Professional Documents

Culture Documents

Strategy For Underground Mines

Strategy For Underground Mines

Uploaded by

Deogratias LaurentOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strategy For Underground Mines

Strategy For Underground Mines

Uploaded by

Deogratias LaurentCopyright:

Available Formats

STRATEGY FOR UNDERGROUND MINES

Ramp Haulage

For small ore bodies, ramp haulage is the default selection because it normally provides

the most flexible and economical choice. (In a cordillera, the terrain may provide relief

adequate for a level entry or “adit.”) A ramp (or adit) drive can typically be oriented to

provide an underground diamond-drilling base and provide shorter crosscuts to the ore

zone. The crosscuts are provided rapidly and economically because they provide a

second heading for the main drive. It is possible to sink and develop from a shaft at the

same time; however, this is a difficult and expensive procedure.

Another advantage to the ramp or adit entry is direct access by mobile equipment when

trackless mining is to be employed. For a typical shaft, the equipment must be

dismantled and reassembled underground. The set-up time required to initiate ramp

driving is usually shorter than for a shaft. One to three months may be required to

provide access and collar a ramp portal, while the collar, hoist, and headframe required

for a shaft may take six months of site work.

For medium sized ore bodies, ramp haulage may still be the best choice where the

orebody is relatively flat lying. In this case, the ramp may have to be enlarged to

accommodate larger trucks. In some cases, it may be practical to provide twin ramp

entries to handle two-way traffic.

Belt Conveyor

For large, flat-lying ore bodies, a belt conveyor is typically the most economical method

of hoisting ore. The legs of the conveyor are put into a ramp that has been driven

straight (i.e. a “decline”) for each leg of the proposed conveyor way.

If the soil overburden is very deep, or deep and water bearing, a ramp or decline may

not be a practical method due to the extraordinary cost of excavating and constructing a

portal. If the ground (bedrock) beneath the overburden is not competent or is heavily

water bearing, a ramp or decline access may be impractical due to the driving time and

cost.

Shaft System

For large steeply dipping ore bodies, a shaft system is usually best. In this scenario, it

may be advisable to have a ramp entry as well to accelerate the pre-production

schedule and later to provide service access to the mine.

Conventional Methods of Ore Transport

At the conceptual stage, it is normally better to consider only conventional methods for

the transport of ore and resort to the unusual methods only under unusual

circumstances. A good example of “unusual” is the aerial tramway installed across a

fjord at the Black Angel Mine in Greenland to access an orebody located high on a cliff

face.

You might also like

- Astm A370 2020Document50 pagesAstm A370 2020امين100% (1)

- PayslipDocument1 pagePayslipAshish Agarwal67% (3)

- 1mining Through Adit, Incline, Decline and ShaftDocument11 pages1mining Through Adit, Incline, Decline and ShaftAkhil Sai KrishnaNo ratings yet

- Jack-Up Rigs Operational Aspects (Offshore Drilling)Document22 pagesJack-Up Rigs Operational Aspects (Offshore Drilling)myusuf_engineer100% (9)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Surface Mining MethodsDocument15 pagesSurface Mining MethodsMatthew Butler50% (2)

- Alternative Process Flow For Underground Mining OpDocument14 pagesAlternative Process Flow For Underground Mining OpEduardo MenaNo ratings yet

- Modes of AccessDocument24 pagesModes of AccessANSHUL YADAVNo ratings yet

- Mine Development - Access To DepositDocument23 pagesMine Development - Access To DepositMuhammad Zaka EmadNo ratings yet

- Mine LayoutDocument7 pagesMine LayoutRavikumar mahadevNo ratings yet

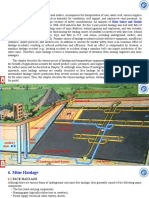

- Mine HaulageDocument54 pagesMine HaulageStef Torcedo100% (6)

- EM202357MAR510ENGGDocument9 pagesEM202357MAR510ENGGRosalie BachillerNo ratings yet

- DRAGLINESDocument19 pagesDRAGLINESEyob FkrNo ratings yet

- Au - AppendixDocument18 pagesAu - AppendixAndres OsorioNo ratings yet

- An Update On In-Pit Crushing-Conveying-Stacking Systems in Surface Metal MinesDocument11 pagesAn Update On In-Pit Crushing-Conveying-Stacking Systems in Surface Metal MinesRobert Knight0% (1)

- Desani ParthDocument26 pagesDesani ParthMateen MahdiNo ratings yet

- Loading Equipment in Board and Pillar MethodDocument8 pagesLoading Equipment in Board and Pillar MethodsamratNo ratings yet

- Site Selection of An Incline or Pit:: R FurtherDocument6 pagesSite Selection of An Incline or Pit:: R FurtherSatyajeet ParidaNo ratings yet

- A PRESENTATION On Modes of EntryDocument28 pagesA PRESENTATION On Modes of EntryRîtweek Þânɖey75% (4)

- 4th Sem - Mining Engg - Th-01Document19 pages4th Sem - Mining Engg - Th-01Satyajeet ParidaNo ratings yet

- Horizon Mining Level Mining: Longwall & Other Methods of WorkingDocument14 pagesHorizon Mining Level Mining: Longwall & Other Methods of WorkingVamshiNo ratings yet

- Mining Magazine - Sinking SkilfullyDocument14 pagesMining Magazine - Sinking SkilfullyLehlohonolo MoqekelaNo ratings yet

- An Introduction To Railway Drydocks and Transfer SystemsDocument9 pagesAn Introduction To Railway Drydocks and Transfer SystemsshahjadaNo ratings yet

- Lres 36Document33 pagesLres 36Vikas BanjareNo ratings yet

- Railway 2000 by Terry ClarkDocument18 pagesRailway 2000 by Terry ClarkHewa Wedage Niroshan AnuruddhaNo ratings yet

- 1 s2.0 S0167903188907773 MainDocument11 pages1 s2.0 S0167903188907773 Main88127050No ratings yet

- Drilling Engineering Chapter 1Document41 pagesDrilling Engineering Chapter 1Wong Jin Yang100% (2)

- Shafts DesignDocument14 pagesShafts DesignIslam AhmedNo ratings yet

- Application of Conveyors For UG HaulageDocument11 pagesApplication of Conveyors For UG Haulageminerito2211No ratings yet

- 4 In-Pit Crushing & ConveyingDocument29 pages4 In-Pit Crushing & ConveyingChandan KumarNo ratings yet

- Transportasi (Tambang) Bawah Tanah # 1Document107 pagesTransportasi (Tambang) Bawah Tanah # 1SandyKingNo ratings yet

- Students: Guerra Esquivel Cristian Hidalgo Pizarro Jimmy Paredes Saldivar JulberDocument14 pagesStudents: Guerra Esquivel Cristian Hidalgo Pizarro Jimmy Paredes Saldivar JulberLalo CotaNo ratings yet

- A Presentation On Underground Stoping Methods - IIDocument68 pagesA Presentation On Underground Stoping Methods - IIANSHUL YADAV100% (1)

- Mining Levels - Stations, Drifts, & CrosscutsDocument11 pagesMining Levels - Stations, Drifts, & Crosscutsrobertchiadzwa2No ratings yet

- Hybrid Underground MethodDocument3 pagesHybrid Underground MethodGerome L. AmperNo ratings yet

- Underground Mining-Supported OpeningsDocument13 pagesUnderground Mining-Supported OpeningsPuvanendran GajananNo ratings yet

- Mining of Narrow Steeply Dipping VeinsDocument31 pagesMining of Narrow Steeply Dipping Veinstd__1985No ratings yet

- Shrinkage Stoping: MethodDocument6 pagesShrinkage Stoping: MethodRiuRiversNo ratings yet

- Shaft Drift Jan14Document44 pagesShaft Drift Jan14shubham hemaneNo ratings yet

- Bauxite ComparisonDocument12 pagesBauxite Comparisondr_drk4503No ratings yet

- Otc 18233Document0 pagesOtc 18233Elendu Emmanuel ChigozieNo ratings yet

- EM202385MAR523ENGGDocument7 pagesEM202385MAR523ENGGRose BachNo ratings yet

- Cut and FillDocument35 pagesCut and FillAnshul yadavNo ratings yet

- Stoping MethodDocument51 pagesStoping MethodRathnakar Reddy100% (1)

- DrainaseDocument6 pagesDrainasepurwanto250No ratings yet

- Tunneling TechniquesDocument87 pagesTunneling TechniquesBinodNo ratings yet

- Surface and UGDocument26 pagesSurface and UGsunilsinghmNo ratings yet

- Cut and Fill: Selections ConsiderationsDocument3 pagesCut and Fill: Selections ConsiderationsRubi KatherineNo ratings yet

- Mine HaulageDocument46 pagesMine HaulageZeph roxNo ratings yet

- Basic Mud LoggingDocument196 pagesBasic Mud LoggingAnonymous 0OU1iqXHNo ratings yet

- PurposeDocument2 pagesPurposeAsisipho MajaliNo ratings yet

- Application of Highwall Mining in IndiaDocument12 pagesApplication of Highwall Mining in IndiaSatish kumarNo ratings yet

- Chutes Design PDFDocument11 pagesChutes Design PDFWaris La Joi Wakatobi100% (1)

- Ecovery of Broken Ore Stocks Left On The Mine Floor and Other Applications of The Underground Mobile SupersuckerDocument7 pagesEcovery of Broken Ore Stocks Left On The Mine Floor and Other Applications of The Underground Mobile SupersuckergeolukeNo ratings yet

- Metodos AtlasCopcopage35Document5 pagesMetodos AtlasCopcopage35lautaroi77No ratings yet

- Cut and FillDocument12 pagesCut and FillNaitsirhc LewisNo ratings yet

- Dredging and ReclamationDocument8 pagesDredging and ReclamationSAMSON WERESON100% (2)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Planning For ServicesDocument1 pagePlanning For ServicesDeogratias LaurentNo ratings yet

- RIPPINGDocument1 pageRIPPINGDeogratias LaurentNo ratings yet

- Vein MiningDocument1 pageVein MiningDeogratias LaurentNo ratings yet

- Room WidthsDocument1 pageRoom WidthsDeogratias LaurentNo ratings yet

- Orientation of Rooms and PillarsDocument1 pageOrientation of Rooms and PillarsDeogratias LaurentNo ratings yet

- LoadDocument1 pageLoadDeogratias LaurentNo ratings yet

- Systems SimulationDocument1 pageSystems SimulationDeogratias LaurentNo ratings yet

- Pillar WidthDocument1 pagePillar WidthDeogratias LaurentNo ratings yet

- BackfillingDocument1 pageBackfillingDeogratias LaurentNo ratings yet

- Walking DraglinesDocument1 pageWalking DraglinesDeogratias LaurentNo ratings yet

- Alluvial FansDocument1 pageAlluvial FansDeogratias LaurentNo ratings yet

- Numerical Hydrogeological ModelsDocument1 pageNumerical Hydrogeological ModelsDeogratias LaurentNo ratings yet

- Pusher Cycle TimeDocument1 pagePusher Cycle TimeDeogratias LaurentNo ratings yet

- Rock Mass AnalysesDocument1 pageRock Mass AnalysesDeogratias LaurentNo ratings yet

- Structural Domain DefinitionDocument1 pageStructural Domain DefinitionDeogratias LaurentNo ratings yet

- Geotechnical RequirementsDocument1 pageGeotechnical RequirementsDeogratias LaurentNo ratings yet

- Ore Body EnvironmentsDocument1 pageOre Body EnvironmentsDeogratias LaurentNo ratings yet

- Detailed Geological MappingDocument1 pageDetailed Geological MappingDeogratias LaurentNo ratings yet

- Characteristics of The Leached Capping or GossanDocument1 pageCharacteristics of The Leached Capping or GossanDeogratias LaurentNo ratings yet

- Genesis of Porphyry Molybdenum DepositsDocument1 pageGenesis of Porphyry Molybdenum DepositsDeogratias LaurentNo ratings yet

- Genesis of CalcDocument1 pageGenesis of CalcDeogratias LaurentNo ratings yet

- Classification of Hydrothermal Gold DepositsDocument1 pageClassification of Hydrothermal Gold DepositsDeogratias LaurentNo ratings yet

- Geological Criteria For Ore ProspectingDocument1 pageGeological Criteria For Ore ProspectingDeogratias LaurentNo ratings yet

- The Relationship Between Ore Deposits and Magma ChemistryDocument2 pagesThe Relationship Between Ore Deposits and Magma ChemistryDeogratias LaurentNo ratings yet

- The Relationship Between Ore Deposits and Magma DifferentiationDocument1 pageThe Relationship Between Ore Deposits and Magma DifferentiationDeogratias LaurentNo ratings yet

- (00 Cari) - Iso - 8466 1 1990Document5 pages(00 Cari) - Iso - 8466 1 1990faridsidikNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- General Revision For Treasury Management (Please See That You Can Answer The Following 32 Questions and The MCQS)Document14 pagesGeneral Revision For Treasury Management (Please See That You Can Answer The Following 32 Questions and The MCQS)RoelienNo ratings yet

- Jambajuicelv-Application-0618 1Document2 pagesJambajuicelv-Application-0618 1api-526082107No ratings yet

- OrganoLithium ReagentDocument6 pagesOrganoLithium ReagentizaowsikNo ratings yet

- MT2OL-Ia6 2 1Document136 pagesMT2OL-Ia6 2 1QUILIOPE, JUSTINE JAY S.No ratings yet

- Native Son Essay TopicsDocument7 pagesNative Son Essay TopicsafabioemwNo ratings yet

- Clique Student Sheet (Manteran Lamo)Document4 pagesClique Student Sheet (Manteran Lamo)Dina Rizkia RachmahNo ratings yet

- Reading Test 1: Questions 1-5 Refer To The Following ArticleDocument14 pagesReading Test 1: Questions 1-5 Refer To The Following ArticletrucNo ratings yet

- Akira - GA - Intro-To-Coding-Html-CssDocument46 pagesAkira - GA - Intro-To-Coding-Html-CssVinoth JayaprakasamNo ratings yet

- Tera Spin PK-1500 Series PK-1600 40 Weighting Arms Jul-2018Document14 pagesTera Spin PK-1500 Series PK-1600 40 Weighting Arms Jul-2018deepakNo ratings yet

- Murphy'S Laws: Anything That Can Go Wrong Will Go WrongDocument2 pagesMurphy'S Laws: Anything That Can Go Wrong Will Go WrongAshwin ReddyNo ratings yet

- Policy Copy 3005 314095178 00 000Document3 pagesPolicy Copy 3005 314095178 00 000alagardharshan2No ratings yet

- Machine Tool TestingDocument4 pagesMachine Tool Testingnm2007k100% (1)

- Genuine Eaton Vicker HidrauDocument28 pagesGenuine Eaton Vicker HidrauJenner Volnney Quispe ChataNo ratings yet

- Ultrasonic InterferometerDocument22 pagesUltrasonic InterferometerakshatguptaNo ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- (Shuangzhu Jia Et Al 2020) Study On The Preparing and Mechanism of Chitosan-Based Nanomesoporous Carbons by Hydrothermal MethodDocument21 pages(Shuangzhu Jia Et Al 2020) Study On The Preparing and Mechanism of Chitosan-Based Nanomesoporous Carbons by Hydrothermal MethodSilvia Devi Eka PutriNo ratings yet

- 1231.322 323 MSDS Sabroe 1507-100 MSDSDocument6 pages1231.322 323 MSDS Sabroe 1507-100 MSDSzhyhhNo ratings yet

- Reducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RDocument5 pagesReducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RKrushnaNo ratings yet

- Английская грамматика в тестах - РомановаDocument152 pagesАнглийская грамматика в тестах - РомановаLi FeNo ratings yet

- Mapeh GR9 First Quarter ReviewerDocument8 pagesMapeh GR9 First Quarter ReviewerRalph Emerson SantillanNo ratings yet

- Setting GuideDocument12 pagesSetting GuideJamesNo ratings yet

- Characterising Roof Ventilators: P 2 A Q CDocument4 pagesCharacterising Roof Ventilators: P 2 A Q CDhirendra Singh RathoreNo ratings yet

- Bullz Audio Catalog 2013Document20 pagesBullz Audio Catalog 2013Jhonne TJ (TJ)No ratings yet

- ScheduleDocument2 pagesScheduleJen NevalgaNo ratings yet

- 10 Science NcertSolutions Chapter 8 ExercisesDocument4 pages10 Science NcertSolutions Chapter 8 ExercisesAnita GargNo ratings yet

- Support/downloads or Scan Above QR Code For Detailed Policy WordingDocument10 pagesSupport/downloads or Scan Above QR Code For Detailed Policy Wordingraj VenkateshNo ratings yet