Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

79 viewsCrane Inspection Checklist Migas

Crane Inspection Checklist Migas

Uploaded by

Anonymous 1ykzuaxWgYCrane Inspection Checklist

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Astm G48Document11 pagesAstm G48thedreampower100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Document256 pages6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Anonymous 1ykzuaxWgY100% (3)

- SLI ManualDocument142 pagesSLI ManualAnonymous 1ykzuaxWgY100% (1)

- 4 - Drawing &datasheet 20-10kDocument131 pages4 - Drawing &datasheet 20-10kAnonymous 1ykzuaxWgYNo ratings yet

- QA QC ReferDocument26 pagesQA QC ReferAnonymous 1ykzuaxWgYNo ratings yet

- Q22-Fat Procedure SN 1676 Mt1-Cr-7350 - BDocument29 pagesQ22-Fat Procedure SN 1676 Mt1-Cr-7350 - BAnonymous 1ykzuaxWgYNo ratings yet

- FWD Favco Crane Boom Drawings Data SheetsDocument27 pagesFWD Favco Crane Boom Drawings Data SheetsAnonymous 1ykzuaxWgYNo ratings yet

- 4 Year MaintenanceDocument4 pages4 Year MaintenanceAnonymous 1ykzuaxWgYNo ratings yet

- 3 - Function SystemDocument70 pages3 - Function SystemAnonymous 1ykzuaxWgYNo ratings yet

- PC1000 Favco Other CraneDocument1,449 pagesPC1000 Favco Other CraneAnonymous 1ykzuaxWgY100% (2)

- 6 - Torque Test, MPIDocument63 pages6 - Torque Test, MPIAnonymous 1ykzuaxWgYNo ratings yet

- Mpmy PM PRC 0001 - 2.0 Document Numbering ProcedureDocument18 pagesMpmy PM PRC 0001 - 2.0 Document Numbering ProcedureAnonymous 1ykzuaxWgYNo ratings yet

- Guardsman G and Guardsman L Series: Smith Meter Turbine MetersDocument12 pagesGuardsman G and Guardsman L Series: Smith Meter Turbine MetersAnonymous 1ykzuaxWgYNo ratings yet

- Mpmy-El-Spc-1005 - 2.0-Specification For Electrical Power, Control and Earthing CablesDocument24 pagesMpmy-El-Spc-1005 - 2.0-Specification For Electrical Power, Control and Earthing CablesAnonymous 1ykzuaxWgYNo ratings yet

- Q & A About SUEZ Membrane Element StorageDocument2 pagesQ & A About SUEZ Membrane Element StorageAnonymous 1ykzuaxWgYNo ratings yet

- Mpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureDocument21 pagesMpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureAnonymous 1ykzuaxWgYNo ratings yet

- BS en Iso 11114-1 1998Document50 pagesBS en Iso 11114-1 1998Anonymous 1ykzuaxWgYNo ratings yet

- Is Iso 10474 1991Document12 pagesIs Iso 10474 1991Anonymous 1ykzuaxWgY100% (2)

- MOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsDocument20 pagesMOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsAnonymous 1ykzuaxWgYNo ratings yet

- MOM-MUR-10-PC-SP-0001!00!1 Process Piping Fabricaton, Inspection and Testing SpecificationDocument52 pagesMOM-MUR-10-PC-SP-0001!00!1 Process Piping Fabricaton, Inspection and Testing SpecificationAnonymous 1ykzuaxWgY100% (1)

- MOM SK311 91 IC SP 0010-00-0 - SAPA Spec For Package Equipment InstrumentationDocument171 pagesMOM SK311 91 IC SP 0010-00-0 - SAPA Spec For Package Equipment InstrumentationAnonymous 1ykzuaxWgYNo ratings yet

- Astm d2022Document107 pagesAstm d2022Anonymous 1ykzuaxWgYNo ratings yet

Crane Inspection Checklist Migas

Crane Inspection Checklist Migas

Uploaded by

Anonymous 1ykzuaxWgY0 ratings0% found this document useful (0 votes)

79 views7 pagesCrane Inspection Checklist

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCrane Inspection Checklist

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

79 views7 pagesCrane Inspection Checklist Migas

Crane Inspection Checklist Migas

Uploaded by

Anonymous 1ykzuaxWgYCrane Inspection Checklist

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 7

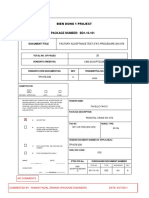

Form: Crane Monthly

Inspection

‘SAFETY INSPECTION CHECK LIST

Ref no : Crane Inspection Monthly

cheeklist

Date: 01/10/09

Rev no 0

Project Site

Date of Inspection

Contractor

Location of Inspection

Type of Crane

MACHINE MODEL

OWNER

SERIAL NO,

LOCATION

ENG MAKE

USER

ENG_NO.

INSPECTOR

HOURS

DATE

YEAR OF MFG

INITIAL

TYPE OF CRANE

tick mark the box

PEDESTAL

CRAWLER | HYDRAULIC

TRUCK_[ ROU

H TERRAIN

BOOM LENGTH

MAX. CAP. MAIN

Holst

MAX, CAP_AUX

nolst

MAX. CAP, MAIN@®

RAD.

MAX CAP_AUX @

RAD.

DESCRIPTION

NO. | CERTIFICATES Crane

o1_| micas

02 | Crane

Bid Party

03_| Boom Hoist Wire Rope

STATUS

REMARKS/RECOMMENDATIONS

04_| Main Block Wire

Rope

(05_| Aux. Block Wire Rope

(06 | Operator's license CRANE LOG

BOOK

(07 _| Daily inspection Cheek

08 _| We«

ly Wire Rope Check

(09_| Weekly Safety Device Test

10_| Limit Switches/Load Indicator

T1_| Weekly Boom Visual

12_| Mainten

nce Schedule

~13 | Replacement/Repair Record

Supervisors Signature

MANUALS/PROCEDURES

15_| Operating Manual

16 | Operating Procedure

17 | Bherpecy Poced

MARKINGS

TS | SWE Marking

19 | Colour Ci

20_| Sign Board

ANNUAL MPLTEST

| Main Block Hook

22 Aun Block Hook

23 | Boom Lacing

wo, | BESCRIPTION aceerrante | soon neptack | REMARKS

UPPER STRUCTURE

24_[ Overall Condition

25 Paint Condon

26 | Mast Condition

27_[ Boom Backsiop

28[ Counterweight

29, | Pendants/Links

30 | Sheaves

Bearings Bushing

33 | Condition A-frame

[roweK rant

34|Constion of Bets

35_| Condition of Radiator

36_[PipingHoses

38 [ Any leakage

39 _[Rngine tempore

40_| Engine oil pressure

41 | Governor option

43_| Condition of e

44_| ESD System

45_| Oil Pressure Gauge

46_| Water Temperature Gauge

7

Air Pressure Gauge

CONVERTER

(Converter condition

| Control linkages/pins

50_| Pipingyhaseseonition

S| Chics

MAIN DRIVE

53_| Drum condition

S4_| Clutch lini _ —_ _ -

35 onto! nkagesipins

56_| Rotating joint

| Shoe? Drum clearance (clutch)

Travel brakes

INDEPENDENT SWING

(@0_| Gear/Pinion condition

61_| Drum condition

@2_| Clutch fining

63_| Control Linkagesiping/pins

4_| Rotating joint

65__| Swing brake lini

(66_| Swing lock, functional

67_| Clutch clearance

ACCEPTABLE,

No, | DESCRIPTION ConpiTion | Poor REPLACE REMARKS

conprmion _| coNpITiON

BOOM HOIST

GeariPinion condition

[Auto brake

‘Aux. Brake

Rotating joint

Tinkages/pins/Pins

Clutch clearance

Boom hoist pawl

Wire rope condition

Leakages?

[FRONT DRUM (HOIST)

GeariPinion condition

Drum condition

Brake lining

Brake clearance

(Clute Ti

(Clutch clearance

| Rotating joint

Tinkages/pins/Pins

Wire rope condition

| REAR DRUM (HOIST)

36_[ Gear Pinion condition

37 [ Drum condition

38_| Brake Inng

$9 | Brake clearance

90 Chute ining

[Tot cht clearance —

92 Rovating joint

93 | Hinkages ins Pins

04 [ Wire ope conto

[CONTROLS AND VALVES

35_[ Condon uetonal of valves

97 | Ryarutic leakages?

98 [Hydraulic hasesiping condon

99 [linkages in Pins

100-[ Wiperter

TO1 | Brakes'Ciuth pedal

ROTATING BED/CAR BODY

TO? | House role, bushing & bearing

TOS | ook oles basing & beat

104 | Condition of ler pth

105 | Travel bake

106 | Pan cover

107 | Linkages Ping Bois in Bot

HYDRAULIC SYSTEM

TO8_| Condition hyeraule pumps

109 | Condon swing motor

111 | Condition aux. Hoist motor

112 | Leaks on pump sais

113 [ Leaks on moor seals

No, | DESCRIPTION ACCEPTABLE | POOR REPLACE, REMARKS

CONDITION

coxpimion_| conpmion

CRAWLER

114 | Drive chain conditionitension

TIS _| Sprocket condition

116 | Intermediate ole

117 [rele

118 | Crawler fame

119-[ Track condiioninson

120

Track pin condition

ELECTRICAL SYSTEM

12

Alternator/Generator charg

‘Wiring condition on engine/panel

All gauges on panel, functional

124 | Starr condition

125 | Swing Ligh & Alam

126 | Crane Reversing Light & Alama

127 | Flectial switches

[CABIN

138 | Safety glans

129"[ Seat and cushion

130"| Doorsvindow

IBL_| Reversing Mirror

132 | Main Hoist Dum Mion

135 | Fie Figg Equipment

134_[ Condition window wipes

LUBRICANT & COOLANT

35 Raditrcoolnt-inhibter

B6

137 |

Engine oil level/condition

Hydraulic oil level/condition

Bs

Chain case oil leveV/eondition

139

1

| Rotating bed sump oil level

140

‘Swing bevel gear case

Accumulator pressure

142 | Greasing point-sheaves, rotating

143 | Parts, roller & ete

SLI SYSTEM

144 | Anti-two block

145 | Load indicator/moment

146 | Angle indicator

147 | Length indicator

148 | Load chart

MISCELLANEOUS

149 | Main Hook block

150_| Main Hook condition

I51_| Aux. Hook block

‘Aux. Hook condition

153 | Safety Lateh

154 | Sheaves

155_| Bearing Bush

156 | Sockeviwedgesielips

157 | Gantry (A-frame)

158 | Boom Cylinder Bushing

159 | Rope Guide Rollers

160 | Boom Lattice/members (bracing|

REMARKS/COMMENTS/ITEMS NOT MENTIONED ABOVE

pected by CTR (HSE & Authorized Person)

‘Acknowledged by: PERTAMINA

Name Name Name

Position Position Position

Sign Sign Sign

Form: Crane Weekly Inspection

SAFETY INSPECTION CHECK

Refno:0

Project Site

Date of Inspection

[dentification(S/N) of erane

Contractor

Location of inspection

NO | DESCRIPTION coop | FAIR | poor | NA | REMARKS

T_| Operator certificate (SIO)

2 | Third party certificate (load testy

3_| MIGAS cenificate

4 | Wiper

S| Hom

6 | ESD. system

Hydraulic sysiem and hose condition

8_| Lightings

9 | Spark Arrestor (if use within DKP area)

n (at counter weight)

12_[ Cabin condition

13_[ Load indicator

T4_| Limit switeh

15_| Safety lateh

16_| Battery connection and it covered

17 | Engine and fuel sysiem (leaks)

18_| Tires condition

19_| Maintenance log book

20 _| Insulation of exhaust

21_| Electrical cable connection, isolation

22 | Load chart (in English’ Indonesian)

SWL, radius, boom length (clearly marking)

First aid kit

26 | Loe book

27_| Colour code

28 | TPEC - CGI inspection sticker

Comments :

Inspected by CTR (HISE & Authorized Person)

Acknowledged by: PERTAMINA

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Astm G48Document11 pagesAstm G48thedreampower100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Document256 pages6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Anonymous 1ykzuaxWgY100% (3)

- SLI ManualDocument142 pagesSLI ManualAnonymous 1ykzuaxWgY100% (1)

- 4 - Drawing &datasheet 20-10kDocument131 pages4 - Drawing &datasheet 20-10kAnonymous 1ykzuaxWgYNo ratings yet

- QA QC ReferDocument26 pagesQA QC ReferAnonymous 1ykzuaxWgYNo ratings yet

- Q22-Fat Procedure SN 1676 Mt1-Cr-7350 - BDocument29 pagesQ22-Fat Procedure SN 1676 Mt1-Cr-7350 - BAnonymous 1ykzuaxWgYNo ratings yet

- FWD Favco Crane Boom Drawings Data SheetsDocument27 pagesFWD Favco Crane Boom Drawings Data SheetsAnonymous 1ykzuaxWgYNo ratings yet

- 4 Year MaintenanceDocument4 pages4 Year MaintenanceAnonymous 1ykzuaxWgYNo ratings yet

- 3 - Function SystemDocument70 pages3 - Function SystemAnonymous 1ykzuaxWgYNo ratings yet

- PC1000 Favco Other CraneDocument1,449 pagesPC1000 Favco Other CraneAnonymous 1ykzuaxWgY100% (2)

- 6 - Torque Test, MPIDocument63 pages6 - Torque Test, MPIAnonymous 1ykzuaxWgYNo ratings yet

- Mpmy PM PRC 0001 - 2.0 Document Numbering ProcedureDocument18 pagesMpmy PM PRC 0001 - 2.0 Document Numbering ProcedureAnonymous 1ykzuaxWgYNo ratings yet

- Guardsman G and Guardsman L Series: Smith Meter Turbine MetersDocument12 pagesGuardsman G and Guardsman L Series: Smith Meter Turbine MetersAnonymous 1ykzuaxWgYNo ratings yet

- Mpmy-El-Spc-1005 - 2.0-Specification For Electrical Power, Control and Earthing CablesDocument24 pagesMpmy-El-Spc-1005 - 2.0-Specification For Electrical Power, Control and Earthing CablesAnonymous 1ykzuaxWgYNo ratings yet

- Q & A About SUEZ Membrane Element StorageDocument2 pagesQ & A About SUEZ Membrane Element StorageAnonymous 1ykzuaxWgYNo ratings yet

- Mpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureDocument21 pagesMpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureAnonymous 1ykzuaxWgYNo ratings yet

- BS en Iso 11114-1 1998Document50 pagesBS en Iso 11114-1 1998Anonymous 1ykzuaxWgYNo ratings yet

- Is Iso 10474 1991Document12 pagesIs Iso 10474 1991Anonymous 1ykzuaxWgY100% (2)

- MOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsDocument20 pagesMOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsAnonymous 1ykzuaxWgYNo ratings yet

- MOM-MUR-10-PC-SP-0001!00!1 Process Piping Fabricaton, Inspection and Testing SpecificationDocument52 pagesMOM-MUR-10-PC-SP-0001!00!1 Process Piping Fabricaton, Inspection and Testing SpecificationAnonymous 1ykzuaxWgY100% (1)

- MOM SK311 91 IC SP 0010-00-0 - SAPA Spec For Package Equipment InstrumentationDocument171 pagesMOM SK311 91 IC SP 0010-00-0 - SAPA Spec For Package Equipment InstrumentationAnonymous 1ykzuaxWgYNo ratings yet

- Astm d2022Document107 pagesAstm d2022Anonymous 1ykzuaxWgYNo ratings yet