Professional Documents

Culture Documents

Ajts QCP Fab Format Rev 01

Ajts QCP Fab Format Rev 01

Uploaded by

Pradip DabhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ajts QCP Fab Format Rev 01

Ajts QCP Fab Format Rev 01

Uploaded by

Pradip DabhiCopyright:

Available Formats

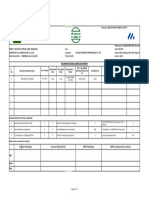

QAP. NO Vendor Doc.

No Rev: 01

Vendor Logo

QUALITY CONTROL PLAN DATE Vendor Doc. Date

PRODUCT xxxxxxx CLIENT AJTS CO. S.A.O.C.

QUANTITY xxxxxxxx CLIENT PO & DATE AJTS PO No & Date

Vendor name

Address & COMPANY

PAGE NO 1 of 4

INTERVENTION

SL.NO ACTIVITY REFERENCE DOCUMENT ACCEPTANCE CRITERIA FORMAT OF RECORD RESPONSIBILITY REMARKS

XXX TPI AJTS

1.0 DESIGN & PROCUREMENT ACTIVITIES

1.1 Quality Control Plan AJTS P.O. & ASME SEC IX Meets AJTS P.O. & ASME SEC IX Approved QCP QA/QC

(QCP) Approval Requirements Engineer A R A

1.2 Welding procedure ASME SEC IX Meets ASME SEC IX TPI Approved QA/QC

Specification Requirements WPS Engineer H R R

1.3 Procedure Qualification ASME SEC IX Meets ASME SEC IX TPI Approved PQR QA/QC

Record Requirements Engineer H R R

1.4 Welder Qualification ASME SEC IX Meets ASME SEC IX TPI Approved QA/QC

Records Requirements WQR Engineer H R R

1.5 Magnetic Particle Test ASME SEC IX/AWS D1.1, ASTM Meets ASME SEC IX/AWS D1.1, Approved MT QA/QC

Procedure E-709 ASTM E-709 Requirements Procedure Engineer H R R

2.0 RAW MATERIALS RECEIPT & INSPECTION

2.1 MS Items ASTM & PO Meets ASTM & PO Incoming Material QA/QC

Requirement Insp. Report & Engineer R R R

MTC

2.2 Welding consumable ASTM & PO Meets ASTM & PO Incoming Material QA/QC

Requirement Insp. Report & Engineer R R R

MTC

2.3 Abrasive Materials PO Meets PO Requirements Incoming Material QA/QC

Insp. Report & Engineer R R R

MTC

2.4 Paint materials PO & Fabrication Drawing Meets Fabrication Drawing & Incoming Material QA/QC Paint data sheet shall be submitted

PO Requirements Insp. Report & Engineer R R A for approval.

MTC

3.0 MATERIAL PREPARATIONS – GAS CUTTING, SHEARING & BENDING

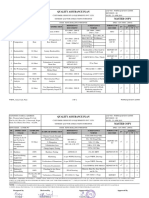

QAP. NO Vendor Doc. No Rev: 01

Vendor Logo

QUALITY CONTROL PLAN DATE Vendor Doc. Date

PRODUCT xxxxxxx CLIENT AJTS CO. S.A.O.C.

QUANTITY xxxxxxxx CLIENT PO & DATE AJTS PO No & Date

Vendor name

Address & COMPANY

PAGE NO 2 of 4

INTERVENTION

SL.NO ACTIVITY REFERENCE DOCUMENT ACCEPTANCE CRITERIA FORMAT OF RECORD RESPONSIBILITY REMARKS

XXX TPI AJTS

3.1 Visual Inspection Fabrication Drawing No Defect In-process Check Supervisor/

Record QA/QC H R R

Inspector

3.2 Dimension Check Fabrication Drawing Allowed Tolerance in In-process Check Supervisor/

Fabrication Drawing Record QA/QC H R R

Inspector

4.0 FABRICATION & FIT-UP COMPONENTS

4.1 Dimensional check Fabrication Drawing Allowed Tolerance in In-process Check Supervisor/

Fabrication Drawing Record QA/QC H W R

Inspector

4.2 Fit-up components, Fabrication Drawing Allowed Tolerance in In-process Check Supervisor/

Holes, PCDs Verifications Fabrication Drawing Record QA/QC H R R

Inspector

5.0 WELDING

5.1 Verification of Applicable ASME SEC IX, WPS & PQR Meets ASME SEC IX, WPS & In-process Check QA/QC

WPS/PQR PQR Requirement Record Inspector H R R

5.2 Verification of Welder ASME SEC IX, WPS & PQR Meets ASME SEC IX, WPS & In-process Check QA/QC

Qualification PQR Requirement Record Inspector H R R

5.3 Visual Inspection ASME SEC IX, WPS & PQR Meets ASME SEC IX, WPS & In-process Check QA/QC Note-Tag No should be include in

PQR Requirement Record Inspector H W R

inspection

5.4 Magnetic particle Test AWS D1.1, ASTM E-709 No Weld Defect MT Report QA/QC

on load bearing welds Inspector H R R

6.0 TANK LEAK TEST

QAP. NO Vendor Doc. No Rev: 01

Vendor Logo

QUALITY CONTROL PLAN DATE Vendor Doc. Date

PRODUCT xxxxxxx CLIENT AJTS CO. S.A.O.C.

QUANTITY xxxxxxxx CLIENT PO & DATE AJTS PO No & Date

Vendor name

Address & COMPANY

PAGE NO 3 of 4

INTERVENTION

SL.NO ACTIVITY REFERENCE DOCUMENT ACCEPTANCE CRITERIA FORMAT OF RECORD RESPONSIBILITY REMARKS

XXX TPI AJTS

6.1 Leak Test with 3.5psi Air Approved Leak Test Procedure 1hour-No Leak Leak Test Record Supervisor/

Pressure QA/QC H W R

Inspector

7.0 SURFACE PREPARATION AND PAINTING ACTIVITIES

7.1 Pre-Blasting Surface ISO 8501 Free from Grease, oil etc. Surface Supervisor/ Surface preparation & Painting

Cleaning Preparation & QA/QC H R R Report format shall be submitted for

Painting Report Inspector AJTS approval.

7.2 Grit Blasting ISO 8501 & Paint Data Sheet SA2½ (Min) Surface Supervisor/

Profile: 30 – 75 Microns Preparation & QA/QC H R R

Painting Report Inspector

7.3 Post-Blasting Surface ISO 8501 Free from Dust & Abrasive Surface Supervisor/

Cleaning Materials Preparation & QA/QC H R R

Painting Report Inspector

7.4 Internal Coating Approved Drawing & Paint DFT ≥ 50 Microns-HOR Surface Supervisor/

(Oil Resistant Paint) Data Sheet Preparation & QA/QC H R R

Painting Report Inspector

7.5 Strip Coat Zinc Rich Primer applied to all Surface Supervisor/

(Before Primer) weld joints by brush. Preparation & QA/QC H R R

Painting Report Inspector

7.6 Primer Coat Approved Drawing & Paint DFT ≥ 50 Microns- Zinc Rich Surface Supervisor/

Data Sheet Primer Preparation & QA/QC H R R

Painting Report Inspector

7.7 Intermediate Coat Approved Drawing & Paint DFT ≥ 150 Microns-High Build Surface Supervisor/ R

Data Sheet Epoxy Undercoat (Primer Preparation & QA/QC H R

Coat + Intermediate Coat) Painting Report Inspector

7.8 Top Coat Approved Drawing & Paint Total DFT ≥ 200 Microns Surface Supervisor/ R

Data Sheet Polyurethane High Gloss Preparation & QA/QC H R

Finish Painting Report Inspector

8.0 FINAL INSPECTION

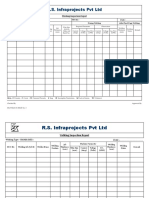

QAP. NO Vendor Doc. No Rev: 01

Vendor Logo

QUALITY CONTROL PLAN DATE Vendor Doc. Date

PRODUCT xxxxxxx CLIENT AJTS CO. S.A.O.C.

QUANTITY xxxxxxxx CLIENT PO & DATE AJTS PO No & Date

Vendor name

Address & COMPANY

PAGE NO 4 of 4

INTERVENTION

SL.NO ACTIVITY REFERENCE DOCUMENT ACCEPTANCE CRITERIA FORMAT OF RECORD RESPONSIBILITY REMARKS

XXX TPI AJTS

8.1 Visual Inspection Fabrication Drawing & No Coating Damages, Sags Final Inspection QA/QC Final inspection report format shall

Approved QCP Report Engineer H W R

be submitted for AJTS approval.

8.2 Dimensional Verification Fabrication Drawing & Dimensions within accepted Final Inspection QA/QC

Approved QCP Report Engineer H W R

tolerance

8.3 BOM Verification Fabrication Drawing & Positions of accessories and Final Inspection QA/QC

Approved QCP Report Engineer H W R

quantities to be matched

8.4 Paint Shade & DFT Fabrication Drawing & Shade: As per Fab. Drawing Final Inspection QA/QC

Verification Approved QCP Report Engineer H W R

DFT ≥ 200 Microns

9.0 DESPATCH ACTIVITIES

9.1 Documentation Fabrication Drawing & Comply Approved QCP 1)MTCs QA/QC

Approved QCP Requirement 2)Painting Report Engineer

3)MT Report H R R

4)Final Inspection

Report

9.2 Final Release Fabrication Drawing & Comply PO, Drawings & Inspection Release QA/QC

Approved QCP Approved QCP Note (IRN) Engineer H H R

Legend: Legend: A = Document Approval, R = Document Review, H = Hold Point, W = Witness

AJTS: Al-Jizzi Transformers & Switchgears Co S.A.O.C, TPI: Third party Inspection Agency.

Endorsement Prepared By: Approved By: AJTS APPROVAL

Signature

Name

Designation

You might also like

- Welding Log BookDocument1 pageWelding Log Booksamsurendran_mech4020No ratings yet

- Sebm024412 Wa-470-5Document1,204 pagesSebm024412 Wa-470-5ramonec123100% (15)

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Quality Procedure Procedure For Weld RepairDocument1 pageQuality Procedure Procedure For Weld Repairbalakumar rajaramNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- Welder Qualification: Procedure Qualification Thickness & Dia LimitsDocument4 pagesWelder Qualification: Procedure Qualification Thickness & Dia LimitsHoque AnamulNo ratings yet

- SA048-WSP-GEN-MTS-MNCR-2 Non-Conformance Report - Tested Stockpile BarricationDocument2 pagesSA048-WSP-GEN-MTS-MNCR-2 Non-Conformance Report - Tested Stockpile BarricationmustafaansmeNo ratings yet

- 8.fixture Inspection ReportDocument1 page8.fixture Inspection ReportBASAVA ENGINEERINGNo ratings yet

- Weekly Safety Inspection Report: SampleDocument3 pagesWeekly Safety Inspection Report: SampleAviects Avie JaroNo ratings yet

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 pageMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan Raja100% (1)

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- 3834 Requirements ListDocument4 pages3834 Requirements ListScott TrainorNo ratings yet

- Chhaparia Industries LTD.: In-Process Inspection ReportDocument4 pagesChhaparia Industries LTD.: In-Process Inspection ReportSwapnil BachhavNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Mau ReportDocument30 pagesMau ReportNguyễn Hoàng DũngNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 pageDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Control Plan m6 Flange NutDocument8 pagesControl Plan m6 Flange NutRANANo ratings yet

- E2 - Equipment Operators Daily ChecklistDocument1 pageE2 - Equipment Operators Daily ChecklistRob WillestoneNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- NO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2Document2 pagesNO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2sonnu151No ratings yet

- Annex-1-Process Flow ChartDocument1 pageAnnex-1-Process Flow ChartDeepak DasNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel Ndifon100% (1)

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDocument2 pagesWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNo ratings yet

- Equipment Calibration LogDocument5 pagesEquipment Calibration Logkero keropiNo ratings yet

- SKH Process Report1Document8 pagesSKH Process Report1Mohan KumarNo ratings yet

- Die Inward Inspection ReportDocument2 pagesDie Inward Inspection ReportRahul DevkateNo ratings yet

- Master List of InstrumentsDocument35 pagesMaster List of Instrumentskrichenaraj6931100% (1)

- Work Instruction For Inspection & ReportingDocument2 pagesWork Instruction For Inspection & ReportingDeepak DasNo ratings yet

- Welding Insection ReportDocument4 pagesWelding Insection ReportRanjeet MouryaNo ratings yet

- Hot Work Procedures: Fire ControlDocument10 pagesHot Work Procedures: Fire ControlSiraj KuvakkattayilNo ratings yet

- MOM - Control PlanDocument17 pagesMOM - Control PlanraghulramasamyNo ratings yet

- Welding Book Revised 2012 07 14Document15 pagesWelding Book Revised 2012 07 14surya1960No ratings yet

- Weld Log - 5000 WeldDocument234 pagesWeld Log - 5000 WeldRichard MitchellNo ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNo ratings yet

- RFI-3410 - Daily Fit Up Inspection Report-OKDocument92 pagesRFI-3410 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- IATF16949,2016Document28 pagesIATF16949,2016Vinni WadeNo ratings yet

- F-05 Corrective Action FormDocument1 pageF-05 Corrective Action Formsuhara hussainNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- ICM Certification (P) LTD.: STANDARD: - ISO 9001: 2015 Audit ReportDocument18 pagesICM Certification (P) LTD.: STANDARD: - ISO 9001: 2015 Audit ReportRohit Attri100% (1)

- Production Procedure ReportDocument1 pageProduction Procedure ReportHarish SivakumarNo ratings yet

- Shielded Metal Arc Welding: Mild Steel III (E6011)Document33 pagesShielded Metal Arc Welding: Mild Steel III (E6011)greatsteelNo ratings yet

- Body Flanges On Shells: (Name and Address of Manufacturer)Document3 pagesBody Flanges On Shells: (Name and Address of Manufacturer)David SantosNo ratings yet

- RCS: 90 & Above Round: Above 100: Heat. No. To Be Provided On Each BarDocument2 pagesRCS: 90 & Above Round: Above 100: Heat. No. To Be Provided On Each BarAmit Kumar UkeNo ratings yet

- 01fitting in FabricationDocument11 pages01fitting in Fabricationv.bhamidi100% (1)

- S355 To Hardox 450Document1 pageS355 To Hardox 450Bien NguyenDuyNo ratings yet

- GM Process SheetDocument1 pageGM Process SheetSuraj RawatNo ratings yet

- Quy Trình Ks Chất LượngDocument18 pagesQuy Trình Ks Chất LượngNguyễn Hoàng DũngNo ratings yet

- PPAP Part Submission WarrantDocument4 pagesPPAP Part Submission WarrantazadNo ratings yet

- PreheatDocument2 pagesPreheatScott TrainorNo ratings yet

- Quality Control PlanDocument13 pagesQuality Control Plandadz mingiNo ratings yet

- QAP K-HouseDocument4 pagesQAP K-HouseAbhinash TamangNo ratings yet

- Tabela de Peso Parafusos Sextavados A325Document5 pagesTabela de Peso Parafusos Sextavados A325w.araujo.xxxxNo ratings yet

- FeedDocument45 pagesFeedcristianNo ratings yet

- Model BV54 Rate of Flow Control Valve: DescriptionDocument4 pagesModel BV54 Rate of Flow Control Valve: DescriptionadrianioantomaNo ratings yet

- (Project Name) : Inspection Checklist - Tiling (Floor & Wall)Document1 page(Project Name) : Inspection Checklist - Tiling (Floor & Wall)Mohd TameziNo ratings yet

- C" Series: Charcoal AdsorbersDocument2 pagesC" Series: Charcoal Adsorbersramana_96392699No ratings yet

- Work Method Statement For X-A T#31 To 34Document8 pagesWork Method Statement For X-A T#31 To 34Twin Bulls100% (1)

- Zincform ASTM A653 Grade 50/1: General Description: Normal / Optional Supply ConditionsDocument1 pageZincform ASTM A653 Grade 50/1: General Description: Normal / Optional Supply ConditionsmuathNo ratings yet

- Chapter 1 Solution of RoboticsDocument4 pagesChapter 1 Solution of RoboticsEngr ShabirNo ratings yet

- Speeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)Document6 pagesSpeeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)naninoNo ratings yet

- Dimension Data of Segmental Box GirderDocument1 pageDimension Data of Segmental Box GirderAlok vermaNo ratings yet

- Presentation On Design of Crankshaft Using Catia V5Document16 pagesPresentation On Design of Crankshaft Using Catia V5Naveen KumarNo ratings yet

- A.2 MC Conexion PIPE A W6x22Document7 pagesA.2 MC Conexion PIPE A W6x22Vivaldi ChangraNo ratings yet

- RA 09 Internal Bill On JMRDocument34 pagesRA 09 Internal Bill On JMRbillingNo ratings yet

- Elasticity Theory Applications and Numerics 4Th Edition Full ChapterDocument41 pagesElasticity Theory Applications and Numerics 4Th Edition Full Chapterwallace.peterson700100% (28)

- Bison Manual Chucks 2022Document128 pagesBison Manual Chucks 2022perfectmachineserviceNo ratings yet

- Worthington IA Dryer PM PlanDocument1 pageWorthington IA Dryer PM PlanUmair A. KhanNo ratings yet

- FG Valves Catalogue 4ppDocument4 pagesFG Valves Catalogue 4ppInternational companyNo ratings yet

- Actuador Valtek PDFDocument8 pagesActuador Valtek PDFEduardo Landa GonzalezNo ratings yet

- Unit 2 - Design of Joints & LeverDocument94 pagesUnit 2 - Design of Joints & LeverAshish ANo ratings yet

- Ficha Tecnica Extractor Gillotina PDFDocument36 pagesFicha Tecnica Extractor Gillotina PDFDarioNo ratings yet

- C-PVC Fire Sprinkler System: ... Your Safety Is Our ConcernDocument4 pagesC-PVC Fire Sprinkler System: ... Your Safety Is Our Concernarjun 11No ratings yet

- Introduction To ASME IXDocument5 pagesIntroduction To ASME IXWilhelm van RooyenNo ratings yet

- Detailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestDocument9 pagesDetailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestMehdi NorouziNo ratings yet

- Chapter 71 - Power Plant: BHT-206L4-MM-9Document54 pagesChapter 71 - Power Plant: BHT-206L4-MM-9Raisa RabeyaNo ratings yet

- MTO Pipe Support LOT-1 - Rev.A - 04.06.2022Document2 pagesMTO Pipe Support LOT-1 - Rev.A - 04.06.2022Pratama - Mech.Eng.No ratings yet

- BS en 10228-4 2016Document30 pagesBS en 10228-4 2016Morteza Shakerien100% (2)

- 13 - Flexistrut Ducting Tech Data v1.1 WebsiteDocument14 pages13 - Flexistrut Ducting Tech Data v1.1 WebsiteThái Trần VănNo ratings yet

- Hydrostatic Pump H1 045/053/060/068Document66 pagesHydrostatic Pump H1 045/053/060/068patitovera0% (1)

- 4th Sem Milling MachineDocument32 pages4th Sem Milling MachineKaran KantiNo ratings yet