Professional Documents

Culture Documents

University Institute of Architecture Subject - Building Material AND Contruction - V Subject Code - 311 Topic - Wall Cladding

University Institute of Architecture Subject - Building Material AND Contruction - V Subject Code - 311 Topic - Wall Cladding

Uploaded by

Saksham Sharma100%(1)100% found this document useful (1 vote)

123 views29 pages- Cladding is material applied over another to provide protection from weather elements and improve aesthetics. It serves decorative and functional purposes like insulation and soundproofing.

- Common cladding materials include stone, brick, metal, and wood for exteriors and timber, PVC, stone, and wallpaper for interiors. Installation methods include attached, curtain wall, and infill systems.

- Proper cladding helps control indoor environment, provides privacy and security, allows daylight and ventilation access, and prevents fire spread and sound transmission between walls. Sample prices and specifications of popular cladding materials were also provided.

Original Description:

TYPES OF CLADDING

Original Title

CLADDING

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document- Cladding is material applied over another to provide protection from weather elements and improve aesthetics. It serves decorative and functional purposes like insulation and soundproofing.

- Common cladding materials include stone, brick, metal, and wood for exteriors and timber, PVC, stone, and wallpaper for interiors. Installation methods include attached, curtain wall, and infill systems.

- Proper cladding helps control indoor environment, provides privacy and security, allows daylight and ventilation access, and prevents fire spread and sound transmission between walls. Sample prices and specifications of popular cladding materials were also provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

123 views29 pagesUniversity Institute of Architecture Subject - Building Material AND Contruction - V Subject Code - 311 Topic - Wall Cladding

University Institute of Architecture Subject - Building Material AND Contruction - V Subject Code - 311 Topic - Wall Cladding

Uploaded by

Saksham Sharma- Cladding is material applied over another to provide protection from weather elements and improve aesthetics. It serves decorative and functional purposes like insulation and soundproofing.

- Common cladding materials include stone, brick, metal, and wood for exteriors and timber, PVC, stone, and wallpaper for interiors. Installation methods include attached, curtain wall, and infill systems.

- Proper cladding helps control indoor environment, provides privacy and security, allows daylight and ventilation access, and prevents fire spread and sound transmission between walls. Sample prices and specifications of popular cladding materials were also provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 29

UNIVERSITY INSTITUTE OF ARCHITECTURE

SUBJECT – BUILDING MATERIAL

AND CONTRUCTION– V

SUBJECT CODE – 311

TOPIC – WALL CLADDING

SUBMITTED TO : SUBMITTED BY :

AR. GEETANJALI KAPOOR SAKSHAM SHARMA

AR. HARDEEP KAUR 19BAR1035

INTRODUCTION –

CLADDING

• Cladding is the application of one material

over another to provide a skin or layer.

• Cladding is used to provide a degree

of thermal insulation and weather resistance,

and to improve the appearance of buildings.

• Cladding is useful not only in terms of

aesthetics but also in terms of structure

because although it does not receive building

loads, it conceals and protects the structure

itself, isolating, delimiting and defining zones,

activities and structural elements.

PURPOSE OF CLADDING

• Cladding can serve both a decorative and a

functional purpose.

• It is used to complement the architectural style

of the building while also offering protection

from rain, wind, snow, and other outside

elements.

• Building cladding can also add insulation to the

structure while minimizing sound transmission

through the walls.

• Rainscreen cladding - is a form of weather

cladding designed to protect against the

elements, but also offers thermal insulation.

USES OF CLADDING

• Cladding is used to create a controlled internal

environment .

• It helps to protect the building from

the external conditions .

• It provides privacy and security .

• It prevents the transmission of sound .

• Provides thermal insulation .

• Provides opening for access , daylight and

ventilation .

• Creates an external façade .

• It prevents the spread of fire .

• It helps to generate a airtight building

envelope .

TYPES OF CLADDING

• INTERIOR CLADDING

• Timber cladding

• PVC cladding

• Stone cladding

• Backpainted glass cladding

• Ceramic cladding

• Wallpaper

TYPES OF CLADDING

• EXTERNAL CLADDING

• Terracotta cladding

• Stone cladding

• Metal cladding

• Stick frame cladding

• Curtain wall ( glass )

• Fibre cement cladding

• Brick cladding

INSTALLATION

SYSTEMS

• ATTACHED SYSTEM - Has exterior

cladding attached directly to

structural frame in large panels

which span one or more stories or

bays.

• Example: precast concrete or

steel-stud frames welded or

bolted to attachments built into

the structural frame.

• Primary advantage: ability to fully

insulate the exterior walls and

protect the structural frame from

deteriorating effects of weather.

INSTALLATION

SYSTEMS

• CURTAIN WALL CLADDING :

• It is similar to attached system except it

is attached to the structural frame with

clip angles or sub-framing.

• Examples: metal or glass walls which

enclose most modern skyscrapers .Also,

natural stones and light weight precast

panels.

• Primary advantage: standard design

requiring less time in pre-construction

and manufacturing.

INSTALLATION SYSTEMS

• INFILL SYSTEM :

• Cladding material is installed between exterior floor slab

edges and the exposed exterior columns of the structural

frame being the identifying feature.

• Example: pre-cast concrete, masonry, glass or combination

of these.

• Disadvantage: Structural frame is difficult to insulate.

• Differential movement between structural frame and

cladding resulting additional heat loss and heat gain to the

interior environment.

• React to climate and change volume as they age.

INTERIOR WALL

CLADDINGS

• TIMBER WALL CLADDING -

Create clean, linear textures

with a natural timber aesthetic

using our Tongue & Groove

Cladding system.

• Timber cladding walls are often

used as architectural features

due to their incredible natural

aesthetic, along with the

durability and the range of

species and finishes available.

INTERIOR WALL

CLADDING

• PVC CLADDING :

• It is used as a decorative interior wall

finish and had unique properties compared to

other wall cladding at the time.

• PVC panels usually have a hollow core and are

lightweight with a smooth surface for

decoration and a tongue-and-groove system

for easy installation.

• Wall and ceiling cladding is such they are quick

to clean and due to the great surface dirt

doesn't gather in cracks, bumps or pores.

INTERIOR WALL

CLADDING

• STONE CLADDING :

• Stone cladding is a refined or thin layer of

natural,artificial stone, which is applied to

an interior (or exterior) wall, to give the

effect that it is made entirely of stone.

• Natural stone is preferred for a more

authentic, rustic and durable finish.

• ADVANATGES :

• It is versatile .

• Durable and has aesthetic appearance .

• It is easy to maintain .

EXTERIOR WALL

CLADDING

• ALUMINIUM CLADDING :

• Aluminium composite cladding consists of a

layer of plastic sandwiched between two

Aluminium sheets.

• And it's the plastic layer, usually made of

polyethene .

• Aluminium cladding is one of the most used

types of cladding for building exteriors.

• Aluminium is often chosen as the optimal

material for building cladding for

economical, functional and aesthetical

reasons.

EXTERIOR WALL

CLADDING

• BRICK WALL CLADDING :

• Brick wall is suitable for both interior and

extereior .

• Brick cladding is designed to shed and

repel water so that the water cannot

reach the internal framing of the building.

• This reduces the risk of damage to the

framing caused by mold and mildew.

• It also keeps the interior dry and

pleasant.

CURTAIN WALL CLADDING

• CURTAIN WALL CLADDING :

• A curtain wall is an outer covering of a building in which the

outer walls are non-structural, utilized only to keep the

weather out and the occupants in.

• The curtain wall façade does not carry any structural load

from the building other than its own dead load weight.

• A curtain wall is designed to resist air and water infiltration,

absorb sway induced by wind and seismic forces acting on

the building, withstand wind loads, and support its own

weight.

TERRACOTTA

CLADDING

• Terracotta cladding are basically

made of clay .

• They are dried in kiln in order to

make them durable .

• The color is given to the tiles by

adding various dyes .

• The can be customised into

various shapes and designs .

• Price – Rs. 7 per pc.

• Size – 200 x 100 x 10

METHODS OF

CLADDING

• Direct Adhered – This is one of the most

common methods. It is thinner, less

expensive and doesn't require any onsite

drilling .

• Spot Bonding – similar to the direct adhered

but epoxy is only applied to about 10% of

the area resulting in gaps or pockets of air

between the stone and the wall reduces the

chances of water staining.

• Mechanical Bonding - This method involves

fixed or embedded anchors or ties being

used to attach the stone to the surface

SAMPLES

STONE CLADDING

EXTERIOIR

SIZE 12"X18"

PRICE 250 PER BOX ( 6 )

STONE CLADDING

EXTERIOIR

SIZE 12"X18"

PRICE 250 PER BOX ( 6 )

CERAMIC CLADDING

EXTERIOIR

SIZE 12"X18"

PRICE 250 PER BOX ( 6 )

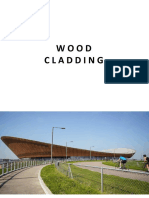

WOOD CLADDING

INTERIOIR

SIZE 12"X18"

PRICE 250 PER BOX ( 6 )

CERAMIC CLADDING

INTERIOIR

SIZE 12"X18"

PRICE 250 PER BOX ( 6 )

CERAMIC CLADDING

INTERIOIR

SIZE 12"X18"

PRICE 250 PER BOX ( 6 )

BRICK CLADDING

INTERIOIR

SIZE 200X100X10

PRICE RS 7 PER PC.

BRICK CLADDING

INTERIOIR

PRICE RS 5 PER SQFT.

ALUMINIUM CLADDING

INTERIOIR

PRICE RS 220 PER SQFT.

ALUMINIUM CLADDING

WOODEN TEXTURE

INTERIOIR

PRICE RS 220 PER SQFT.

THANK YOU

You might also like

- Check List For Cable Glanding & TerminationDocument1 pageCheck List For Cable Glanding & TerminationImran Khan100% (4)

- 5.a. Piping Fabrication PlanDocument15 pages5.a. Piping Fabrication PlanOkeyman100% (7)

- Letter For Fire PreventionDocument5 pagesLetter For Fire Preventionstafe fsNo ratings yet

- 357.3r 14 Guide For Design and Construction of Waterfront and Coastal Concrete Marine StructuresDocument52 pages357.3r 14 Guide For Design and Construction of Waterfront and Coastal Concrete Marine StructuresAdel A. Abdelaziz100% (1)

- Glass As A Building MaterialDocument45 pagesGlass As A Building MaterialADITYA GUPTANo ratings yet

- Exterior Walling System - Group No. - 04Document27 pagesExterior Walling System - Group No. - 04latika100% (1)

- Construction Technology3Document24 pagesConstruction Technology3api-288135534No ratings yet

- Acp CladdingDocument21 pagesAcp CladdingSACHIDANANDA S100% (1)

- Building Materials & Construction TechnologyDocument24 pagesBuilding Materials & Construction TechnologySaurav ShresthaNo ratings yet

- Aluminium PartitioningDocument58 pagesAluminium PartitioningShreyas soni100% (1)

- Wall FinishesDocument5 pagesWall FinishesRicha adhikariNo ratings yet

- Door Sealing Systems: Product CatalogueDocument184 pagesDoor Sealing Systems: Product CatalogueFábio AndréNo ratings yet

- Glass and Glazing (Document)Document10 pagesGlass and Glazing (Document)maygracedigolNo ratings yet

- VijayDocument67 pagesVijayvijay kumarNo ratings yet

- Glass As A Building MaterialDocument29 pagesGlass As A Building MaterialMichaelKipronoNo ratings yet

- Unit 2 PlasticsDocument18 pagesUnit 2 PlasticsNivedhaNo ratings yet

- Fire ResistanceDocument7 pagesFire ResistancesayoojNo ratings yet

- Materails & Techniques of Vernacular ArchitectureDocument37 pagesMaterails & Techniques of Vernacular ArchitectureRohit SharmaNo ratings yet

- Causes of Decay of BuildingsDocument20 pagesCauses of Decay of Buildingsthrigya myakalaNo ratings yet

- Timber 1Document36 pagesTimber 1CHIRAG SNo ratings yet

- Indian Institute of Architects PDFDocument12 pagesIndian Institute of Architects PDFparvathiNo ratings yet

- Sem 7 MMBC Module 1 - WoodsDocument8 pagesSem 7 MMBC Module 1 - WoodsARTFOLIO .49No ratings yet

- What Is Building Envelope ?: Function and PerformanceDocument7 pagesWhat Is Building Envelope ?: Function and PerformanceSumi MathewNo ratings yet

- False Ceiling: Done and Submitted By: Bushra Khan and Siddhartha VermaDocument17 pagesFalse Ceiling: Done and Submitted By: Bushra Khan and Siddhartha VermaAshuthosh MurulyaNo ratings yet

- FLOORINGDocument16 pagesFLOORINGSachin Kumar PatelNo ratings yet

- Spider Catalogue EXDocument36 pagesSpider Catalogue EXnindyaputri97No ratings yet

- Timber CladdingDocument13 pagesTimber CladdingMegha RajNo ratings yet

- 04 - Sanjana Bhandiwad - PC CladdingDocument16 pages04 - Sanjana Bhandiwad - PC CladdingSanjana BhandiwadNo ratings yet

- Curtain Wall (Jaskirat)Document29 pagesCurtain Wall (Jaskirat)JaskiratNo ratings yet

- Insulation Floors P65 76Document12 pagesInsulation Floors P65 76Jennifer NavarroNo ratings yet

- Layers of A Floor - Anatomy, and Parts (Illustrated)Document8 pagesLayers of A Floor - Anatomy, and Parts (Illustrated)Melaine A. FranciscoNo ratings yet

- Partition Walls 23-09-20Document21 pagesPartition Walls 23-09-20Fredrick Stephen RajNo ratings yet

- TIMBERDocument51 pagesTIMBERktnatashaNo ratings yet

- Building Construction: DoorsDocument48 pagesBuilding Construction: DoorsZHEHAT TNo ratings yet

- BLOCKBOARDDocument9 pagesBLOCKBOARDANJALI GAUTAM100% (1)

- Doors and WindowsDocument77 pagesDoors and WindowsVipulParashar0% (1)

- Encraft - Aluminium CatalogueDocument6 pagesEncraft - Aluminium CatalogueParesh PatelNo ratings yet

- FLOORING Module 3 Final VersionDocument28 pagesFLOORING Module 3 Final Versionrevathi hariharan100% (1)

- Construction MaterialsDocument20 pagesConstruction MaterialsmariyaNo ratings yet

- Building Construction: Report OnDocument15 pagesBuilding Construction: Report Ony2kareinNo ratings yet

- Wood and Wood DerivativesDocument19 pagesWood and Wood DerivativesShyam WanaskarNo ratings yet

- Curtain WallsDocument16 pagesCurtain WallsSACHIDANANDA SNo ratings yet

- Waterproofing CombinedDocument197 pagesWaterproofing CombinedIshita SehgalNo ratings yet

- General Principles in Acoustics For Architectural DesignDocument13 pagesGeneral Principles in Acoustics For Architectural DesignSiddharth BhandariNo ratings yet

- Unit 3Document58 pagesUnit 3Yoghi KalamNo ratings yet

- Wall CladdingDocument24 pagesWall CladdingRemya R. KumarNo ratings yet

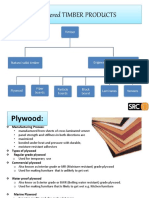

- Engineered TIMBER PRODUCTSDocument9 pagesEngineered TIMBER PRODUCTSAr Ayoushika Abrol0% (1)

- Thermal Insulation, Sound Insulation and FireDocument59 pagesThermal Insulation, Sound Insulation and FireSamata MahajanNo ratings yet

- Vinyl Composition TileDocument37 pagesVinyl Composition TileJehanzeb SiddiquiNo ratings yet

- Structural Glazing PresentationDocument18 pagesStructural Glazing Presentationsougata dasNo ratings yet

- WPC SpecificationDocument3 pagesWPC SpecificationArch HalaNo ratings yet

- Exterior FinishesDocument14 pagesExterior Finishespratiksha590No ratings yet

- Wood & Wood DerivativesDocument8 pagesWood & Wood DerivativesPriya ManeNo ratings yet

- Mechanical VentatilationDocument17 pagesMechanical VentatilationAkriti GhildiyalNo ratings yet

- Laurence Wilfred BakerDocument40 pagesLaurence Wilfred BakerbhavyaNo ratings yet

- Unit 3 - Sizing Beams, Joist and Lintels-ExamDocument63 pagesUnit 3 - Sizing Beams, Joist and Lintels-ExamSparki100% (1)

- 2020 BUILDING TECHNOLOGY 1 Module 1 Lecture 2b - Stone and Concrete MasonryDocument43 pages2020 BUILDING TECHNOLOGY 1 Module 1 Lecture 2b - Stone and Concrete Masonrylia immie rigoNo ratings yet

- 07 GlassDocument22 pages07 GlassSergeyOleshkoNo ratings yet

- IGBC Green Interior CasestudiesDocument18 pagesIGBC Green Interior CasestudiesTejasNo ratings yet

- Concrete As Building MaterialDocument92 pagesConcrete As Building MaterialUmed Abd-alsatarNo ratings yet

- 4 BMC III (Arch 3171) - Cladding PDFDocument48 pages4 BMC III (Arch 3171) - Cladding PDFabel alemuNo ratings yet

- CladdingDocument68 pagesCladdingShafnaFawaz100% (1)

- Cladding and GlazingDocument20 pagesCladding and Glazingmichelle geejoNo ratings yet

- Wall Cladding-Stone Cladding, Tile Cladding, and Metal CladdingDocument25 pagesWall Cladding-Stone Cladding, Tile Cladding, and Metal CladdingAlexNo ratings yet

- Housing 3 (3) - NEWDocument2 pagesHousing 3 (3) - NEWSaksham SharmaNo ratings yet

- Mukhiram Ward (No.-08) : Built Up Area Net Area and Gross DensityDocument2 pagesMukhiram Ward (No.-08) : Built Up Area Net Area and Gross DensitySaksham SharmaNo ratings yet

- Saksham Sharma 19bar1035 4 AssignmentDocument2 pagesSaksham Sharma 19bar1035 4 AssignmentSaksham SharmaNo ratings yet

- University Institute of Architecture Bachelor of Architecture History of Architecture (Arp-315) Topic: Assignment-1Document6 pagesUniversity Institute of Architecture Bachelor of Architecture History of Architecture (Arp-315) Topic: Assignment-1Saksham SharmaNo ratings yet

- 31.01.22 - Design Problem 1 - Group HousingDocument5 pages31.01.22 - Design Problem 1 - Group HousingSaksham SharmaNo ratings yet

- Architectural Legislation ARP-365: MOHD KASHAN (19BAR1048) Ar. Amar Singh SolankiDocument11 pagesArchitectural Legislation ARP-365: MOHD KASHAN (19BAR1048) Ar. Amar Singh SolankiSaksham SharmaNo ratings yet

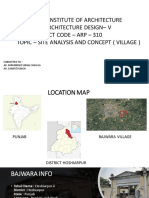

- University Institute of Architecture Subject - Architecture Design - V Subject Code - Arp - 310 Topic - Site Analysis and Concept (Village)Document39 pagesUniversity Institute of Architecture Subject - Architecture Design - V Subject Code - Arp - 310 Topic - Site Analysis and Concept (Village)Saksham SharmaNo ratings yet

- University Institute of Architecture Subject - Building Material and Contruction - V Subject Code - 311 Topic - Ferrous and Non - Ferrous MetalsDocument34 pagesUniversity Institute of Architecture Subject - Building Material and Contruction - V Subject Code - 311 Topic - Ferrous and Non - Ferrous MetalsSaksham SharmaNo ratings yet

- 19bar1035 Saksham Sharma Aluminum PartitionDocument8 pages19bar1035 Saksham Sharma Aluminum PartitionSaksham SharmaNo ratings yet

- Erection Drawing SST 36MDocument14 pagesErection Drawing SST 36MyuwonoNo ratings yet

- Masterflow 885: High-Precision, Non-Shrink Metallic Aggregate Grout With Extended Working TimeDocument4 pagesMasterflow 885: High-Precision, Non-Shrink Metallic Aggregate Grout With Extended Working TimeSky MoonNo ratings yet

- Industrial Arts 4Document18 pagesIndustrial Arts 4cynthiataculog35No ratings yet

- Method Statement For Construction For Sub-Base and Road Base WorksDocument20 pagesMethod Statement For Construction For Sub-Base and Road Base WorksBleep NewsNo ratings yet

- Tube-Mac Metric CatalogeDocument279 pagesTube-Mac Metric CatalogeTheAnonymousLugia100% (2)

- Screw FasteningDocument25 pagesScrew FasteningVimukthi LakshanNo ratings yet

- Annexure-IV Status of Under Execution Hydro Electric Projects (Above 25 MW) in The CountryDocument14 pagesAnnexure-IV Status of Under Execution Hydro Electric Projects (Above 25 MW) in The CountryGD GOENKA MOOTNo ratings yet

- 101 Oral Viva Questions For Concrete TechnologyDocument3 pages101 Oral Viva Questions For Concrete TechnologyShekhar V kumbarNo ratings yet

- Road Grader: Building Line EquipmentDocument3 pagesRoad Grader: Building Line Equipmentshaine schoolNo ratings yet

- Doka Auto Sliding Door Operator Drawings Booklet 0917 Aus PDFDocument52 pagesDoka Auto Sliding Door Operator Drawings Booklet 0917 Aus PDFkothaunghtikeNo ratings yet

- Floor Bia 1002Document16 pagesFloor Bia 1002Nicholas Ee Han MingNo ratings yet

- Hoist CapacityDocument2 pagesHoist CapacityKish Shan S SubediNo ratings yet

- 19 2 1mm Bronze II Stranded ConductorDocument1 page19 2 1mm Bronze II Stranded ConductorCarlos PanccaNo ratings yet

- The Three Little PigsDocument4 pagesThe Three Little PigsRyuDan2255No ratings yet

- HiroshimaDocument8 pagesHiroshimaGeorg GergiouNo ratings yet

- Silty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-52Document8 pagesSilty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-5201 - HUTOMO KASPAR KURNIAWANNo ratings yet

- Fiber Reinforced ConcreteDocument16 pagesFiber Reinforced ConcreteNaviya K NaviyaNo ratings yet

- Electrical Fixture Layout Plan For Ground Floor 01Document1 pageElectrical Fixture Layout Plan For Ground Floor 01habibur Rahman KhanNo ratings yet

- FT - #GR6 - Cable VerdeDocument2 pagesFT - #GR6 - Cable Verdeolivares91No ratings yet

- General Guide For Scaffolds and Scaffolding WorkDocument16 pagesGeneral Guide For Scaffolds and Scaffolding Workputra2azanNo ratings yet

- Leca® LWA Construction Control (21.4.11)Document8 pagesLeca® LWA Construction Control (21.4.11)anele_amisNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- 1 - NBC Form B-01 - Building Permit FormDocument1 page1 - NBC Form B-01 - Building Permit Formm0uth_wash1ngNo ratings yet

- About Lumira Aerogel: Reduce Your Carbon Footprint Hear The DifferenceDocument6 pagesAbout Lumira Aerogel: Reduce Your Carbon Footprint Hear The DifferenceFacundo OrtizNo ratings yet

- SD 511Document11 pagesSD 511serginho_vlNo ratings yet

- Stair Case PressurizationDocument2 pagesStair Case PressurizationMohammed Hassan Mohiuddin Khan100% (2)