the retainer

cause early bush failure and / or poor, rough traveling. the bush and shaft, and clearance between the bush but apply the cylinder circumference with a proper jig

The clearance adjustable linear bush and open linear and housing are required according to the application. and push the linear bush into the housing by hand or

bush can be clearance adjusted when assembled in Table 2 shows recommended fit of the bush: lightly knock it in. (See Fig.1) In inserting the shaft after

the housing which can control the outside cylinder mounting the bush, be careful nto to shock the balls.

diameter. However, too much clearance adjustment Note that if two shafts are used in parallel, the parallelism

increases the deformation of is the most important factor to assure the smooth linear

movement. Take care in setting the shats.

Table 2

Division Shaft Housing

Model Normal fit Transitional loose fit Tight fit

LM High class g6 h6 H7 J7 Examples of Mounting

LMB The popular way to mount a linear bush is to operate it with an appropriate interference. it is recommended, however,

LME High class h6 j6 H7 J7 to make a loose fit in principle because otherwise precision is apt to be minimized. The following examples (Figs. 2 to 6)

show assembling of the inserted bush in terms of desinging and mounting, for reference.

Note: The clearance may be zero or negative. Please attention the movement.

Fig.2 Fig.5

Shaft and Housing

To optimize performance of the KOLMB linear bushing high precision of the shaft and housing is required.

1.Shaft

The rolling balls in the KOLMB linear bushing are 3.The shaft diameter for the clearance adjustable

in point contact with the shaft surface Therefore, linear bush and open linear bush should as much

the shaft dimensions, tolerance, surface finish, as possible be of the lower value of the inscribed Fig.4

and hardness greatly affect the traveling circle diameter in the specification table. Do not

performance of the bush. The shaft should be set the shaft diameter to the upper value.

manufactured with due attention to the following 4.Zero clearance or negative clearance increases

points: the frictional resistance slightly. if the negative

1.since the surface finish critically affects smooth clearance is too tight, the deformation of the

rolling of balls, grind the shaft at 1.5 S or better outside cylinder will become larger,to shorten

Fig.3 Fig.6

2.Thebest hardness of the shaft is HRC 60 to 64. the bush life.

Hardness less than HRC 60 decreases the life

considerably, and hence reduces the permissible 2.Housing

load. On the other hand, hardness over HRC 64 There is a wide range of housings differing in

accelerates ball weer. design, machining, and mounting. For the fitness

and shapes of housings, see Table 2 and the

following section on mounting.

07 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 08

Japan Japan

KH Series

D

d

Japan

KH

Main Dimensions Basic Load Rating Weight

Part No. C Co (g)

d D B CN CON

KH-0622 6 12 22 400 239 7

KH-0824 8 15 24 435 280 12

KH-1026 10 17 26 500 370 14.5

KH-1228 12 19 28 620 510 18.5

KH-1428 14 21 28 620 520 20.5

KH-1630 16 24 30 800 620 27.5

KH-2030 20 28 30 950 790 32.5

KH-2540 25 35 40 1990 1670 66

KH-3050 30 40 50 2800 2700 95

KH-4060 40 52 60 4400 4450 182

KH-5070 50 62 70 5500 6300 252

1N=0.102kgf

Type number format:

KH 20 30 PP

KH-Mini(Pressing Bush)LineaR Bearing

P=seal one side.PP=seal both sides

Shaft Diameter Length Dimension

09 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 10

Japan Japan

LM Series LM Series

L

LM LM -OP LM -AJ

B

W W

h

h1

dr dr

dr

D D1

LM LM OP LM AJ

Main Dimensions and Tolerance Eccentricity

Radial Basic Load

Ball Ball Adjustable Ball Weight Clearance Rating

Part No. Open Type dr Tolerance D Tolerance L Tolerance B Tolerance W D1 h h1 (max) Part No.

Circuit Circuit Type Circuit g (max) C Co

(mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) (mm) (mm) m

m CN CON

LM4 4 4 2 4 8 12 - - - - - - 88 127 LM4

0 0 0 8

-8 -9 -120 - - -

LM5UU 4 LM5UUAJ 4 4 5 10 15 10.2 1.1 9.6 167 206 LM5UU

LM6UU 4 LM6UUAJ 4 8.5 6 12 19 13.5 1.1 11.5 - - - -3 206 265 LM6UU

0 - - -

LM8SUU 4 LM8SUUAJ 4 11 8 15 17 11.5 1.1 14.3 176 216 LM8SUU

-11

LM8UU 4 LM8UUAJ 4 17 8 15 24 17.5 1.1 14.3 - - - 274 392 LM8UU

0

-9

LM10UU 4 LM10UUAJ 4 36 10 19 29 0 22 0 1.3 18 - 6.8 80 12 372 549 LM10UU

-200 -200

LM12UU 4 LM12UU-OP 3 LM12UUAJ 4 42 12 21 30 23 1.3 20 1.5 8 80 -4 510 784 LM12UU

0

4 4 -13 1.5

LM13UU LM13UU-OP 3 LM13UUAJ 49 13 23 32 23 1.3 22 9 80 510 784 LM13UU

LM16UU 5 LM16UU-OP 4 LM16UUAJ 5 76 16 28 37 26.5 1.6 27 1.5 11 80 774 1180 LM16UU

LM20UU 5 LM20UU-OP 4 LM20UUAJ 5 100 20 0 32 42 30.5 1.6 30.5 1.5 11 60 -6 882 1370 LM20UU

-10 0

LM25UU 6 LM25UU-OP 5 LM25UUAJ 6 240 25 40 59 41 1.85 38 2 12 50 15 980 1570 LM25UU

-15

LM30UU 6 LM30UU-OP 5 LM30UUAJ 6 270 30 45 64 44.5 1.85 43 2.5 15 50 1570 2740 LM30UU

-8

LM35UU 6 LM35UU-OP 5 LM35UUAJ 6 425 35 52 70 0 49.5 0 2.1 49 2.5 17 50 1670 3140 LM35UU

0 0 -300 -400

LM40UU 6 LM40UU-OP 5 LM40UUAJ 6 654 40 60 80 60.5 2.1 57 3 20 50 20 -10 2160 4020 LM40UU

-12 -19

LM50UU 6 LM50UU-OP 5 LM50UUAJ 6 1700 50 80 100 74 2.6 76.5 3 25 50 3820 7940 LM50UU

-13

LM60UU 6 LM60UU-OP 5 LM60UUAJ 6 2000 60 0/-15 90 0/-22 110 85 3.15 86.5 3 30 50 25 4700 10000 LM60UU

1N=0.102kgf

11 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 12

Japan Japan

LME Series LME Series

L LME LME -OP LME -AJ

B

W W

h

h1

D D1

LME LME OP LME AJ

Main Dimensions and Tolerance Eccentricity

Radial Basic Load

Ball Ball Adjustable Ball Weight Clearance Rating

Part No. Open Type

dr Tolerance D Tolerance L Tolerance B Tolerance W D1 h h1 (max) Part No.

Circuit Circuit Type Circuit (g) (max) C Co

(mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) (mm) (mm) m

m CN CON

LME5UU 4 LME5UUAJ 4 11 5 12 22 14.5 1.1 11.5 - - - 206 265 LME5UU

0

+8 -8 -3

LME8UU 4 LME8UUAJ 4 22 8 16 25 16.5 1.1 15.2 - - - 265 402 LME8UU

0 12

0 LME12UU

LME12UU 4 LME12UU-OP 3 LME12UUAJ 4 45 12 22 32 22 0 1.3 21 1.5 7.5 78 510 784

0 -200

-9 -300 -4

LME16UU 5 LME16UU-OP 4 LME16UUAJ 5 60 16 26 36 24.9 1.3 24.9 1.5 10 78 578 892 LME16UU

+9

LME20UU 5 LME20UU-OP 4 LME20UUAJ 5 102 20 -1 32 45 31.5 1.6 30.3 2 60 862 1370 LME20UU

10

0 -6

LME25UU 6 LME25UU-OP 5 LME25UUAJ 6 235 25 +11 40 -11 58 44.1 1.85 37.5 2 12.5 60 15 980 1570 LME25UU

-1

LME30UU 6 LME30UU-OP 5 LME30UUAJ 6 360 30 47 68 0 52.1 0 1.85 44.5 2 12.5 50 1570 2740 LME30UU

-300 -400 -8

LME40UU 6 LME40UU-OP 5 LME40UUAJ 6 770 40 62 80 60.6 2.15 59 3 16.8 50 2160 4020 LME40UU

0 17

+13 -13

LME50UU 6 LME50UU-OP 5 LME50UUAJ 6 1250 50 75 100 77.6 2.65 72 3 21 50 3820 7940 LME50UU

-2 -13

LME60UU 6 LME60UU-OP 5 LME60UUAJ 6 2220 60 90 0/-15 125 (0/-400) 101.7 3.15 86.5 3 27.2 54 20 4700 9800 LME60UU

1N=0.102kgf

13 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 14

Japan Japan

LMB Series LMB Series

LMB LMB -OP LMB -AJ

L

B

W W h

h1

D D1

LMB LMB OP LMB AJ

Main Dimensions and Tolerance

Basic Load

Ball Ball Ball Weight Eccen-

Part No. Seal Type Seal Type Rating Part No.

Circuit Circuit Circuit g dr Tolerance D Tolerance L Tolerance B Tolerance D1 W h h1 tricity

( m) ( m) ( m) ( m) C Co

CN CON

0.25 0.5 0 0.75 0.511 0.4687 0.039 0.04

LMB04 3 3 9.5 206 265 LMB04

6.35 12.7 -11 19.05 12.98 11.906 0.992 1

0.375 0.625 0.875 0.6385 0.588 0.039 0.04

LMB06 4 4 15 225 314 LMB06

9.525 15.875 22.225 16.15 14.935 0.992 1

0

-9 12

0.5 0.875 0 1.25 0 0.9625 0 0.8209 0.0459 0.06 0.34

LMB08 4 LMB08OP 3 LMB08AJ 4 42 80 510 784 LMB08

12.7 22.225 -13 31.75 -200 24.46 -200 20.853 1.168 1.5 7.9375

0.625 1.125 1.5 1.1039 1.059 0.0559 0.06 0.375

LMB10 4 LMB10OP 3 LMB10AJ 4 85 80 774 1180 LMB10

15.875 28.575 38.1 28.04 26.899 1.422 1.5 9.525

0.75 1.25 1.625 1.1657 1.176 0.0559 0.06 0.4375

LMB12 5 LMB12OP 4 LMB12AJ 5 104 60 862 1370 LMB12

19.05 31.75 41.275 29.61 29.87 1.422 1.5 11.1125

0 0

15

-10 -16

1 1.5625 2.25 1.7547 1.4687 0.0679 0.06 0.5625

LMB16 5 LMB16OP 4 LMB16AJ 5 220 50 980 1570 LMB16

25.4 39.688 57.15 44.57 37.306 1.727 1.5 14.2875

1.25 2 2.625 2.0047 1.8859 0.0679 0.10 0.625

LMB20 6 LMB20OP 5 LMB20AJ 6 465 50 1570 2740 LMB20

31.75 50.8 66.675 50.92 47.904 1.727 2.5 15.875

0 0 0

20

-19 -300 -300

1.5 0 2.375 3 2.4118 2.2389 0.0859 0.12 0.75

LMB24 6 LMB24OP 5 LMB24AJ 6 720 50 2180 4020 LMB24

38.1 -12 60.325 76.2 61.26 56.87 2.184 3 19.05

2 3 0 4 3.1917 2.8379 0.1029 0.12 1

LMB32 6 LMB32OP 5 LMB32AJ 6 1310 50 25 3820 7940 LMB32

50.8 76.2 -22 101.6 81.07 72.085 2.616 3 25.4

1N=0.102kgf

15 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 16

Japan Japan

LM L Series LME L Series

L L

B B

W W W

W

dr dr

D1

D1

D

D

LM L LME L

Main dimensions and Tolerance Basic Load Main dimensions and Tolerance Basic Load

Ball Weight Rating Rating

Part No. (g) dr Tolerance D Tolerance L Tolerance B Tolerance W D1 Part No. Ball Weight dr Tolerance D Tolerance L Tolerance B Tolerance W D1

Circuit C Co C Co

(mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) N N Circuit (g) (mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) N N

LM6LUU 4 16 6 12 35 27 1.1 11.5 323 530 LME8LUU 4 40 8 16 0/-9 46 33 1.1 15.2 421 804

0 +9

-13 -1 45.8

LM8LUU 4 31 8 15 45 35 1.1 14.3 431 784 LME12LUU 4 80 12 22 0 61 0 0 1.3 21 813 1570

-11 -300 -400

LM10LUU 4 62 10 0 19 55 44 1.3 18 588 1100 LME16LUU 5 115 16 26 68 49.8 1.3 24.9 921 1780

+11

-10 0 0 -1

LM12LUU 4 80 12 21 57 46 1.3 20 813 1570 LME20LUU 5 180 20 32 80 61 1.6 30.5 1370 2740

0 -300 -400

-16 0

LM13LUU 4 90 13 23 61 46 1.3 22 813 1570 LME25LUU 6 430 25 40 112 82 1.85 38 1570 3140

+13 -13

5 -2 104.2

LM16LUU 145 16 28 70 53 1.6 27 1230 2350 LME30LUU 6 615 30 47 123 1.85 44.5 2500 5490

0 0

LM20LUU 5 180 20 32 80 61 1.6 30.5 1400 2740 LME40LUU 6 1400 40 62 151 121.2 2.15 59 3430 8040

0 -400 -500

0 0 +16 -15

LM25LUU 6 440 25 40 112 82 1.85 38 1560 3140 LME50LUU 6 2320 50 75 192 155.2 2.65 72 6080 15900

-12 -19 -4

LM30LUU 6 480 30 45 123 89 1.85 43 2490 5490 LME60LUU 6 3920 60 90 0/-20 209 170 3.15 86.5 7550 20000

LM35LUU 6 795 35 52 135 99 2.1 49 2650 6270 1N=0.102kgf

0 0

0 0 -400 -500

LM40LUU 6 1170 40 60 -22 151 121 2.1 57 3430 8040

-15

LM50LUU 6 3100 50 80 192 148 2.6 76.5 6080 15900

LM60LUU 6 3500 60 0/-20 90 0/-25 209 170 3.15 86.5 7550 20000

1N=0.102kgf

17 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 18

Japan Japan

LMF/K/ H Series LMF/K/ H Series

L

H W

W F

h

d2

d1

D D

P.C. P.C.

dr

D1

A

D

LMF LMK

A A

LMF LMK LMH13 or less LMH16 or more

LMH

Eccentricity

Radial Basic Load Main Dimensions and Tolerance

Weight

Ball Clearance Rating

Part No. (g) (max) Part No.

Circuit (max) C Co dr Tolerance D Tolerance L Tolerance D1 Tolerance H PCD K W A F

m d1xd2xh

F K H m N N (mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) (mm) (mm) (mm) (mm)

LMF6UU LMK6UU LMH6UU 4 24 18 21 206 265 6 12 19 28 5 20 22 18 20 - 3.5x6x3.1 LMF/K/H6UU

0

-3 -13

LMF8UU LMK8UU LMH8UU 4 37 29 33 274 392 8 15 24 32 5 24 25 21 24 - 3.5x6x3.1 LMF/K/H8UU

LMF10UU LMK10UU LMH10UU 4 72 52 64 372 549 10 19 29 40 6 29 30 25 29 - 4.5x7.5x4.1 LMF/K/H10UU

12 0 0 0

LMF12UU LMK12UU LMH12UU 4 76 57 68 -4 510 784 12 -9 21 30 -200 42 -200 6 32 32 27 32 - 4.5x7.5x4.1 LMF/K/H12UU

0

-16 -

LMF13UU LMK13UU LMH13UU 4 88 72 81 510 784 13 23 32 43 6 33 34 29 33 4.5x7.5x4.1 LMF/K/H13UU

LMF16UU LMK16UU LMH16UU 5 120 104 112 774 1180 16 28 37 48 6 38 37 34 31 22 4.5x7.5x4.1 LMF/K/H16UU

LMF20UU LMK20UU LMH20UU 5 180 145 167 -6 882 1370 20 32 42 54 8 43 42 38 36 24 5.5x9x5.1 LMF/K/H20UU

0 0

LMF25UU LMK25UU LMH25UU 6 340 300 325 15 980 1570 25 40 59 62 8 51 50 46 40 32 5.5x9x5.1 LMF/K/H25UU

-10 -19

LMF30UU LMK30UU LMH30UU 6 470 375 388 1570 2740 30 45 64 74 10 60 58 51 49 35 6.6x11x6.1 LMF/K/H30UU

-8 0

LMF35UU LMK35UU 6 650 560 1670 3140 35 52 70 82 0 10 67 64 6.6x11x6.1 LMF/K/35UU

-300

0 0 -300

LMF40UU LMK40UU 6 1060 880 20 -10 2160 4020 40 60 80 96 13 78 75 9x14x8.1 LMF/K/40UU

-12 -22

LMF50UU LMK50UU 6 2200 2000 3820 7940 50 80 100 116 13 98 92 9x14x8.1 LMF/K/50UU

-13

LMF60UU LMK60UU 6 3000 2560 25 4700 10000 60 0/-15 90 0/-25 110 0/-400 134 18 112 106 11x17x11.1 LMF/K/60UU

1N=0.102kgf

19 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 20

Japan Japan

LMEF/K Series LMEF/K Series

L

H

h

K

d2

d1

D

PC

D PC

D1

D

LMEF LMEK A A LMEK

LMEF

Weight Eccentricity

Radial Basic Load Main Dimensions and Tolerance

Ball (g) Clearance Rating

Part No. (max)

dr Tolerance D Tolerance L Tolerance D1 Tolerance H PCD K Part No.

Circuit (max) C Co d1xd2xh

m (mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) (mm)

F K m N N

LMEF8UU LMEK8UU 4 41 33 -3 265 402 8 16 0/-13 25 32 5 24 25 3.5x6x3.1 LMEF/K/8UU

+8

0 LMEF/K/12UU

LMEF12UU LMEK12UU 4 80 64 12 510 784 12 22 32 42 6 32 32 4.5x7.5x4.1

0 0 0

-4

-16 -200 -200 LMEF/K/16UU

LMEF16UU LMEK16UU 5 103 90 578 892 16 +9 26 36 46 6 36 35 4.5x7.5x4.1

5 -1 LMEF/K/20UU

LMEF20UU LMEK20UU 182 147 862 1370 20 32 45 54 8 43 42 5.5x9x5.1

-6

LMEF25UU LMEK25UU 6 335 295 15 980 1570 25 40 0 58 62 8 51 50 5.5x9x5.1 LMEF/K/25UU

+11 -19

-1 LMEF/K/30UU

LMEF30UU LMEK30UU 6 560 465 1570 2740 30 47 68 76 10 62 60 6.6x11x6.1

0

-8 -300 0

LMEF40UU LMEK40UU 6 1175 975 2160 4020 40 62 80 98 13 80 75 9x14x8.1 LMEF/K/40UU

0 -300

20 +13 -22

LMEF50UU LMEK50UU 6 1745 1545 3820 7940 50 75 100 112 13 94 88 9x14x8.1 LMEF/K/50UU

-2

-13

LMEF60UU LMEK60UU 6 3220 2780 25 4700 9800 60 90 0/-25 125 0/-400 134 18 112 106 11x17x11.1 LMEF/K/60UU

1N=0.102kgf

21 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 22

Japan Japan

LMF/K/H L Series LMF/K/H L Series

W

L

H W F

K

d2

d1

D D

PC PC

dr

A

A

D1

D

LMK L

LMF L

A

A

LMF L LMK L LMH13L or less LMH L16 or more

LMH L

Eccentricity

Radial Basic Load Main Dimensions and Tolerance

Weight

Ball Clearance Rating

Part No. (g) (max) dr Tolerance Part No.

Circuit C Co D Tolerance L Tolerance D1 Tolerance H PCD K W A F

(max) d1xd2xh

m (mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) (mm) (mm) (mm) (mm)

F K H m N N

LMF6LUU LMK6LUU LMH6LUU 4 31 25 28 15 -3 323 530 6 12 35 28 5 20 22 18 20 - 3.5x6x3.1 LMF/K/H6LUU

0

-13 -

LMF8LUU LMK8LUU LMH8LUU 4 51 43 47 15 -3 431 784 8 15 45 32 5 24 25 21 24 3.5x6x3.1 LMF/K/H8LUU

LMF10LUU LMK10LUU LMH10LUU 4 98 78 90 15 -4 588 1100 10 19 55 40 6 29 30 25 29 - 4.5x7.5x4.1 LMF/K/H10LUU

0

-10 0 0

LMF12LUU LMK12LUU LMH12LUU 4 110 90 102 15 -4 813 1570 12 21 0 57 42 6 32 32 27 32 - 4.5x7.5x4.1 LMF/K/H12LUU

-300 -200

-16

LMF13LUU LMK13LUU LMH13LUU 4 130 108 123 15 -4 813 1570 13 23 61 43 6 33 34 29 33 - 4.5x7.5x4.1 LMF/K/H13LUU

LMF16LUU LMK16LUU LMH16LUU 5 190 165 182 15 -6 1230 2350 16 28 70 48 6 38 37 34 31 22 4.5x7.5x4.1 LMF/K/H16LUU

LMF20LUU LMK20LUU LMH20LUU 5 260 225 247 20 -6 1400 2740 20 32 80 54 8 43 42 38 36 24 5.5x9x5.1 LMF/K/H20LUU

0 0

LMF25LUU LMK25LUU LMH25LUU 6 540 500 525 20 -6 1560 3140 25 40 112 62 8 51 50 46 40 32 5.5x9x5.1 LMF/K/H25LUU

-12 -19

LMF30LUU LMK30LUU LMH30LUU 6 680 590 645 20 -8 2490 5490 30 45 123 74 10 60 58 51 49 35 6.6x11x6.1 LMF/K/H30LUU

LMF35LUU LMK35LUU 6 1020 930 25 -8 2650 6270 35 52 135 0 82 0 10 67 64 - - - 6.6x11x6.1 LMF/K/H35LUU

0 0 -400 -300

LMF40LUU LMK40LUU 6 1570 1380 25 -10 3430 8040 40 60 151 96 13 78 75 - - - 9x14x8.1 LMF/K/H40LUU

-15 -22

LMF50LUU LMK50LUU 6 3600 3400 25 -13 6080 15900 50 80 192 116 13 98 92 - - - 9x14x8.1 LMF/K/H50LUU

LMF60LUU LMK60LUU 6 4500 4060 25 -13 7550 20000 60 0/-20 90 0/-25 209 134 18 112 106 - - - 11x17x11.1 LMF/K/H60LUU

1N=0.102kgf

23 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 24

Japan Japan

LMEF/K L Series LMEF/K L Series

L

H

d1

d2

K

D1

D

D

PC D

PC

A

A

LMEF L LMEK L

LMEF L LMEK L

Eccentricity

Radial Basic Load Main Dimensions and Tolerance

Ball Weight Clearance Rating

Part No. (max) dr Tolerance D Tolerance L Tolerance D1 Tolerance H PCD K Part No.

Circuit (g) (max) C Co d1xd2xh

m (mm) ( m) (mm) ( m) (mm) ( m) (mm) ( m) (mm) (mm) (mm)

m N N

LMEF8LUU LMEK8LUU 4 59 51 15 -3 421 804 8 16 0/-13 46 32 5 24 25 3.5x6x3.1 LMEF/K8LUU

+9

-1

LMEF12LUU LMEK12LUU 4 110 90 15 -4 813 1570 12 22 61 0 42 0 6 32 32 4.5x7.5x4.1 LMEF/K12LUU

0

-16 -300 -200

LMEF16LUU LMEK16LUU 5 160 135 15 -4 921 1780 16 26 68 46 6 36 35 4.5x7.5x4.1 LMEF/K16LUU

+11

-1

LMEF20LUU LMEK20LUU 5 260 225 17 -6 1370 2740 20 32 80 54 8 43 42 5.5x9x5.1 LMEF/K20LUU

0

LMEF25LUU LMEK25LUU 6 540 500 17 -6 1570 3140 25 40 112 62 8 51 50 5.5x9x5.1 LMEF/K25LUU

+13 -19

-2

LMEF30LUU LMEK30LUU 6 815 720 17 -8 2500 5490 30 47 123 76 10 62 60 6.6x11x6.1 LMEF/K30LUU

0 0

LMEF40LUU LMEK40LUU 6 1805 1600 20 -8 3430 8040 40 62 151 98 13 80 75 9x14x8.1 LMEF/K40LUU

0 -400 -300

+16 -22

LMEF50LUU LMEK50LUU 6 2820 2620 20 -13 6080 15900 50 75 192 112 13 94 88 9x14x8.1 LMEF/K50LUU

-4

LMEF60LUU LMEK60LUU 6 4920 4480 25 -13 7550 20000 60 90 0/-25 209 134 18 112 106 11x17x11.1 LMEF/K60LUU

1N=0.102kgf

25 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 26

Japan Japan

LMF/KC Series LMEF/KC Series

Main Dimensions and Tolerance Basic Main Dimensions and Tolerance Basic

Ball Weight Load Weight Eccen- Load

Eccen- Rating Ball Rating

Part No. Circuit tricity C Co Part No. Circuit tricity

(g) dr Tolerance D Tolerance L Tolerance I D1 K H PCD d1 d2 h (g) dr Tolerance D Tolerance L Tolerance I D1 K H PCD d1 d2 h C Co

( m) ( m)

Mm ( m) mm ( m) mm ( m) mm mm mm mm mm mm mm mm CN CON mm ( m) mm ( m) mm ( m) mm mm mm mm mm mm mm mm CN CON

F K F K

LMFC6 LMEFC8 0

4 31 25 6 12 35 15 28 22 5 20 3.5 6 3.1 323 529 4 59 51 8 16 46 20.5 32 25 5 24 3.5 6 3.1 431 804

LMKC6 0 LMEKC8 -13

+9

LMFC8 -13 LMEFC12 -1

4 51 43 8 15 45 20 32 25 5 24 3.5 6 3.1 431 784 4 110 90 12 22 61 27.5 42 32 6 32 4.5 7.5 4.1 15 813 1570

LMKC8 LMEKC12 0 0

LMFC10 LMEFC16 -16 -300

4 98 78 10 19 55 24.5 40 30 6 29 4.5 7.5 4.1 588 1100 5 160 135 16 26 68 31 46 35 6 36 4.5 7.5 4.1 921 1780

LMKC10 0 LMEKC16 +11

-10 15 -1

LMFC12 LMEFC20

4 110 90 12 21 57 -300 25.5 42 32 6 32 4.5 7.5 4.1 813 1570 5 260 225 20 32 80 36 54 42 8 43 5.5 9 5.1 1370 2740

LMKC12 0 LMEKC20

LMFC13 -16 LMEFC25 0

4 130 108 13 23 61 27.5 43 34 6 33 4.5 7.5 4.1 813 1570 6 540 500 25 40 112 52 62 50 8 51 5.5 9 5.1 17 1570 3140

LMKC13 LMEKC25 +13 -19

LMFC16 LMEFC30 -2

5 190 165 16 28 70 32 48 37 6 38 4.5 7.5 4.1 1230 2350 6 815 720 30 47 123 56.5 76 60 10 62 6.6 11 6.1 2500 5490

LMKC16 LMEKC30

LMFC20 LMEFC40 0

5 260 225 20 32 80 36 54 42 8 43 5.5 9 5.1 1400 2740 6 1805 1600 40 62 151 69 98 75 13 80 9 14 8.1 3430 8040

LMKC20 LMEKC40 0 -400

-22 20

LMFC25 0 0 LMEFC50 +16

6 540 500 25 40 112 52 62 50 8 51 5.5 9 5.1 20 1560 3140 6 2820 2620 50 -4 75 192 89.5 112 88 13 94 9 14 8.1 6080 15900

LMKC25 -12 -19 LMEKC50

LMFC30 LMEFC60 0

6 680 590 30 45 123 56.5 74 58 10 60 6.6 11 6.1 2490 5490 6 4920 4480 60 90 209 95.5 134 106 18 112 11 17 11.1 25 7550 20000

LMKC30 LMEKC60 -25

LMFC35 1N=0.102kgf

6 1020 930 35 52 135 62.5 82 64 10 67 6.6 11 6.1 2650 6270

LMKC35 0

LMFC40 0 0 -400

6 1570 1380 40 60 154 69 96 75 13 78 9 14 8.1 25 3430 8040

LMKC40 -15 -22

LMFC50

6 3600 3400 50 80 192 89.5 116 92 13 98 9 14 8.1 6080 15900

LMKC50

LMFC60 0 0

6 4500 4060 60 90 209 95.5 134 106 18 112 11 17 11.1 30 7550 20000

LMKC60 -20 -25

1N=0.102kgf

27 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 28

Japan Japan

Slide unit SC Type

L

W

4-S1

B +_ 0.2 E C

h +_ 0.02

A

e

Japan

G

H

4-S2 D+_ 0.02

SC S

Main dimensions mm Basic Load

Rating Weight

Part No.

C Co g

h D W H G A B E S1xe S2 C L

N N

SC8UU 11 17 34 22 18 6 24 5 M4X8 3.4 7.7 15.4 274 392 27

SC10UU 13 20 40 26 21 8 28 6 M5X12 4.3 9.95 19.9 372 549 53

SC12UU 15 21 42 28 24 8 30.5 5.75 M5X12 4.3 10.45 20.9 510 784 60

SC13UU 15 22 44 30 24.5 8 33 5.5 M5X12 4.3 10.45 20.9 510 784 64

SC16UU 19 25 50 38.5 32.5 9 36 7 M5X12 4.3 12 24 774 1180 110

SC20UU 21 27 54 41 35 11 40 7 M6X12 5.2 14 28 882 1370 144

SC25UU 26 38 76 51.5 42 12 54 11 M8X18 7 18.9 37.8 980 1570 340

SC30UU 30 39 78 59.5 49 15 58 10 M8X18 7 20.65 41.3 1574 2740 424

SC35UU 34 45 90 68 54 18 70 10 M8X18 7 22.65 45.3 1670 3140 626

SC40UU 40 51 102 78 62 20 80 11 M10X25 8.7 28.15 56.3 2160 4020 1000

SC50UU 52 61 122 102 80 25 100 11 M10X25 8.7 34.4 68.8 3820 7940 2100

29 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 30

Japan Japan

Slide unit SC Type Slide unit SC Type

W

4-S1 W

B +_ 0.2 E L L

4-S1

B +_ 0.2 E C +_ 0.2

C _ 0.2

+

h +_ 0.02

A

h +_ 0.02

A

e

G

G

H

H

A-M6x1

D+_ 0.02 N

SC L 4-S2

4-S2 D+_ 0.02

SC

Main dimensions mm Basic Load Main dimensions mm Basic Load

Rating Weight Rating Weight

Part No. Part No.

h D W H G A B E S1 e S2 C L C Co (g) C Co (g)

h D W H G A N B E S1 e S2 C L

N N N N

SC6UU 9 15 30 18 15 6 20 5 M4 8 M3 15 25 206 265 34 SC8LUU 11 17 34 22 18 6 7 24 5 M4 8 M3 42 58 431 784 102

SC8UU 11 17 34 22 18 6 24 5 M4 8 M3 18 30 274 392 52 SC10LUU 13 20 40 26 21 8 7 28 6 M5 12 M4 46 68 588 1100 180

SC10UU 13 20 40 26 21 8 28 6 M5 12 M4 21 35 372 549 92 SC12LUU 15 21 42 28 24 8 6.5 30.5 5.75 M5 12 M4 50 70 813 1570 205

SC12UU 15 21 42 28 24 8 30.5 5.75 M5 12 M4 26 36 510 784 102 SC13LUU 15 22 44 30 24.5 8 6.5 33 5.5 M5 12 M4 50 75 813 1570 240

SC13UU 15 22 44 30 24.5 8 33 5.5 M5 12 M4 26 39 510 784 120 SC16LUU 19 25 50 38.5 32.5 9 6 36 7 M5 12 M4 60 85 1230 2350 400

SC16UU 19 25 50 38.5 32.5 9 36 7 M5 12 M4 34 44 774 1180 200 SC20LUU 21 27 54 41 35 11 7 40 7 M6 12 M5 70 96 1400 2740 570

SC20UU 21 27 54 41 35 11 40 7 M6 12 M5 40 50 882 1370 255 SC25LUU 26 38 76 51.5 42 12 4 54 11 M8 18 M6 100 130 1560 3140 1200

SC25UU 26 38 76 51.5 42 12 54 11 M8 18 M6 50 67 980 1570 600 SC30LUU 30 39 78 59.5 49 15 5 58 10 M8 18 M6 110 140 2490 5490 1480

SC30UU 30 39 78 59.5 49 15 58 10 M8 18 M6 58 72 1570 2740 735 SC35LUU 34 45 90 68 54 18 5.5 70 10 M8 18 M6 120 155 2650 6270 2200

SC35UU 34 45 90 68 54 18 70 10 M8 18 M6 60 80 1670 3140 1100 SC40LUU 40 51 102 78 62 20 5 80 11 M10 25 M8 140 175 3430 8040 3200

SC40UU 40 51 102 78 62 20 80 11 M10 25 M8 60 90 2160 4020 1590 SC50LUU 52 61 122 102 80 25 5 100 11 M10 25 M8 160 215 6080 15900 6700

SC50UU 52 61 122 102 80 25 100 11 M10 25 M8 80 110 3820 7940 3340 1N=0.102kgf

1N=0.102kgf

31 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 32

Japan Japan

Slide Unit SME Type Slide Unit SMY Type

W L W

E 0.02 E 0.02

4-S

_ 0.2

C+ 4-S L

B 0.2 B 0.2

C 0.2

T

T

h 0.02

h 0.02

e

e

F

F

N

h1 h1

SME ¦È

SMY ¦È

Main dimensions mm Main dimensions mm

Basic Load Weight Basic Load Weight

Part No. Slide Bush Rating Part No . Slide Bush Rating

(g) e (g)

h E W L F A h1 B C S e N N h E W L F T N h1 B C S N N

SME16UU 20 22.5 45 45 33 9 10 80 32 30 M5 12 LM16UU-OP 774 1180 150 SMY16UU 20 25 50 45 33 9 6 10 80 36 30 M5 12 LM16UU-OP 774 1180 170

SME20UU 23 24 48 50 39 11 10 60 35 35 M6 12 LM20UU-OP 882 1370 200 SMY20UU 23 27 54 50 39 11 7 10 60 40 35 M6 12 LM20UU-OP 882 1370 240

SME25UU 27 30 60 65 47 14 11.5 50 40 40 M6 12 LM25UU-OP 980 1570 450 SMY25UU 27 38 76 65 47 14 7 11.5 50 54 40 M6 12 LM25UU-OP 980 1570 580

SME30UU 33 35 70 70 56 15 14 50 50 50 M8 18 LM30UU-OP 1570 2740 630 SMY30UU 33 39 78 70 56 15 7 14 50 58 50 M8 18 LM30UU-OP 1570 2740 720

SME35UU 37 40 80 80 63 18 16 50 55 55 M8 18 LM35UU-OP 1670 3140 925 1N=0.102kgf

1N=0.102kgf

33 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 34

Japan Japan

Shaft Support SK Type

_ 0.05

G+

2-T

Japan

C

_ 0.02

h+

E

S R

SK

A B

Main dimensions mm Clamping Mounting

Shaft Weight

Part No . bolt bolt

diameter h G W B C E F R S T (g)

designation designation

SK-8 8 20 21 42 14 32.8 6 18 32 5 5.5 M4 M5 24

SK-10 10 20 21 42 14 32.8 6 18 32 5 5.5 M4 M5 24

SK-12 12 23 21 42 14 37.5 6 20 32 5 5.5 M4 M5 30

SK-13 13 23 21 42 14 37.5 6 20 32 5 5.5 M4 M5 30

SK-16 16 27 24 48 16 44 8 25 38 5 5.5 M4 M5 40

SK-20 20 31 30 60 20 51 10 30 45 7.5 6.6 M5 M6 70

SK-25 25 35 35 70 24 60 12 38 56 7 6.6 M6 M6 130

SK-30 30 42 42 84 28 70 12 44 64 10 9 M6 M8 180

SK-35 35 50 49 98 32 82 15 50 74 12 11 M8 M10 270

SK-40 40 60 57 114 36 96 15 60 90 12 11 M8 M10 420

SK-50 50 70 63 126 40 120 18 74 100 13 14 M12 M12 750

35 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 36

Japan Japan

Shaft Support SHF T ype Base Support SA Type

G 0.02

L T K

H 0.02

B

F

2-S

E

P

J

N MxP N

T S

H

G

SA A B

SHF F

Main dimensions mm

Shaft Weight

Part No .

Dia H G A B C J K L N MxP S T U (g)

h E F

SA16-200L 200 25 1x150 200

SA16-300L 300 75 1x150 300

Main dimensions mm SA16-400L 16 25 20 40 400 17.8 5 11.7 18.5 8 80 50 2x150 30 5.5 M5 400

Clamping Mounting

Shaft Weight SA16-500L 500 25 3x150 500

Part No . bolt bolt

diameter L T F B G H S (g) SA16-600L 600 75 3x150 600

designation designation

SA20-200L 200 25 1x150 200

SA20-300L 300 75 1x150 300

SHF-10 10 43 10 5 32 20 24 5.5 M5 M4 13

SA20-400L 20 27 22.5 45 400 17.7 5 10 19 8 50 50 2x150 30 5.5 M6 400

SHF-12 12 47 13 7 36 25 28 5.5 M5 M4 20

SA20-500L 500 25 3x150 510

SHF-13 13 47 13 7 36 25 28 5.5 M5 M4 20 SA20-600L 600 75 3x150 610

16 8 31 M5 M4 SA25-300L 300 50 1x200 430

SHF-16 50 16 40 28 5.5 27

SA25-400L 400 100 1x200 580

SHF-20 20 60 20 8 48 34 37 7 M6 M5 40 25 33 27.5 55 21 6 12 21.5 8 50 35 6.5 M6

SA25-500L 500 50 2x200 730

SHF-25 25 70 25 10 56 40 42 7 M6 M5 60 SA25-600L 600 100 2x200 880

SHF-30 30 80 30 12 64 46 50 9 M8 M6 110 SA30-300L 300 50 1x200 550

SA30-400L 400 100 1x200 730

SHF-35 35 92 35 14 72 50 58 12 M10 M8 380 30 37 30 60 22.8 7 13 26.5 103 50 40 6.5 M8

SA30-500L 500 50 2x200 920

SHF-40 40 102 40 16 80 56 67 12 M10 M10 510 SA30-600L 600 100 2x200 1100

SHF-50 50 122 50 19 96 70 83 14 M12 M12 890 SA35-300L 300 50 1x200 700

SA35-400L 400 100 1x200 950

35 43 32.5 65 26.5 8 15.5 28 13 50 45 9 M8

SA35-500L 500 50 2x200 1190

SA35-600L 600 100 2x200 1420

37 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 38

Japan Japan

Slide Unit TA Type Slide Shaft SFP Type

E G

1.5S

h X S1

D

T

a1

a2 d1

O N P MxP N

C L

L

B

TA SFP

Material: Chrome Steel(SUJ2)

Part Dimensions (mm) Mounting Dimension(mm)

Shaft Weight Treatment: Heat treatment, Grinding & Surface Hard Chrome

No. Diameter (g) Hardress: HRC 62+2

E h B L H T X C N MxP S1 a1 a2 d1

Surface Roughness: 1.5um Rmax

190 1x150 200 Special(Machining on raghent)

340 2x150 360

TA16 16 25 22.14 50 14.84 6 8 60 o 37 20 5.5 6 9.5 5.5

640 4x150 670 Main dimensions mm

Effective Case Weight

940 6x150 980 Part No Max Longth

D Tolercnce Herdened Zone (g)

340 2x150 365

640 4x150 690

TA20 20 27.5 29.01 55 19.64 8 8 50 o 40 20 5.5 6.5 11 6.5 SFP-3 3 250 0.06

940 6x150 1015

SFP-4 4 -4 300 0.10

1240 8x150 1340

250 1x200 400 SFP-5 5 -12 300 0.16

450 2x200 715 SFP-6 6 1000 0.23

TA25 25 32.5 31.97 65 20 10 8 50 o 45 25 6.6 6.5 11 6.6

850 4x200 1350 1.5

SFP-8 8 -5 1000 0.40

1250 6x200 1990

SFP-10 10 -14 1000 0.62

450 2x200 900

850 4x200 1680 SFP-12 12 2000 0.89

TA30 30 37.5 36.52 75 22.28 12 10.3 50 o 55 25 6.6 8.5 14 9 -6

1250 6x200 2500 SFP-13 13 2000 1.05

-17

1450 7x200 2900

SFP-16 16 3000 1.58

SFP-20 20 2.0 3000 2.47

Type number format: -7

SFP-25 25 3000 3.85

-20

TA 190L SFP-30 30 3000 5.55

2.5

SFP-35 35 3000 7.55

-9

SFP-40 40 3000 9.87

-25

SFP-50 50 3000 15.41

SFP-60 60 -10 3.0 3000 22.20

SFP-80 80 -29 3000 39.46

SFP-100 100 -12 3000 61.66

-34

39 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 40

Japan Japan

Slide Shaft SFP Type Dimensions of Assemble

C

A1 D 0.2

G 4-J

B1 0.2

1.5S

Dg6

B

G1

F

H 0.2

E A

P/2 P 0.1 P/2

h

L

G2

Hard Chromed for the surface the shafting K B2

CL

E 0.2 A2 DL 0.2

Main dimensions mm

Part No .

D A B P L E

SFPT 16 16 M5x0.8P 12 150 3000 6

SFPT 20 20 M6x1.0P 16 150 3000 7.8

SFPT 25 25 M6x1.0P 20 200 3000 7.8

2 4 1

SFPT 30 30 M8x1.25P 25 200 3000 8.5

SFPT 35 35 M8x1.25P 30 200 3000 8.5

Main dimensions mm

Shaft

Diameter H h E A1 A2 B1 B2 C CL DL D F G1 G2 J K

16 45 25 2.5 45 40 32 30 45 82 82 30 33 9 5 M5x12 5.5

Main dimensions mm 20 50 27 1.5 48 45 35 30 50 92 92 35 39 11 5 M6x12 5.5

Part No . 25 60 33 2.5 60 55 40 35 65 124 100 40 47 14 6 M6x12 6.5

P/2 P L

30 70 37 5 70 60 50 40 70 134 115 50 56 15 7 M8x18 6.5

SFPT 16 75 150 300 400 500 600 900 1200 1500 1800 2100 2400 2700 3000

35 80 43 7.5 80 65 55 45 80 150 126 55 63 18 8 M8x18 9

SFPT 20 75 150 300 400 500 600 900 1200 1500 1800 2100 2400 2700 3000

1 Support: SA Type

SFPT 25 100 200 300 400 500 600 800 1000 1200 1600 2000 2400 2800 3000

2 Shaft: SFPT Type

SFPT 30 100 200 300 400 500 600 800 1000 1200 1600 2000 2400 2800 3000

3 Slide Unit: SME Type(Standard Type)

SFPT 35 100 200 300 400 500 600 800 1000 1200 1600 2000 2400 2800 3000 SMY Type(Adjustable Type)

4 Slide Unit: SME L Type(Long Type)

41 NATEC CORPORATION LTD. JAPAN NATEC CORPORATION LTD. JAPAN 42

Japan

BALL BUSHING COMPARISON LIST

KOYO IKO THK NSK NB EASE

LM6UU SDM6 LM61219 LM-6 SM-6 SDM6

LM8SUU SDM8S LM81517 LM-8S LB-8A SM-8S SDM8S

LM8UU SDM8 LM81524 LM-8 LB-8 SM-8 SDM8

Lm10UU SDM10 LM101929 LM-10 LB-10 SM-10 SDM10

Lm12UU SDM12 LB-12 SDM12

LM13UU SDM13 LM132332 LM-13 LB-13 SM-13 SDM13

Lm16UU SDM16 LM162837 LM-16 LB-16 SM-16 SDM16

Lm20UU SDM20 LM203242 LM-20 LB-20 SM-20 SDM20

LM25UU SDM25 LM254059 LM-25 LB-25 SM-25 SDM25

LM30UU SDM30 LM304564 LM-30 LB-30 SM-30 SDM30

LM35UU SDM35 LM355270 LM-35 LB-35 SM-35 SDM35

SDM38 LM385776 LM-38 SM-38 SDM38

Lm40UU SDM40 LM406080 LM-40 LB-40 SM-40 SDM40

Lm50UU SDM50 LM5080100 LM-60 LB-50 SM-50 SDM50

LM60UU SDM60 LM6090110 LM-50 LB-60A SM-60 SDM60

SDM80 LM80120140 LM-80 LB-80A SM-80 SDM80

SDM100 LM100150175 LM-100 SM-100 SDM100

LME5UU SDE5 LME51222 LME-5 LBE-5 KB-5 SDE5

LME8UU SDE8 LME81625 LME-8 LBE-8 KB-8 SDE8

LME12UU SDE12 LME122232 LME-12 LBE-12 KB-12 SDE12

LME16UU SDE16 LME162636 LME-16 LBE-16 KB-16 SDE16

LME20UU SDE20 LME203245 LME-20 LBE-20 KB-20 SDE20

LME25UU SDE25 LME254058 LME-25 LBE-25 KB-25 SDE25

LME30UU SDE30 LME304768 LME-30 LBE-30 KB-30 SDE30

LME40UU SDE40 LME406280 LME-40 LBE-40 KB-40 SDE40

LME50UU SDE50 LME5075100 LME-50 LBE-50 KB-50 SDE50

LME60UU SDE60 LME6090125 LME-60 LBE-60 KB-60 SDE60

SDE80 LME80120165 LME-80 LBE-80 KB-80 SDE80

LMB4UU SDB4 LMB4812 LMB-4 SW-4 SDB4

LMB6UU SDB6 LMB61014 LMB-6 LIB-6 SW-6 SDB6

LMB8UU SDB8 LMB81420 LMB-8 LIB-8 SW-8 SDB8

SDB10 LIB-10 SDB10

LMB12UU SDB12 LMB122026 LMB-12 LIB-12 SW-12 SDB12

LMB16UU SDB16 LMB162536 LMB-16 LIB-16 SW-16 SDB16

LMB20UU SDB20 LMB203242 LMB-20 LIB-20 SW-20 SDB20

LMB24UU SDB24 LMB243848 LMB-24 LIB-24 SW-24 SDB24

LMB32UU SDB32 LMB324864 LMB-32 LIB-32 SW-32 SDB32

SDB40 LMB406080 LMB-40 LIB-40 SW-40 SDB40

SDB48 LMB487296 LMB-48 LIB-48 SW-48 SDB48

SDB64 LMB6496128 LMB-64 LIB-64 SW-64 SDB64

43 NATEC CORPORATION LTD. JAPAN

You might also like

- CSWIP 3.1 - Welding Inspector WIS5 (2017)Document699 pagesCSWIP 3.1 - Welding Inspector WIS5 (2017)reezman96% (70)

- Helicopter Flight Control High Level Software Requirements DocumentDocument7 pagesHelicopter Flight Control High Level Software Requirements DocumentLoc HuynhNo ratings yet

- Connect LabVIEW To Any PLC With ModbusDocument8 pagesConnect LabVIEW To Any PLC With ModbusLoc HuynhNo ratings yet

- Curves SurfacesDocument0 pagesCurves Surfacesnaveenbabu19100% (1)

- Haver Roto PackerDocument24 pagesHaver Roto Packercassindrome100% (2)

- Youssef Hashash: Duhee Park Chi-Chin TsaiDocument28 pagesYoussef Hashash: Duhee Park Chi-Chin TsaicabelmarNo ratings yet

- Roller Element Bearing ProblemDocument17 pagesRoller Element Bearing ProblemShivanshu BaranwalNo ratings yet

- Definition of Dynamic and Static Radial Load RatingsDocument2 pagesDefinition of Dynamic and Static Radial Load Ratingsalfrelia100% (1)

- Calculation of Life Span of Linear Systems 1: 'Technical CalculationsDocument1 pageCalculation of Life Span of Linear Systems 1: 'Technical CalculationsRan CoiNo ratings yet

- 13 Seat Belt Anchorage Analysis (ECER14) PDFDocument6 pages13 Seat Belt Anchorage Analysis (ECER14) PDFroparnNo ratings yet

- 13 Seat Belt Anchorage Analysis (ECER14)Document6 pages13 Seat Belt Anchorage Analysis (ECER14)JayDeep KhajureNo ratings yet

- Bearing Life EstimationDocument5 pagesBearing Life EstimationAhmad DarweeshNo ratings yet

- 1GA14ME118Document34 pages1GA14ME118Gurusharan Narasimha MurthyNo ratings yet

- Comparison of OMF IMF and SMFDocument2 pagesComparison of OMF IMF and SMFCarlo Dizon100% (1)

- Performance Study For Reinforced Concrete Bridge Piers Considering Seismic Capacity and DemandDocument37 pagesPerformance Study For Reinforced Concrete Bridge Piers Considering Seismic Capacity and DemandAslam KyonNo ratings yet

- 7.DisenoSismicoPortEsp Part2Document34 pages7.DisenoSismicoPortEsp Part2Richard SantosNo ratings yet

- Vacon NX Brake Resistor User ManualDocument38 pagesVacon NX Brake Resistor User Manualclaudir.calazansNo ratings yet

- Vacon NX Brake ResistorDocument26 pagesVacon NX Brake ResistorpeshoNo ratings yet

- Summary ReportDocument9 pagesSummary ReportMariappan .PNo ratings yet

- Summary Report JAGANDocument11 pagesSummary Report JAGANMariappan .PNo ratings yet

- Sun 2007Document5 pagesSun 2007Abdul AsifNo ratings yet

- Michael DarterDocument43 pagesMichael Darternajuka ghodvindeNo ratings yet

- Section 4006 Charging SystemDocument14 pagesSection 4006 Charging Systemlungu mihaiNo ratings yet

- N Series Crossed Roller Bearings: Compact, Lightweight and Highly Rigid Factory-Adjusted For Easy HandlingDocument5 pagesN Series Crossed Roller Bearings: Compact, Lightweight and Highly Rigid Factory-Adjusted For Easy HandlingkrisNo ratings yet

- Summary ReportkkkDocument10 pagesSummary ReportkkkMariappan .PNo ratings yet

- D90 Manual EngDocument1 pageD90 Manual EngshahzadNo ratings yet

- Summary ReportDocument36 pagesSummary ReportGhiyats D. U.No ratings yet

- Motor m49sp 2k eDocument1 pageMotor m49sp 2k emanuelantoniomenaNo ratings yet

- Paper Api 579 Free PDFDocument15 pagesPaper Api 579 Free PDFnegron_78No ratings yet

- 2019 Nascc - Emasa Heavy Lifts FinalDocument43 pages2019 Nascc - Emasa Heavy Lifts FinalLuiz Francisco Scudelari de MacedoNo ratings yet

- ZAPOTE - SLOPE STABILITY - LTPDocument3 pagesZAPOTE - SLOPE STABILITY - LTPAntoniette Samantha NacionNo ratings yet

- SKF Bearing SelectDocument3 pagesSKF Bearing Selectmechanical09No ratings yet

- Design Report of Idco Intake WellDocument38 pagesDesign Report of Idco Intake Wellbhanu1053No ratings yet

- Long Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesDocument24 pagesLong Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesPervy SageNo ratings yet

- Experimental Seismic Performance Evaluation of Bridge PiersDocument6 pagesExperimental Seismic Performance Evaluation of Bridge Piersaizaz ahmadNo ratings yet

- Crane Gantry Girder Design: Default Example: Input DataDocument13 pagesCrane Gantry Girder Design: Default Example: Input DataA MumtazNo ratings yet

- SKF - Product - Select ROLO ReenvioDocument7 pagesSKF - Product - Select ROLO Reenviojoaquin joseNo ratings yet

- RCDCODEDocument6 pagesRCDCODEGiemhel GeleraNo ratings yet

- SKF Bearing SelectDocument7 pagesSKF Bearing SelectJaimeNo ratings yet

- Reach Truck RTR 16Document2 pagesReach Truck RTR 16Dahn NguyenNo ratings yet

- Hydraulic Fracturing Design For Optimum WellDocument33 pagesHydraulic Fracturing Design For Optimum WellAoun Fateh100% (2)

- Research Paper On Nonlinear Optics FromDocument4 pagesResearch Paper On Nonlinear Optics FromSoumya Ranjan dasNo ratings yet

- Six KipsDocument10 pagesSix Kipsyoshdog@gmail.comNo ratings yet

- Rodamiento 6404: Informe CintaDocument7 pagesRodamiento 6404: Informe CintaMoco LocoNo ratings yet

- Laterally LoadDocument92 pagesLaterally LoadMadhusudan MadhuNo ratings yet

- Sedile 8Document1 pageSedile 8temporaneoNo ratings yet

- Electric Machinery Fundamentals Power EnergyDocument4 pagesElectric Machinery Fundamentals Power EnergyxflyNo ratings yet

- Summary ReportsssDocument12 pagesSummary ReportsssMariappan .PNo ratings yet

- Unistrut Engineering DataDocument18 pagesUnistrut Engineering DatazaxaxazNo ratings yet

- Suggested Procedure For Earthquake AnalysisDocument4 pagesSuggested Procedure For Earthquake AnalysisThomas John Doblas AgrabioNo ratings yet

- Diode 1N5341B THRU 1N5388B 1N53xxB DatasheetDocument3 pagesDiode 1N5341B THRU 1N5388B 1N53xxB DatasheetmaciejNo ratings yet

- Section 55 - Electrical System - Chapter 7Document14 pagesSection 55 - Electrical System - Chapter 7Cristian SterieNo ratings yet

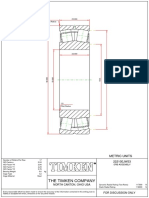

- The Timken Company: North Canton, Ohio UsaDocument1 pageThe Timken Company: North Canton, Ohio UsaDuc NguyenNo ratings yet

- 22210EJW33 TheTimkenCompany 2DSalesDrawing 07 06 2020 PDFDocument1 page22210EJW33 TheTimkenCompany 2DSalesDrawing 07 06 2020 PDFDuc NguyenNo ratings yet

- Silo Lifting Lug Weld Check (Shell To Lug) Jamtkraft Biofuel Vertical WeldDocument1 pageSilo Lifting Lug Weld Check (Shell To Lug) Jamtkraft Biofuel Vertical Weldanuj SinghNo ratings yet

- 3.4 Pushover AnalysisDocument40 pages3.4 Pushover AnalysisKetanNo ratings yet

- Project Job No.: Load Envelope - Combination 1 35.120Document4 pagesProject Job No.: Load Envelope - Combination 1 35.120alexanderNo ratings yet

- PT Beam - Analysis - PresentationDocument9 pagesPT Beam - Analysis - PresentationCường Nguyễn MạnhNo ratings yet

- 16th ASEP International Convetion - Presentation Paper - JOSE SY - 2Document9 pages16th ASEP International Convetion - Presentation Paper - JOSE SY - 2Ray RamiloNo ratings yet

- Seismic Load CalculationsDocument34 pagesSeismic Load CalculationsMuzaffarNo ratings yet

- Motor m42sp 6k eDocument1 pageMotor m42sp 6k eعبد القادر زيدوNo ratings yet

- W005M W10M: FeaturesDocument3 pagesW005M W10M: FeaturesCarlos SouzaNo ratings yet

- Polyspace Code Verification: Call Hierarchy Report For Project: PolyspaceDocument7 pagesPolyspace Code Verification: Call Hierarchy Report For Project: PolyspaceLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument27 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument12 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- Polyspace Code Verification: Call Hierarchy Report For Project: PolyspaceDocument6 pagesPolyspace Code Verification: Call Hierarchy Report For Project: PolyspaceLoc HuynhNo ratings yet

- Certkitiec Hdlcoder CDTDocument13 pagesCertkitiec Hdlcoder CDTLoc HuynhNo ratings yet

- DO Qualification Kit: Simulink Test™ Tool Qualification PlanDocument15 pagesDO Qualification Kit: Simulink Test™ Tool Qualification PlanLoc HuynhNo ratings yet

- Qualkitdo Rptgenext Qualificationreport SDD DiscreteDocument42 pagesQualkitdo Rptgenext Qualificationreport SDD DiscreteLoc HuynhNo ratings yet

- DO Qualification Kit: Simulink Design Verifier™ Tool Qualification PlanDocument16 pagesDO Qualification Kit: Simulink Design Verifier™ Tool Qualification PlanLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument29 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- How To Activate AutoDesk Any Product For FreeDocument8 pagesHow To Activate AutoDesk Any Product For FreeLoc HuynhNo ratings yet

- Neural Spiking and Synaptic Transmission: Action PotentialDocument6 pagesNeural Spiking and Synaptic Transmission: Action PotentialLoc HuynhNo ratings yet

- Sltest RefDocument610 pagesSltest RefLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument30 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- A Practical Applications of Virtual PLC Using LabVIEW SoftwareDocument6 pagesA Practical Applications of Virtual PLC Using LabVIEW SoftwareLoc HuynhNo ratings yet

- Developing Servo Indexing System Using Timing Screw For Automatic Liquid Filler in Manufacturing EnvironmentDocument17 pagesDeveloping Servo Indexing System Using Timing Screw For Automatic Liquid Filler in Manufacturing EnvironmentLoc HuynhNo ratings yet

- Cam - Follwer - B - en CF BearingDocument4 pagesCam - Follwer - B - en CF BearingLoc HuynhNo ratings yet

- Introduction To NI SoftMotion For SolidWorks - enDocument8 pagesIntroduction To NI SoftMotion For SolidWorks - enLoc HuynhNo ratings yet

- IEC Certification Kit: Simulink Requirements™ ISO 26262 Tool Qualification PackageDocument26 pagesIEC Certification Kit: Simulink Requirements™ ISO 26262 Tool Qualification PackageLoc HuynhNo ratings yet

- F940wgot-Twd-E: 7-I W I ADocument8 pagesF940wgot-Twd-E: 7-I W I ALoc HuynhNo ratings yet

- EG-Series-HIWIN CatalogDocument17 pagesEG-Series-HIWIN CatalogLoc HuynhNo ratings yet

- FP 80tDocument2 pagesFP 80tLoc HuynhNo ratings yet

- IEC Certification Kit: Model-Based Design For ISO 25119:2018Document18 pagesIEC Certification Kit: Model-Based Design For ISO 25119:2018Loc HuynhNo ratings yet

- MAL SeriesDocument5 pagesMAL SeriesSolikin PatiNo ratings yet

- Hydrofoil Seminar Report 2010Document27 pagesHydrofoil Seminar Report 2010Abhiram P Mohan100% (1)

- 6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitDocument17 pages6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitMuthu AlaguRajNo ratings yet

- Steinmetz Circuit Influence On The Electric System Harmonic ResponseDocument8 pagesSteinmetz Circuit Influence On The Electric System Harmonic ResponseLuis Angel Garcia ReyesNo ratings yet

- Pearson Coefficient of SkewnessDocument2 pagesPearson Coefficient of SkewnessTan Chin Huat100% (1)

- MerseburgDocument7 pagesMerseburgAkuwh SyaSyaNo ratings yet

- 8780.0ST.0000.00 I-Ret Antenna Tbb65 1.4M Alxt-824-960/1710-2170-65-14.7i/15i/15i-Ai - DDocument1 page8780.0ST.0000.00 I-Ret Antenna Tbb65 1.4M Alxt-824-960/1710-2170-65-14.7i/15i/15i-Ai - DDenny WijayaNo ratings yet

- Carbon Dioxide Removal by Ionic Liquid Sorbent (CDRILS) System DevelopmentDocument15 pagesCarbon Dioxide Removal by Ionic Liquid Sorbent (CDRILS) System Developmentfindersinc8111No ratings yet

- A Review On Flow Injection Analysis For Indirect Determination of Cyanide Ion in Environment by Flame Atomic Absorption SpectrometerDocument13 pagesA Review On Flow Injection Analysis For Indirect Determination of Cyanide Ion in Environment by Flame Atomic Absorption SpectrometerMamta AgarwalNo ratings yet

- Rolling Element Bearing Methodology Application Guide - 164934 PDFDocument36 pagesRolling Element Bearing Methodology Application Guide - 164934 PDFAbdoEmanuelMalverdiNo ratings yet

- Science Process Skills Hypothesis: Black BoxDocument11 pagesScience Process Skills Hypothesis: Black BoxMd KhairNo ratings yet

- Ssab Astm A537 C2Document2 pagesSsab Astm A537 C2vasotermiNo ratings yet

- Physio: TherapyDocument17 pagesPhysio: TherapyEd VikaNo ratings yet

- 6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysDocument12 pages6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysMuhammad Umer Farooq AwanNo ratings yet

- Second Order SystemDocument16 pagesSecond Order SystemAbdelrahman SelimNo ratings yet

- Untitled NotebookDocument12 pagesUntitled NotebookPuffy KungNo ratings yet

- Atoms, Molecules, and IonsDocument54 pagesAtoms, Molecules, and Ionsarsekerci813601No ratings yet

- Improved Synthesis of Cellulose Carbamates With Minimum Urea Based On An Easy Scale-Up MethodDocument8 pagesImproved Synthesis of Cellulose Carbamates With Minimum Urea Based On An Easy Scale-Up MethodRuchira WijesenaNo ratings yet

- Energy IsolamentoDocument24 pagesEnergy IsolamentoArtur KinalNo ratings yet

- Electrical Safety Analyzer: User ManualDocument28 pagesElectrical Safety Analyzer: User ManualJuan Diego Sierra TiradoNo ratings yet

- KDS R50XBR1R60XBR1Document300 pagesKDS R50XBR1R60XBR1Fay KingNo ratings yet

- Physics PracticalDocument7 pagesPhysics PracticalayarpitNo ratings yet

- Lktyr235a01 PH I Adv 1Document28 pagesLktyr235a01 PH I Adv 1Atharva GuptaNo ratings yet

- Earthquake Design and Protection of Underground StructuresDocument30 pagesEarthquake Design and Protection of Underground StructuresDebasis BarmanNo ratings yet

- On The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and CognitionDocument14 pagesOn The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and Cognitiondw wwNo ratings yet

- LR BendDocument9 pagesLR BendGiridharan GanesanNo ratings yet

- Unidad Lineal ParkerDocument14 pagesUnidad Lineal ParkerIsmael RiosNo ratings yet

- Experiment 302 Heat and CalorimetryDocument2 pagesExperiment 302 Heat and CalorimetryJasmin DionisioNo ratings yet