Professional Documents

Culture Documents

UN1020 User Manual

UN1020 User Manual

Uploaded by

Mehar Tariq GoheerCopyright:

Available Formats

You might also like

- Spare Part List MNS 2.0 and MNS 3.0 R0Document12 pagesSpare Part List MNS 2.0 and MNS 3.0 R0Jatupol Pongsirisart33% (3)

- UNITROL® 1010 User Manual: Automatic Voltage RegulatorDocument166 pagesUNITROL® 1010 User Manual: Automatic Voltage RegulatorKaleem Ullah75% (4)

- ZAB - UN1020 User Manual 3BHS335648 E82 PDFDocument195 pagesZAB - UN1020 User Manual 3BHS335648 E82 PDFdhinakaran100% (5)

- Advant OCS Pidcona: Functional Units Part 7Document154 pagesAdvant OCS Pidcona: Functional Units Part 7Mandar GandhiNo ratings yet

- 4-Cylinder Head Piston Coneecting Road & LinerDocument44 pages4-Cylinder Head Piston Coneecting Road & LinerMehar Tariq GoheerNo ratings yet

- Index: User's Manual Fully Automatic Washing MachineDocument16 pagesIndex: User's Manual Fully Automatic Washing MachineMehar Tariq GoheerNo ratings yet

- Unitrol 1020 ManualDocument2 pagesUnitrol 1020 ManualKarthick Kumaresan50% (2)

- Acs 2000ad Appl SW Amc TableDocument445 pagesAcs 2000ad Appl SW Amc TableChinna babu100% (5)

- VT240S Instruction Manual Reclaim Drive PDFDocument443 pagesVT240S Instruction Manual Reclaim Drive PDFShrikant Wagh100% (1)

- Sh. Bhardwaj CTR PDFDocument34 pagesSh. Bhardwaj CTR PDFSofyan Andika Yusuf100% (1)

- WASHING MACHINE Samsung Service Manual SWV-1200F/1100F/1000F/800F P1291/P1091/P8091/P6091Document24 pagesWASHING MACHINE Samsung Service Manual SWV-1200F/1100F/1000F/800F P1291/P1091/P8091/P6091politruk0% (1)

- Zab - Un1020 User Manual 3bhs335648 E82Document187 pagesZab - Un1020 User Manual 3bhs335648 E82Sueli E FranciscoNo ratings yet

- Medium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in IndiaDocument8 pagesMedium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in Indiaharshad_soni7912No ratings yet

- MRG3 Relay CatalogueDocument80 pagesMRG3 Relay Cataloguealdi siberian100% (1)

- Tuc 6 WF Manual PDFDocument92 pagesTuc 6 WF Manual PDFDhananjay MahakudNo ratings yet

- Grid-Tie Transformerless Solar Inverter: Rpi M50A Operation and Installation ManualDocument76 pagesGrid-Tie Transformerless Solar Inverter: Rpi M50A Operation and Installation ManualLars MaesNo ratings yet

- PC D235 A - Ac 800pec Cio-Fu Combined Input Output Data SheetDocument2 pagesPC D235 A - Ac 800pec Cio-Fu Combined Input Output Data SheetNguyen Duc Nha100% (1)

- Pid - 5030 Digital Pid Controller: Operator's ManualDocument22 pagesPid - 5030 Digital Pid Controller: Operator's Manualஇராம் பாபு100% (1)

- Premier 300Document2 pagesPremier 300Ranjith Kumar100% (1)

- GA700 Technical ManualDocument936 pagesGA700 Technical ManualTuanson Pham0% (1)

- UpsDocument8 pagesUpsrahu111112000100% (2)

- ACS580 Troubleshooting: Fault TracingDocument25 pagesACS580 Troubleshooting: Fault TracingMohamed Ayman Hefny MohamedNo ratings yet

- Manual Book Soft Starter Renle JJR8000Document70 pagesManual Book Soft Starter Renle JJR8000Herie HeriadieNo ratings yet

- Part Number Codes ACS-800 - enDocument3 pagesPart Number Codes ACS-800 - enmix111No ratings yet

- Acs 580Document36 pagesAcs 580Francisco ArellanoNo ratings yet

- 8204 User ManualDocument41 pages8204 User ManualDhaniraj SinghNo ratings yet

- Avr Abb 1000 UnitrolDocument8 pagesAvr Abb 1000 UnitrolSatyaKrishna Palla100% (2)

- Siemens VFD Manual 193Document328 pagesSiemens VFD Manual 193nitinsomanathanNo ratings yet

- GUTOR PDW DataDocument4 pagesGUTOR PDW Dataeng_iqbalNo ratings yet

- UNITROL 5000 User's Manual Appendix,: Unitrol 5000 AVR Controls ON-LINE Maintenance InstructionsDocument18 pagesUNITROL 5000 User's Manual Appendix,: Unitrol 5000 AVR Controls ON-LINE Maintenance Instructionssaravan1891No ratings yet

- Microtapper ManualDocument49 pagesMicrotapper ManualDeb SushitNo ratings yet

- EN - Tapcon 230 Expert Manual Instruþ Es de OperaþÒoDocument186 pagesEN - Tapcon 230 Expert Manual Instruþ Es de OperaþÒojoan75No ratings yet

- Dsai 130Document228 pagesDsai 130Gabriel Romero100% (1)

- Users Manual UNITROL 1000-PM40 PDFDocument19 pagesUsers Manual UNITROL 1000-PM40 PDFAlexandre100% (1)

- Hardware Manual ACS580 01Document218 pagesHardware Manual ACS580 01Mohsin YasinNo ratings yet

- Application Notes Interfacing Deif Equipment 4189340670 UkDocument46 pagesApplication Notes Interfacing Deif Equipment 4189340670 UkAikaAhNo ratings yet

- ATS Dwgs & PLC Manuals 1Document15 pagesATS Dwgs & PLC Manuals 1gigo_dreamNo ratings yet

- ABB Unitrol 6800 Brochure PDFDocument12 pagesABB Unitrol 6800 Brochure PDFhvhung165No ratings yet

- 1008S User ManualDocument38 pages1008S User ManualHardev Singh100% (1)

- LM 390A Discontinued PDFDocument68 pagesLM 390A Discontinued PDFsivaNo ratings yet

- Instruction Manual: Energy MeterDocument2 pagesInstruction Manual: Energy MeterIshwar ranawatNo ratings yet

- Elite 440 MFM - User - ManualDocument88 pagesElite 440 MFM - User - ManualtusharNo ratings yet

- C&S DMPR PDFDocument19 pagesC&S DMPR PDFDipankar Chakraborty100% (1)

- Masibus Tcs 4050m - Loop Calibrator - Cb-2 - tcs4050m - r2 - 0110Document2 pagesMasibus Tcs 4050m - Loop Calibrator - Cb-2 - tcs4050m - r2 - 0110kazishahNo ratings yet

- Pic152 User ManualDocument4 pagesPic152 User ManualCak Rony100% (2)

- 11g Blackbox Upload InstructionsDocument7 pages11g Blackbox Upload InstructionsCristhianLoayzaTacoNo ratings yet

- TI VSD ABB ACS800 Trouble Shooting 2946 0703 01 PDFDocument17 pagesTI VSD ABB ACS800 Trouble Shooting 2946 0703 01 PDFLenin PachecoNo ratings yet

- 4RB9512-8CD50 - Reaktif Kontrol Rölesi++Document120 pages4RB9512-8CD50 - Reaktif Kontrol Rölesi++omar omarNo ratings yet

- INTECONT® Tersus For Measuring Systems: % Compact Weighing Electronics ForDocument4 pagesINTECONT® Tersus For Measuring Systems: % Compact Weighing Electronics Forgnazareth_100% (1)

- Numerical Protection PDFDocument14 pagesNumerical Protection PDFDrashti PatelNo ratings yet

- New - Spectronic E-CatalogueDocument58 pagesNew - Spectronic E-CatalogueCARLOS LÓPEZNo ratings yet

- Manual 820-Pp AsDocument12 pagesManual 820-Pp AsjabalpuramitNo ratings yet

- PS451 ManualDocument106 pagesPS451 ManualUsama Sheikh100% (1)

- Digital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartDocument13 pagesDigital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartAnagha Deb100% (1)

- Rish Master 3428 MFMDocument5 pagesRish Master 3428 MFMAmit KumarNo ratings yet

- MAS100 Auto Synch RelayDocument18 pagesMAS100 Auto Synch RelayAdetunji Taiwo100% (1)

- Millmate Roll Force Systems With Millmate Controller 400: User ManualDocument234 pagesMillmate Roll Force Systems With Millmate Controller 400: User ManualChung NgoNo ratings yet

- Digital Voltage Regulator: Installation and MaintenanceDocument20 pagesDigital Voltage Regulator: Installation and MaintenanceAteeqNo ratings yet

- Advant Controller 410Document502 pagesAdvant Controller 410cristhian.eduardo99No ratings yet

- Abb Copa XFDocument64 pagesAbb Copa XFAndres FragosoNo ratings yet

- Bender A-Isometer IRDH575 User ManualDocument96 pagesBender A-Isometer IRDH575 User ManualAndreea Mitu HlandanNo ratings yet

- JUMO Quantrol LC100/LC200/LC300: Universal PID Controller SeriesDocument40 pagesJUMO Quantrol LC100/LC200/LC300: Universal PID Controller SeriesmikeNo ratings yet

- Inverter MannualDocument35 pagesInverter MannualMehar Tariq GoheerNo ratings yet

- Qpro 4fa Engls 120401Document2 pagesQpro 4fa Engls 120401Mehar Tariq GoheerNo ratings yet

- Qpro 4la Engls 141101Document9 pagesQpro 4la Engls 141101Mehar Tariq GoheerNo ratings yet

- Qpro 4aa Engls 120401Document4 pagesQpro 4aa Engls 120401Mehar Tariq GoheerNo ratings yet

- 9 Cooling SystemDocument11 pages9 Cooling SystemMehar Tariq GoheerNo ratings yet

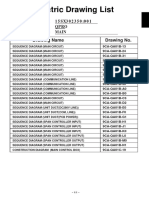

- Electric DrawingsDocument34 pagesElectric DrawingsMehar Tariq GoheerNo ratings yet

- 5-Cameshaft Drive Train & Tappet BlockDocument23 pages5-Cameshaft Drive Train & Tappet BlockMehar Tariq GoheerNo ratings yet

- 8-Lubricating Oil SystemDocument20 pages8-Lubricating Oil SystemMehar Tariq GoheerNo ratings yet

- 15-Parts List ELS12 MK2Document150 pages15-Parts List ELS12 MK2Mehar Tariq GoheerNo ratings yet

- Qpro 1 ENGLS 150801Document20 pagesQpro 1 ENGLS 150801Mehar Tariq GoheerNo ratings yet

- 3-Crankcase & CrankshaftDocument41 pages3-Crankcase & CrankshaftMehar Tariq GoheerNo ratings yet

- 6-Air Inlet & Exhaust SystemDocument10 pages6-Air Inlet & Exhaust SystemMehar Tariq GoheerNo ratings yet

- 7 Fuel SystemDocument21 pages7 Fuel SystemMehar Tariq GoheerNo ratings yet

- Temp O Tron User Manual UrduDocument6 pagesTemp O Tron User Manual UrduMehar Tariq GoheerNo ratings yet

- 2 Technical DataDocument10 pages2 Technical DataMehar Tariq GoheerNo ratings yet

- Washing Machine: Installation, 2-3 F ARDocument36 pagesWashing Machine: Installation, 2-3 F ARMehar Tariq GoheerNo ratings yet

- 1-Introduction ESL12 MK2Document9 pages1-Introduction ESL12 MK2Mehar Tariq GoheerNo ratings yet

- 0 Instruction ManualDocument419 pages0 Instruction ManualMehar Tariq Goheer100% (2)

- Temp 1000 New ManualDocument54 pagesTemp 1000 New ManualMehar Tariq GoheerNo ratings yet

- Temp R-Tron 612 Version 2.2 U Operation ManualDocument41 pagesTemp R-Tron 612 Version 2.2 U Operation ManualMehar Tariq GoheerNo ratings yet

- GS150 User ManualDocument53 pagesGS150 User ManualMehar Tariq Goheer33% (3)

- Manual Temp R Tron en 01 Sep 2016Document23 pagesManual Temp R Tron en 01 Sep 2016Mehar Tariq GoheerNo ratings yet

- Electrical Engineer: Tariq Maqsood TabassamDocument5 pagesElectrical Engineer: Tariq Maqsood TabassamMehar Tariq GoheerNo ratings yet

- Honda CG125Document2 pagesHonda CG125Mehar Tariq Goheer100% (3)

- Honda CD 70 Urdu-2Document30 pagesHonda CD 70 Urdu-2Mehar Tariq Goheer100% (7)

- Repair Manual For Universal Machine Power Supply (UMPS) (P/No 220010) Doc. No. 957-001 Revision A02Document14 pagesRepair Manual For Universal Machine Power Supply (UMPS) (P/No 220010) Doc. No. 957-001 Revision A02German ParceroNo ratings yet

- Manual Fx20gmDocument8 pagesManual Fx20gmHarmawan FebriantoNo ratings yet

- DB-03 FM Compact Transmitter 30W 5KW-DPM Green RF Series DB - 8 - LR - 2Document4 pagesDB-03 FM Compact Transmitter 30W 5KW-DPM Green RF Series DB - 8 - LR - 2Idhee Arkan ZoolhumNo ratings yet

- Service Manual: Air-Conditioner (Split Type)Document114 pagesService Manual: Air-Conditioner (Split Type)pastilhasNo ratings yet

- V T V5-H High Performance Sensorless Vector Control Variable Speed Drive ManualDocument166 pagesV T V5-H High Performance Sensorless Vector Control Variable Speed Drive ManualLeandroNo ratings yet

- The ALCO Controls EC3-75xDocument8 pagesThe ALCO Controls EC3-75xMaria DazaNo ratings yet

- Load Sequencing LSC2Document11 pagesLoad Sequencing LSC2IDA HAMIDAHNo ratings yet

- TW 4M 1 NDocument1 pageTW 4M 1 NStancu BranNo ratings yet

- Voltage RegulatorsDocument3 pagesVoltage RegulatorsNisha Kotyan G R100% (1)

- 6SL3120-1TE24-5AC0 Datasheet enDocument2 pages6SL3120-1TE24-5AC0 Datasheet enBojan BankovicNo ratings yet

- 03 LF - SS1101 - E01 - 1 Product Description of FDD LTE eNodeB 49Document49 pages03 LF - SS1101 - E01 - 1 Product Description of FDD LTE eNodeB 49Tinh Share PNo ratings yet

- Denyo DLW-300LS Instruction ManualDocument50 pagesDenyo DLW-300LS Instruction Manualhaimay118No ratings yet

- SCADAPack 350 Hardware ManualDocument110 pagesSCADAPack 350 Hardware ManualLászló LósNo ratings yet

- Atos Ben Marine lmn5 Electromagnetic Speed LogDocument1 pageAtos Ben Marine lmn5 Electromagnetic Speed Logromanov8812No ratings yet

- Manual Maya-625A S - Series PDFDocument25 pagesManual Maya-625A S - Series PDFHữu Dũng NguyễnNo ratings yet

- A 3150Document167 pagesA 3150Jim HarmkeNo ratings yet

- InCCA 2015 User's Manual v2.09.05 PDFDocument238 pagesInCCA 2015 User's Manual v2.09.05 PDFMDD EngineeringNo ratings yet

- LR-TB5000CL US en-USDocument2 pagesLR-TB5000CL US en-USGergő FaragóNo ratings yet

- Submittal Asd872aDocument9 pagesSubmittal Asd872ajibanez003No ratings yet

- UMD Series AC Servo User's ManualDocument201 pagesUMD Series AC Servo User's Manualcristian quispe lopezNo ratings yet

- Picaxe Projects by Enigma Part 1Document9 pagesPicaxe Projects by Enigma Part 1Carlos Ramirez100% (1)

- Microsoft Word Jz20 t40 Jz20 J t40 Instal Guide 06 14Document6 pagesMicrosoft Word Jz20 t40 Jz20 J t40 Instal Guide 06 14Kleber Abarca PachecoNo ratings yet

- REM610 Ref Manual IECDocument160 pagesREM610 Ref Manual IECfiatraj1No ratings yet

- Regulated Power Supply, 100 To 240V AC, 24V, 2.5A, Single Phase, ModularDocument11 pagesRegulated Power Supply, 100 To 240V AC, 24V, 2.5A, Single Phase, ModularDodongNo ratings yet

- UntitledDocument53 pagesUntitledThong Dang SyNo ratings yet

- Manual Alarma S120Document23 pagesManual Alarma S120Gustavo Agüero100% (1)

- CCPE - 2011 - Implementation of Zigbee Based Power ManagementDocument5 pagesCCPE - 2011 - Implementation of Zigbee Based Power Managementf_adbeNo ratings yet

- Zen Manual 311011Document20 pagesZen Manual 311011armin heidariNo ratings yet

UN1020 User Manual

UN1020 User Manual

Uploaded by

Mehar Tariq GoheerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UN1020 User Manual

UN1020 User Manual

Uploaded by

Mehar Tariq GoheerCopyright:

Available Formats

Wärtsilä id: DBAD431286 a

ABB

UNITROL® 1020 User Manual

Automatic Voltage Regulator

Compact voltage regulator for synchronous machines

up to 20 A exciter current

Product Release 5.111

DSP Control: 5.110

MCU Control: 5.101

CMT1000: 5.110

Document No. 3BHS335648 E82

Revision Status Rev. -

Date 08 / 2011

UNITROL 1020 User Manual 3BHS335648 E82 i

Wärtsilä id: DBAD431286 a

ABB

ABB reserves all rights to this document and to the information and

topics contained in it. This also applies to any possible claims to

copyright or patents. Forwarding and/or the duplicating of this document

without the express permission of ABB is forbidden.

This document has been prepared and checked with great care. If

however it still contains errors, please report them to ABB.

ii 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB

Table of Contents

Table of Contents ...............................................................................................................iii

Terms and Abbreviations .................................................................................................vii

Chapter 1 - Introduction .................................................................................................1-1

1.1 General ..........................................................................................................................1-1

1.2 Field of Application ........................................................................................................1-1

1.3 Contents of this Manual .................................................................................................1-2

1.4 Intended Audience.........................................................................................................1-3

1.5 Manufacturer’s Address.................................................................................................1-3

Chapter 2 - Safety Instructions ......................................................................................2-1

2.1 General ..........................................................................................................................2-1

2.2 Qualifications and Responsibilities ................................................................................2-1

2.2.1 Qualifications and Responsibilities ......................................................................................... 2-1

2.2.2 Consequences of Non-Compliance ........................................................................................ 2-1

2.3 Safety Concept ..............................................................................................................2-2

2.3.1 General ................................................................................................................................... 2-2

2.3.2 Safety Rules............................................................................................................................ 2-2

2.3.3 Residual Danger Areas........................................................................................................... 2-2

2.4 Safety Regulations.........................................................................................................2-1

2.4.1 Structure of Safety Instructions............................................................................................... 2-1

2.5 Instructions for Emergency Situations ...........................................................................2-2

2.5.1 Firefighting .............................................................................................................................. 2-2

2.5.2 First Aid Measures for Electrical Installations......................................................................... 2-2

2.5.3 Pacemaker.............................................................................................................................. 2-3

2.6 Danger signs..................................................................................................................2-3

Chapter 3 - Device Overview..........................................................................................3-5

3.1 General ..........................................................................................................................3-5

3.2 Description of the Excitation System .............................................................................3-5

3.2.1 Introduction ............................................................................................................................. 3-5

3.3 Hardware .......................................................................................................................3-6

3.3.1 Connection Diagram ............................................................................................................... 3-6

3.3.2 Control Interfaces.................................................................................................................... 3-7

3.3.3 Overview of the Device Connections.................................................................................... 3-13

3.3.4 Device Connections .............................................................................................................. 3-14

3.3.5 Digital Inputs ......................................................................................................................... 3-17

3.3.6 Digital Outputs ...................................................................................................................... 3-19

3.3.7 Analog Inputs ........................................................................................................................ 3-20

3.3.8 Analog Outputs ..................................................................................................................... 3-22

3.3.9 Communication Ports............................................................................................................ 3-23

3.4 Software.......................................................................................................................3-29

3.4.1 Operating Modes .................................................................................................................. 3-30

3.4.2 Startup Functions.................................................................................................................. 3-33

3.4.3 On-line Operation Functions................................................................................................. 3-39

3.4.4 Limiters and Monitor Functions............................................................................................. 3-41

UNITROL 1020 User Manual 3BHS335648 E822

Wärtsilä id: DBAD431286 a

ABB

3.4.5 Miscellaneous Functions....................................................................................................... 3-53

3.4.6 Modbus for remote Access ................................................................................................... 3-56

3.4.7 Access Levels ....................................................................................................................... 3-57

Chapter 4 - Installation and Storage ............................................................................. 4-1

4.1 General ......................................................................................................................... 4-1

4.2 Safety Regulations........................................................................................................ 4-1

4.3 Unpacking ..................................................................................................................... 4-1

4.4 Mechanical Installation.................................................................................................. 4-2

4.5 Electrical Installation ..................................................................................................... 4-3

4.6 Storage ......................................................................................................................... 4-3

4.6.1 Storage Conditions.................................................................................................................. 4-3

4.6.2 Disposal................................................................................................................................... 4-3

Chapter 5 - Commissioning........................................................................................... 5-1

5.1 General ......................................................................................................................... 5-1

5.2 Safety Regulations........................................................................................................ 5-1

5.3 Setting Aids................................................................................................................... 5-2

5.3.1 Setting Aids ............................................................................................................................. 5-2

5.4 Work carried out while Machine is at Standstill............................................................. 5-8

5.5 Work carried out while Machine is Running .................................................................. 5-9

5.5.1 No-load Tests (nominal speed, not synchronized) ................................................................. 5-9

5.5.2 Tests under Load .................................................................................................................... 5-9

5.5.3 Synchronization..................................................................................................................... 5-10

5.6 Concluding Work after Commissioning ....................................................................... 5-11

Chapter 6 - Operation..................................................................................................... 6-1

6.1 General ......................................................................................................................... 6-1

6.2 Safety Regulations........................................................................................................ 6-1

6.3 Panel Operation ............................................................................................................ 6-2

6.3.1 Panel Start-up ......................................................................................................................... 6-2

6.3.2 Display elements..................................................................................................................... 6-3

6.3.3 Keypad Operation ................................................................................................................... 6-3

6.3.4 Emergency Excitation OFF ..................................................................................................... 6-4

6.3.5 Setpoint Adjustment ................................................................................................................ 6-4

6.3.6 Menu Structure........................................................................................................................ 6-5

6.3.7 Setpoint Step........................................................................................................................... 6-8

6.3.8 Save to EEPROM ................................................................................................................... 6-8

6.3.9 Limiters.................................................................................................................................... 6-9

6.3.10 Alarms and Fault Messages.................................................................................................. 6-10

6.4 PC Software Tool........................................................................................................ 6-11

6.4.1 PC Software Tool .................................................................................................................. 6-11

6.4.2 System Requirements for CMT1000 Release 5.1 ................................................................ 6-11

6.4.3 Installing CMT1000 Software ................................................................................................ 6-12

6.4.4 Starting with CMT1000.......................................................................................................... 6-17

6.4.5 Menu Structure of CMT 1000................................................................................................ 6-20

6.4.6 Setup Menu........................................................................................................................... 6-36

6.4.7 Tune Menu ............................................................................................................................ 6-56

6.4.8 Save Parameter File ............................................................................................................. 6-58

Chapter 7 - Preventive Maintenance ............................................................................. 7-1

7.1 General ......................................................................................................................... 7-1

iv 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB

7.2 Safety Regulations.........................................................................................................7-1

7.3 Standard Procedures for Maintenance ..........................................................................7-1

Chapter 8 - Troubleshooting ..........................................................................................8-1

8.1 General ..........................................................................................................................8-1

8.2 Safety Regulations.........................................................................................................8-1

8.3 List of Possible Faults....................................................................................................8-1

8.4 Repair ............................................................................................................................8-4

8.5 Compatibility ..................................................................................................................8-4

Chapter 9 - Technical Data .............................................................................................9-1

9.1 General ..........................................................................................................................9-1

9.1.1 Ordering Information ............................................................................................................... 9-1

9.1.2 Electrical Data of AVR UN1020: ............................................................................................. 9-1

9.1.3 Environmental data: ................................................................................................................ 9-3

9.1.4 Reliability UNITROL 1020....................................................................................................... 9-3

9.1.5 Battery life time information .................................................................................................... 9-3

9.1.6 Mechanical data...................................................................................................................... 9-4

9.2 Settings Record for UNITROL 10X0..............................................................................9-5

9.3 Parameter Settings, Default Values...............................................................................9-6

Chapter 10 - Appendix ....................................................................................................10-1

10.1 Documentation References .........................................................................................10-1

UNITROL® 1020 User Manual 3BHS335648 E82 v

Wärtsilä id: DBAD431286 a

Wärtsilä id: DBAD431286 a

ABB

Terms and Abbreviations

AC Alternating Current

AIO Analog Input and Output

AUTO Automatic Voltage Regulation (Auto Mode)

AVR Automatic Voltage Regulator

Bat Battery

CAN Controller-area network

CB Circuit Breaker

MAIN Main Channel in double channel systems.

REDUNDANT Redundant (Backup) Channel in double channel systems.

CT Current Transformer

DC Direct Current

DIO Digital Input and Output

DSP Digital Signal Processor: referred as the main controller of the

AVR, responsible of regulation, control and communication.

ESD Electrostatic Discharge

ETH Ethernet Terminal

EXC Excitation

FCB Field Circuit Breaker

GEN Generator

GFR Ground Fault Relay (Rotor Ground Fault Protection)

HW Hardware

IGBT Insulated Gate Bipolar Transistor

MANUAL Field Current Regulation (Manual Mode)

MCU Microcontroller unit

PC Personal Computer

PCB Printed Circuit Board

PDF Portable Document Format

PE Protective Earth (Protective Ground)

PF Power Factor Mode

PPE Personal Protective Equipment

PS Power Supply

PSS Power System Stabilizer

PT Potential Transformer

PWM Pulse Width Modulation

Q Reactive Power

RDM Rotating Diode Monitoring

SW Software

UMAUX UM Auxiliary Input Measurement

VAR Reactive Power Mode

V/Hz Volt per Hertz (-Limiter)

VDC Voltage Droop Compensation

VM Voltage Matching

UNITROL 1020 User Manual 3BHS335648 E822

Wärtsilä id: DBAD431286 a

Wärtsilä id: DBAD431286 a

ABB

Chapter 1 - Introduction

1.1 General

The User Manual provides detailed information on the

safety instructions

description of the product,

installation,

commissioning & operation,

maintenance and troubleshooting

of the UNITROL 1020, including detailed descriptions of the functions and

the hardware of the device. Technical data is included as well.

1.2 Field of Application

This advanced-design automatic voltage regulator is used for the excitation of indirectly

excited synchronous machines and motors. The regulator can also be switched over to

function as a reactive power-, power factor- or field current regulator.

Back-up Channel

Batt

.

SM = Synchronous Machine

E = Exciter

Optional:

- Power System Stabilizer (PSS)

- Synchronization unit

- Data Logger

SM E

- Event Recorder

UNITROL 1020 User Manual 3BHS335648 E82 1-1

Wärtsilä id: DBAD431286 a

Chapter 1 - Introduction ABB

SM = Synchronous Machine

E = Exciter

PMG = Permanent Magnet Gen.

PMG

Generator or motor excitation with

PMG or external supply.

SM E

1.3 Contents of this Manual

Chapter 1 - Introduction describes the contents of the User Manual and

provides the manufacturer’s information.

Chapter 2 - Safety Instructions explains the safety instruction levels and

provides general instructions on safety, which need to be strictly observed.

Chapter 3 - Device Overview outlines the description of the device,

operation modes, hardware capabilities and software features.

Chapter 4 - Installation and Storage provides information on environmental

conditions to be maintained during transportation and storage, information

on disposal and recycling of materials.

Chapter 5 - Commissioning provides information on preparing the device

for commissioning.

Chapter 6 - Operation describes the instructions how to operate the device.

Chapter 7 - Preventive Maintenance contains the maintenance schedule

and step-by-step instructions for specific maintenance tasks to be carried

out by the customer.

Chapter 8 -Troubleshooting provides instructions on how to proceed when

encountering problems.

Chapter 9 - Technical Data describes the technical data from the device,

ordering number and parameter list.

1-2 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 1 - Introduction

1.4 Intended Audience

The User Manual addresses the following target groups:

Engineering

Installation personnel

Operators

Maintenance and repair personnel

1.5 Manufacturer’s Address

If any questions arise, consult the local ABB representative or the

manufacturer:

IMPORTANT!

When calling ABB, please leave your name, department and phone

number. This will allow the responsible ABB representative to call back

without delay.

ABB Switzerland Ltd

Static Excitation Systems, Voltage Regulators

and Synchronizing Equipment

CH-5300 Turgi / Switzerland

Telephone: +41 58 589 24 86

Fax: +41 58 589 23 33

Email: pes@ch.abb.com

Internet: http://www.abb.com/unitrol

24 h – Hotline for urgent service inquiries: +41 844 845 845

Email contact for questions and UNITROL 1000 support:

UNITROL1000Support@ch.abb.com

ABB is constantly striving for the best product and service offerings for our

customers. Therefore ABB appreciates your valuable feedback or

suggestions for improvements of UNITROL products.

Please send your comments to "unitrol.feedback@ch.abb.com". Your

information will be forwarded to the responsible persons in order to improve

ABB’s future offerings.

UNITROL 1020 User Manual 3BHS335648 E82 1-3

Wärtsilä id: DBAD431286 a

Wärtsilä id: DBAD431286 a

ABB

Chapter 2 - Safety Instructions

2.1 General

Chapter 2 - Safety Instructions includes the safety instructions that must

be followed during installation, operation and maintenance of the

excitation system. Please read all instructions carefully before operating

the device and keep this manual for future reference.

2.2 Qualifications and Responsibilities

2.2.1 Qualifications and Responsibilities

Personnel involved in installation work and commissioning of the

UNITROL 1020 must be familiar, specially instructed and informed about

the residual danger areas according to the regulations currently in force.

Operating personnel is not permitted to work at the control system.

Specially instructed personnel must only carry out maintenance and

repair work.

The maintenance personnel must be informed about the emergency

shutdown measures and must be capable of turning off the system in

case of emergency.

The maintenance personnel must be familiar with the accident prevention

measures at their workplace and must be instructed in first aid and fire

fighting.

It is the owner’s responsibility to ensure that each person involved in the

installation and commissioning of the UNITROL 1020 has received the

appropriate training or instructions and has thoroughly read and clearly

understood the safety instructions in this chapter.

2.2.2 Consequences of Non-Compliance

Failure to comply with the safety instructions increases the risk of electric

shock and damage to the equipment. Third parties who approach the

installation are also at risk.

If the scheduled maintenance activities are performed only partially or not

at all, damage may occur with associated expensive repair costs.

UNITROL 1020 User Manual 3BHS335648 E82 2-1

Wärtsilä id: DBAD431286 a

Chapter 2 - Safety Instructions ABB

2.3 Safety Concept

2.3.1 General

The safety regulations in this chapter generally apply when working on

the excitation system. You will find additional instructions and warnings

related to particular topics or actions throughout the manual where

relevant.

The following regulations must be strictly observed:

The technical specifications and the typical application of the

excitation system (see Chapter 1 - Introduction, Field of Application)

must be strictly adhered to.

Training of personnel: only trained personnel are allowed to install,

operate, maintain or service the excitation system.

Modifications without authorization: modifications and constructional

changes of the equipment are not allowed.

Duty of maintenance: The owner must ensure that the excitation

system is used only under proper conditions and in a fully serviceable

state.

2.3.2 Safety Rules

The following safety procedures according to EN 50110-1 must absolutely

be followed if any (maintenance) work is carried out on the excitation

system:

1 Disconnect completely.

2 Secure against re-connection.

3 Verify that the installation is dead.

4 Carry out grounding and short-circuiting.

5 Provide protection against adjacent live parts.

2.3.3 Residual Danger Areas

Danger areas that cannot be eliminated by technical measures are clearly

marked with warning labels.

The operating voltage in the control cubicles is above 50 V. In the power

part, voltages can reach 300 V ac and short-circuit currents can be very

high. In order to warn personnel against opening the doors during

operation, warning labels are affixed to all cubicle doors.

If the device is built into a whole system, other warning labels are

attached to the inside of the cubicle doors and to the covers of the power

converter modules.

2-2 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 2 - Safety Instructions

The following residual danger areas must be taken into account when

working on the excitation system:

Danger from live equipment inside the excitation system, if the

protective covers are removed.

Hazardous voltage from the rotor field winding and the secondary

side of the excitation transformer.

Capacitors may still be charged if a power converter cubicle door is

opened immediately after stopping the system.

Danger from main and auxiliary voltages in cubicles when cubicle

doors are open.

Attention must be paid when installing / replacing the UNITROL 1020.

The unit has large capacitors, which might be charged even after

disconnecting the unit.

An orange blinking LED warns the user in case the internal voltage

exceeds 50 V dc. Depending on the size of the condenser, this can take a

couple of minutes. Do not connect or disconnect the unit when the

LED is still blinking. There is the risk of electric shock.

UNITROL 1020 User Manual 3BHS335648 E82 2-3

Wärtsilä id: DBAD431286 a

Wärtsilä id: DBAD431286 a

ABB

2.4 Safety Regulations

2.4.1 Structure of Safety Instructions

Signal Word!

Symbol Situation - Type of Hazard Statement

Possible consequence - Consequence Statement

Essential safety measure - Avoidance Statement

The safety instructions always appear at the beginning of each chapter

and/or precede any instruction in the context where a potentially

dangerous situation may appear. The safety instructions are divided into

five categories and emphasized by the use of the following layout and

safety signs:

DANGER!

This symbol indicates an imminent danger resulting from mechanical

forces or high voltage. Non-observance leads to life-threatening physical

injury or death.

WARNING!

! This symbol indicates a dangerous situation. Non-observance can result

in bad or life-threatening physical injury or death.

CAUTION!

This symbol indicates a dangerous situation. Non-observance can lead

to physical injury or cause damage to the installation.

NOTICE!

This symbol emphasizes important information. Non-observance can

cause damage to the installation or to objects close to it.

IMPORTANT!

This symbol indicates useful information. Not to be used to indicate

dangerous situations.

UNITROL 1020 User Manual 3BHS335648 E82 2-1

Wärtsilä id: DBAD431286 a

Chapter 2 - Safety Instructions ABB

2.5 Instructions for Emergency Situations

2.5.1 Firefighting

All personnel must be familiar with the location of fire extinguishers and

emergency exits and must be able to operate the fire extinguishers.

Fire extinguishers are carbon dioxide (CO2) or foam-based.

CO2 fire extinguishers are intended for fighting fires in electrical

installations and may not be directed at persons.

Foam extinguishers are intended for fighting fires in non-electrical

equipment. They may be directed at persons but must not be used

for extinguishing fires in electrical equipment.

DANGER!

In case of fire,

Be aware of voltage, toxic gases, overheating.

See the instructions below.

1 Shut down the system.

Operators must be familiar with the emergency shutdown sequence.

2 Put on a protection mask.

3 Use only CO2 to extinguish the fire, no foam, no water.

2.5.2 First Aid Measures for Electrical Installations

In case of an emergency, follow the instructions below:

DANGER!

A person is in contact with electricity.

There is a danger of electric shock for the first aider as well.

Do not touch the person until the system is grounded.

1 Shut down the plant.

Operators must be familiar with the emergency shutdown sequence

of the system.

DANGER!

Residual voltage of the rotating machine is present immediately after

shut-down of the system.

There is a danger of electric shock.

Wait until the system is grounded.

2-2 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 2 - Safety Instructions

1 Switch off all power supplies and ground the system.

2 Remove the injured person from the dangerous location.

3 Provide first aid for electric shock.

4 Call for emergency assistance.

2.5.3 Pacemaker

DANGER!

Electrical and magnetic fields.

The system can cause malfunction of pacemakers.

Avoid being close to the excitation system.

Electrical and magnetic fields can influence pacemakers. It is difficult to

predict the general sensitivity of pacemakers.

2.6 Danger signs

Danger signs are attached to any equipment/location with a potential

danger.

The degree and likelihood of such dangers are described by the signal

words DANGER, WARNING and CAUTION. The content of the warning

sign contains information about the respective situation and the

preventive safety measures that must be taken.

Structure of danger signs:

Sign Description

Signal word

DANGER

Situation

Hazardous voltage inside.

Essential safety measures

Disconnect power and

ground equipment before

maintenance work.

Meaning of signal words and consequence statement:

Sign Description of the signal word

DANGER, electrical

DANGER

This symbol indicates imminent danger that will result

in life-threatening physical injury or death.

UNITROL 1020 User Manual 3BHS335648 E82 2-3

Wärtsilä id: DBAD431286 a

Chapter 2 - Safety Instructions ABB

WARNING, electrical

WARNING This symbol indicates a possible dangerous situation

that could result in serious physical injury or death.

CAUTION, electrical

CAUTION This symbol indicates a possible dangerous situation

that could result in moderate physical injury. This

signal word can also be used for warnings related to

equipment damage.

2-4 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

Chapter 3 - Device Overview

3.1 General

Chapter 3 - Device Overview provides the technical data of the device.

This chapter contains:

Hardware description

Operation modes and software features

Parameter description

3.2 Description of the Excitation System

3.2.1 Introduction

UNITROL 1020 is an automatic voltage regulator of the latest design for

synchronous generators and synchronous motors. The unit contains the

most advanced microprocessor technology together with IGBT

semiconductor technology (Insulated Gate Bipolar Transistor).

All operations are effected through a practical and simple-to-operate

panel on the unit. In addition, user-friendly software facilitates

commissioning and allows optimization of operation.

The mechanical construction is extremely compact and robust.

The UNITROL 1020 unit can be connected to a 40 A Power Module

called UNITROL 1000-PM40. For further information please refer to the

separate User Manual.

UNITROL 1020 User Manual 3BHS335648 E82 3-5

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

3.3 Hardware

Casing

The device’s base is an aluminum back plane.

Cooling is done by the main heat sink on top of

the device. The unit itself is covered with plastic

and provides an IP20 protection.

Power electronics

The power part is fitted with an IGBT semi-

conductor. The average value of the output

voltage is always positive. The output is current-

280.25 mm

302 mm

limited and thus short-circuit-proof.

Control elements

The display panel and connectors for the USB

and Ethernet interface are located on the unit

cover.

Installation

The site of installation must be dry and free of

147.5 mm dust.

170 mm

3.3.1 Connection Diagram

Digital I/Os

Analog I/Os

UNITROL 1020

AUX L1

Measurement

~

and control

UNET AUX L2

= AUX L3

inputs

UM ETH

USB

AVR

IM2

RS- 485

PWM CAN

ExCap(-)

Supply

power electronics

Ie -

PWR L1

SM E

E PWR L2

Ie PWR L3

+

3-6 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

3.3.2 Control Interfaces

The UN1020 device can be operated and controlled in different ways as described in the

rest of this section.

3.3.2.1 Digital and analog IO

The UN1020 can be controlled by means of digital and analog inputs and can therefore

set up several configurations to fulfill most target applications. Digital and analog IO has

highest priority and can not be overridden by any other controls.

3.3.2.2 Keyboard and Panel Display

The four-line display and the four keys are sufficient to

allow full operation.

All settings can be carried out directly on the unit without

additional equipment:

Configuration of inputs and outputs

Parameter setting

Display of important measuring values.

The operation of the Panel is described in detail in

section 6.3 Panel Operation.

3.3.2.3 Remote Access using MODBUS

The Remote Access feature allows device access and control from local or remote

locations by using MODBUS as application protocol. The communication can be

performed either via RS485 or TCP/IP. More information about the connection

possibilities can be found in Chapter 3.3.9 - Communication Ports.

Basic features and advantage of Remote Access

Configuration of parameters and I/O signals.

Measurement reading.

Setpoint adjustment and PID tuning.

Possibility to create a custom application that uses Remote Access to fully control the

device.

Monitor only and full control possible.

The Remote Access feature is fully interoperable with the CMT1000 software; both

interfaces can access and read from the device at the same moment and control

permission (write parameters) is handled automatically by the AVR microcontroller. The

Remote Access feature is described in detail in Chapter 3.4.6 - Modbus for remote

Access.

3.3.2.4 Terminal Blocks

The terminal blocks are separated regarding their functions, see Figure 3-1.

UNITROL 1020 User Manual 3BHS335648 E82 3-7

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

Power

U AUX

U PWR

Excitation output

USB Measurement

STATUS Um, Unet, Im

ETHERNET

CAN (X1302)

RS-485 (X1300)

Digital I/Os Analog I/Os

Figure 3-1Terminal Block of UN1020

3-8 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

Ref. Label Signal Description

17 PE Protection Earth

16 PWR L1 Main L1

15 AUX L1(+) Power Supply L1 (+)

14 PWR L2 Main L2

13 AUX L2(-) Power Supply L2 (-)

12 PWR L3 Main L3

11 AUX L3 Power Supply L3

10 IE + Exciter Current +

9 IE - Exciter Current -

8 ExCap(-) External Capacitor -

7 ML1 Machine L1

6 ML2 Machine L2

5 ML3 Machine L3

4 NW1 Network L1

3 NW3 Network L3

2 MC2+ Machine Current +

1 MC2- Machine Current -

UNITROL 1020 User Manual 3BHS335648 E82 3-9

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

Ref. Label Signal Description

20 G2 GND

21 G1 GND

22 D12 Digital Input 12

23 D11 Digital Input 11

24 D10 Digital Input 10

25 D9 Digital Input 9

26 V6 24V Power

27 V5 24V Power

Digital IO Terminal

28 D8 Digital Input / Output 8

29 D7 Digital Input / Output 7

30 D6 Digital Input / Output 6

31 D5 Digital Input / Output 5

32 V4 24V Power

33 V3 24V Power

34 D4 Digital Input / Output 4

35 D3 Digital Input / Output 3

36 D2 Digital Input / Output 2

37 D1 Digital Input / Output 1

38 V2 24V Power

39 V1 24V Power

Ref. Label Signal Description

40 BO2 GND Analog Output 2

41 AO2 Analog Output 2

Analog IO Terminal

42 BO1 GND Analog Output 1

43 AO1 Analog Output 1

44 BRN GND Negative Reference

45 ARN -10V Negative Reference

46 BRP GND Positive Reference

47 ARP +10V Positive Reference

3-10 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

48 BI3 Analog Input 3 –

Analog IO Term.

49 AI3 Analog Input 3 +

50 BI2 Analog Input 2 –

51 AI2 Analog Input 2 +

52 BI1 Analog Input 1 –

53 AI1 Analog Input 1 +

70 72 74 76

71 73 75 77

The jumpers must be

plugged as shown in

the drawing on the left.

X1300 X1302

Ref. Label Signal Description

70 RH RS-485 +

RS-485 / CAN Terminal

71 CH CAN High

72 RS RS-485 shield

73 CS CAN Shield

74 RL RS-485 -

75 CL CAN Low

76 CV CAN Power 5V

77 CG CAN GND

UNITROL 1020 User Manual 3BHS335648 E82 3-11

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

D804

D802

USB Ethernet

D800

Pin Label Signal Description

1 Transmitter +

2 Transmitter –

3 Receiver +

4 Do not use [connected to magnetics]

Ethernet

5 Do not use [connected to magnetics]

6 Receiver –

7 Do not use [connected to magnetics]

8 Do not use [connected to magnetics]

LED Green ETH Link OK

LED Yellow ETH Data Traffic

Ref. Label Signal Description

1 USB Power 5V

USB

2 Data -

3 Data +

4 GND

Ref. Color Description

D800 Green Power ON status

ON: DSP and MCU is powered

Blinking: Target SW is running

Status LEDs

D802 Yellow Excitation ON, Blinking: Limiter active

D804 Red Device status

ON: Alarm or trip active

Blinking:

Startup failure, target could not load parameters

Excitation output is blocked

Save parameter to EEPROM first before starting excitation

3-12 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

3.3.3 Overview of the Device Connections

(+10 V) +Vref AUX L1

(-10 V) -Vref

AUX L2

(+24 V) +Vdig UAUX

AGND AUX L3

PE

DGND

PWR L1 IE+

PWR L2 IE-

Main Ie

PWR L3 ExCap

RS-485

RL

RHVDC

ML1 L1 or

Machine ML2 PID X1300 Remote

L2

voltage ML3 L3 RS Access

MC2+ positive CAN Bus

Machine gnd CG

current MC2- negative CH

DSP CL

NW1 positive

Network NW3 X1302 CAN

negative

CS

ETH

CMT1000 USB 2.0

or Remote 4 pol CMT1000

Access or Remote

AI1 to AI3

Access

BI1 to BI3 AO1

ARP +10V # AGND BO1

Analog

inputs BRP ~ Analog

ARN

AGND

-10V

# ~ AGND

AO2

BO2

output

BRN AGND

in, norm.

+24V V1 to V4

V5, V6 +24V norm.

D1 to D8 Digital

D9 to D12 in, inv.

Digital IO's

out, inv.

inputs

G2 DGND inv. DGND G1

out, norm.

UNITROL 1020 User Manual 3BHS335648 E82 3-13

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

3.3.4 Device Connections

Terminal Signal Circuit

designation

Auxiliary Power Supply UAUX

15 = AUX L1 - Auxiliary Power Supply L1 (+) External 3~

9 ... 300 V~ L1,L2,L3

13 = AUX L2 - Auxiliary Power Supply L2 (-)

11 = AUX L3 - Auxiliary Power Supply L3 1~

50 ... 300 V~ L1, L2

2=

18 ... 300 V= L1, L2

Power Electronics Supply UPWR

16 = PWR L1 - Main L1 External 3~

0 ... 300 V~ L1,L2,L3

14 = PWR L2 - Main L2

12 = PWR L3 - Main L3 1~

0 ... 300 V~ L1, L2

2=

0 ... 300 V= L1, L2

External Capacitor

IE-

8 = ExCap(-) - Capacitor: 1000 µF, 550 V External

ExCap(-)

+

E

Warning: IE+

Reverse polarity of external

capacitor will damage device

Machine Voltage three-phase UM External

7 = ML1 - Machine L1 ML1

6 = ML2 - Machine L2 ML2

5 = ML3 - Machine L3 ML3

* max. 500 V / 0.2 VA

Machine Current single-phase IM2 SM

2 = MC2+ - Machine Current +

1 = MC2- - Machine Current - MC1

IM2 5 A / 0.1 VA

MC2

Machine Voltage single-phase UM

7 = ML1 - Main L1

External

*

5 = ML3 - Main L3

ML1

ML3

Machine Voltage three-phase

with ground UM * max. 500 V / 0.2 VA

7 = ML1 - Machine L1 External

6 = ML2 - Machine L2 ML1

5 = ML3 - Machine L3 ML2

ML3

*PT & CTs must be grounded L1 L2 L3 * max. 500 V / 0.2 VA

Line Voltage measurement External

single-phase UNET NW1

4 = NW1 Network L1 NW3

3 = NW3 Network L3

* max. 500 V / 0.2 VA

*PT & CTs must be grounded

Excitation Current Output Ie External

IE+

10 = IE + - Exciter Current + 0 to 300 V=

E

20 A =

9 = IE - - Exciter Current - IE-

17 = PE Protection Earth

3-14 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

Terminal Signal Circuit

designation

Digital input / output

External

24V

37 = D1 Digital Input / Output 1 V1

36 = D2 Digital Input / Output 2 20 ... 28 V

V2

35 = D3 Digital Input / Output 3

34 = D4 Digital Input / Output 4

31 = D5 Digital Input / Output 5

D1 ADC

30 = D6 Digital Input / Output 6

29 = D7 Digital Input / Output 7 2k

28 = D8 Digital Input / Output 8

Caution:

Configured as outputs, DIO1 … External

24V

DIO8 must not be connected V1

20 ... 28 V

directly with 24 V Power V2

(causes short circuit via internal

transistor)

max. 100 mA

D1

39 = V1 24V Power

38 = V2 24V Power

33 = V3 24V Power

32 = V4 24V Power

20 = G1 GND

21 = G2 GND

Digital input only

25 = D9 Digital Input 9

24 = D10 Digital Input 10

23 = D11 Digital Input 11

22 = D12 Digital Input 12

27 = V5 24V Power

26 = V6 24V Power

20 = G2 GND

Note: The internal 24 V supply (V1 to V6) can be loaded with a maximum of 600 mA by

all used digital inputs and outputs.

UNITROL 1020 User Manual 3BHS335648 E82 3-15

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

Terminal designation Signal Circuit

53 = AI1, 52 = BI1 Analog Inputs External 10 V DC

51 = AI2, 50 = BI2 AIx/BIx ARP

4.7k

49 = AI3, 48 = BI3 AI1 100k

+

R 47k

BI1

47 = ARP +10 V pos Ref -

100k

45 = ARN -10 V neg Ref BRP

47k

AGND

4.7k

ARN

BRP = 46 GND Positive Reference -10 V DC

BRN = 44 GND Negative Reference

External

max. ±10 V

AI1 + 100k

+

47k

BI1 -

-

100k

47k

Analog Inputs digitally

assigned 10 V DC

53 = AI1, 52 = BI1 AIx/BIx ARP

51 = AI2, 50 = BI2 4.7k

100k

AI1

49 = AI3, 48 = BI3 see Chapter 3.3.7 - + Ain

Analog Inputs 47k

BI1

-

100k

47k

Analog Outputs

AOx to BOx max. ±10 V

43 = AO1 (AGND = BO1, BO2) + AO1

41 = AO2 -

42 = BO1

BO1

40 = BO2

Serial interface RS-485

RH

72 = RS RS-485_SHIELD +

RS

RS485+

RS485_SHIELD

70 = RH RS-485 + - RL RS485-

74 = RL RS-485 – +

5V

Two jumpers X1300 for - X1300

the bus terminating

resistor.

Jumpers must be placed

at both ends of the bus

CAN Bus CG CAN_GND

77 = CG CAN_GND +

CL

CS

CAN_L

CAN_SHIELD

75 = CL CAN_L - CH CAN_H

VC

73 = CS CAN_SHIELD +

CAN_POWER

71 = CH CAN_H -

X1302

Two jumpers X1302 for

See terminals the bus terminating

resistor.

Jumpers must be placed

at both ends of the bus

3-16 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

3.3.5 Digital Inputs

Input Function Description

None Input not assigned

Excitation ON active Excitation ON command active:

- Field flashing begins if Off Level > 0%

- Auto mode: Soft start begins after the Off Level has been reached,

and rises up to the Auto Initial Setpoint.

- Other modes: Initial Setpoint is used.

Excitation ON not active Excitation ON command not active: Mode Initial Setpoint

All setpoints are immediately set to Auto 100%

their initial values and remain fixed Manual 0%

there (see table on the right).

Open Loop 0%

Auto, Manual and Open loop Initial PF 1.0

setpoints can be changed from their Var 0%

standard start-up values.

Gen CB Closed Status Circuit-breaker closed status active:

active - Activates current measurement

- This message immediately triggers the ramp of the Softstart as if

still the hold time.

Gen CB Closed Status no Circuit-breaker closed status Mode Final Value

longer active changes from active to not active. Manual 90% Ie No Load

All setpoints are immediately set to

Open Loop 90% 1/Kceil

the following values:

Auto 100%

Parallel with Grid Status Parallel with grid status active:

- Together with Gen CB Closed, enables the possibility to change

over to PF and Var modes.

- Disables VDC mode.

Increase Increase setpoint of active regulator

Decrease Decrease setpoint of active regulator

Reset Setpoint Status reset setpoint is active: Mode Final Value

The setpoint of the active regulator Manual Ie No Load

goes to the following value at ramp Open Loop 100% 1/Kceil

speed:

PF 1.0

Var 0%

Auto 100%

Remote SP Enable When active it enables the setpoint adjustment from an analog input

(remote setpoints should be configured in Analog Input section).

PF Enable 5 Activates Power factor regulation.

Var Enable 5 Activates Reactive power regulation.

Manual Enable Activates Manual operation mode (field current regulation).

Open Loop Enable Open loop, direct control of power transistor active

Synchronize 3 Activates Synchronization or Voltage Matching:

If Synchronization SW (optional) is not available in the device, the

input signal will activate Voltage Matching only.

VDC Enable 4 Activates the Voltage Droop Compensation (VDC) control mode.

Secondary Net 4 Selects the Secondary Net 2 for VDC operation.

3

Requires Synchronization SW

4

Requires Voltage Droop Compensation (VDC) SW

UNITROL 1020 User Manual 3BHS335648 E82 3-17

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

5

Requires the PF/VAR SW

Input Function Description

Reset Alarm Clear the following alarms:

- SW Alarm

- Supervision Alarm 1

- Supervision Trip 1

- Changeover 1

Standby When the AVR is in Standby mode:

- The excitation output of the AVR is turned off

- Boost is disabled

- Field flashing is off

- Integrator is kept in 1/Kceiling

- All limits are disabled

- No VDC data is transmitted via the RS-485.

- The AVR displays Standby as Operation Mode.

- DCH Follow-up1 operates, only if DCH communication is active;

otherwise the Channel Follow-up operates instead. For more

information see Chapter 3.4.4.3.4 - DCH Follow-Up and 3.4.1.5 -

Channel Follow-up.

- Alarm and Trip statuses1 output their values via digital outputs only

if they are configured to behave like that. For more information see

Chapter 3.4.4.3.2 - DCH Supervision.

RC Fieldbus Block It disables the Fieldbus communication in local operation.

FCB closed Status Field circuit breaker closed status active.

Reserved Reserved for future software expansions

External Alarm1 Input to use as External Alarm input1.

EmergencyExcitationOff Excitation OFF command

1

Requires Double Channel SW.

3.3.5.1 Polarity

Polarity can be configured for all digital input/output ports separately, and each one has a

separate polarity configuration when configured as input or output. Each DIO port can be

configured as only input or only output at the same time.

24 V DC 24 V DC

inverted

DIO1 to 8 DIO1 to 8

DI9 to 12 DI9 to 12

normal DI13 to 18 DI13 to 18

3.3.5.2 Forcing Digital Input Signals

Each digital input signal can be set to a predefined value (i.e. active/not active) by means

of configuration, without the need to make connections at the device's terminals; this

process is also known as forcing.

Forcing a digital input terminal can be done by configuring the Polarity parameter of an

input to Normal or Inverted. When Polarity is set to Normal, the digital input is set to not

active, i.e. false or logical 0. When it is set to Inverted, the input is set to active, i.e. true

or logical 1. The digital input which is being configured, must not be wired at the device

3-18 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

terminals. For more information about configuration see Chapter 6 - Operation.

3.3.6 Digital Outputs

Output Function Description

None Output not assigned

Boost Status signal boost is active

Boost supports excitation in the event of line short circuit or heavy load.

The boost function is blocked during field flashing and Softstart.

Field Flashing Field flashing (voltage build up) active, if Excitation ON.

See section 2.4.2 The next field flashing can only be started after Excitation ON or after the

power has been switched off.

During field flashing the output of the regulator is blocked in all operation

modes.

Limit Active One of the limiters (V/Hz, Ie, PQ or UM) is active

or setpoint limit has been reached (min. or max. position)

V/Hz Limit Active V/Hz limiter active

SP Limit Reached Setpoint limit has been reached

SP Minimum Minimum setpoint has been reached

Reached

SP Maximum Maximum setpoint has been reached

Reached

Operational Limit Ie, PQ, UM limiter or Diode Alarm active

Active

Min Ie Active Ie minimum current limiter active

Max Ie Active Ie maximum current limiter active

Min PQ Active PQ limiter active

Min UM Active Limit value for minimum machine voltage is under-run,

voltage limiter active

Max UM Active Limit value for maximum machine voltage is exceeded,

voltage limiter active

Voltage Relay Active = machine voltage below boost threshold

Inactive = boost threshold plus hysteresis exceeded

Not dependent on signal Excitation ON.

Close CB The command is released:

Command 3 - Angle is in a value where it would take the Total CB Closing Time for the

breaker to close at zero degrees with current speed and acceleration.

- Sync Check demand active

- The command is active as long as the command Sync Check is active

Sync Check 3 Sync Check demand to be active:

- Generator circuit breaker is open

- Machine voltage is higher than 50%

- Synchronization is possible (unit with Sync-Option)

- Synchronize is enabled

- Slip is between minimum slip and maximum slip

- Machine voltage is deviating from network voltage maximum Delta U

- Angle is between -maximum delta angle and +maximum delta angle

SW Alarm Software program process is out of order

Diode Alarm2 Event of open diode

Diode Trip2 Event of a shorted diode

2

Requires Rotating Diode Monitoring SW.

3

Requires Synchronization SW.

UNITROL 1020 User Manual 3BHS335648 E82 3-19

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

Output Function Description

MODBUS Com Alarm Loss of MODBUS command

Close FCB Command Command to close the field circuit breaker

Open FCB Command Command to open the field circuit breaker

Alarm signal that can be connected to several monitoring

Supervision Alarm1

functions1.

Trip signal that can be connected to several monitoring

Supervision Trip1

functions1.

1

Requires Double Channel SW.

3.3.7 Analog Inputs

Input Function Description

None Input not assigned

Auto Remote Setpoint External setpoint input to Auto regulator

PF Remote Setpoint 5 External setpoint input to PF regulator

Var Remote Setpoint 5 External setpoint input to Var regulator

Manual Remote Setpoint External setpoint input to Manual regulator

Open Loop Remote SP External setpoint input to open loop

UM Aux 6 Auxiliary supply to the summing point of Auto regulator

Reserved Reserved.

Cooling Media Temperature Input temperature measurement for the temperature influence

limiter

Reserved 9 to 12 Reserved for future software expansions

Digital Input 13(+) & 14(-) Assign digital inputs

Digital Input 15(+) & 16(-) Assign digital inputs

Digital Input 17(+) & 18(-) Assign digital inputs

5

Requires PF/VAR SW.

6

Requires UM AUX SW.

Note: When configuring an external setpoint from the analog input list shown above, the

"Remote SP Enable" digital input should also be configured. For more information see

Chapter 3.3.5 Digital Inputs.

3-20 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

3.3.7.1 Level of the Analog Inputs

Internal signal value [%]

External setpoint input

Setpoint max

Setpoint min

Ext. Setpoint Auto

-10 10 [V]

Uin0% Uin100%

UM Aux [%]

Input to the summing 10

point max

Uin0% Analog in

-10 10 [V]

min Uin100%

-10

Input voltage of the cooling media temperature

Range: Uin0% = - 10.0 V refers to - 100 °C

Uin100% = +10.0 V refers to +100 °C

DI13 = 1

Condition of the

digital inputs

-5.0 -2.0 DI13 = 0

DI14 = 0 Uin

(DI 13 to DI18) 2.0 5.0 [V]

DI14 = 1

Status of the digital -> Din13(+) = 0 -> Din13(+) = 1

inputs -> Din14(-) = 1 -> Din14(-) = 0

Note: AI and BI must not be active simultaneously, DI13 and DI14 will both be “0”

UNITROL 1020 User Manual 3BHS335648 E82 3-21

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

3.3.8 Analog Outputs

Output Function Description

None Output not assigned

Excitation Current Excitation current

PWM Pulse width modulation, control value is limited to a minimum of 2%

Fbias Analog continuous signal presenting difference between UNET and UM

Fbias = fNET – fNOM – (SlipMAX – SlipMIN)/2

Output signal Fbias is forced to zero:

- Not in Sync mode

- Synchronization function not enabled (unit without Sync-Option)

- Network frequency is not between 45 … 66 Hz

Slip Slip between Network and Machine frequencies

Active Power Machine Active Power

Note: The assignment of the analog outputs to the 2 terminals AO1 and AO2 can be

selected freely.

3.3.8.1 Level of the Analog Outputs

Excitation Current Aout [V]

10

Caution: Uout 100%

Ie0% must be less than

Ie100% Uout 0%

Ie

400 [%]

-10

Ie 0% Ie100%

Aout [V]

10

Uout 100%

Fbias

Uout 0% Fbias

-10 10 [Hz]

Fbias0% Fbias 100%

-10

Aout [V]

10

Uout 100%

PWM Output

Uout 0% PWM

100 [%]

-10

3-22 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

Aout [V]

10

Slip

Uout 100%

(max) Slip

* The parameter "Slip0%" -10 10 [Hz]

cannot be set by the user.

This parameter is internally Uout 0%

(min)

set as the negative of "Slip

100%": -10

"Slip0%" = (-)"Slip100%" Slip 0%* Slip 100%*

(min) (max)

Aout [V]

10

ActivePower Uout 100%

(max)

ActivePower

200 [%]

Uout 0%

(min)

-10

ActivePower 100%

(max)

Note: The full voltage range runs from -10 V to 10 V at a resolution of 10 bits.

3.3.9 Communication Ports

The UN1020 has three main communication ports to share several features which can be

used in combination to cover the requirements of an application.

USB is a point-to-point interface that can be used to connect the UNITROL 1020

with a PC and is used by the CMT1000 software to control the device.

The Ethernet port is used to connect the UNITROL 1020 to a multiple point

Ethernet network in order to connect the CMT1000 remotely and to access the

UNITROL 1020 by a plant control system in parallel.

RS-485 is a multi-point interface that could be used for Remote Access (Modbus

RTU) or VDC; only one feature can be used at the same time.

CAN is a multi-point interface used to connect a UN1000-PM40 module and uses

the Double Channel feature for setpoint follow-up of the second channel. Only one

of the above features can be used at same time.

This section describes the hardware and wiring requirements for the communication

interfaces. The software features that use these communication interfaces are explained

in Chapter 3.4 Software.

UNITROL 1020 User Manual 3BHS335648 E82 3-23

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

3.3.9.1 USB Interface

The serial USB port of UN1020 can be used to connect a PC that runs a CMT1000

software (see Error! Reference source not found.).

Maximum cable length = 3 meters

USB

(point–to–point)

CMT1000

Figure 3-2 USB connection to a PC

NOTICE!

Use only the USB cable that is supplied with the device. Using

another cable might cause communication failure or power over

USB might not work correctly so that the device does not start.

3.3.9.2 Ethernet Interface

Modbus TCP over Ethernet

Network

(multi – point)

Remote

Terminal

CMT1000

Figure 3-3 Ethernet TCP/IP connection

The Ethernet TCP/IP connection:

Ethernet allows monitoring and control from a remote location.

Max. one CMT1000 connection can simultaneously access the AVR

3-24 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

Multiple Remote Control connections can simultaneously access the

AVR

TCP Ports

1 Ethernet scanning Port 5002/5003

(CMT1000 function)

2 Modbus TCP Port 502

3 SNTP server Port 123

More information about these software features and configuration can be found in

Chapters 3.4.6 Modbus for remote Access and 6.4 PC Software Tool.

UNITROL 1020 User Manual 3BHS335648 E82 3-25

Wärtsilä id: DBAD431286 a

Chapter 3 - Device Overview ABB

3.3.9.3 RS485 Interface

UN1020 provides a RS485 interface for both VDC and Remote Access; however only

one can be operated with the RS485 interface. If both features are simultaneously

required, the solution is the usage of Remote Access over Modbus TCP/IP and VDC over

RS485 (Figure 3-4).

Modbus TCP (Ethernet)

Remote

VDC communication over RS485 Terminal

SM1 SM2

Figure 3-4 ABB solution if both Remote Access and VDC features are required.

The electrical connections of the RS485 bus should be performed according to EIA485

standard specification. The 120 Ohm resistor normally used to terminate a RS485 bus is

already included in UN1020 and should be used by placing a jumper bridge over the

X1300 terminals. The X1300 location is shown in Chapter 3.3.2.4 Terminal Block.

Cable type requirements

Cable cross-section: 2 x 0.25mm2

Cable impedance: 100 to 120 Ohm

Shielded twisted pair.

500m max cable length

(in case of UNITROL 1000-15 in the bus only 250m)

Bus topology

64 devices maximum

59.7 kBaud

The cable shielding shall be grounded as closely as possible to the device's terminals as

shown in Figure 3-5.

3-26 3BHS335648 E82 UNITROL 1020 User Manual

Wärtsilä id: DBAD431286 a

ABB Chapter 3 - Device Overview

485 CAN

- gnd

- 5V Shield

+

RH RL RS CG CH CL CV CS

CAN

X1302

RH RS RL CV

CH CS CL CG

RS-485 Max.

X1300 30 mm

Shielding

should be

grounded.

Figure 3-5 Shielding and wiring recommendation when using the RS-485 interface.

RS485 for VDC and remote access

When configuring the RS485 interface for VDC or remote access, a jumper bridge should

be placed over the X1300 terminals of each AVR located at the end of the bus; and it

should be removed from those not located at the end (see Figure 3-6). No resistor should

be placed externally, i.e. on the device's terminals, when the jumper bridge of the