Professional Documents

Culture Documents

Project: Global Hospitals, Chennai. Client: M/s. Global Hospitals, Chennai

Project: Global Hospitals, Chennai. Client: M/s. Global Hospitals, Chennai

Uploaded by

lakshminarayananOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project: Global Hospitals, Chennai. Client: M/s. Global Hospitals, Chennai

Project: Global Hospitals, Chennai. Client: M/s. Global Hospitals, Chennai

Uploaded by

lakshminarayananCopyright:

Available Formats

Project : Global Hospitals, Chennai.

Client : M/s. Global Hospitals, Chennai.

GLOBAL HOSPITAL AIR HANDLING UNITS (AHU) BOQ

Sl. No. Description SUPPLY INR INSTALLATION INR

AIR HANDLING UNIT Qty Unit RATE AMOUNT RATE AMOUNT

2.5 Exposed Type Floor Mounted Chilled water Treated Fresh air Units with Canopy

Supply,Transport to site, Installation, Testing and Commisioning of Double Skin with Thermal Break Profile of 43+/-2 mm high

pressure PUF injected with density of 40 kg/cu.m and aluminium corner profile Air handling Unit with necessary Protection,

comprising of the following as,

Supply DIDW Aerofoil fan not less than 80% efficiency along with EFF1 motor should be used. The fan and motor shall be

completely isolated from the unit casing with antivibration isolaters along with drive package. Fan outlet should have fire

retardant type flexible connection to prevent vibration transmission to the casing. Drive motor suitable for 400 +/- 15% V, 50

Hz, 3P, TEFC squirrel cage induction motor and suitable for VFD operation.

Chilled water fed cooling coils with 8 Row Deep Coil. Face Velocity across the coils should not exceed 420 FPM. Chilled water

cooling coils shall be constructed from premium quality copper tubes and mechanically bonded to alumiunium fins. Chilled

water Inlet is 8 deg C and outlet is 13 deg C (To be Matched with Existing Chiller Data)

The drain pan shall be 20-gauge stainless steel, sloped, and positioned under the dehumidifier coil. The drain pan shall be

TIG welded and securely attached to the evaporator endplates to avoid shifting. The drain pan shall be fitted with a minimum

1” SS 304 grade drain connection

with filter of 10 microns Prefilter & 5micron filter.

Blower motors shall be Compatable with Variable frequency Drives selected operating current with 15% safety.

Variable frequency drive with the panel for the AHU motor.

The Starter panel should be supplied along with AHU and it should complete with VFD, relays, protections, ammeter with

CT, Voltmeter along with selector switch, On/Off indication and other auxiliary components, as necessary. BMS Conntectivity

provisions with are - ON/OFF command, ON/OFF/TRIP status, Auto/Manual status should be included. The necessary card /

modbus should be included. All AHUs should have fire trip facility.Control panels shall contain factory mounted and wired fan

motor starters and auxiliary controls, plus a factory mounted and wired terminals strip within the panel conveniently located.

Plug fans and motors with VFD assemblies shall be factory mounted on a tubular structural steel base common. Control panel

shall be factory pre-wired for the system and shall be supplied with fuses, contactors, starters, control transformer, overload

protection, selector switch and all necessary components to insure continuous automatic operation.

The motor selected shall be energy efficient having efficiency EFF1 (Class I) at full load ranging between 82.5% to 92% in

accordance with motor rating as per specification

The unit shall also be consists of anti vibration mounts, service doors / inspection windows, Double skin rexin flexible

connection for fan outlet, Light and door limit switch, Filters as specified and additional commissioning filters during the

commisioning period. The filters as per BOQ will be installed after commising the system.

Air Treatment Engineering Private Limited

Project : Global Hospitals, Chennai.

Client : M/s. Global Hospitals, Chennai.

Unit components are Fresh air inlet, 10 micron filter, Inspection chamber, chilled water cooling coil, Inspection chamber,

Supply air fan, and weather canopy

The Supply / Return Blower Static Pressure - 75 mm wc.

Entering Air Temperature - DBT : 40 ºC(Chennai Outside Condition)

Leaving Air Temperature - DBT : 11ºC

The Chilled water in let / out let temperature : 8 ºC / 13 ºC.

The below Cfm should be achived at 40Hz of VFD Speed.

The noise level of the Ahu at 1m Should be less than 45dB(A) and the selection fan noise should not be more than 80dB(A).

AHU Factory pressure testing should be performed

Treated Fresh air Unit with the above specifications

Second Floor

37TR / 5500CFM 1 Nos - -

20TR / 3000CFM 1 Nos

Supply, Installation, Testing and commisioning of PN16 Rated Pre insulated Valve Package like Extended inlet chilled

water with Sluice valves, Y-Strainer, with additional motorized on/off valve with BMS integration, pressure gauge,

thermometer, and drain valve and pre insulated Valve Package like Extended Outlet chilled water with Sluice Valves,

CONTROL VALVE- ELECTRIC PR. INDEPENDENT VALVE WITH FLOW METER INBUILT, with additional motorized on/off

valve with BMS integration, pressure gauge, thermometer, and Air puge valve.

B

Dia 65mm 1 Set - -

Dia 50mm 1 Set - -

- -

GRAND TOTAL - -

NOTES: to be used at site should be approved by the consultant before delivery at site. All the deviation from the approved drawings during construction

Products

should be approved by the consultant. If the materials delivered at site and deviation without approval will not be paid. Copy of approved drawings and

submittals should

All Cost Should be kept

Include Taxat&site strictly.

Final Price should be indicated

Air Treatment Engineering Private Limited

You might also like

- CompTIA A Certification All-in-One Exam PDFDocument3 pagesCompTIA A Certification All-in-One Exam PDFsh s12% (25)

- Examples of Psychrometric Calculations For Summer and WinterDocument50 pagesExamples of Psychrometric Calculations For Summer and WinterlakshminarayananNo ratings yet

- Examples of Psychrometric Calculations For Summer and WinterDocument50 pagesExamples of Psychrometric Calculations For Summer and WinterlakshminarayananNo ratings yet

- Solved Problems in PsychrometryDocument86 pagesSolved Problems in Psychrometrylakshminarayanan67% (9)

- Hitachi ChillerDocument8 pagesHitachi Chillertrantrunghoa1984No ratings yet

- Peter Turner Drawing Duplications Vol 5 PDFDocument65 pagesPeter Turner Drawing Duplications Vol 5 PDFsteflan50% (2)

- Week 30 Lesson PlanDocument13 pagesWeek 30 Lesson Plannurulhuda287No ratings yet

- TS-02 Ventilation Fans - Toilet & BasementDocument11 pagesTS-02 Ventilation Fans - Toilet & BasementPraveen KumarNo ratings yet

- Hvac Boq - R0 - 2914Document46 pagesHvac Boq - R0 - 2914Vikash TiwariNo ratings yet

- Guide Specifications - TVR Inverter ENDocument22 pagesGuide Specifications - TVR Inverter ENHazem HassonNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- Hidronicos 2Document17 pagesHidronicos 2Gerardo Zumbado MNo ratings yet

- LG Multi V SPECDocument21 pagesLG Multi V SPECJavier SordoNo ratings yet

- Tech Specification VSDDocument9 pagesTech Specification VSDDony SaputraNo ratings yet

- Reference Costing 040419Document24 pagesReference Costing 040419Bency ThomasNo ratings yet

- Enquiry - AHUDocument31 pagesEnquiry - AHUrkpatel40No ratings yet

- Valves SpecsDocument3 pagesValves SpecsTareq AlsadiNo ratings yet

- Specif-Dust Extraction SystemDocument12 pagesSpecif-Dust Extraction SystemChristopher LloydNo ratings yet

- Minerbolter Class NotesDocument10 pagesMinerbolter Class NotesSivalya SivaramanNo ratings yet

- Mechanical Specifications For VillasDocument30 pagesMechanical Specifications For VillasdreamagiczNo ratings yet

- Fan BOQDocument16 pagesFan BOQpd statusNo ratings yet

- HVAC Tender BOQ 24.12.17Document22 pagesHVAC Tender BOQ 24.12.17yohannes haileNo ratings yet

- B800-1 ManualEDocument35 pagesB800-1 ManualESLAMET PAMBUDINo ratings yet

- HVAC BOQ - HOSPITAL at KozhikkodeDocument7 pagesHVAC BOQ - HOSPITAL at KozhikkodeVysakhan KrishnanNo ratings yet

- TRC Unit SpecDocument12 pagesTRC Unit SpecJohn ChirinosNo ratings yet

- MEPF BOQ - AZURE TargetDocument33 pagesMEPF BOQ - AZURE TargetUpendra ChariNo ratings yet

- Tech - Spec - OIL TYPE TRANSFORMERDocument2 pagesTech - Spec - OIL TYPE TRANSFORMERanup singhNo ratings yet

- SL No. Description Unit QTY: or 10mm ArmasoundDocument4 pagesSL No. Description Unit QTY: or 10mm ArmasoundAnkit JainNo ratings yet

- Hvac EstimateDocument18 pagesHvac Estimateraghu kiranNo ratings yet

- Catalogue For TFM-FR-TZ-TX-B PDFDocument15 pagesCatalogue For TFM-FR-TZ-TX-B PDFGuru Vaga50% (2)

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocument12 pagesThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNo ratings yet

- FHP Apseries WSHPDocument16 pagesFHP Apseries WSHPsajuhereNo ratings yet

- MDBFPDocument21 pagesMDBFPRaja Vignesh100% (2)

- 11.MechnicalSpec 253to318Document66 pages11.MechnicalSpec 253to318gaurangagola1991No ratings yet

- 42CN 2013Document16 pages42CN 2013Augusto OrellanaNo ratings yet

- VRVII Cooling Only Specification SMC 1-8-03 - TestDocument7 pagesVRVII Cooling Only Specification SMC 1-8-03 - TestAlexOdarteyBannermanNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- Parker Pvplus Installation ManualDocument16 pagesParker Pvplus Installation Manualym0224382856No ratings yet

- O&M Manual Fans SKMC 29feb2024Document122 pagesO&M Manual Fans SKMC 29feb2024Robert LazaroNo ratings yet

- Innovair PEK 60Hz R410a Commercial Package Brochure EnglishDocument12 pagesInnovair PEK 60Hz R410a Commercial Package Brochure Englishcris melos100% (1)

- AP Specs 2008Document39 pagesAP Specs 2008Ghiban ConstantinNo ratings yet

- Posicionadores Centac ViejosDocument13 pagesPosicionadores Centac Viejosalexander3233No ratings yet

- Power TransformerDocument17 pagesPower TransformerANANDNo ratings yet

- Parker PV SeriesDocument20 pagesParker PV SeriesPedro Piñero Cebrian0% (1)

- LM20020 A AHF AHK Installation Instructions 02 15Document12 pagesLM20020 A AHF AHK Installation Instructions 02 15Lisa TerzoNo ratings yet

- New Age GeneratorDocument26 pagesNew Age GeneratorDaud Ahmed Fihawango100% (1)

- General Notes On PRDSDocument6 pagesGeneral Notes On PRDSmkbeast60No ratings yet

- Winezone Air Handler System: Wzah #4 1Document29 pagesWinezone Air Handler System: Wzah #4 1constantin.iacomi3837No ratings yet

- 2x1400 Sayhoot Technical Documents CompletedDocument17 pages2x1400 Sayhoot Technical Documents Completedengnajeeb75No ratings yet

- Spec VRF - Water CooledDocument11 pagesSpec VRF - Water CooledUpul Samantha LiyanaarachchiNo ratings yet

- 2 Installation Maintenance - FantechDocument12 pages2 Installation Maintenance - FantechLoi Chan TuNo ratings yet

- WIND TUNNEL ManualDocument35 pagesWIND TUNNEL ManualSanjay KumarNo ratings yet

- Power TransformerDocument19 pagesPower TransformerMaruf Hossain KhanNo ratings yet

- Installation Instructions: GP/GPC, XP/XPC, XR SeriesDocument8 pagesInstallation Instructions: GP/GPC, XP/XPC, XR SeriesSai Sunil ChandraaNo ratings yet

- Ine - Chiller Carrier - 30rb090Document13 pagesIne - Chiller Carrier - 30rb090yves2329No ratings yet

- Bangalore Job OfferDocument25 pagesBangalore Job OfferPuneet AggarwalNo ratings yet

- B800 Series Frequency Inverter: Bedford (Quanzhou) Electronic Co., LTDDocument32 pagesB800 Series Frequency Inverter: Bedford (Quanzhou) Electronic Co., LTDAthaNo ratings yet

- Eastman Industries - BoqDocument6 pagesEastman Industries - BoqcivilNo ratings yet

- Kaukan Oil Cooler Instruction HandbookDocument14 pagesKaukan Oil Cooler Instruction HandbooksunhuynhNo ratings yet

- Accessory Manual - Operation Flow Meter FMBC2000 OIM (106761)Document10 pagesAccessory Manual - Operation Flow Meter FMBC2000 OIM (106761)Pkk Siam Rayong co-saleNo ratings yet

- ÉSECÈ Group - Steam Boiler - Mar12 ENGDocument4 pagesÉSECÈ Group - Steam Boiler - Mar12 ENGDiego Otero RodríguezNo ratings yet

- Axial & Jet Fans SpecificationDocument8 pagesAxial & Jet Fans SpecificationRamakrishnanNo ratings yet

- ATEX Construction (ENG)Document8 pagesATEX Construction (ENG)Carlos PintoNo ratings yet

- BOQ MergedDocument4 pagesBOQ Mergedfakir mohammadNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Load Schedule Calculation SheetDocument6 pagesLoad Schedule Calculation SheetlakshminarayananNo ratings yet

- CWC Report PDFDocument1 pageCWC Report PDFlakshminarayananNo ratings yet

- Air Change Rates NewDocument3 pagesAir Change Rates NewlakshminarayananNo ratings yet

- EDH Engineering GuideDocument3 pagesEDH Engineering GuidelakshminarayananNo ratings yet

- Week 2 Vent PsychChart InsulationDocument35 pagesWeek 2 Vent PsychChart InsulationlakshminarayananNo ratings yet

- Engineering GuideDocument34 pagesEngineering GuidelakshminarayananNo ratings yet

- HVAC Ducting - Principles and FundamentalsDocument56 pagesHVAC Ducting - Principles and FundamentalsRiddhi Patel100% (2)

- Desiccant Dehumidification Rotor and Cassette - 0Document15 pagesDesiccant Dehumidification Rotor and Cassette - 0lakshminarayananNo ratings yet

- Clean Room StandardsDocument12 pagesClean Room StandardslakshminarayananNo ratings yet

- HVAC Design For Cleanroom FacilitiesDocument33 pagesHVAC Design For Cleanroom FacilitieslakshminarayananNo ratings yet

- ABC of PhyscrometricsDocument50 pagesABC of Physcrometricsbibinme_b4uNo ratings yet

- NRLS-1215-National Cleani - Homes-2010.08.02-V1Document42 pagesNRLS-1215-National Cleani - Homes-2010.08.02-V1lakshminarayananNo ratings yet

- Evap Cooling Media Data PDFDocument1 pageEvap Cooling Media Data PDFlakshminarayananNo ratings yet

- Evap Cooling Media Data PDFDocument1 pageEvap Cooling Media Data PDFlakshminarayananNo ratings yet

- Evap Cooling Media Data PDFDocument1 pageEvap Cooling Media Data PDFlakshminarayananNo ratings yet

- Primary Exams 2023Document4 pagesPrimary Exams 2023Omel StephenNo ratings yet

- Cracking The GMATDocument605 pagesCracking The GMATMandeep SinghNo ratings yet

- Prestressed Concrete - Lecture 1 & 2Document69 pagesPrestressed Concrete - Lecture 1 & 2Banda RajeshNo ratings yet

- Media News ItemDocument10 pagesMedia News ItemArman DullahNo ratings yet

- AC2 Specification SheetDocument4 pagesAC2 Specification SheetWiwa Hernandez DonosoNo ratings yet

- Use of Electrochemical Techniques in Metal Conservation: Programme, Abstracts and Details of The SpeakersDocument8 pagesUse of Electrochemical Techniques in Metal Conservation: Programme, Abstracts and Details of The SpeakersFred LeviNo ratings yet

- Self Healing RobotsDocument5 pagesSelf Healing RobotsshaluNo ratings yet

- Chapter 7 Foundations of PlanningDocument5 pagesChapter 7 Foundations of PlanningAndrea KhoNo ratings yet

- X6642 VTiuDocument1 pageX6642 VTiuCesar Ivan Parra FigueroaNo ratings yet

- Hust H9C CNC: Connecting ManualDocument150 pagesHust H9C CNC: Connecting Manuals_barriosNo ratings yet

- Astronomic TarotDocument17 pagesAstronomic TarotNancy ZecchelNo ratings yet

- (4) Involuteσ Worm And Helical Gear Design SystemDocument3 pages(4) Involuteσ Worm And Helical Gear Design SystemIrena SavuNo ratings yet

- Lesson Plan MG6851Document3 pagesLesson Plan MG6851EZHILMARANNo ratings yet

- Annual Report 2013Document48 pagesAnnual Report 2013Shankar DasNo ratings yet

- Siae Microelettronica Alc User Manual - Mn00142e-007Document234 pagesSiae Microelettronica Alc User Manual - Mn00142e-007rubic3330% (1)

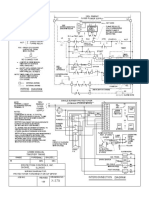

- 3.wiring Diagram Loto 2 System, Esd Cabin, ST Light Amber)Document2 pages3.wiring Diagram Loto 2 System, Esd Cabin, ST Light Amber)SyahriantoNo ratings yet

- Astm 388Document8 pagesAstm 388Joseph RefuerzoNo ratings yet

- Malnad College of Engineering, Hassan - 573 202, Karnataka: (An Autonomous Institution Under VTU, Belagavi)Document6 pagesMalnad College of Engineering, Hassan - 573 202, Karnataka: (An Autonomous Institution Under VTU, Belagavi)Shivaraj K YadavNo ratings yet

- Vol IDocument188 pagesVol IgaurangpatelNo ratings yet

- Tip Sheet 19 Environmental MonitoringDocument4 pagesTip Sheet 19 Environmental MonitoringmaritaNo ratings yet

- Data Modeling Entity Relationship DiagramsDocument27 pagesData Modeling Entity Relationship DiagramsPrachi SaxenaNo ratings yet

- A Arte Da Brevidade - Virginia WoolfDocument100 pagesA Arte Da Brevidade - Virginia WoolfAdriane LimaNo ratings yet

- FastLink CAT6 (SFTP) OutdoorDocument3 pagesFastLink CAT6 (SFTP) OutdoorHaiderNo ratings yet

- Professional Project ManagementDocument2 pagesProfessional Project ManagementVirginia Virgie100% (3)

- TAC QuickReferenceGuideDocument4 pagesTAC QuickReferenceGuideAlaa Al-saggafNo ratings yet

- Personalizing Dialogue Agents: I Have A Dog, Do You Have Pets Too?Document16 pagesPersonalizing Dialogue Agents: I Have A Dog, Do You Have Pets Too?Laksh KumarNo ratings yet

- CH 1 - Introduction To FMADocument22 pagesCH 1 - Introduction To FMAIPloboNo ratings yet