Professional Documents

Culture Documents

3.3 Qualification of Welders, Welding Operators, and Tack Welders

3.3 Qualification of Welders, Welding Operators, and Tack Welders

Uploaded by

Ibrahim shaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.3 Qualification of Welders, Welding Operators, and Tack Welders

3.3 Qualification of Welders, Welding Operators, and Tack Welders

Uploaded by

Ibrahim shaikCopyright:

Available Formats

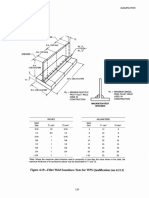

CLAUSE 3. QUALIFICATION AWS D1.2/D1.

2M:2014

Group AWS (1) Position 1G (Flat)—The test plates shall be placed

Designation Filler Metal Classification in an approximately horizontal plane and the weld metal

deposited from the upper side [see Figure 3.3(A)].

F21 ER1100, ER1188, R1100, R1188

(2) Position 2G (Horizontal)—The test plates shall be

F22 ER5183, ER5356, ER5554, ER5556, placed in an approximately vertical plane with the groove

ER5654, R5183, R5356, R5554, R5556, approximately horizontal [see Figure 3.3(B)].

R5654

(3) Position 3G (Vertical)—The test plates shall be

F23 ER4010, ER4043, ER4047, ER4145, placed in an approximately vertical plane with the groove

ER4643, R4010, R4043, R4047, R4145, approximately vertical [see Figure 3.3(C)].

R4643

(4) Position 4G (Overhead)—The test plates shall be

F24 ER4009, R206.0, R357.0, R-A356.0, placed in an approximately horizontal plane and the weld

R-A357.0, R4009, R-C355.0, R4011 metal deposited from the underside [see Figure 3.3(D)].

F25 ER2319, R2319 3.4.1.2 Groove Welds—Pipe (see Figure 3.4). The

term pipe as used herein shall include all tubular shapes.

3.2.3 Unlisted Material. When an alloy not listed in In making the tests to qualify groove welds, the test pipe

Table 4.1 is approved under the provisions of the contract shall be welded in the following positions:

documents the WPS shall be qualified by the Contractor

(1) Position 1G (Pipe Horizontal-Rotated)—The test

in conformance with Clause 3.

pipe shall be placed with its axis approximately horizon-

tal and the groove approximately vertical. The pipe shall

be rotated during welding so the weld metal is deposited

3.3 Qualification of Welders, Welding from the upper side [see Figure 3.4(A)].

Operators, and Tack Welders

(2) Position 2G (Pipe Vertical-Fixed)—The test pipe

3.3.1 Welders, welding operators, and tack welders to be shall be placed with its axis approximately vertical and

employed on work under this code shall be qualified in the groove approximately horizontal. The pipe shall not

conformance with Part D of this clause, or other qualifi- be rotated during welding [see Figure 3.4(B)].

cation as approved by the Engineer. Welders and welding

operators qualified by standard test to AWS B2.1, Stan- (3) Position 5G (Pipe Horizontal-Fixed)—The test

dard for Welding Procedure and Performance Qualifica- pipe shall be placed with its axis approximately horizon-

tion, may, in this manner, be accepted for use in this tal and the groove approximately vertical. The pipes shall

code. not be rotated during welding [see Figure 3.4(C)].

3.3.2 The welder’s, welding operator’s, or tack welder’s (4) Position 6G (Pipe Inclined-Fixed)—The test pipe

qualification, as specified in Clause 3, Part D, shall be shall be inclined at approximately 45° with the hori-

considered as remaining in effect indefinitely unless (1) zontal. The pipe shall not be rotated during welding [see

the person is not engaged in a given process of welding Figure 3.4(D)].

for which that person is qualified for a period exceeding

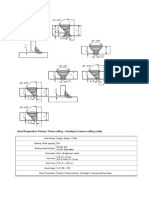

3.4.1.3 Fillet Welds—Plate (see Figure 3.5). In mak-

six months, or (2) there is reason to question the individ-

ing the tests to qualify welds on plate, test plates shall be

ual’s ability.

welded in the positions outlined below:

(1) Position 1F (Flat)—The test plates shall be so

3.4 Position of Test Welds placed that each fillet weld is deposited with its axis

approximately horizontal and its throat approximately

3.4.1 Each WPS shall be qualified by positioning and vertical [see Figure 3.5(A)].

welding the test assembly in the manner stated below and

as shown in Figures 3.1 through 3.6 for the position for (2) Position 2F (Horizontal)—The test plates shall be

which it is to be qualified. These positions are classified so placed that each fillet weld is deposited on the upper

as: (1) flat, (2) horizontal, (3) vertical, or (4) overhead in side of a horizontal surface and against a vertical surface

conformance with Figures 3.1 and 3.2. [see Figure 3.5(B)].

3.4.1.1 Groove Welds—Plate (see Figure 3.3). In (3) Position 3F (Vertical)—The test plates shall be

making the tests to qualify groove welds, test plates shall placed in approximately vertical planes, and each fillet

be welded in the following positions: weld deposited on vertical surfaces [see Figure 3.5(C)].

12

You might also like

- AWS D1.2 AluminiumDocument2 pagesAWS D1.2 AluminiumAslamsherkhan Ibn Hussain Kandamangalam44% (9)

- Method Statement For Field Erection Storage TanksDocument29 pagesMethod Statement For Field Erection Storage TanksTee Klong Rung100% (1)

- AWS D1.2 at Extent of TestingDocument1 pageAWS D1.2 at Extent of TestingIbrahim shaikNo ratings yet

- AWS D17.1 WPQR Guides PDFDocument2 pagesAWS D17.1 WPQR Guides PDFTAGUI100% (3)

- ABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14Document14 pagesABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14cupidkhhNo ratings yet

- ASTM D 2573-94 Standard Test Method For Field Vane Shear Test in Cohesive SoilDocument3 pagesASTM D 2573-94 Standard Test Method For Field Vane Shear Test in Cohesive SoilPablo Antonio Valcárcel Vargas75% (4)

- ASME B31.3 2014 NDT AcceptanceDocument9 pagesASME B31.3 2014 NDT AcceptanceWalter Trajada83% (6)

- pc300 8Document1 pagepc300 8Kieran RyanNo ratings yet

- 4WD Driver's Guide - Cooper TyresDocument16 pages4WD Driver's Guide - Cooper TyresJohn EvansNo ratings yet

- 3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaDocument1 page3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaIbrahim shaikNo ratings yet

- Jsce-Sf4 WordDocument6 pagesJsce-Sf4 WordandreNo ratings yet

- Modul Tambahan Kualifikasi Las (KL)Document27 pagesModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- BTH 1 2008Document1 pageBTH 1 2008EnriqueGDNo ratings yet

- 4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsDocument1 page4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsIbrahim shaikNo ratings yet

- 4 Tension MemberDocument15 pages4 Tension Memberhari1008108No ratings yet

- (PDF) Concrete T-Beam Bridge Design - CompressDocument3 pages(PDF) Concrete T-Beam Bridge Design - CompressSachin AnandNo ratings yet

- 2016 - Modeling of Closed-Die Forging For Estimating Forging LoadDocument9 pages2016 - Modeling of Closed-Die Forging For Estimating Forging LoadNguyen Hoang DungNo ratings yet

- Certificate Format-Thesis Correction Recommended External ExaminersDocument2 pagesCertificate Format-Thesis Correction Recommended External Examinerssa1108No ratings yet

- Bend Test AceptenDocument1 pageBend Test AceptenArung IdNo ratings yet

- Reaffirmed 2006Document13 pagesReaffirmed 2006harikri3113No ratings yet

- Qualification Tests For Shop Welding: Office of MaterialsDocument5 pagesQualification Tests For Shop Welding: Office of MaterialsMichael DanielNo ratings yet

- ABS 2014 High Speed Naval Craft - Propellers, HSNC - Part - 4 - E-Feb14Document13 pagesABS 2014 High Speed Naval Craft - Propellers, HSNC - Part - 4 - E-Feb14cupidkhhNo ratings yet

- 2016 - Modeling of Closed-Die Forging For Estimating Forging LoadDocument12 pages2016 - Modeling of Closed-Die Forging For Estimating Forging LoadNguyen Hoang DungNo ratings yet

- Procedure QualificationDocument68 pagesProcedure QualificationParvee K Nakwal100% (1)

- Paes 132 PDFDocument21 pagesPaes 132 PDFReggie SilodNo ratings yet

- TorsionDocument17 pagesTorsionkalpanaadhi100% (1)

- Tugas 07Document6 pagesTugas 07aingNo ratings yet

- Concrete T-Beam Bridge DesignDocument3 pagesConcrete T-Beam Bridge Designjclou021167% (12)

- Ujian 1 1314 Sem 1 With SKEMA PDFDocument15 pagesUjian 1 1314 Sem 1 With SKEMA PDFYap Jin YeeNo ratings yet

- Ujian 1 1314 Sem 1 (With SKEMA)Document15 pagesUjian 1 1314 Sem 1 (With SKEMA)Lew IceNo ratings yet

- Dcc3093-Lecture Note Series - t5Document23 pagesDcc3093-Lecture Note Series - t5Alif KarimiNo ratings yet

- HSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fDocument14 pagesHSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fTerraManNo ratings yet

- E 1813 - 96 R02 - Rte4mtmDocument11 pagesE 1813 - 96 R02 - Rte4mtmpechugonisNo ratings yet

- Rating Dozer BladesDocument4 pagesRating Dozer BladesAdriana GrajedaNo ratings yet

- Chapter 3 (Torsion)Document12 pagesChapter 3 (Torsion)znabu asefaNo ratings yet

- Tension MemberDocument9 pagesTension Membersanket_loveyouNo ratings yet

- c4 Addendum 13 Attachment 01 10,12 14Document28 pagesc4 Addendum 13 Attachment 01 10,12 14Sunil Sekhar RathNo ratings yet

- Procedure For Welder QualificationDocument28 pagesProcedure For Welder Qualificationjagannath100% (1)

- Appendix B. Supplemental Welder Qualification Testing ProcedureDocument2 pagesAppendix B. Supplemental Welder Qualification Testing ProcedureRicardoNo ratings yet

- No. 105 Qualification Scheme For Welders of Aluminium Alloys No. 105Document12 pagesNo. 105 Qualification Scheme For Welders of Aluminium Alloys No. 105yoonchankim0911No ratings yet

- AWS D9.1 GuidesDocument2 pagesAWS D9.1 Guidescycsi02No ratings yet

- B31Code Cases IterpretationDocument12 pagesB31Code Cases IterpretationayoungaNo ratings yet

- Procedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Document14 pagesProcedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Sayed Diab AlsayedNo ratings yet

- BS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 4.3.2.2 Intermittent Fillet WeldsDocument5 pagesBS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 4.3.2.2 Intermittent Fillet Weldsmn4webNo ratings yet

- Welding - Group G - Welding-02Document27 pagesWelding - Group G - Welding-02christofer kevinNo ratings yet

- Measuring Rolling Friction Characteristics of A Spherical Shape On A Flat Horizontal PlaneDocument9 pagesMeasuring Rolling Friction Characteristics of A Spherical Shape On A Flat Horizontal PlaneالGINIRAL FREE FIRENo ratings yet

- 1757 1988Document4 pages1757 1988Ramesh BNo ratings yet

- CHAPTER 3 Installation Conditions: 3.1 Dimensions 3.2 Mounting 3.3 Connections With Host SystemDocument12 pagesCHAPTER 3 Installation Conditions: 3.1 Dimensions 3.2 Mounting 3.3 Connections With Host SystemLeón Van de PavertNo ratings yet

- ASTM A 125-96 Standard Specification For Steel Springs, Helical, Heat-TreatedDocument6 pagesASTM A 125-96 Standard Specification For Steel Springs, Helical, Heat-Treatedfredy picaulyNo ratings yet

- Section VII. Technical SpecificationDocument17 pagesSection VII. Technical SpecificationBalkrishna PangeniNo ratings yet

- Is Iso 1660-1992Document9 pagesIs Iso 1660-1992mwasicNo ratings yet

- Specification Specification For Welding Repairs: Laser Interferometer Gravitational Wave ObservatoryDocument1 pageSpecification Specification For Welding Repairs: Laser Interferometer Gravitational Wave Observatorynate anantathatNo ratings yet

- Rec 105 Rev 1 Corr 1Document12 pagesRec 105 Rev 1 Corr 1marufuddin0No ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Bc-10 Phase 3 CTR 31: Tamba BVDocument47 pagesBc-10 Phase 3 CTR 31: Tamba BVIbrahim shaikNo ratings yet

- Pipe Bending: Case StudyDocument4 pagesPipe Bending: Case StudyIbrahim shaikNo ratings yet

- Induction Training Record - Itr: Elmar Marinas LLC PO Box 4955, Umm Al Quwain, United Arab EmiratesDocument1 pageInduction Training Record - Itr: Elmar Marinas LLC PO Box 4955, Umm Al Quwain, United Arab EmiratesIbrahim shaikNo ratings yet

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- ISO 9001 2015 CluasesDocument1 pageISO 9001 2015 CluasesIbrahim shaikNo ratings yet

- 3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaDocument1 page3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaIbrahim shaikNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- 2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Document1 page2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Ibrahim shaikNo ratings yet

- Pipe & Tube BrochureDocument18 pagesPipe & Tube BrochureIbrahim shaikNo ratings yet

- Figure 4.21-Test Plate For Unlimited Thickness-Welder Qualification (See 4.23.1)Document1 pageFigure 4.21-Test Plate For Unlimited Thickness-Welder Qualification (See 4.23.1)Ibrahim shaikNo ratings yet

- 4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsDocument1 page4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsIbrahim shaikNo ratings yet

- 2.7 Filler Plates: AWS D1.2/D1.2M:2014 Clause 2. DesignDocument1 page2.7 Filler Plates: AWS D1.2/D1.2M:2014 Clause 2. DesignIbrahim shaikNo ratings yet

- Design: 2.1 ScopeDocument1 pageDesign: 2.1 ScopeIbrahim shaikNo ratings yet

- Ergonomic Notations: Guide ForDocument76 pagesErgonomic Notations: Guide ForIbrahim shaikNo ratings yet

- Figure 4.19-Fillet Weld Soundness Tests For WPS Qualification (See 4.11.2)Document1 pageFigure 4.19-Fillet Weld Soundness Tests For WPS Qualification (See 4.11.2)Ibrahim shaikNo ratings yet

- Stainless Steel Socket Button and Flat Countersunk Head Cap Screws (Metric)Document6 pagesStainless Steel Socket Button and Flat Countersunk Head Cap Screws (Metric)Ibrahim shaikNo ratings yet

- FAB-QMF-60 (Outsources Process Audit Report)Document6 pagesFAB-QMF-60 (Outsources Process Audit Report)Ibrahim shaikNo ratings yet

- Figure 4.20-Pipe Fillet Weld Soundness Test-WPS Qualification (See 4.11.2)Document1 pageFigure 4.20-Pipe Fillet Weld Soundness Test-WPS Qualification (See 4.11.2)Ibrahim shaikNo ratings yet

- 14 EN 14509:2013 AVCP3: Declared Performance For IND - INDUSTRIAL Panel 1120 - 1180mmDocument1 page14 EN 14509:2013 AVCP3: Declared Performance For IND - INDUSTRIAL Panel 1120 - 1180mmIbrahim shaikNo ratings yet

- Bevel PreparationDocument1 pageBevel PreparationIbrahim shaikNo ratings yet

- Signature FormDocument2 pagesSignature FormIbrahim shaikNo ratings yet

- Joints Edge PreparationDocument4 pagesJoints Edge PreparationIbrahim shaikNo ratings yet

- ACCP L2 Continued EmploymentDocument5 pagesACCP L2 Continued EmploymentIbrahim shaikNo ratings yet

- Background:: Public Health & Safety Department Guidelines For First-Aid Requirement DM-PH&SD-P4-TG17Document4 pagesBackground:: Public Health & Safety Department Guidelines For First-Aid Requirement DM-PH&SD-P4-TG17Ibrahim shaikNo ratings yet

- MasterspecDocument11 pagesMasterspecIbrahim shaikNo ratings yet

- Dokumen - Tips - Astm d1037 12 For Bio CompositesDocument16 pagesDokumen - Tips - Astm d1037 12 For Bio CompositesIbrahim shaikNo ratings yet

- En 131-2-2010+a2-2017Document6 pagesEn 131-2-2010+a2-2017Ibrahim shaik100% (1)

- Type Approval Certificate: Hydratight LTDDocument3 pagesType Approval Certificate: Hydratight LTDIbrahim shaikNo ratings yet

- The Factors Influencing Procurement Strategy Construction EssayDocument5 pagesThe Factors Influencing Procurement Strategy Construction EssayDivina Teja Rebanal-GlinoNo ratings yet

- IEEE STD 3004.8 - 2016: Protection & CoordinationDocument17 pagesIEEE STD 3004.8 - 2016: Protection & Coordinationvanessa quispeNo ratings yet

- Upload A Document - ScribdDocument6 pagesUpload A Document - ScribdPedro de MoraisNo ratings yet

- Smartcool Energy Saving UK Technology PresentationDocument40 pagesSmartcool Energy Saving UK Technology PresentationSaleem AhmedNo ratings yet

- Yamaha An1x DatalistDocument20 pagesYamaha An1x DatalistSal CarolloNo ratings yet

- Final Cut Pro 7Document602 pagesFinal Cut Pro 7Ty WarbosskillaskullsmashaNo ratings yet

- Bucayao DecDocument49 pagesBucayao DecAngelika Calingasan0% (1)

- Package QueryDocument51 pagesPackage QuerySiddiq MohammedNo ratings yet

- Blaser D99Document9 pagesBlaser D99JustinNo ratings yet

- MORTABOND Premium Tile Adhesive: Application As Wall RendersDocument1 pageMORTABOND Premium Tile Adhesive: Application As Wall RendersGelyDelaCruzNo ratings yet

- Startup Shutdown ProceduresDocument1 pageStartup Shutdown Proceduresbiron rumangunNo ratings yet

- Vane Motors - 21,6 To 37,5 CM /R (1.32 To 2.29 in /R) : Characteristics EfficiencyDocument7 pagesVane Motors - 21,6 To 37,5 CM /R (1.32 To 2.29 in /R) : Characteristics EfficiencysyediliyassikandarNo ratings yet

- NPTL ADMITCardDocument1 pageNPTL ADMITCardPraneshwar KNo ratings yet

- Top 9 Ethics IssuesDocument4 pagesTop 9 Ethics IssuesJuan Pablo SerraNo ratings yet

- ProjectDocument2 pagesProjectarry_rullyawanNo ratings yet

- Po 0069098Document3 pagesPo 0069098Divino Edgar LacambraNo ratings yet

- Autism and Computing For Children Under 5: How Can A Computer HelpDocument5 pagesAutism and Computing For Children Under 5: How Can A Computer HelpIris De La CalzadaNo ratings yet

- Why Do We Believe in Economy of Scale? Professor John Seddon, Managing Director Vanguard. July 2010Document12 pagesWhy Do We Believe in Economy of Scale? Professor John Seddon, Managing Director Vanguard. July 2010Ashok MehrotraNo ratings yet

- 64-2103 Tweco Flux Core SEFCDocument2 pages64-2103 Tweco Flux Core SEFCcarlosNo ratings yet

- Mcdonals PDFDocument29 pagesMcdonals PDFPancho1407No ratings yet

- Topic 11-SD Edit-Qualitative Data AnalysisDocument14 pagesTopic 11-SD Edit-Qualitative Data AnalysisLieya Nur Irdina RuzaimanNo ratings yet

- Cotton, Polyester & Cotton Polyester BlendDocument4 pagesCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Lcinga Installation and ConfigurationDocument5 pagesLcinga Installation and ConfigurationPathum FernandoNo ratings yet

- Nca Form Ap03aDocument5 pagesNca Form Ap03adreamtechbusiness24No ratings yet

- Current Information and Advancement About The Solar SystemDocument6 pagesCurrent Information and Advancement About The Solar SystemEnz Ognilla71% (7)

- Deloitte Digital - Front-End DeveloperDocument3 pagesDeloitte Digital - Front-End DeveloperLolNo ratings yet

- MILLING CATALOG 38 - 2021 p001 094Document94 pagesMILLING CATALOG 38 - 2021 p001 094MeuMundoMinecraftNo ratings yet