Professional Documents

Culture Documents

Electrical Submersible Pump (ESP) Downhole Sensor Systems

Electrical Submersible Pump (ESP) Downhole Sensor Systems

Uploaded by

Жанбулат УразалинOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Submersible Pump (ESP) Downhole Sensor Systems

Electrical Submersible Pump (ESP) Downhole Sensor Systems

Uploaded by

Жанбулат УразалинCopyright:

Available Formats

Electrical Submersible Pump (ESP)

Downhole Sensor Systems

Fight your decline curve with the most reliable downhole ESP sensor

CUSTOMER BEN E FI T S Fighting production decline curves and reducing lease operating expenses, all

while improving safety performance, is a constant challenge for any oil and gas

operator. Any oilfield service company delivering artificial lift services should

Reduce well workovers with the be focused on supporting their clients continuous improvement in each of

most reliable ESP sensor these areas. Selecting the industry’s most reliable downhole ESP sensor is a

Extend production with sensor sure way to improve all three areas.

data you can trust

PROVEN RELIABILITY + COST EFFECTIVENESS

Lower LOE by re-running sensors

Reduce safety risks with smaller

and more reliable device over

7K+ 2 20+

costs

ACE DOWNHOLE SENSORS YEAR WARRANTY THE NUMBER OF TRIPS

INSTALLED WORLDWIDE NO OTHER BRAND COMES CLOSE ACE SENSORS HAVE BEEN RE-RUN

PRODUCT HIGHLIGHTS The ACE Downhole ESP sensor system has four main components. Two are

installed at surface and two are mounted below the ESP motor. Optional

testing units are available to verify signal and system integrity.

World’s only ESP sensor with two-

year warranty

DOWNHOLE SENSORS:

Patented electronics that withstand No serviceable parts inside

high voltage and current overloads Industry standard threads that mount

to any additional downhole components

Completely sealed and welded

that may be used

device Standard pressure, Xtreme temperature,

and Dual pressure models available

Half the size and weight of

competing units

UL/CSA certified surface DOWNHOLE SENSOR ADAPTERS:

Stock one sensor and run on any size

system with low cost adapters

Six most used sizes available in metric or

english

Available in carbon steel or stainless

steel pressure models

(918) 876-3246 | www.acedownhole.com | office@acedownhole.com

SURFACE READOUT UNITS: HIGH-VOLTAGE INTERFACE: INSTALLATION/TESTING

Provides downhole data to downhole device, Provides a protective safety interface between Hydraulic pressure test unit to enable system

verifies encrypted data, and displays results on the high-voltage 3-phase ESP power and the verification at surface

LED display surface readout unit Portable surface readout unit enables testing

SRU2 includes ethernet and USB connectivity NEMA 4, 4X, 12, 13 enclosure from the wellhead to the variable speed drive

SRU3i connects directly to a Baker Hughes/ GE The ACE Spooler provides live readings via WiFi

Advantage or GCS drive, plus provides WiFi to any personnel near wellsite

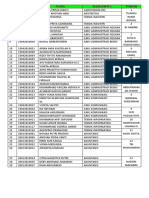

ACE Standard Models ACE Mid Range Models Ace Xtreme Temperature ACE Xtreme Temperature Dual

Intake Pressure Range 0-3000 psi & 0-5000 psi 0-3000 psi & 0-5000 psi 0-6000 & 0-8000 psi 0-6000 & 0-8000 psi

Intake Pressure Accuracy +/- 0.25% BFSL 1% FS +/- 0.25% BFSL 1% FS +/- 0.1% Typical 0.2% FS +/- 0.1% Typical 0.2% FS

Intake Pressure Resolution 1 PSI SRU, 0.1psi SRU2, 0.01psi 1 PSI SRU, 0.1psi SRU2, 0.01psi 1 PSI SRU, 0.1psi SRU2, 0.01psi 1 PSI SRU, 0.1psi SRU2, 0.01psi

Spooler & SRU3i Spooler & SRU3i Spooler & SRU3i Spooler & SRU3i

Transducer Type Silicon Strain Gauge Silicon Strain Gauge Digital Strain Gauge Digital Strain Gauge

Discharge Pressure Range N/A N/A N/A 0 – 6000 psi

Discharge Pressure Accuracy N/A N/A N/A +/- 0.1% Typical 0.2% FS

Discharge Pressure Resolution N/A N/A N/A 1 PSI SRU, 0.1psi SRU2, 0.01psi

Spooler & SRU3i

Intake Temperature Range

D OWNHOL E I N ST RUM ENT S

32°F - 257°F, 0°C - 125°C 32°F - 302°F, 0°C - 150°C 32°F - 350°F, 0°C - 177°C 32°F - 350°F, 0°C - 177°C

Intake Temperature Accuracy 3.5°F, 2°C 3.5°F, 2°C 3.5°F, 2°C 3.5°F, 2°C

1°F SRU, 0.1°F SRU2, 0. 01°F 1°F SRU, 0.1°F SRU2, 0. 01°F 1°F SRU, 0.1°F SRU2, 0.01°F 1°F SRU, 0.1°F SRU2, 0.01°F

Intake Temperature Resolution

Spooler & SRU3i Spooler & SRU3i Spooler & SRU3i Spooler & SRU3i

Motor Winding Temperature Range 32°F - 600°F, 0°C - 316°C 32°F - 600°F, 0°C - 316°C 32°F - 600°F, 0°C - 316°C 32°F - 600°F, 0°C - 316°C

Motor Winding Temperature Accuracy 3.5°F, 2°C 3.5°F, 2°C 3.5°F, 2°C 3.5°F, 2°C

( WIT H OU T M OT OR A DA P T E R )

1°F SRU, 0.1°F SRU2, 0.01°F 1°F SRU, 0.1°F SRU2, 0.01°F 1°F SRU, 0.1°F SRU2, 0.01°F 1°F SRU, 0.1°F SRU2, 0.01°F

Motor Winding Temperature Resolution

Spooler & SRU3i Spooler & SRU3i Spooler & SRU3i Spooler & SRU3i

Vibration Range

N/A 0 – 10G 0 – 10G 0 – 10G

Vibration Accuracy 0.50% 0.50% 0.50%

N/A

Vibration Resolution N/A N/A 0.01G 0.01G

Insulation Resistance 200 kOhms-60MOhms 200 kOhms-60MOhms 200 kOhms-60MOhms 200 kOhms-60MOhms

Maximum Motor Voltage 4160 VAC 4160 VAC 4160 VAC 4160 VAC

Physical Diameter 3.72” 3.72” 3.72” or 3.94” 3.94”

Physical Length 18.5” 18.5” 18.5” 23.0”

Physical Weight 35 lbs, 16 kG 35 lbs, 16 kG 42 lbs, 19 kG 44 lbs, 20 kG

Material 1020 CS, 316 SS 1020 CS, 316 SS 316 SS 316 SS

Surface Readout Unit SRU2i SRU3i

Power 115VAC +/- 15% 50/60Hz 115VAC +/- 15% 50/60Hz 115 VAC +/- 15% 50/60Hz

Display Type 6 digit Alpha Numeric LED 8 digit Alpha Numeric LED -

Motor Controller Connection iCON Series Interface. Support for legacy (F3/F5 iCON Series Interface. Support for legacy (F3/F5 Commander Supports GCS Legacy CITIbus & Advantage

(Isolated) Commander series) controllers. series) controllers plus additional RS-485 Modbus port. CITIbus

S U R F A CE R EA D OU T U N IT S

Modbus RS-485 (Isolated) 3 wire standard 3 wire standard 3 wire standard

Modbus RS-232 (Isolated) 3 wire, no handshaking required. 3 wire, no handshaking required. 3 wire standard

USB Modbus (Isolated) - Standard USB ‘B’ Standard USB-A

Ethernet Modbus (Isolated) - Standard CAT5E 8 Pin connector. -

WiFi Interface - - Standard worldwide, license free 802.11 b/g/n

Analog Outputs (Isolated) - 4x 0-20mA User configurable (SRU2 sources power) -

Relay Outputs (Isolated) - 2x Form C User configurable 240VAC / 8 Amps -

SD Datalogger - Up to 32 GByte (SDHC mode supported). -

Internal Memory (SRU2X version) - 32 GByte -

Operating Temperature 0°F - 158°F, -18°C to 50°C 0°F - 158°F, -18°C to 50°C 0°F to 158°F, -18°C to 50°C

Insulation Resistance Support NO YES YES

Dimensions 6.00” x 5.25” x 2.25” 9.50” x 5.75” x 1.75” 7.38”x 5.75” x 1.75”

Weight 1.5 lbs 2.0 lbs 2 lb

UL Certification Conforms to UL Std. 61010-1 Conforms to UL Std. 61010-1 Conforms to UL Std. 61010-1

CSA Certification Certified to CAN/CSA Std. C22.2# 61010-1 Certified to CAN/CSA Std. C22.2# 61010-1 Certified to CAN/CSA Std. C22.2# 61010-1

(918) 876-3246 | www.acedownhole.com | office@acedownhole.com

You might also like

- Air TicketDocument3 pagesAir TicketJustin AlwarNo ratings yet

- Vallen AMSY-6: The Acoustic Emission CompanyDocument6 pagesVallen AMSY-6: The Acoustic Emission CompanyMaria Cristina DijmarescuNo ratings yet

- EN 05038 en NaDocument2 pagesEN 05038 en NaFernando Tellez CordovaNo ratings yet

- Daniel Seniorsonic and Juniorsonic Gas Flow Meters With Mark Iii ElectronicsDocument12 pagesDaniel Seniorsonic and Juniorsonic Gas Flow Meters With Mark Iii ElectronicsSang RòmNo ratings yet

- Hightest - ARES-200 BLUE, 200 A DC MICRO-OHM METER - Aresblue - 2betaDocument4 pagesHightest - ARES-200 BLUE, 200 A DC MICRO-OHM METER - Aresblue - 2betahightestNo ratings yet

- Performance + Reliability + Flexibility. It All Adds Up To PowerDocument4 pagesPerformance + Reliability + Flexibility. It All Adds Up To PowerCamel FangNo ratings yet

- Mek-2500 Rotoforce™: Rotating Consistency TransmitterDocument3 pagesMek-2500 Rotoforce™: Rotating Consistency TransmitterGunandar GunandarNo ratings yet

- ADSE 650 Pitot-Static: One of The Most Compact Pitot-Static Tester On The MarketDocument2 pagesADSE 650 Pitot-Static: One of The Most Compact Pitot-Static Tester On The Marketnicole vargas ponceNo ratings yet

- Infineon TLI4971 A120T5 E0001 DataSheet v01 - 01 ENDocument19 pagesInfineon TLI4971 A120T5 E0001 DataSheet v01 - 01 ENmaurilioctbaNo ratings yet

- Portable Vibration Calibrator: Lab Accuracy To The FieldDocument2 pagesPortable Vibration Calibrator: Lab Accuracy To The Fieldenghemo89No ratings yet

- Digital Storage Oscilloscopes: TPS2000B Series Data SheetDocument14 pagesDigital Storage Oscilloscopes: TPS2000B Series Data SheetEmanuel OanceaNo ratings yet

- Vibrating Wire Pressure CellDocument4 pagesVibrating Wire Pressure Cells pradhanNo ratings yet

- Foxboro® Vortex Flowmeters: Model 84C - Temperature CompensatedDocument2 pagesFoxboro® Vortex Flowmeters: Model 84C - Temperature CompensatedLuis Fernando Becerra JimenezNo ratings yet

- ES Relay - Feb 2019Document18 pagesES Relay - Feb 2019Filipe BrandaoNo ratings yet

- Combustion Oxygen Monitor: Endura AZ30Document24 pagesCombustion Oxygen Monitor: Endura AZ30Carlos Andrés Vargas OsornoNo ratings yet

- Digital Storage Oscilloscopes: TPS2000B Series Data SheetDocument15 pagesDigital Storage Oscilloscopes: TPS2000B Series Data SheetDavidNo ratings yet

- TOCSIN 750 - Datasheet NEWDocument7 pagesTOCSIN 750 - Datasheet NEWabcd8482No ratings yet

- CSI 2117A Series: CollectorDocument2 pagesCSI 2117A Series: CollectorFilipe RosaNo ratings yet

- Ds GillAC v2.2Document4 pagesDs GillAC v2.2mahmoud yaseenNo ratings yet

- 9110D Portable Vibration Calibrator Datasheet DS 0103Document2 pages9110D Portable Vibration Calibrator Datasheet DS 0103Adhitya ReNo ratings yet

- Level Measurement VEGAPULS 61 DatasheetDocument2 pagesLevel Measurement VEGAPULS 61 Datasheetcyrano1091No ratings yet

- Field Devices - Pressure: Product SpecificationsDocument24 pagesField Devices - Pressure: Product SpecificationsPhaniNo ratings yet

- DIN-Rail EMC/RFI Filter With Minimum Leakage Current: Sheet 3-Phase Filters FN 3025/FN 3026Document6 pagesDIN-Rail EMC/RFI Filter With Minimum Leakage Current: Sheet 3-Phase Filters FN 3025/FN 3026Santosh KumarNo ratings yet

- Us 27c WebDocument4 pagesUs 27c Webdong zhouNo ratings yet

- Sensidyne Sensalert-Asi Datasheet LowresDocument4 pagesSensidyne Sensalert-Asi Datasheet LowresEmrah MertyürekNo ratings yet

- Omega OS523 - OS524Document2 pagesOmega OS523 - OS524mazmojNo ratings yet

- ETNA 2 Especificaciones TécnicasDocument2 pagesETNA 2 Especificaciones TécnicasSergio CM100% (1)

- Ge Druck PTX 7535Document2 pagesGe Druck PTX 7535ICSSNo ratings yet

- Cryogenic Level SystemsDocument5 pagesCryogenic Level SystemsEvgeny AzarovNo ratings yet

- 05 PowerSupplies PDFDocument11 pages05 PowerSupplies PDFMilan StanojevicNo ratings yet

- The Solution For All Your Magmeter Applications: Advanced TechnologyDocument2 pagesThe Solution For All Your Magmeter Applications: Advanced TechnologyClash KingNo ratings yet

- Centrix BR enDocument12 pagesCentrix BR en오재명No ratings yet

- Immunity Test SystemDocument64 pagesImmunity Test SystemannitangrayaNo ratings yet

- Detectores Temperatura HOCHIKIDocument2 pagesDetectores Temperatura HOCHIKIHugo RomoNo ratings yet

- 05 UPS Sentinel Pro SEPDocument4 pages05 UPS Sentinel Pro SEPbdaviesNo ratings yet

- 6303Document2 pages6303Sistemas abogacíaNo ratings yet

- Advanced Eddy Current Tube Inspection Solutions: Inspection Planning Data Collection Data Analysis ReportingDocument8 pagesAdvanced Eddy Current Tube Inspection Solutions: Inspection Planning Data Collection Data Analysis ReportingBAHADIRNo ratings yet

- Astm Compression Tester Accessories: ADR Advanced Digital ReadoutDocument7 pagesAstm Compression Tester Accessories: ADR Advanced Digital ReadoutJorge SanchezNo ratings yet

- DS - AZ30-EN Rev. ADocument24 pagesDS - AZ30-EN Rev. ACarlos Andrés Vargas OsornoNo ratings yet

- Ilx FPM 8200Document4 pagesIlx FPM 8200Bengkel Las DekorasiNo ratings yet

- HAEFELY ONYX DatasheetDocument8 pagesHAEFELY ONYX DatasheetUrasProLab CoNo ratings yet

- Ewaq FDocument69 pagesEwaq FCarlos Aguirre100% (1)

- DS - AZ30-EN Rev. CDocument24 pagesDS - AZ30-EN Rev. CCarlos Andrés Vargas OsornoNo ratings yet

- Catalogue Transmetteur Pression Differentielle Honeywell STD924-34-ST-03-65 - 2013Document22 pagesCatalogue Transmetteur Pression Differentielle Honeywell STD924-34-ST-03-65 - 2013romuald konhawoNo ratings yet

- BW051P Programmable Bargraph DatasheetDocument2 pagesBW051P Programmable Bargraph DatasheetRobert OberfrankNo ratings yet

- Catálogo ACE 6000Document4 pagesCatálogo ACE 6000Luis NovaisNo ratings yet

- Datum Electronics: Series 460 Bolt-On Strain Gauge SensorsDocument7 pagesDatum Electronics: Series 460 Bolt-On Strain Gauge Sensorsmuhammad taufik rahmanNo ratings yet

- V2KDocument2 pagesV2KLindgrenNo ratings yet

- Strong, Loud and Clear With LRAD 300XDocument2 pagesStrong, Loud and Clear With LRAD 300XDante MelendezNo ratings yet

- 15Kv Digital Surge/Dc Hipot/ Resistance and Bar-To-Bar TesterDocument2 pages15Kv Digital Surge/Dc Hipot/ Resistance and Bar-To-Bar TesterkarthimeenaNo ratings yet

- Product Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667Document12 pagesProduct Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667jhon vargasNo ratings yet

- 34 ST 03 63Document22 pages34 ST 03 63Manzoor-ul- HassanNo ratings yet

- 84F Product SpecificationsDocument40 pages84F Product SpecificationsAntonio CodoceoNo ratings yet

- Datasheet Foxboro Eckardt SRD998 - 18000305Document4 pagesDatasheet Foxboro Eckardt SRD998 - 18000305pauloNo ratings yet

- GE USM 35 KawoshkaranDocument4 pagesGE USM 35 Kawoshkaranmh hNo ratings yet

- Whitelegg AWAIV DatasheetDocument4 pagesWhitelegg AWAIV DatasheetselvamuthukumarNo ratings yet

- Megohmmeter/IR TesterDocument2 pagesMegohmmeter/IR TesterSandro ChiliquingaNo ratings yet

- Medidor de Tangente Delta Midas Micro2883Document4 pagesMedidor de Tangente Delta Midas Micro2883Selk CLNo ratings yet

- Digital Winding Tester: Advanced Test Equipment RentalsDocument2 pagesDigital Winding Tester: Advanced Test Equipment RentalsDavid PolitoNo ratings yet

- SADPmini2 Portable Dewpoint Meter DatasheetDocument3 pagesSADPmini2 Portable Dewpoint Meter Datasheetsreenivas1234No ratings yet

- Varistor Products Overview Radial Lead VaristorsDocument106 pagesVaristor Products Overview Radial Lead VaristorsIgor PNo ratings yet

- EDC Model Document Revision 2Document33 pagesEDC Model Document Revision 2milomeixell50% (2)

- ESAS Actual Board. Thank Me LaterDocument5 pagesESAS Actual Board. Thank Me LaterRhea Pardo PeralesNo ratings yet

- AnnualReport2017 18 PDFDocument198 pagesAnnualReport2017 18 PDFDhanes GuptaNo ratings yet

- Gama Dimat Catalog Be17Document16 pagesGama Dimat Catalog Be17ELMIR ADILNo ratings yet

- Petrophysics Overview RMBDocument11 pagesPetrophysics Overview RMBwandaNo ratings yet

- Vernier CaliperDocument11 pagesVernier CaliperKrishh GuptaNo ratings yet

- Director's StatementDocument5 pagesDirector's StatementMeganPhillipsNo ratings yet

- Circulation in A LaundryDocument4 pagesCirculation in A LaundryDyna Wylene GardoniaNo ratings yet

- Pinjra 1Document4 pagesPinjra 1azharNo ratings yet

- Atlas Copco Desiccant Dryers: BD 100, BD 150, BD 185, BD 250, BD 300Document38 pagesAtlas Copco Desiccant Dryers: BD 100, BD 150, BD 185, BD 250, BD 300FEDOR100% (4)

- Daftar Kelompok Kepemimpinan G402Document2 pagesDaftar Kelompok Kepemimpinan G402Merry DiandaNo ratings yet

- Revised RCSC Specification-Simplified, Clarified, AndImprovedDocument5 pagesRevised RCSC Specification-Simplified, Clarified, AndImprovedCarlos Javier Goez TarraNo ratings yet

- Air Force Magazine 2017-02Document88 pagesAir Force Magazine 2017-02Nadeem Ansari100% (1)

- PHD by BOLA SHOYEMI-IBRAHIM (DRMOLOVA) ALL RIGHTS RESERVED FOR THE BOO FOUNDATIONDocument1 pagePHD by BOLA SHOYEMI-IBRAHIM (DRMOLOVA) ALL RIGHTS RESERVED FOR THE BOO FOUNDATIONBola DrmolovaNo ratings yet

- Machining Guidelines - For Semi Finished Plastics PDFDocument28 pagesMachining Guidelines - For Semi Finished Plastics PDFDhean AdhaNo ratings yet

- SSPX 513 Sitema de Monitoreo.Document11 pagesSSPX 513 Sitema de Monitoreo.cotecobein19No ratings yet

- List of Acknowledgements: Chapter 1. Polyesters: Synthesis and Chemical AspectsDocument21 pagesList of Acknowledgements: Chapter 1. Polyesters: Synthesis and Chemical AspectsLailatulmuna MonaNo ratings yet

- Linkan For OfficeDocument3 pagesLinkan For OfficeArshad SadatNo ratings yet

- Verna 1.4L CVVT (2010-2014)Document3 pagesVerna 1.4L CVVT (2010-2014)miguel sousaNo ratings yet

- D7G 92VDocument184 pagesD7G 92Valexander100% (3)

- CMOS Fabrication Steps 3Document54 pagesCMOS Fabrication Steps 3Yogesh MisraNo ratings yet

- Commodore 128 Programmer's Reference GuideDocument756 pagesCommodore 128 Programmer's Reference GuideDSpawnZNo ratings yet

- 201710-Chemical Engineering - October 2017Document104 pages201710-Chemical Engineering - October 2017zawe36827No ratings yet

- Gupta Answer KeyDocument25 pagesGupta Answer KeyBenjamin MullenNo ratings yet

- "Result: ": //#1#: Use MD'S Update Method. Use Data - To - Hash - Tobytearray As Input To MD'S Update MethodDocument2 pages"Result: ": //#1#: Use MD'S Update Method. Use Data - To - Hash - Tobytearray As Input To MD'S Update MethodHugoNo ratings yet

- Coo-Var Suregrip (All Colours) 125/G139/ ALL COLOURS: TDS: CVG139Document2 pagesCoo-Var Suregrip (All Colours) 125/G139/ ALL COLOURS: TDS: CVG139DunkMeNo ratings yet

- ChhhhheeerDocument2 pagesChhhhheeerapi-407075083No ratings yet

- Arm Amba AhbDocument18 pagesArm Amba AhbgeethaNo ratings yet