Professional Documents

Culture Documents

Inspection and Test Plan (Itp) Rades-C 450 MW CCPP Project: Gama Supplier/Subcontractor 3Rd Party Steg

Inspection and Test Plan (Itp) Rades-C 450 MW CCPP Project: Gama Supplier/Subcontractor 3Rd Party Steg

Uploaded by

Ramzi ZoghlamiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Test Plan (Itp) Rades-C 450 MW CCPP Project: Gama Supplier/Subcontractor 3Rd Party Steg

Inspection and Test Plan (Itp) Rades-C 450 MW CCPP Project: Gama Supplier/Subcontractor 3Rd Party Steg

Uploaded by

Ramzi ZoghlamiCopyright:

Available Formats

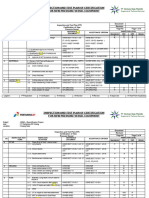

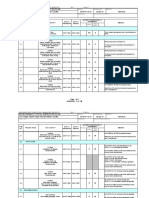

Date: 30/07/2019

ITP No: RADES-56-YC-QA-QP-CERI-7115

Rev: 0

Page No: 7

INSPECTION AND TEST PLAN (ITP)

RADES-C 450 MW CCPP PROJECT Report No:

Doc. Nr. :RADES-56-YC_-QA-QP-CERI-7115 LOCATION:RADES C 450 MW CCPP Site

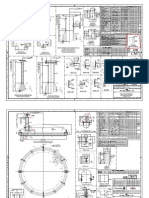

EQUIPMENT/PART SERIAL NO: STEAM TURBINE GENERATOR DRAWING NO:

INSPECTION LEVEL

REFERENCED ACCEPTANCE INSPECTION VERIFYING SUPPLIER/SUBCONTRACTOR GAMA 3RD PARTY STEG

ITEM NO ACTIVITY DESCRIPTION NOTES

DOCUMENTS CRITERIA FREQUENCY RECORD

LEVEL DATE SIGN LEVEL DATE SIGN LEVEL DATE SIGN LEVEL DATE SIGN

1 Before Starting activities

Approved Dwg, Manual of As per Vendor

1.1 Document review: • Verify IFU drawings & Check revision status 100% _ H R N.A R

installation Dwg/Specification

Material Receipt: • Check materials compliance with Spec. and Material Requisition in Approved Dwg, Manual of As per Vendor

1.2

terms of mechanical and chemical features. installation Dwg/Specification

100% _ H W S

1.3 Welding Book: check presence of welding book (WPS, PQR, WPQR…) ASME IX ASME IX 100% _ H S N.A S

1.4 Welders qualification ASME IX ASME IX 100% WPQR H H H W

Approved Dwg, Manual of As per Vendor

1.5 Foundation Release

installation Dwg/Specification

100% Site Handover H H N.A H

2 FOUNDATION WORKS OF ST GENERATOR

2.1 Inspection of Foundation

Approved Dwg, Manual of As per Vendor

2.1.1 Location and height of the foundation bolt. 100% 2 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

2.1.2 Location of the piping duct and opening. 100% _ H S N.A R

installation Dwg/Specification

2.2 Installation of Embedment for Generator

Approved Dwg, Manual of As per Vendor

2.2.1 Check Arrangement&Elevation&Location of Jack Plate and Flat Base Plate 100% 1,3 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

2.2.2 Blue Contact Check between Taper Key&Flat Base Plate 100% _ H W N.A S

installation Dwg/Specification

3 POSITIONING OF ST GENERATOR

Approved Dwg, Manual of As per Vendor

3.1 Check Setting of Seating Plate 100% 5 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.2 Check that no damage on generator stator 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.3 Check Cleanliness of Foundation & GEN Feet 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.4 Pre-set on floor level CT Trunk to GEN 100% _ H S N.A R

installation Dwg/Specification

Date: 30/07/2019

ITP No: RADES-56-YC-QA-QP-CERI-7115

Rev: 0

Page No: 7

INSPECTION AND TEST PLAN (ITP)

RADES-C 450 MW CCPP PROJECT Report No:

Doc. Nr. :RADES-56-YC_-QA-QP-CERI-7115 LOCATION:RADES C 450 MW CCPP Site

EQUIPMENT/PART SERIAL NO: STEAM TURBINE GENERATOR DRAWING NO:

INSPECTION LEVEL

REFERENCED ACCEPTANCE INSPECTION VERIFYING SUPPLIER/SUBCONTRACTOR GAMA 3RD PARTY STEG

ITEM NO ACTIVITY DESCRIPTION NOTES

DOCUMENTS CRITERIA FREQUENCY RECORD

LEVEL DATE SIGN LEVEL DATE SIGN LEVEL DATE SIGN LEVEL DATE SIGN

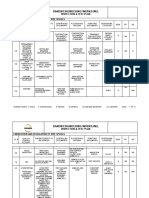

Approved Dwg, Manual of As per Vendor

3.5 Check Dismantling of Transportation Cover before Lifting 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.6 ST GEN on Bolt 100% _ H S N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.7 Check Visual Inspection of Stator, Windings,Core,Bearing Zone against any damage 100% _ H S N.A S

installation Dwg/Specification

Check Visual Inspection Rotor Surface, Rotor Body,Journal,Coupling and Ventilation Hole Approved Dwg, Manual of As per Vendor

3.8

against any damage.

100% _ H S N.A S

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.9 Check Insulation Resistance Measurement of Stator&Rotor 100% 22 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

3.10 Adjustment of Transport Lock Device-Check Gap of Stator Supporting Bolt 100% _ H S N.A S

installation Dwg/Specification

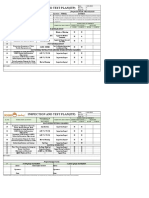

4 Installation Activities of ST GEN & Brushless Exciter

Approved Dwg, Manual of As per Vendor

4.1 Check Installation of CT Trunk, Bolt Tightening & Locking of Bolts 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.2 Check Installation of Main Lead and Bolt Tighetening 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.3 Check Insulation Tapping of Main Lead- Insulation Resistance of Stator Winding 100% 21 H W N.A S

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.4 Check Leakage Test of Air Cooler 100% 15 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.5 Check Installation of Air Make Up 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.6 Check Installation of Flow Sight 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.7 Check Initial Alignment of ST&STG 100% 10 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.8 Check Foundation of Brushless Exciter& Anchor Bolts 100% 6 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.9 Check Setting of Jack Plate, Flat Plates 100% 7 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.10 Check Grouting of Seating Plate 100% 8 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.11 Check Final Alignment of ST&STG Rotors 100% 11,13 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.12 Check Run Out at coupling after Combining ST&STG Rotors 100% 12 H W N.A W

installation Dwg/Specification

Date: 30/07/2019

ITP No: RADES-56-YC-QA-QP-CERI-7115

Rev: 0

Page No: 7

INSPECTION AND TEST PLAN (ITP)

RADES-C 450 MW CCPP PROJECT Report No:

Doc. Nr. :RADES-56-YC_-QA-QP-CERI-7115 LOCATION:RADES C 450 MW CCPP Site

EQUIPMENT/PART SERIAL NO: STEAM TURBINE GENERATOR DRAWING NO:

INSPECTION LEVEL

REFERENCED ACCEPTANCE INSPECTION VERIFYING SUPPLIER/SUBCONTRACTOR GAMA 3RD PARTY STEG

ITEM NO ACTIVITY DESCRIPTION NOTES

DOCUMENTS CRITERIA FREQUENCY RECORD

LEVEL DATE SIGN LEVEL DATE SIGN LEVEL DATE SIGN LEVEL DATE SIGN

Approved Dwg, Manual of As per Vendor

4.13 Check Adjustment of Anchor Keys 100% 14,9 H W N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.14 Check Setting of Upper Bed for Brushless Exciter 100% _ H S N.A S

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.15 Check Final Alignment of STG&Brushless Exciter 100% 17,2 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.16 Check Coupling of ST GEN & Exciter and Swing Check 100% 18,19 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.17 Check Leakage Test of Brushless Exciter Air Cooler 100% 16 H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.18 Check Final Installation of Manhole Cover 100% _ H S N.A S

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

4.19 Check Installaiton of Brushless Exciter Housing 100% _ H S N.A R

installation Dwg/Specification

5 Installation Activities of Lube Oil and Cooling Water Piping

Approved Dwg, Manual of As per Vendor

5.1 Check Piping Assembly of Lube Oil Piping 100% _ H S N.A R

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

5.2 Check Piping Pressure&Leakage Tests 100% ITR-MW-128A H W N.A W

installation Dwg/Specification

Approved Dwg, Manual of As per Vendor

5.3 Check Oil Flushing Confirmation 100% ITR-MW-129 H W N.A R

installation Dwg/Specification

SUPPLIER/SUBCONTRACTOR APPROVAL GAMA APPROVAL THIRD PARTY/AUTHORIZED INSPECTOR APPROVAL CONSORSIUM APPROVAL STEG APPROVAL

NAME/DATE/SIGN: NAME/DATE/SIGN: NAME/DATE/SIGN: NAME/DATE/SIGN: NAME/DATE/SIGN:

LEGENDS

R REVIEW OF DOCUMENTS H HOLD POINT I INSPECTION W WITNESS POINT S SPOT WITNESS

Forms & Technical Appendixes

RADES-56-YC-QA-QP-CERI-7115

You might also like

- Cracked Addons2.2Document84 pagesCracked Addons2.2Erik Andreoni0% (1)

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Inspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegDocument1 pageInspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegRamzi Zoghlami100% (1)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- Dynamic Response of Fixed Offshore Structures Under Environmental LoadsDocument16 pagesDynamic Response of Fixed Offshore Structures Under Environmental LoadsxautraixxxxxxNo ratings yet

- Piping Erection ItpDocument22 pagesPiping Erection ItpHaythem Ben Zid100% (1)

- Ongc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Document7 pagesOngc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Ankit Kumar100% (1)

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- Inspection & Test Plan (Itp) : Mechanical (Machine & Equipment)Document2 pagesInspection & Test Plan (Itp) : Mechanical (Machine & Equipment)ikramNo ratings yet

- ITP For Installation of Automatic Sliding DoorDocument1 pageITP For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Itp TankageDocument7 pagesItp TankageIr FankovicNo ratings yet

- Piping ITPDocument12 pagesPiping ITPFiras AlbaweiNo ratings yet

- ITP ContohDocument24 pagesITP Contohyoyok isbanuNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Inspection & Test Plan (Itp)Document6 pagesInspection & Test Plan (Itp)Pahlevi MattasanNo ratings yet

- Ecc Mech Sharq 22 016 Rev 01Document6 pagesEcc Mech Sharq 22 016 Rev 01Muthu SaravananNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Inspection and Test Plan: S. H. Joo D. H. YounDocument2 pagesInspection and Test Plan: S. H. Joo D. H. YounfitriatitisariNo ratings yet

- P1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkDocument9 pagesP1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkEILA545 QAQCNo ratings yet

- Itp Tank RappDocument4 pagesItp Tank Rapprizky youlandaNo ratings yet

- Rencana Uji RiksaDocument3 pagesRencana Uji RiksawingwiryawanNo ratings yet

- Draft ITP PV NEW PEP ScrubberDocument4 pagesDraft ITP PV NEW PEP Scrubberinspectionzona11No ratings yet

- QAP FormatsDocument13 pagesQAP Formatsavvari sureshNo ratings yet

- Pp4 CM Ir 1004 001 - Rev. A - Itp For PipingDocument7 pagesPp4 CM Ir 1004 001 - Rev. A - Itp For PipingHungManhNo ratings yet

- 1029 Itp Asme R.ADocument23 pages1029 Itp Asme R.AAnonymous dj2xK2XONo ratings yet

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopDocument3 pagesNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priNo ratings yet

- 1 SATIP-A-004-05 Leak Testing Per SAES-A-004 - Rev1Document1 page1 SATIP-A-004-05 Leak Testing Per SAES-A-004 - Rev1j fNo ratings yet

- Centrale À Cycle Combiné Bi-Arbres Rades C 1 X 450MW: Inspection and Test PlanDocument6 pagesCentrale À Cycle Combiné Bi-Arbres Rades C 1 X 450MW: Inspection and Test PlanHaythem Ben ZidNo ratings yet

- Quality Assurance Plan For Api Pump (Qap)Document3 pagesQuality Assurance Plan For Api Pump (Qap)sanjay joshiNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- PM210014-TCC000-FI3-00003 - 00 - IFA - ITP For Static Equipment Installation - Rev 01Document73 pagesPM210014-TCC000-FI3-00003 - 00 - IFA - ITP For Static Equipment Installation - Rev 01problematic NymphNo ratings yet

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Inspection and Testing Plan Pressure VesselDocument6 pagesInspection and Testing Plan Pressure Vesselmuhammad afrizalNo ratings yet

- ENV-SPV-DR-B-002 Inspection and Test Plan-Rev - ADocument4 pagesENV-SPV-DR-B-002 Inspection and Test Plan-Rev - AyoeyNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Inspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Document4 pagesInspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Delta akathehuskyNo ratings yet

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- Đính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)Document9 pagesĐính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)The GunnersNo ratings yet

- # Inspection Test Plan #: Dokumen EngineeringDocument2 pages# Inspection Test Plan #: Dokumen EngineeringDIANTORONo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument13 pagesSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289No ratings yet

- TSP Adaptation Project No: Q3510: Inspection and Test Plan of Shop Fabricated Stainless Steel TanksDocument2 pagesTSP Adaptation Project No: Q3510: Inspection and Test Plan of Shop Fabricated Stainless Steel TanksfbellimamNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Satip N 110 01Document11 pagesSatip N 110 01jerinNo ratings yet

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyNo ratings yet

- ITP For HRSG OperationDocument5 pagesITP For HRSG Operationmister pogi0% (1)

- ITP Transformer Testing and CommissioningDocument1 pageITP Transformer Testing and CommissioningguspriyNo ratings yet

- Inspection and Test Plan (Itp)Document2 pagesInspection and Test Plan (Itp)Abdul Gafoor ShaikhNo ratings yet

- Danem Engineering Works - WLL: Inspection & Test PlanDocument3 pagesDanem Engineering Works - WLL: Inspection & Test PlanRejoy babyNo ratings yet

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- Jsa Installation of Supports and Cable Racks1Document16 pagesJsa Installation of Supports and Cable Racks1loveson709100% (3)

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDocument3 pagesInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- SATIP-P-113-01 Rev 7 FinalDocument5 pagesSATIP-P-113-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Npe SD Sqe Pip Ax4303 0009 Pad Leak TestDocument7 pagesNpe SD Sqe Pip Ax4303 0009 Pad Leak TestYulian Adhriansyah100% (1)

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- Ms For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Document15 pagesMs For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Ramzi ZoghlamiNo ratings yet

- Certificate WelderDocument5 pagesCertificate WelderRamzi ZoghlamiNo ratings yet

- Itr-Mw 242Document1 pageItr-Mw 242Ramzi ZoghlamiNo ratings yet

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- Itr-Mw 242Document1 pageItr-Mw 242Ramzi ZoghlamiNo ratings yet

- Itr-Mw - 240 2Document1 pageItr-Mw - 240 2Ramzi ZoghlamiNo ratings yet

- Certs Smart ControlDocument4 pagesCerts Smart ControlRamzi ZoghlamiNo ratings yet

- Ain Tsila Development Project: Reference From TODocument1 pageAin Tsila Development Project: Reference From TORamzi ZoghlamiNo ratings yet

- Petrofac International (Uae) Llc. Sub Contractor Document TransmittalDocument2 pagesPetrofac International (Uae) Llc. Sub Contractor Document TransmittalRamzi ZoghlamiNo ratings yet

- P-Qac-Pro-200-38242 Welding Procedure Specification (WPS) Register Rev BDocument1 pageP-Qac-Pro-200-38242 Welding Procedure Specification (WPS) Register Rev BRamzi ZoghlamiNo ratings yet

- WPS RegDocument1 pageWPS RegRamzi ZoghlamiNo ratings yet

- TR Ceri Piul 0049Document1 pageTR Ceri Piul 0049Ramzi ZoghlamiNo ratings yet

- A-Qac-Pro-730-38926-A Welding Machine Calibration ProcedureDocument25 pagesA-Qac-Pro-730-38926-A Welding Machine Calibration ProcedureRamzi Zoghlami100% (1)

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- A-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- C MEC DWG 730 40558 B - Code 1Document4 pagesC MEC DWG 730 40558 B - Code 1Ramzi ZoghlamiNo ratings yet

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNo ratings yet

- C MEC DWG 730 40554 B - Code 1Document1 pageC MEC DWG 730 40554 B - Code 1Ramzi ZoghlamiNo ratings yet

- C MEC DWG 730 40556 B Code 1Document2 pagesC MEC DWG 730 40556 B Code 1Ramzi ZoghlamiNo ratings yet

- TM Meeting Roles HBDDocument4 pagesTM Meeting Roles HBDHB DayaratneNo ratings yet

- Effective Communication ActivityDocument4 pagesEffective Communication ActivityLaura Ruiz BallesterosNo ratings yet

- Quickstart Guide: EnglishDocument10 pagesQuickstart Guide: EnglishAnnekiNo ratings yet

- Computer Repair Invoice TemplateDocument2 pagesComputer Repair Invoice TemplateAnonymous A6Jnef04No ratings yet

- SSR UW DNIP 0003 ESC XXXX 001 00 Signed PDFDocument12 pagesSSR UW DNIP 0003 ESC XXXX 001 00 Signed PDFKrishna KnsNo ratings yet

- Golden Power ATF DEX III TDSDocument1 pageGolden Power ATF DEX III TDSsimon.clove034No ratings yet

- 2020 - Cementing The European Green DealDocument38 pages2020 - Cementing The European Green Dealdr_akanNo ratings yet

- RElatório Global Teacher 2018 PDFDocument105 pagesRElatório Global Teacher 2018 PDFKimbellyNo ratings yet

- Faulty Code Description SolutionDocument5 pagesFaulty Code Description SolutionOppoNo ratings yet

- AIM R16 WS02 Rear SpoilerDocument30 pagesAIM R16 WS02 Rear SpoilerAnonymous PJP78mSxNo ratings yet

- Lesson Plan Template - Social EmotionalDocument2 pagesLesson Plan Template - Social Emotionalapi-573540610No ratings yet

- PDF Kurasa Kasihmu Koor Campuran CompressDocument2 pagesPDF Kurasa Kasihmu Koor Campuran CompressRsppb PertamedikaNo ratings yet

- Flat Sheets and FacadesDocument41 pagesFlat Sheets and FacadesSarisha HarrychundNo ratings yet

- Understanding Feyerabend On GalileoDocument5 pagesUnderstanding Feyerabend On Galileorustycarmelina108No ratings yet

- Drilling RigsDocument39 pagesDrilling RigsIsrar Ahmed100% (1)

- TV Productor Service Manual: Approved SignaturesDocument61 pagesTV Productor Service Manual: Approved SignaturesJCNo ratings yet

- Handbook Measuring Equity Education 2018 enDocument142 pagesHandbook Measuring Equity Education 2018 endanyjorgeNo ratings yet

- Astm F467MDocument9 pagesAstm F467Mhouk sukNo ratings yet

- Paint Finishing Quality and Defect AnalysisDocument6 pagesPaint Finishing Quality and Defect AnalysisAnurag SrivastavaNo ratings yet

- 11 Biology Respiration in Plants Test 01 Answer 0k2aDocument5 pages11 Biology Respiration in Plants Test 01 Answer 0k2aJaskirat SinghNo ratings yet

- Axle Order Form: Axles Wheel Stud InformationDocument2 pagesAxle Order Form: Axles Wheel Stud InformationHaytham AjibNo ratings yet

- Biomaterials and Nanotechnology For Tissue Engineering KrishnanDocument371 pagesBiomaterials and Nanotechnology For Tissue Engineering KrishnanRêmulo FariasNo ratings yet

- Achievement Report PDFDocument4 pagesAchievement Report PDFAnonymous IpBC61ZNo ratings yet

- 10002NB01510001Document12 pages10002NB01510001manoj6189No ratings yet

- Data SheetDocument8 pagesData SheetMr.K chNo ratings yet

- Croon's Bias-Corrected Factor Score Path Analysis For Small-To Moderate - Sample Multilevel Structural Equation ModelsDocument23 pagesCroon's Bias-Corrected Factor Score Path Analysis For Small-To Moderate - Sample Multilevel Structural Equation ModelsPhuoc NguyenNo ratings yet

- General Physics Lesson 1 Methods of Electrostatic ChargingDocument46 pagesGeneral Physics Lesson 1 Methods of Electrostatic ChargingLeoj Levamor D. AgumbayNo ratings yet

- Direção - Kia Picanto 2012Document16 pagesDireção - Kia Picanto 2012kiwel.01No ratings yet