Professional Documents

Culture Documents

IEC Certification Kit: Embedded Coder ISO 26262 Tool Qualification Package

IEC Certification Kit: Embedded Coder ISO 26262 Tool Qualification Package

Uploaded by

Loc HuynhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEC Certification Kit: Embedded Coder ISO 26262 Tool Qualification Package

IEC Certification Kit: Embedded Coder ISO 26262 Tool Qualification Package

Uploaded by

Loc HuynhCopyright:

Available Formats

IEC Certification Kit

Embedded Coder®

ISO 26262 Tool Qualification Package

R2020b

July 22, 2020 certkitiec_ecoder_tqp

How to Contact MathWorks

Latest news: www.mathworks.com

Sales and services: www.mathworks.com/sales_and_services

User community: www.mathworks.com/matlabcentral

Technical support: www.mathworks.com/support/contact_us

Phone: 508-647-7000

The MathWorks, Inc.

1 Apple Hill Drive

Natick, MA 01760-2098

IEC Certification Kit Embedded Coder® ISO 26262 Tool Qualification Package

© COPYRIGHT 2009-2020 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used or

copied only under the terms of the license agreement. No part of this manual may be photocopied or reproduced

in any form without prior written consent from The MathWorks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation by, for, or

through the federal government of the United States. By accepting delivery of the Program or Documentation, the

government hereby agrees that this software or documentation qualifies as commercial computer software or

commercial computer software documentation as such terms are used or defined in FAR 12.212, DFARS Part

227.72, and DFARS 252.227-7014. Accordingly, the terms and conditions of this Agreement and only those rights

specified in this Agreement, shall pertain to and govern the use, modification, reproduction, release, performance,

display, and disclosure of the Program and Documentation by the federal government (or other entity acquiring for

or through the federal government) and shall supersede any conflicting contractual terms or conditions. If this

License fails to meet the government’s needs or is inconsistent in any respect with federal procurement law, the

government agrees to return the Program and Documentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand names may be

trademarks or registered trademarks of their respective holders.

Patents

MathWorks products are protected by one or more U.S. patents. Please see www.mathworks.com/patents

for more information.

July 22, 2020 certkitiec_ecoder_tqp

Revision History

September 2009 New for Version 1.1 (Applies to Release 2009b)

March 2010 Revised for Version 1.2 (Applies to Release 2010a)

April 2010 Revised for Version 1.3 (Applies to Release 2009bSP1)

September 2010 Revised for Version 1.3 (Applies to Release 2010b)

March 2011 Revised for Version 1.4 (Applies to Release 2010bSP1)

April 2011 Revised for Version 1.4 (Applies to Release 2011a); renamed to Embedded

Coder® ISO 26262 Tool Qualification Package

September 2011 Revised for Version 2.0 (Applies to Release 2011b)

March 2012 Revised for Version 2.1 (Applies to Release 2012a)

September 2012 Revised for Version 3.0 (Applies to Release 2012b)

March 2013 Revised for Version 3.1 (Applies to Release 2013a)

September 2013 Revised for Version 3.2 (Applies to Release 2013b)

March 2014 Revised for Version 3.3 (Applies to Release 2014a)

October 2014 Revised for Version 3.4 (Applies to Release 2014b)

March 2015 Revised for Version 3.5 (Applies to Release 2015a)

September 2015 Revised for IEC Certification Kit Version 3.6 (Applies to Release 2015b)

March 2016 Revised for IEC Certification Kit Version 3.7 (Applies to Release 2016a)

September 2016 Revised for IEC Certification Kit Version 3.8 (Applies to Release 2016b)

March 2017 Revised for IEC Certification Kit Version 3.9 (Applies to Release 2017a)

September 2017 Revised for IEC Certification Kit Version 3.10 (Applies to Release 2017b)

March 2018 Revised for IEC Certification Kit Version 3.11 (Applies to Release 2018a)

September 2018 Revised for IEC Certification Kit Version 3.12 (Applies to Release 2018b)

March 2019 Revised for IEC Certification Kit Version 3.13 (Applies to Release 2019a)

September 2019 Revised for IEC Certification Kit Version 3.14 (Applies to Release 2019b)

March 2020 Revised for IEC Certification Kit Version 3.15 (Applies to Release 2020a)

September 2020 Revised for IEC Certification Kit Version 3.16 (Applies to Release 2020b)

July 22, 2020 certkitiec_ecoder_tqp

Contents

1 Introduction ................................................................................................................................................ 1-1

2 Application Identification ........................................................................................................................... 2-1

3 Tool Identification and Qualification Artifacts Summary ........................................................................... 3-1

3.1 Tool Identification............................................................................................................................... 3-1

3.2 Tool Qualification Artifacts Summary ................................................................................................. 3-1

4 Software Tool Criteria Evaluation Report ................................................................................................... 4-1

4.1 Tool Environment ............................................................................................................................... 4-1

4.2 Tool Configuration .............................................................................................................................. 4-1

4.3 Reference Workflow ........................................................................................................................... 4-1

4.4 Tool Use Cases .................................................................................................................................... 4-2

4.5 Generic Tool Classification.................................................................................................................. 4-2

4.5.1 Potential Malfunctions or Erroneous Output .......................................................................... 4-2

4.5.2 Error Prevention and Detection Measures .............................................................................. 4-3

4.5.3 Tool Classification Summary .................................................................................................... 4-5

5 Software Tool Qualification Report ............................................................................................................ 5-1

5.1 Requirement for Tool Qualification .................................................................................................... 5-1

5.2 Tool Qualification Documentation ..................................................................................................... 5-1

6 Confirmation Review of Tool Classification and Qualification .................................................................... 6-1

6.1 Requirement for Confirmation Review............................................................................................... 6-1

6.2 Validity of Generic Tool Classification ................................................................................................ 6-1

6.2.1 Validity of Tool Use Cases ........................................................................................................ 6-1

6.2.2 Validity of Error Prevention and Detection Measures ............................................................. 6-4

6.2.3 Validity of Tool Classification Summary ................................................................................... 6-6

6.3 Validity of Generic Tool Qualification ................................................................................................. 6-7

6.4 Conformance with Reference Workflow ............................................................................................ 6-7

July 22, 2020 certkitiec_ecoder_tqp i

1 Introduction

This document constitutes the ISO 26262 Tool Qualification Package for the Embedded Coder® product. This

document is intended for use in the ISO 26262 tool classification and qualification process for software

tools. It contains templates for the ISO 26262 tool qualification work products (see ISO 26262-8:2018,

Section 11).

The applicant shall review this template for applicability to the application under consideration, and then

tailor and complete the information.

See also:

• IEC Certification Kit: User’s Guide, R2019b

• ISO 26262-8:2018, Section 11

ISO 26262-8:2018, Clause 11 provides provisions for software tools that are used to tailor activities or tasks

required by ISO 26262. The standard outlines a two-step approach to establish the required confidence in

the tools:

• Tool classification determines the required level of confidence in the software tool.

• Depending on the result of the tool classification, you might need to carry out a formal tool qualification.

This document includes the following work products that need to be created when applying this approach

to a software tool (see ISO 26262-8:2018, 11.5):

• Software Tool Criteria Evaluation report, which provides the tool classification.

• Software Tool Qualification report, which provides the tool qualification information (if required).

Note ISO 26262-8:2018 is used as a basis for tool classification and qualification. This approach is

considered suitable for the other standards supported by the IEC Certification Kit for

Embedded Coder: IEC 61508, IEC 62304, EN 50128, EN 50657, or ISO 25119.

The applicant needs to review this template for applicability to the project under consideration and insert

missing information.

This document is intended for use with:

• Embedded Coder Reference Workflow (certkitiec_ecoder_workflow)1

• Embedded Coder Conformance Demonstration Template (certkitiec_ecoder_cdt)1

As you review this document, notice the use of <Insert Information>. This tag indicates where you should

customize the document for the project under consideration.

The following figures provide information to help understand how the IEC Certification Kit documentation

correlates to the user’s development workflow, tool classification, and tool qualification.

1 This document is available in the IEC Certification Kit Artifacts Explorer, the Embedded Coder folder.

July 22, 2020 certkitiec_ecoder_tqp 1-1

Figure 1 demonstrates the process of integrating the Embedded Coder reference workflow with your

project’s development workflow. It identifies workflow components and documentation that may be

affected by the consolidation.

Figure 1 Consolidation of the Embedded Coder Reference Workflow and Project Workflow

Figure 2 illustrates the correlation between the tool use cases, tool classification, and tool qualification.

Figure 2 Tool Classification and Tool Qualification Approach

July 22, 2020 certkitiec_ecoder_tqp 1-2

2 Application Identification

Applicant: <Insert Information>

Application under consideration <Insert Information>

July 22, 2020 certkitiec_ecoder_tqp 2-1

3 Tool Identification and Qualification

Artifacts Summary

3.1 Tool Identification

Embedded Coder® is a code generator that transforms executable models into C or C++ code. The input

languages comprise Simulink®, Fixed-Point Designer™, and Stateflow®. Embedded Coder is an extension of

Simulink Coder™ that generates C or C++ code for embedded, discrete-time systems.1

Embedded Coder with AUTOSAR Blockset supports the generation of production code and files for

AUTOSAR application software components as follows:

• For AUTOSAR Classic software, generation of C code

• For AUTOSAR Adaptive software, generation of C++ code

AUTOSAR Blockset also allows you to develop Classic and Adaptive AUTOSAR software using

Simulink® models.

Table 1 Tool Identification

Software Tool Version (Release) Tool Vendor

Embedded Coder® Version 7.5 (R2020b) The MathWorks, Inc.

1 Apple Hill Drive

AUTOSAR Blockset Version 2.3 (R2020b) Natick, MA, 01760-2098 USA

IEC Certification Kit Version 3.16 (R2020b)

3.2 Tool Qualification Artifacts Summary

For the Embedded Coder product, Table 2 lists:

• Prerequisites

• Supporting information

• Tool qualification work products

The tool qualification artifacts listed in the table are mapped to sections in this document and artifacts

found elsewhere.

1 All products require MATLAB® as the underlying base software. Simulink® Coder™ requires MATLAB® Coder™.

July 22, 2020 certkitiec_ecoder_tqp 3-1

Table 2 Tool Qualification Artifacts

ISO 26262- Tool Certification Artifact Corresponding Documents/Artifacts

8:2018,

section

11.3.1 Safety plan <Insert Information. Include document title, version,

filename, and link>

11.3.1 Organization-specific rules and <Insert Information. Include document title, version,

processes for functional safety filename, and link >

11.3.1 Applicable prerequisites of the <Insert software lifecycle phase(s) and prerequisite(s)>

lifecycle phases where software

tool is used

11.3.2 Predetermined maximum ASIL <Insert ASIL>

11.3.2 Software tool documentation Embedded Coder:

Embedded Coder Getting Started Guide, R2020b

ecoder_newgs.pdf

Embedded Coder User’s Guide, R2020b

ecoder_ug.pdf

Embedded Coder Reference, R2020b

ecoder_ref.pdf

Embedded Coder Release Notes, R2020b

rn.pdf

AUTOSAR Blockset:

AUTOSAR Blockset User’s Guide, R2020b

autosar_ug.pdf

AUTOSAR Blockset Reference, R2020b

autosar_ref.pdf

AUTOSAR Blockset Release Notes, R2020b

rn.pdf

11.3.2 Environment and constraints of MathWorks® bug report system at

the software tool www.mathworks.com/support/bugreports/

<Insert a list of the applicable bug reports. Include

reference to the bug reports analysis and, if applicable,

patches installation reports>

July 22, 2020 certkitiec_ecoder_tqp 3-2

ISO 26262- Tool Certification Artifact Corresponding Documents/Artifacts

8:2018,

section

11.5.1 Software tool criteria evaluation Customized and completed Chapter 4: Software Tool

report Criteria Evaluation Report of Embedded Coder ISO 26262

Tool Qualification Package (this document)

certkitiec_ecoder_tqp.docx

Embedded Coder Reference Workflow, R2020b

certkitiec_ecoder_workflow.pdf

Certificate

certkitiec_ecoder_certificate.pdf

Report to the Certificate

certkitiec_ecoder_certreport.pdf

<If applicable, insert additional documentation. Include

document title, version, filename, and link>

11.5.2 Software tool qualification Customized and completed Chapter 5: Software Tool

report Qualification Report in the Embedded Coder ISO 26262 Tool

Qualification Package (this document)

certkitiec_ecoder_tqp.docx

Customized and completed Embedded Coder Conformance

Demonstration Template

certkitiec_ecoder_cdt.docx

Certificate

certkitiec_ecoder_certificate.pdf

Report to the Certificate

certkitiec_ecoder_certreport.pdf

<If applicable, insert additional documentation. Include

document title, version, filename, and link>

July 22, 2020 certkitiec_ecoder_tqp 3-3

4 Software Tool Criteria Evaluation

Report

4.1 Tool Environment

It is assumed that Embedded Coder® will be used in the following environment (see ISO 26262-8:2018,

11.4.4.1d):

<Insert Information, such as operating system or pertinent environment information>

4.2 Tool Configuration

It is assumed that Embedded Coder will be used in the following tool configuration provided in Table 3

when generating code (see ISO 26262-8:2018, 11.4.4.1b):

Table 3 Tool Configuration

Configuration Parameter Setting

Code Generation Pane

System target file <Insert .tlc file name of the ERT-based or

AUTOSAR system target file>

Language <Insert project-specific setting>

<Insert configuration parameter> <Insert project-specific setting>

Optimization Pane

<Insert configuration parameter> <Insert project-specific setting>

Hardware Implementation Pane

<Insert configuration parameter> <Insert project-specific setting>

4.3 Reference Workflow

It is assumed that Embedded Coder will be used as described in the reference workflow documented in

Embedded Coder Reference Workflow.1

1 This document is available in the IEC Certification Kit Artifacts Explorer, the Embedded Coder folder.

July 22, 2020 certkitiec_ecoder_tqp 4-1

4.4 Tool Use Cases

It is assumed that Embedded Coder will be used as described by one or more of the following use cases (see

ISO 26262-8:2018, 11.4.4.1c). Additional information about the assumed usage of Embedded Coder can be

found in the following documents:

• Embedded Coder Reference Workflow

• Embedded Coder User’s Guide1

• (if using AUTOSAR Blockset) AUTOSAR Blockset User’s Guide2

[ECoder_UC1] Generating C Code from the Model Used for Production Code Generation

Embedded Coder code generator will be used to transform an executable model (model used for

production code generation) into production C code for application software components.

The input languages to the code generator comprise Simulink®, Fixed-Point Designer™, Stateflow®, and

MATLAB® code. The C source code generated by the code generator is transformed by the compiler/linker

tool chain into executable object code.

[ECoder_UC2] Generating C++ Code from the Model Used for Production Code Generation

Embedded Coder code generator will be used to transform an executable model (model used for

production code generation) into production C++ code for application software components.

The input languages to the code generator comprise Simulink, Fixed-Point Designer, Stateflow, and MATLAB

code. The C++ source code generated by the code generator is transformed by the compiler/linker tool

chain into executable object code.

[ECoder_UC3] Generating C/C++ Code and Files for AUTOSAR Application Software

Components from the Model Used for Production Code Generation

Embedded Coder code generator with AUTOSAR Blockset will be used to:

• Transform an executable model (model used for production code generation) into production C/C++

code and files for AUTOSAR application software components.

• Create an AUTOSAR configuration for a model, model AUTOSAR elements, and generate AUTOSAR XML

and AUTOSAR-compatible C/C++ code from a model.

4.5 Generic Tool Classification

The tool classification for Embedded Coder was performed in a generic manner, independently from the

development of a specific safety-related item or element.

For the generic tool classification, the use cases listed in Tool Use Cases above have been considered. The

tool classification is based on the potential malfunctions or erroneous outputs and error prevention and

detection measures listed in the following, corresponding sections.

4.5.1 Potential Malfunctions or Erroneous Output

The following potential malfunctions or erroneous outputs were considered as part of the tool classification

process:

2 This document is available in the IEC Certification Kit Artifacts Explorer, the Embedded Coder/doc/autosar folder.

July 22, 2020 certkitiec_ecoder_tqp 4-2

[ECoder_E1] Embedded Coder produces incorrect or incomplete C or C++ code

Embedded Coder produces C/C++ code that is incorrect or does not have the same functionality as the

source model, for example:

• An element of the model is not translated to the code, therefore the corresponding functionality is

missing in the code.

• An element of the model is translated with error, so the corresponding code functionality does not

match the model. (for example, gain value in the model is 5 but is translated to gain value 3 in the code)

[ECoder_E2] Embedded Coder produces C or C++ code with unintended functionality

Embedded Coder produces C/C++ code that is not related to the content of the source model. For example,

Embedded Coder generates code with functionality that does not exist in the original model.

[ECoder_E3] Embedded Coder produces files for AUTOSAR application software

components with incorrect content

Embedded Coder produces files for AUTOSAR application software components with content that does not

correspond to the content of the source model.

[MISC_E1] Usage of incorrect input data

Incorrect input data is used, resulting in tool malfunction and erroneous output.

[MISC_E2] Misinterpretation of tool results

User interprets tool results incorrectly.

[MISC_E3] Incorrect tool usage

User does not follow established procedures when using the tool, or the tool has been not been used in the

intended operational environment, resulting in tool malfunction and erroneous output.

[MISC_E4] Incorrect, modified, or incompatible with environment tool installation

User does not follow established procedures when installing the tool, installs the tool in an incorrect

operational environment, modifies a valid installation, or available bug reports for the tool have not been

analyzed and available patches have not been installed. This might result in tool malfunction and erroneous

output.

4.5.2 Error Prevention and Detection Measures

The following measures, which mitigate potential malfunctions and corresponding erroneous outputs of

Embedded Coder, are referenced in the tool classification process. Additional considerations are described

in Embedded Coder Reference Workflow.

[ECoder_M1] Back-to-back testing

Software-in-the-loop (SIL) and processor-in-the-loop (PIL) back-to-back testing of generated C/C++ code

versus source model can be used to verify the functional equivalence between the source model and

generated code. See “Back-To-Back Simulation” in the Embedded Coder™ Reference Workflow.

[ECoder_M2] Static code analysis

Static code analysis can be used to assess compliance with coding standards, determine code size and

complexity, and quality metrics. See “Static Code Analysis” in the Embedded Coder™ Reference Workflow.

July 22, 2020 certkitiec_ecoder_tqp 4-3

[ECoder_M3] Prevention of unintended functionality

Code coverage analysis can be used to find code that is not related to the subsystem elements, i.e.

unintended functionality. See the “Code Coverage Comparison” section of “Prevention of Unintended

Functionality” in the Embedded Coder™ Reference Workflow.

Static code analysis can be used to assess compliance with coding standards, determine code size and

complexity and quality metrics. See “Static code analysis” in the Embedded Coder™ Reference Workflow.

Manual review of the Traceability Report for the generated C/C++ code can be used to find code that is not

related to the subsystem elements, i.e. unintended functionality. See “Traceability in the Code Generation

Report” in the Embedded Coder™ Reference Workflow.

[ECoder_M4] Review of the files for AUTOSAR application software components

Review of the files for AUTOSAR application software components.

[ECoder_M5] Validation of files for AUTOSAR application software components in the

AUTOSAR development environment

AUTOSAR development environment can be used to validate the schema for AUTOSAR application software

components files.

[MISC_M1] Configuration management and revision control

Configuration management, including revision control, shall be applied in accordance with Clause 7 of ISO

26262-8:2018 to the tools input and outputs, as well as for other applicable work products specified in the

respective safety standard.

For additional information, see “Configuration Management and Revision Control” in the tool-specific

reference workflow artifact.

[MISC_M2] Competency of the project team

Those carrying out activities using the tools shall be competent for the activities undertaken. For additional

information, see “Competency of the Project Team” in the tool-specific reference workflow artifact.

[MISC_M3] Adherence to installation instructions and validation of tool installation integrity

Adhere to the installation instructions for the tool (including dependent tools) and verify the version and

integrity of the tool. Validate modifications or additions made to the shipping product(s), if applicable, by

re-running the validation test suite provided in the IEC Certification Kit.

For additional information, see “Installation Integrity and Release Compatibility” in the tool-specific

reference workflow artifact.

[MISC_M4] Analysis of available bug report information

Assess and analyze the tool’s bug report information that is provided by MathWorks® and comply with the

recommendations and workarounds, if applicable.

For additional information, see “Bug Reporting” in the tool-specific reference workflow artifact.

[MISC_M5] Addressing tool errors and warnings

The tool reports abnormal operating modes, such as invalid tool inputs or incompatible settings that result

from incorrect tool usage, by issuing errors and warnings. All errors and warnings should be reviewed, and

appropriate action shall be taken.

July 22, 2020 certkitiec_ecoder_tqp 4-4

4.5.3 Tool Classification Summary

Table 4 Tool Classification Summary

Potential Use Cases TI Justification for TI Prevention / TD Justification for TD TCL

Malfunction or Detection Measures

Erroneous Output

[ECoder_E1] [ECoder_UC1] TI2 Incorrect code [ECoder_M1] Back- TD1 Back-to-back testing between generated TCL1

Embedded Coder could introduce to-back testing code and model ensures the numerical

produces [ECoder_UC2]

incorrect behavior [ECoder_M2] Static equivalence of the source model and

incorrect or [ECoder_UC3] of the target generated code.

incomplete C or code analysis

application This measure addresses the applicable

C++ code component verification methods recommended by

ISO 26262-8 and 26262-11 and

therefore provide a high degree of

confidence that code generation errors

will be detected.

[ECoder_E2] [ECoder_UC1] TI2 C/C++ code with [ECoder_M3] TD1 Review of a traceability report for the TCL1

Embedded Coder unintended Prevention of generated code and code coverage

produces C or C++ [ECoder_UC2] unintended

functionality could analysis can be used to detect code that

code with [ECoder_UC3] introduce functionality is not related to the model elements,

unintended unintended i.e. unintended functionality.

functionality [ECoder_M2] Static

behavior of the This measure addresses the applicable

code analysis

target application verification methods recommended by

component ISO 26262-8 and 26262-11 and

therefore provide a high degree of

confidence that code with unintended

functionality will be detected.

ECoder_E3] [ECoder_UC3] TI2 AUTOSAR [ECoder_M4] TD1 Review of the generated AUTOSAR files TCL1

Embedded Coder application Review of the files provide a high degree of confidence that

produces files for software for AUTOSAR incorrect content will be detected.

AUTOSAR components with application software AUTOSAR development environment

application incorrect content components can be also used to validate the schema

software could result in for AUTOSAR application software

components with incorrect [ECoder_M5] components files and support the

incorrect content component Validation of files for review.

implementation. AUTOSAR

application software

components in the

AUTOSAR

development

environment

[MISC_E1] Usage All TI2 Incorrect input data [MISC_M1] TD1 Revision control and configuration TCL1

of incorrect input could result in Configuration management provides integrity of the

data incorrect or management and input data. Using checksums allows the

incomplete analysis revision control unique identification the input data.

results. It could [MISC_M5] Invalid or corrupted input data will be

introduce or fail to

Addressing tool reported by the tool and addressed by

detect an error in a

errors and warnings the user.

safety-related items

or elements being

developed.

[MISC_E2] All TI2 Misinterpretation of [MISC_M2] TD1 Training of users can prevent these TCL1

Misinterpretation analysis results Competency of the issues.

of tool results could prevent project team

errors from being

detected

July 22, 2020 certkitiec_ecoder_tqp 4-5

Potential Use Cases TI Justification for TI Prevention / TD Justification for TD TCL

Malfunction or Detection Measures

Erroneous Output

[MISC_E3] All TI2 Incorrect tool usage [MISC_M2] TD1 Training of users can ensure correct TCL1

Incorrect tool could result in Competency of the usage of tool.

usage incorrect or project team

incomplete analysis [MISC_M5] Invalid tool inputs or incompatible

results. It could Addressing tool settings that are caused by incorrect

introduce or fail to

errors and warnings tool usage will be reported by the tool

detect an error in a

and addressed by the user.

safety-related items

or elements being

developed.

[MISC_E4] All TI2 Incorrect or [MISC_M3] TD1 Adherence to installation guide TCL1

Incorrect, modified Adherence to instructions provides a seamless

modified, or installation could installation installation.

incompatible with result in incorrect instructions and

environment tool Validation of the installed tool provides

or incomplete validation of tool

installation integrity of the tool installation. This

analysis results. It installation integrity could include re-running the validation

could introduce or tests shipping with the IEC Certification

fail to detect an

Kit before using the tool.

error in a safety-

related items or [MISC_M4] Analysis TD1 Analysis of the bug report information TCL1

elements being of available bug and use of recommendations and

developed. report information workarounds minimizes impact of tool

bugs.

Based on the preceding analysis of the potential malfunctions or erroneous output for the tool use cases

[ECoder_UC1], [ECoder_UC2] and [ECoder_UC3], the maximum tool impact of Embedded Coder is TI2.

Use of the error detection measures [ECoder_M1] to [MISC_M5] provides high degree of confidence (TD1)

that tool malfunctions will be detected. Therefore, the tool confidence level for the capabilities

implementing the tool use cases [ECoder_UC1], [ECoder_UC2] and [ECoder_UC3] is TCL1.

A suitable subset of the reference workflow and error detection measures can be selected to achieve a

medium degree of confidence (TD2) that tool malfunctions will be detected. In this case, the resulting tool

confidence level is TCL2.

TÜV SÜD reviewed the generic tool classification and confirmed the results in the Report to the Certificate.

July 22, 2020 certkitiec_ecoder_tqp 4-6

5 Software Tool Qualification Report

5.1 Requirement for Tool Qualification

If TCL1 is claimed for the Embedded Coder® product, additional tool qualification methods are not

necessary per ISO 26262-8:2018, clause 11.4.6.1. The applied tool qualification methods described below

are voluntary and provide additional confidence.

If TCL2 is claimed for the Embedded Coder product, additional tool qualification methods appropriate for

the predetermined maximum ASIL for the application under consideration are necessary per ISO 26262-

8:2018, clause 11.4.6.1. Permissible tool qualification methods for TCL2 are listed in ISO 26262-8:2018 table

5.

5.2 Tool Qualification Documentation

MathWorks® carried out an application-independent prequalification of the Embedded Coder product on a

voluntary basis to provide additional confidence using the following method:

• Evaluation of the tool development process (ISO 26262-8:2018, Table 5, method 1b).

TÜV SÜD reviewed the generic tool qualification artifacts for Embedded Coder and confirmed the results in

the Report to the Certificate.

Note TÜV SÜD qualification assessment for the method “Validation of the software tool” is carried

out for the tool use scope specified in Chapter 4 of this document. Modified tool use cases or

error prevention and detection measures are not covered by the TÜV SÜD qualification

assessment.

July 22, 2020 certkitiec_ecoder_tqp 5-1

6 Confirmation Review of Tool

Classification and Qualification

6.1 Requirement for Confirmation Review

The tool classification (see Chapter 4) was carried out independently from the development of the

application under consideration. Therefore, the resulting, predetermined tool confidence level shall be

confirmed by the applicant prior to Embedded Coder® being used for the development of a particular

safety-related item or element for the application under consideration (see ISO 26262-8:2018, 11.4.2).

If TCL2 is confirmed, the prequalification shall be confirmed prior to Embedded Coder being used for the

development of a particular safety-related item or element for the application under consideration. The

confirmation is required, because the prequalification was carried out independently from the development

of the application under consideration.

If TCL1 is confirmed, tool qualification and hence confirmation of the tool qualification are not required.

The generic tool classification assumes that Embedded Coder is being used as described in the reference

workflow documented in Embedded Coder Reference Workflow. Therefore, conformance with the entire

reference workflow (for TCL1) or the suitable subset (for TCL2) in the application under consideration shall

be confirmed by the applicant.

Note The applicant needs to document the applicable Tool Confidence Level (TCL1 or TCL2) claimed

for the application under consideration and the translation validation workflow followed. The

selected TCL influences the required rigor of the translation validation process. Therefore, the

applicant needs to document the actual translation validation workflow used for the

application under consideration.

6.2 Validity of Generic Tool Classification

Applicable Tool Confidence Level: < Insert TCL1 or TLC2>

<Insert results of the confirmation review and reference the conformation review documentation>

6.2.1 Validity of Tool Use Cases

Table 5 identifies the Embedded Coder use cases that were considered as part of the tool classification

process and identifies whether the use cases were modified, added, or deleted for the project under

consideration.

The table is structured as follows:

• The first column identifies whether the use case was modified:

o No change — Use case did not change.

o Update — Use case was updated.

July 22, 2020 certkitiec_ecoder_tqp 6-1

o Delete — Use case was not needed; therefore, it was removed.

o New — New use case was required.

The second column provides the use case as described in section Tool Use Cases on page 4-2 with the

following exceptions:

o If the Change Status is “Update”, this column provides the modified use case.

o If the Change Status is “New”, this column provides the new use case.

• The third column states the use case as a checklist question, which is to be asked with regard to your

project. The following applies:

o If the Change Status is “Update” and a use case was updated, this column provides the modified

checklist question.

o If the Change Status is “New”, this column provides the checklist questions as appropriate for the

new use case.

• The fourth column defines whether the use case was applicable for the project. This column can provide

additional information or clarification with regard to how the use case was applied in the project. The

following applies:

o If the Change Status is “Delete”, provide an explanation as to why this use case was not applicable

to the project.

Table 5 Validity of Tool Use Cases

Change Status Use Case Checklist Applicable to

Project?

<Insert [ECoder_UC1] Generating C code from the Is Embedded Coder being <Insert Yes or No and

Information> model used for production code generation used to generate C code for provide additional

Embedded Coder code generator will be used the model used for details if needed>

to transform an executable model (model used production code generation?

for production code generation) into

production C code for application software

components.

<Insert [ECoder_UC2] Generating C++ code from the Is Embedded Coder being <Insert Yes or No and

Information> model used for production code generation used to generate C++ code for provide additional

Embedded Coder code generator will be used the model used for details if needed>

to transform an executable model (model used production code generation?

for production code generation) into

production C++ code for application software

components.

<Insert [ECoder_UC3] Generating C/C++ Code and Is Embedded Coder code <Insert Yes or No and

Information> Files from AUTOSAR Application Software generator with AUTOSAR provide additional

Components for the Model Used for Blockset being used to details if needed>

Production Code Generation transform an executable

Embedded Coder code generator with graphical model into

AUTOSAR Blockset will be used to: production C code and files

for AUTOSAR Classic software

components?

July 22, 2020 certkitiec_ecoder_tqp 6-2

Change Status Use Case Checklist Applicable to

Project?

• Transform an executable model (model Is Embedded Coder code <Insert Yes or No and

used for production code generation) into generator with AUTOSAR provide additional

production C/C++ code and files for Blockset being used to create details if needed>

AUTOSAR application software an AUTOSAR configuration for

components. a model, model AUTOSAR

• Create an AUTOSAR configuration for a elements, and generate

model, model AUTOSAR elements, and AUTOSAR XML and AUTOSAR

generate AUTOSAR XML and AUTOSAR- Classic platform-compatible C

compatible C/C++ code from a model. code from a model?

Is Embedded Coder code <Insert Yes or No and

generator with AUTOSAR provide additional

Blockset being used to details if needed>

transform an executable

graphical model into

production C++ code and files

for AUTOSAR Adaptive

software components?

Is Embedded Coder code <Insert Yes or No and

generator with AUTOSAR provide additional

Blockset being used to create details if needed>

an AUTOSAR configuration for

a model, model AUTOSAR

elements, and generate

AUTOSAR XML and AUTOSAR

Adaptive platform-compatible

C++ code from a model?

Are there any tool use cases not considered? <Insert Yes or No. If yes, identify tool use case(s) and

provide rationale.>

July 22, 2020 certkitiec_ecoder_tqp 6-3

6.2.2 Validity of Error Prevention and Detection Measures

Table 6 identifies Embedded Coder error prevention and detection measures that were considered as part

of the tool classification process and whether they were modified, added, or deleted for the project under

consideration.

Table 6 Validity of Error Prevention and Detection Measures

Change Status Error Prevention and Detection Measure Checklist Applicable to

Project?

<Insert [ECoder_M1] Back-to-back testing Is the back-to-back testing of <Insert Yes or No and

Information> Software-in-the-loop (SIL) and processor- generated C/C++ code versus provide additional

in-the-loop (PIL) back-to-back testing of source model being used to verify details if needed>

generated C/C++ code versus source the numerical equivalence

model can be used to verify the between the source model and

functional equivalence between the generated code?

source model and generated code.

<Insert [ECoder_M2] Static code analysis Is static code analysis being used <Insert Yes or No and

Information> Static code analysis can be used to assess to assess compliance with coding provide additional

compliance with coding standards, standards, determine code size details if needed>

determine code size and complexity and and complexity, and quality

quality metrics. metrics?

<Insert [ECoder _M3] Prevention of unintended Is an analysis of the code coverage

Information> functionality being used to find code that is not

Code coverage analysis can be used to related to the subsystem

find code that is not related to the elements?

subsystem elements, i.e. unintended

Do you conduct a manual review <Insert Yes or No and

functionality

of a traceability report for the provide additional

Manual review of the Traceability Report generated code to ensure there is details if needed>

for the generated C/C++ code can be no code that is not related to the

used to find code that is not related to subsystem elements?

the subsystem elements, i.e. unintended

functionality.

<Insert [ECoder _M3] Model and code coverage Do you conduct a review of model <Insert Yes or No and

Information> analysis and code coverage reports to provide additional

Model and code coverage analysis can be ensure there is no code that is not details if needed>

used to find code that is not related to related to the subsystem

the subsystem elements, i.e. unintended elements?

functionality.

<Insert [MISC_M1] Configuration management Is configuration of the tool’s input <Insert Yes or No and

Information> and revision control and output data managed in provide additional

Configuration management, including accordance with Clause 7 of ISO details if needed>

revision control, shall be applied in 26262-8:2018?

accordance with Clause 7 of ISO 26262-

8:2018 to the tool input and outputs, as

well as for other applicable work

products specified in the respective

safety standard.

July 22, 2020 certkitiec_ecoder_tqp 6-4

Change Status Error Prevention and Detection Measure Checklist Applicable to

Project?

<Insert [MISC_M2] Competency of the project Are users who carry out activities <Insert Yes or No and

Information> team using the tool competent for the provide additional

Those carrying out activities using the activities undertaken? details if needed>

tool shall be competent for the activities

Are users trained to ensure <Insert Yes or No and

undertaken. Training of users can be

correct usage of the tool? provide additional

performed to ensure correct usage of

details if needed>

tool.

<Insert [MISC_M3] Adherence to installation Did users adhere to the <Insert Yes or No and

Information> instructions and validation of tool installation instructions for the provide additional

installation integrity tool (including dependent tools)? details if needed>

Adhere to the installation instructions for

Did user verify the version and <Insert Yes or No and

the tool (including dependent tools) and

integrity of the tool? provide additional

verify the version and integrity of the

details if needed>

tool. Validate modifications or additions

made to the shipping product(s), if Did users validate modifications or <Insert Yes or No and

applicable, by re-running the validation additions made to the shipping provide additional

test suite provided in the IEC Certification product(s), if applicable, by re- details if needed>

Kit. running the validation test suite

provided in the IEC Certification

Kit?

<Insert [MISC_M4] Analysis of available bug Did users assess and analyze bug <Insert Yes or No and

Information> report information report information for the tool? provide additional

Assess and analyze the tool’s bug report details if needed>

information that is provided by

Did users comply with the <Insert Yes or No and

MathWorks® and comply with the

recommendations and provide additional

recommendations and workarounds, if

workarounds, if applicable? details if needed>

applicable.

<Insert [MISC_M5] Addressing tool errors and Did the user review all errors and <Insert Yes or No and

Information> warnings warnings? provide additional

The tool reports abnormal operating details if needed>

modes, such as invalid tool inputs or

Was appropriate action taken in <Insert Yes or No and

incompatible settings that result from

response to the errors and provide additional

incorrect tool usage, by issuing errors and

warning? details if needed>

warnings. All errors and warnings should

be reviewed, and appropriate action shall

be taken.

Are there any error prevention and detection measures <Insert Yes or No. If yes, identify tool use case(s) and

not considered? provide rationale.>

July 22, 2020 certkitiec_ecoder_tqp 6-5

6.2.3 Validity of Tool Classification Summary

Table 6 provides a tool classification summary for the project under consideration and should be updated to

include any modifications that are identified in these sections (if any):

• Validity of Tool Use Cases on page 6-1

• Validity of Error Prevention and Detection Measures on page 6-4

Table 6 Validity of Tool Classification Summary

Potential Use Cases TI Justification for TI Prevention / TD Justification for TD TCL

Malfunction or Detection Measures

Erroneous Output

[ECoder_E1] [ECoder_UC1] TI2 Incorrect code [ECoder_M1] Back- TD1 Back-to-back testing between generated TCL1

Embedded Coder could introduce to-back testing code and model ensures the numerical

produces [ECoder_UC2]

incorrect behavior equivalence of the source model and

incorrect or [ECoder_UC3] of the target generated code.

incomplete C or application

C++ code This measure addresses the applicable

component verification methods recommended by

ISO 26262-8 and 26262-11 and

therefore provide a high degree of

confidence that code generation errors

will be detected.

[ECoder_E2] [ECoder_UC1] TI2 C/C++ code with [ECoder_M3] TD1 Review of a traceability report for the TCL1

Embedded Coder unintended Prevention of generated code and code coverage

produces C or C++ [ECoder_UC2] unintended

functionality could analysis can be used to detect code that

code with [ECoder_UC3] introduce functionality is not related to the model elements,

unintended unintended i.e. unintended functionality.

functionality [ECoder_M2] Static

behavior of the This measure addresses the applicable

code analysis

target application

verification methods recommended by

component ISO 26262-8 and 26262-11 and

therefore provide a high degree of

confidence that code with unintended

functionality will be detected.

[MISC_E1] Usage All TI2 Incorrect input data [MISC_M1] TD1 Revision control and configuration TCL1

of incorrect input could result in Configuration management provides integrity of the

data incorrect or management and input data. Using checksums allows the

incomplete analysis revision control unique identification the input data.

results. It could [MISC_M5] Invalid or corrupted input data will be

introduce or fail to Addressing tool reported by the tool and addressed by

detect an error in a

errors and warnings the user.

safety-related items

or elements being

developed.

[MISC_E2] All TI2 Misinterpretation of [MISC_M2] TD1 Training of users can prevent these TCL1

Misinterpretation analysis results Competency of the issues.

of tool results could prevent project team

errors from being

detected

[MISC_E3] All TI2 Incorrect tool usage [MISC_M2] TD1 Training of users can ensure correct TCL1

Incorrect tool could result in Competency of the usage of tool.

usage incorrect or project team

incomplete analysis [MISC_M5] Invalid tool inputs or incompatible

results. It could Addressing tool settings that are caused by incorrect

introduce or fail to

errors and warnings tool usage will be reported by the tool

detect an error in a

and addressed by the user.

safety-related items

or elements being

developed.

July 22, 2020 certkitiec_ecoder_tqp 6-6

Potential Use Cases TI Justification for TI Prevention / TD Justification for TD TCL

Malfunction or Detection Measures

Erroneous Output

[MISC_E4] All TI2 Incorrect or [MISC_M3] TD1 Adherence to installation guide TCL1

Incorrect, modified Adherence to instructions provides a seamless

modified, or installation could installation installation.

incompatible with result in incorrect instructions and

environment tool Validation of the installed tool provides

or incomplete validation of tool integrity of the tool installation. This

installation analysis results. It installation integrity could include re-running the validation

could introduce or tests shipping with the IEC Certification

fail to detect an

Kit before using the tool.

error in a safety-

related items or [MISC_M4] Analysis TD1 Analysis of the bug report information TCL1

elements being of available bug and use of recommendations and

developed. report information workarounds minimizes impact of tool

bugs.

6.3 Validity of Generic Tool Qualification

Applicable Tool Confidence Level: <Insert TCL1 or TCL2>

<Insert results of the confirmation review or reference the conformation review documentation.>

6.4 Conformance with Reference Workflow

< Applicable Tool Confidence Level: <Insert TCL1 or TCL2>

<Insert reference to customized and completed Conformance Demonstration Template for the project.>

July 22, 2020 certkitiec_ecoder_tqp 6-7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BrainVision PyCorder UM PDFDocument86 pagesBrainVision PyCorder UM PDFrm7029No ratings yet

- Helicopter Flight Control High Level Software Requirements DocumentDocument7 pagesHelicopter Flight Control High Level Software Requirements DocumentLoc HuynhNo ratings yet

- Connect LabVIEW To Any PLC With ModbusDocument8 pagesConnect LabVIEW To Any PLC With ModbusLoc HuynhNo ratings yet

- +Ctrl-Eng IIoT Report 2017Document87 pages+Ctrl-Eng IIoT Report 2017Cyrix.OneNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument27 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- Polyspace Code Verification: Call Hierarchy Report For Project: PolyspaceDocument6 pagesPolyspace Code Verification: Call Hierarchy Report For Project: PolyspaceLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument12 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- Polyspace Code Verification: Call Hierarchy Report For Project: PolyspaceDocument7 pagesPolyspace Code Verification: Call Hierarchy Report For Project: PolyspaceLoc HuynhNo ratings yet

- DO Qualification Kit: Simulink Design Verifier™ Tool Qualification PlanDocument16 pagesDO Qualification Kit: Simulink Design Verifier™ Tool Qualification PlanLoc HuynhNo ratings yet

- DO Qualification Kit: Simulink Test™ Tool Qualification PlanDocument15 pagesDO Qualification Kit: Simulink Test™ Tool Qualification PlanLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument30 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- Qualkitdo Rptgenext Qualificationreport SDD DiscreteDocument42 pagesQualkitdo Rptgenext Qualificationreport SDD DiscreteLoc HuynhNo ratings yet

- Polyspace Code Verification: Coding Standards Report For Project: PolyspaceDocument29 pagesPolyspace Code Verification: Coding Standards Report For Project: PolyspaceLoc HuynhNo ratings yet

- Certkitiec Hdlcoder CDTDocument13 pagesCertkitiec Hdlcoder CDTLoc HuynhNo ratings yet

- Sltest RefDocument610 pagesSltest RefLoc HuynhNo ratings yet

- EG-Series-HIWIN CatalogDocument17 pagesEG-Series-HIWIN CatalogLoc HuynhNo ratings yet

- IEC Certification Kit: Simulink Requirements™ ISO 26262 Tool Qualification PackageDocument26 pagesIEC Certification Kit: Simulink Requirements™ ISO 26262 Tool Qualification PackageLoc HuynhNo ratings yet

- Neural Spiking and Synaptic Transmission: Action PotentialDocument6 pagesNeural Spiking and Synaptic Transmission: Action PotentialLoc HuynhNo ratings yet

- How To Activate AutoDesk Any Product For FreeDocument8 pagesHow To Activate AutoDesk Any Product For FreeLoc HuynhNo ratings yet

- Introduction To NI SoftMotion For SolidWorks - enDocument8 pagesIntroduction To NI SoftMotion For SolidWorks - enLoc HuynhNo ratings yet

- Developing Servo Indexing System Using Timing Screw For Automatic Liquid Filler in Manufacturing EnvironmentDocument17 pagesDeveloping Servo Indexing System Using Timing Screw For Automatic Liquid Filler in Manufacturing EnvironmentLoc HuynhNo ratings yet

- IEC Certification Kit: Model-Based Design For ISO 25119:2018Document18 pagesIEC Certification Kit: Model-Based Design For ISO 25119:2018Loc HuynhNo ratings yet

- FP 80tDocument2 pagesFP 80tLoc HuynhNo ratings yet

- A Practical Applications of Virtual PLC Using LabVIEW SoftwareDocument6 pagesA Practical Applications of Virtual PLC Using LabVIEW SoftwareLoc HuynhNo ratings yet

- Cam - Follwer - B - en CF BearingDocument4 pagesCam - Follwer - B - en CF BearingLoc HuynhNo ratings yet

- F940wgot-Twd-E: 7-I W I ADocument8 pagesF940wgot-Twd-E: 7-I W I ALoc HuynhNo ratings yet

- MAL SeriesDocument5 pagesMAL SeriesSolikin PatiNo ratings yet

- Accountancy and Auditing-2010Document5 pagesAccountancy and Auditing-2010Umar ZamarNo ratings yet

- Polymer Mix Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesPolymer Mix Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- Adressverificationdocview Wss PDFDocument21 pagesAdressverificationdocview Wss PDFabreddy2003No ratings yet

- Bridging The Gap - Decoding The Intrinsic Nature of Time in Market DataDocument15 pagesBridging The Gap - Decoding The Intrinsic Nature of Time in Market DatashayanNo ratings yet

- 6.03 Example Research PaperDocument21 pages6.03 Example Research PaperCarole Ezell BishopNo ratings yet

- AP Physics1 KE and PE WorksheetDocument3 pagesAP Physics1 KE and PE WorksheetTrevor RivardNo ratings yet

- GRF Presentation 21-22 Oct 2020Document35 pagesGRF Presentation 21-22 Oct 2020AI OPSNo ratings yet

- WO FLOW - VendorDocument2 pagesWO FLOW - VendorklukluxlandNo ratings yet

- Onboarding Guide To The Microsoft Azure Enterprise Portal (Indirect Enrollment)Document57 pagesOnboarding Guide To The Microsoft Azure Enterprise Portal (Indirect Enrollment)Juan VarelaNo ratings yet

- 8.3.3.3 Lab - Collecting and Analyzing NetFlow DataDocument7 pages8.3.3.3 Lab - Collecting and Analyzing NetFlow DataJorge Juan0% (1)

- Assignment CHPT 12Document3 pagesAssignment CHPT 12Sultan LimitNo ratings yet

- Introduction To Electronics: Dr. Lory Liza D. Bulay-OgDocument24 pagesIntroduction To Electronics: Dr. Lory Liza D. Bulay-OgLory Liza Bulay-ogNo ratings yet

- Week 12 DigestDocument16 pagesWeek 12 DigestEdz Votefornoymar Del RosarioNo ratings yet

- CAC ScoreDocument25 pagesCAC ScoreNyoman Ririn Chandrika SariNo ratings yet

- Toxin ReportDocument240 pagesToxin ReportTRUMPET OF GODNo ratings yet

- Netflix EnriquezDocument4 pagesNetflix EnriquezJoshua ReyesNo ratings yet

- Basel Committee On Banking SupervisionDocument16 pagesBasel Committee On Banking Supervisionsh_chandraNo ratings yet

- 2023-06-28Document1,532 pages2023-06-28X YzNo ratings yet

- KEN ReportDocument15 pagesKEN ReportCrishan KarunapalaNo ratings yet

- Sta301 Solved Subjective Final Term by JunaidDocument16 pagesSta301 Solved Subjective Final Term by Junaidtassawar naseerNo ratings yet

- MathML With HTML5Document10 pagesMathML With HTML5devendraNo ratings yet

- Sample Layer Farming Project Report 10,000 Birds - The Big Book Project Org PDFDocument12 pagesSample Layer Farming Project Report 10,000 Birds - The Big Book Project Org PDFnicholson oriiNo ratings yet

- Research Paper (Final)Document35 pagesResearch Paper (Final)Ipsita Dutta BanikNo ratings yet

- The Use of Monitored Attendance SMS System To The Late Students in Unida Christian Colleges A.Y. 2022-2023Document7 pagesThe Use of Monitored Attendance SMS System To The Late Students in Unida Christian Colleges A.Y. 2022-2023Jude De LeonNo ratings yet

- Design and Implementation of An Online Death and Birth Registration System PDFDocument20 pagesDesign and Implementation of An Online Death and Birth Registration System PDFLove ANo ratings yet

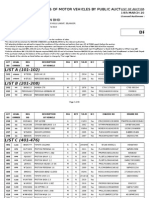

- Draft List: Proclamation of Sales of Motor Vehicles by Public AuctDocument20 pagesDraft List: Proclamation of Sales of Motor Vehicles by Public AuctHd YusNo ratings yet

- Introduction To Python: A Dynamically Typed Programming Language Allowing Multiple Paradigms - OO, FunctionalDocument34 pagesIntroduction To Python: A Dynamically Typed Programming Language Allowing Multiple Paradigms - OO, Functionalsabar5No ratings yet

- Chapter 5,6 Regression AnalysisDocument44 pagesChapter 5,6 Regression AnalysisSumeshNo ratings yet