Professional Documents

Culture Documents

Cast Steel G50Crmo4 Technical Specifications: Eb01.33.211 /A Norm Executory

Cast Steel G50Crmo4 Technical Specifications: Eb01.33.211 /A Norm Executory

Uploaded by

yusuf tolga öksüzCopyright:

Available Formats

You might also like

- Audi AllroadDocument76 pagesAudi AllroadSimon Chell100% (6)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- AGCO Beauvais Engineering: General Specification For Cast IronsDocument8 pagesAGCO Beauvais Engineering: General Specification For Cast IronsRafa Lopez PuigdollersNo ratings yet

- Lamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical SpecificationsDocument4 pagesLamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical Specificationsyusuf tolga öksüz100% (1)

- ISO 11971 - Steel and Iron Castings - Visual Examination On Surface QualityDocument8 pagesISO 11971 - Steel and Iron Castings - Visual Examination On Surface QualityCristian RodeghelNo ratings yet

- s543b - Electrozi Basic 7018 Info ENGDocument2 pagess543b - Electrozi Basic 7018 Info ENGVlad AdrianNo ratings yet

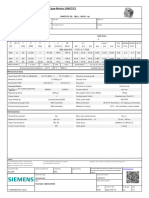

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- Aluminum Alloys Designation NormDocument15 pagesAluminum Alloys Designation NormBurcu YıldızNo ratings yet

- Dimensioning of Welding Equipment: GE34.SO.194 /C Guide ApplicableDocument8 pagesDimensioning of Welding Equipment: GE34.SO.194 /C Guide Applicablehassan eijyNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Fisa Electrozi Bazici 7018 - EngDocument2 pagesFisa Electrozi Bazici 7018 - EngGeorgeBungarzescuNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- Allbro Material-Properties-Smc-DmcDocument1 pageAllbro Material-Properties-Smc-Dmcfajar agungNo ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- Greenlam High Pressure Laminates (European Standard) - 0.8mmDocument3 pagesGreenlam High Pressure Laminates (European Standard) - 0.8mmJames ParkerNo ratings yet

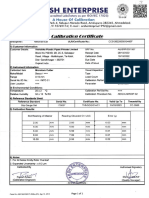

- 3-Microtome Calibration CartificateDocument1 page3-Microtome Calibration Cartificatemba213No ratings yet

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- Dmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument6 pagesDmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode Mosfetzigmund zigmundNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Fortis DatasheetDocument1 pageFortis DatasheetlukaNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PTio SNo ratings yet

- 0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enDocument1 page0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enRupaliNo ratings yet

- P01696-0019-4 - AsBuilt Painting ProcedureDocument2 pagesP01696-0019-4 - AsBuilt Painting ProcedureMahmoud GaberNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- Conarc49c EngDocument2 pagesConarc49c EngtNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-0DB32-3FA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-0DB32-3FA4-Zjitendra patelNo ratings yet

- DOP CE EGGER Eurospan Mmex Rec301 ENDocument2 pagesDOP CE EGGER Eurospan Mmex Rec301 ENMateusz Latosiński LSD.STUDIO ✖No ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- MBR10150C: High Voltage Power Schottky RectifierDocument8 pagesMBR10150C: High Voltage Power Schottky Rectifiereki miftakhul firdausNo ratings yet

- LCP Lycordeck®Document23 pagesLCP Lycordeck®Lokey EnNiNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4nizarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-444Document1 pagePages From SIMABUS Tubular Busbar Accesories-444asi midobarNo ratings yet

- Dual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D ADocument6 pagesDual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D AErkanNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- LED Chip LGDocument18 pagesLED Chip LGMinh Khuê Nguyễn ThịNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- 2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument5 pages2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetErkanNo ratings yet

- Kryo1 EngDocument2 pagesKryo1 EngtNo ratings yet

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- 1LE1601 2DC03 4AB4 Z L51 Datasheet enDocument2 pages1LE1601 2DC03 4AB4 Z L51 Datasheet enFaziNo ratings yet

- Finalloy EBP-820/2 C16: DescriptionDocument1 pageFinalloy EBP-820/2 C16: DescriptionYouness LATAFINo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- 3 Phase Motor DetailDocument1 page3 Phase Motor Detailhashir zamanNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Berulit GA 400Document1 pageBerulit GA 400Johan TeoNo ratings yet

- 245LEN0040H10XLB00V50MR2Document16 pages245LEN0040H10XLB00V50MR2Sting DâuNo ratings yet

- TDS 16560 Jotamastic 90 Euk GBDocument7 pagesTDS 16560 Jotamastic 90 Euk GBNgô Trung NghĩaNo ratings yet

- 2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorDocument6 pages2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorErkanNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- Scientific Study On External Ionising Radiation Exposure During Cargo / Vehicle Radiographic InspectionsDocument10 pagesScientific Study On External Ionising Radiation Exposure During Cargo / Vehicle Radiographic InspectionsIRUNo ratings yet

- Approved SystemsDocument25 pagesApproved SystemsadrianrrccNo ratings yet

- Engine Performance With Variable Valve TimingDocument4 pagesEngine Performance With Variable Valve TimingWilliam KibbeNo ratings yet

- Xsan 2 Admin GuideDocument140 pagesXsan 2 Admin GuidedebshubraNo ratings yet

- OpCo Audit ProgramDocument11 pagesOpCo Audit ProgramMarco Giovani ZancanellaNo ratings yet

- SG II QUALITY Annex 24.12.2015Document89 pagesSG II QUALITY Annex 24.12.2015parthaNo ratings yet

- International Standard: Power Transformers - Loading Guide For Oil-Immersed Power TransformersDocument8 pagesInternational Standard: Power Transformers - Loading Guide For Oil-Immersed Power TransformersLuis Villalobos Dzib50% (4)

- Big Ass Fan Model 4900Document104 pagesBig Ass Fan Model 4900VeronicaSanJoséNo ratings yet

- Spam Trojan Detection With Mikrotik RouterOSDocument3 pagesSpam Trojan Detection With Mikrotik RouterOSmsuoodh0% (1)

- Timber Strength GradingDocument2 pagesTimber Strength GradingJamesNo ratings yet

- $RI5QA26Document54 pages$RI5QA26achatNo ratings yet

- NCM Chapter SixDocument20 pagesNCM Chapter Sixdimberu yirgaNo ratings yet

- Iso 22475 1 2021Document15 pagesIso 22475 1 2021ANo ratings yet

- As ISO 389.2-2007 Acoustics - Reference Zero For The Calibration of Audiometric Equipment Reference EquivalenDocument8 pagesAs ISO 389.2-2007 Acoustics - Reference Zero For The Calibration of Audiometric Equipment Reference EquivalenSAI Global - APACNo ratings yet

- PES Template V1.1Document126 pagesPES Template V1.1BudiWirahmiNo ratings yet

- 05 - Teleprotection and Weak InfeedDocument21 pages05 - Teleprotection and Weak InfeedJosé Miguel Ochoa AcerosNo ratings yet

- Asme Section Ix InterpretationsDocument72 pagesAsme Section Ix InterpretationsEmmanuelNo ratings yet

- Qos Evaluation of Voip End-Points: Wenyu Jiang Kazuumi Koguchi Henning SchulzrinneDocument5 pagesQos Evaluation of Voip End-Points: Wenyu Jiang Kazuumi Koguchi Henning Schulzrinneeugene123No ratings yet

- HP Pavilion DV6000 Quanta AT6 Intel SchematicsDocument45 pagesHP Pavilion DV6000 Quanta AT6 Intel Schematicsmou tiemNo ratings yet

- Trolleybus 333 enDocument2 pagesTrolleybus 333 enRodrigo SampaioNo ratings yet

- As 3669-2006 Non-Destructive Testing - Qualification and Approval of Personnel - AerospaceDocument9 pagesAs 3669-2006 Non-Destructive Testing - Qualification and Approval of Personnel - AerospaceSAI Global - APACNo ratings yet

- BS en 13160-4 2016Document42 pagesBS en 13160-4 2016CK CkkouNo ratings yet

- CME Deleting The Name of The PersonDocument3 pagesCME Deleting The Name of The PersonkhalidNo ratings yet

- Check Point 1430/1450 Appliance: Getting Started Guide Centrally ManagedDocument85 pagesCheck Point 1430/1450 Appliance: Getting Started Guide Centrally Managedchinmay mandalNo ratings yet

- Posidrive Security Gate: Installation, Operation, and Maintenance ManualDocument96 pagesPosidrive Security Gate: Installation, Operation, and Maintenance ManualHaris MahmoodNo ratings yet

- SyncServer S250Document6 pagesSyncServer S250faraz2010No ratings yet

- M03-014 - HVAC Variable Refrigerant Flow (VRF) SystemsDocument38 pagesM03-014 - HVAC Variable Refrigerant Flow (VRF) Systemsjadewest100% (1)

- Dial Gauge 1Document1 pageDial Gauge 1arnolhariNo ratings yet

- Modems, Shiron IRG-DVB-S2 Modems, Linkstar Modems, Cometech SCPC Modems in Countries Such AsDocument8 pagesModems, Shiron IRG-DVB-S2 Modems, Linkstar Modems, Cometech SCPC Modems in Countries Such AsAhmed N. MusaNo ratings yet

Cast Steel G50Crmo4 Technical Specifications: Eb01.33.211 /A Norm Executory

Cast Steel G50Crmo4 Technical Specifications: Eb01.33.211 /A Norm Executory

Uploaded by

yusuf tolga öksüzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cast Steel G50Crmo4 Technical Specifications: Eb01.33.211 /A Norm Executory

Cast Steel G50Crmo4 Technical Specifications: Eb01.33.211 /A Norm Executory

Uploaded by

yusuf tolga öksüzCopyright:

Available Formats

EB01.33.

211 /A

Cast steel G50CrMo4 ________________________________________

Norm

Technical specifications ________________________________________

Statut Executory

Important Note: This document has been translated from the French. In the event of any dispute, only the French

version is referred to as the reference text and is binding on the parties.

Purpose Define the technical characteristics concerning the supply and the acceptance of special

low alloy cast steel G50CrMo4, fit for treatment and intended for the Renault Group.

This grade is used among other for the blanking and drawing tools (blades, blanking

punch, etc.)

All the characteristics that are not specified in this document must conform to the norms

EN 1559-1 and EN 1559-2.

Scope Renault group

Issuer 68140 - Metals and processes of transformation

Confidentiality No confidential

Approved by Position Signature Date of application

B. Macquaire Head of Department 68140 01/2007

© RENAULT 2007 Origin : PEGI - Renault Page : 1 / 4

EB01.33.221 /A

Revision Record

Version Update Subject of main modifications Author

A 01/2007 Original issue Laporte Jean Joseph

Remplace CNOMO standard E01.33.211.N of 02/2002

Available from In Renault internal, on Intranet : http://gdxpegi.ava.tcr.renault.fr

In Renault external, on Internet : www.cnomo.com

E-mail : norminfo.moyens@renault.com

Documents cited Regulations :

ISO/IEC : ISO 3887.

European : EN 1371-1, EN 1559-1, EN 1559-2.

NF :

CNOMO :

Renault : EB01.05.205.

Other internal docs :

Other external docs :

Code ICS : 77.140.50

Class E01

Key words G50CrMo4, acier moulé, cast steel

Language English

© RENAULT 2007 Origin : PEGI - Renault Page : 2 / 4

EB01.33.221 /A

1 Chemical composition in % (of weight)

C Si Mn S P Cr Mo Cu Ni

Min. 0,47 - - - - 0,90 0,20 - -

Max. 0,53 0,60 0,80 0,035 0,040 1,50 0,40 0,20 0,25

2 Delivery state

2.1 Metallurgical state

In accordance with norm EB01.05.205: T3 (hardened, tempered) with predominant tempered martensite

structure, free of ferrite.

2.2 Presentation

Rough treatment.

Surfaced (to be specified upon ordering).

2.3 Mechanical characteristics upon acceptance

Mechanical Rp 0,2 Portable electronic harness

Rm Hardness

characteristics A% meter with bounce

Mpa Mpa HBW

LD LG

State

min. min. max. min. min. max. min. max. min. max.

T3 650 800 1000 10 240 300 520 577 488 540

After 2 h tempering at 600 °C, the mechanical properties of the product must remain unchanged.

2.4 Decarburization

in accordance ISO 3887

The depth of decarburization is defined as the distance between the surface and the limit beyond which

the minimum hardness specified in paragraph 2.3 is reached.

The decarburization must not exceed 3 mm in depth.

No decarburization is allowed on the machined areas of the part.

3 Metallurgical properties

The minimum hardness to be reached after a local heating, in accordance with the following table, must

be of 54 HRC or 756 LD, with a portable electronic hardness meter with bounce.

Requirements

Heat treatment

Heating Hardness (*)

Hardening Revenu Portable electronic harness

Method Temperature HRC meter with bounce LD

Oxyacetylene 850 °C ± 25 °C With air blow 180 °C ≥ 54 ≥ 756

torch on passage -2h

(*) The hardness is checked on the horizontal and vertical sides, at 2 mm of the treated edges.

© RENAULT 2007 Origin : PEGI - Renault Page : 3 / 4

EB01.33.221 /A

4 Health check

A non destructive check by penetrant inspection must be performed on all the areas designated for this

(Zd). The observed image must not show linear faults. The circular faults must correspond at most with

the SP2 standard image of the norm EN 1371-1.

5 List of documents quoted

NOTE: For undated documents , the last version in force applie

ISO 3887 : Unalloyed or low alloy steels - Determination of the depth of decarburization.

EN 1371-1 : Foundry - Penetrant inspection - Part 1: Sand molded, chill cast, gravity molded, and

low pressure molded parts.

EN 1559-1 : Founding. Technical conditions of delivery. Part 1: General

EN 1559-2 : Founding. Technical conditions of delivery. Part 2: Additional requirements for steel

castings

NF A 32-058 : Cast products - Cast steels and white cast iron resistant to abrasive wear.

EB01.05.205 : Ferrous alloys - Symbolization of treatments.

© RENAULT 2007 Origin : PEGI - Renault Page : 4 / 4

You might also like

- Audi AllroadDocument76 pagesAudi AllroadSimon Chell100% (6)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- AGCO Beauvais Engineering: General Specification For Cast IronsDocument8 pagesAGCO Beauvais Engineering: General Specification For Cast IronsRafa Lopez PuigdollersNo ratings yet

- Lamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical SpecificationsDocument4 pagesLamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical Specificationsyusuf tolga öksüz100% (1)

- ISO 11971 - Steel and Iron Castings - Visual Examination On Surface QualityDocument8 pagesISO 11971 - Steel and Iron Castings - Visual Examination On Surface QualityCristian RodeghelNo ratings yet

- s543b - Electrozi Basic 7018 Info ENGDocument2 pagess543b - Electrozi Basic 7018 Info ENGVlad AdrianNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- Aluminum Alloys Designation NormDocument15 pagesAluminum Alloys Designation NormBurcu YıldızNo ratings yet

- Dimensioning of Welding Equipment: GE34.SO.194 /C Guide ApplicableDocument8 pagesDimensioning of Welding Equipment: GE34.SO.194 /C Guide Applicablehassan eijyNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Fisa Electrozi Bazici 7018 - EngDocument2 pagesFisa Electrozi Bazici 7018 - EngGeorgeBungarzescuNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- Allbro Material-Properties-Smc-DmcDocument1 pageAllbro Material-Properties-Smc-Dmcfajar agungNo ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- Greenlam High Pressure Laminates (European Standard) - 0.8mmDocument3 pagesGreenlam High Pressure Laminates (European Standard) - 0.8mmJames ParkerNo ratings yet

- 3-Microtome Calibration CartificateDocument1 page3-Microtome Calibration Cartificatemba213No ratings yet

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- Dmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument6 pagesDmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode Mosfetzigmund zigmundNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Fortis DatasheetDocument1 pageFortis DatasheetlukaNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PTio SNo ratings yet

- 0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enDocument1 page0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enRupaliNo ratings yet

- P01696-0019-4 - AsBuilt Painting ProcedureDocument2 pagesP01696-0019-4 - AsBuilt Painting ProcedureMahmoud GaberNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- Conarc49c EngDocument2 pagesConarc49c EngtNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-0DB32-3FA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-0DB32-3FA4-Zjitendra patelNo ratings yet

- DOP CE EGGER Eurospan Mmex Rec301 ENDocument2 pagesDOP CE EGGER Eurospan Mmex Rec301 ENMateusz Latosiński LSD.STUDIO ✖No ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- MBR10150C: High Voltage Power Schottky RectifierDocument8 pagesMBR10150C: High Voltage Power Schottky Rectifiereki miftakhul firdausNo ratings yet

- LCP Lycordeck®Document23 pagesLCP Lycordeck®Lokey EnNiNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4nizarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-444Document1 pagePages From SIMABUS Tubular Busbar Accesories-444asi midobarNo ratings yet

- Dual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D ADocument6 pagesDual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D AErkanNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- LED Chip LGDocument18 pagesLED Chip LGMinh Khuê Nguyễn ThịNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- 2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument5 pages2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetErkanNo ratings yet

- Kryo1 EngDocument2 pagesKryo1 EngtNo ratings yet

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- 1LE1601 2DC03 4AB4 Z L51 Datasheet enDocument2 pages1LE1601 2DC03 4AB4 Z L51 Datasheet enFaziNo ratings yet

- Finalloy EBP-820/2 C16: DescriptionDocument1 pageFinalloy EBP-820/2 C16: DescriptionYouness LATAFINo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- 3 Phase Motor DetailDocument1 page3 Phase Motor Detailhashir zamanNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Berulit GA 400Document1 pageBerulit GA 400Johan TeoNo ratings yet

- 245LEN0040H10XLB00V50MR2Document16 pages245LEN0040H10XLB00V50MR2Sting DâuNo ratings yet

- TDS 16560 Jotamastic 90 Euk GBDocument7 pagesTDS 16560 Jotamastic 90 Euk GBNgô Trung NghĩaNo ratings yet

- 2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorDocument6 pages2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorErkanNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- Scientific Study On External Ionising Radiation Exposure During Cargo / Vehicle Radiographic InspectionsDocument10 pagesScientific Study On External Ionising Radiation Exposure During Cargo / Vehicle Radiographic InspectionsIRUNo ratings yet

- Approved SystemsDocument25 pagesApproved SystemsadrianrrccNo ratings yet

- Engine Performance With Variable Valve TimingDocument4 pagesEngine Performance With Variable Valve TimingWilliam KibbeNo ratings yet

- Xsan 2 Admin GuideDocument140 pagesXsan 2 Admin GuidedebshubraNo ratings yet

- OpCo Audit ProgramDocument11 pagesOpCo Audit ProgramMarco Giovani ZancanellaNo ratings yet

- SG II QUALITY Annex 24.12.2015Document89 pagesSG II QUALITY Annex 24.12.2015parthaNo ratings yet

- International Standard: Power Transformers - Loading Guide For Oil-Immersed Power TransformersDocument8 pagesInternational Standard: Power Transformers - Loading Guide For Oil-Immersed Power TransformersLuis Villalobos Dzib50% (4)

- Big Ass Fan Model 4900Document104 pagesBig Ass Fan Model 4900VeronicaSanJoséNo ratings yet

- Spam Trojan Detection With Mikrotik RouterOSDocument3 pagesSpam Trojan Detection With Mikrotik RouterOSmsuoodh0% (1)

- Timber Strength GradingDocument2 pagesTimber Strength GradingJamesNo ratings yet

- $RI5QA26Document54 pages$RI5QA26achatNo ratings yet

- NCM Chapter SixDocument20 pagesNCM Chapter Sixdimberu yirgaNo ratings yet

- Iso 22475 1 2021Document15 pagesIso 22475 1 2021ANo ratings yet

- As ISO 389.2-2007 Acoustics - Reference Zero For The Calibration of Audiometric Equipment Reference EquivalenDocument8 pagesAs ISO 389.2-2007 Acoustics - Reference Zero For The Calibration of Audiometric Equipment Reference EquivalenSAI Global - APACNo ratings yet

- PES Template V1.1Document126 pagesPES Template V1.1BudiWirahmiNo ratings yet

- 05 - Teleprotection and Weak InfeedDocument21 pages05 - Teleprotection and Weak InfeedJosé Miguel Ochoa AcerosNo ratings yet

- Asme Section Ix InterpretationsDocument72 pagesAsme Section Ix InterpretationsEmmanuelNo ratings yet

- Qos Evaluation of Voip End-Points: Wenyu Jiang Kazuumi Koguchi Henning SchulzrinneDocument5 pagesQos Evaluation of Voip End-Points: Wenyu Jiang Kazuumi Koguchi Henning Schulzrinneeugene123No ratings yet

- HP Pavilion DV6000 Quanta AT6 Intel SchematicsDocument45 pagesHP Pavilion DV6000 Quanta AT6 Intel Schematicsmou tiemNo ratings yet

- Trolleybus 333 enDocument2 pagesTrolleybus 333 enRodrigo SampaioNo ratings yet

- As 3669-2006 Non-Destructive Testing - Qualification and Approval of Personnel - AerospaceDocument9 pagesAs 3669-2006 Non-Destructive Testing - Qualification and Approval of Personnel - AerospaceSAI Global - APACNo ratings yet

- BS en 13160-4 2016Document42 pagesBS en 13160-4 2016CK CkkouNo ratings yet

- CME Deleting The Name of The PersonDocument3 pagesCME Deleting The Name of The PersonkhalidNo ratings yet

- Check Point 1430/1450 Appliance: Getting Started Guide Centrally ManagedDocument85 pagesCheck Point 1430/1450 Appliance: Getting Started Guide Centrally Managedchinmay mandalNo ratings yet

- Posidrive Security Gate: Installation, Operation, and Maintenance ManualDocument96 pagesPosidrive Security Gate: Installation, Operation, and Maintenance ManualHaris MahmoodNo ratings yet

- SyncServer S250Document6 pagesSyncServer S250faraz2010No ratings yet

- M03-014 - HVAC Variable Refrigerant Flow (VRF) SystemsDocument38 pagesM03-014 - HVAC Variable Refrigerant Flow (VRF) Systemsjadewest100% (1)

- Dial Gauge 1Document1 pageDial Gauge 1arnolhariNo ratings yet

- Modems, Shiron IRG-DVB-S2 Modems, Linkstar Modems, Cometech SCPC Modems in Countries Such AsDocument8 pagesModems, Shiron IRG-DVB-S2 Modems, Linkstar Modems, Cometech SCPC Modems in Countries Such AsAhmed N. MusaNo ratings yet