Professional Documents

Culture Documents

Downloaded From Manuals Search Engine

Downloaded From Manuals Search Engine

Uploaded by

David QuispeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Downloaded From Manuals Search Engine

Downloaded From Manuals Search Engine

Uploaded by

David QuispeCopyright:

Available Formats

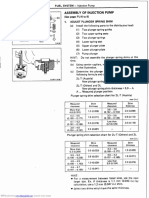

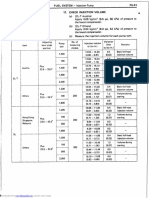

FUEL SYSTEM - Injection Pump FU-21

(3) With the push rod pushed in to the maximum,

measure dimension "L3" with vernier calipers

as shown.

Select shim A to adjust "A L1" obtained as the

difference between "L3" and "L2" obtained in

(2) above.

Difference "A L1":

Austria 0.67 - 0.97 mm (0.0264 - 0.0382 in.)

Others 1.23 - 1.33 mm (0.0484 - 0.0524 in.)

Adjusting shim thickness: 1.1 mm (0.043 in.

1.3 mm (0.051 in.

1.5 mm (0.059 in.

1.7 mm (0.067 in.

1.9 mm (0.075 in.

2.1 mm (0.083 in.

2.3 mm (0.090 in.

2.5 mm (0.098 in.

2.7 mm (0.106 in.

2.9 mm (0.1 14 in.

3.1 mm (0.122 in.

3.3 mm (0.130 in.

(4) Remove the diaphragm and push rod.

(c) Insert 1.5 - 2.5 cc (0.09 - 0.15 cu in.) of engine oil

into the bushing hole.

(d) Install the following parts:

(1) Boost compensator shim A

(2) Main spring

(3) Diaphragm and push rod

(4) Sub spring (Austria only)

(5) Boost compensator shim B (Austria only)

(e) Using a 5 mm hexagonal wrench, install the four bolts

and governor cover.

Downloaded from www.Manualslib.com manuals search engine

FU-22 FUEL SYSTEM - lniection P u m ~

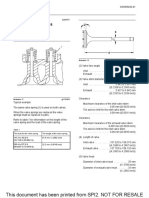

Austria (f) Measure the distance between the control lever end

surface and the attachment measure.

(Austria)

( 1) Measure dimension "L4" with vernier calipers

as shown.

Adjust the difference "AL2" between "L2"

measured in (b) and "L4" by rotating the guide

bushing.

-

Difference "A L2": 1.30 1.SO mm (0.0512 - 0.0591 in.)

(2) Apply 350 mmHg (13.8 in.Hg, 46.7 kPa) of ab-

solute pressure to the boost compensator and

measure dimension "L5" with vernier calipers as

-shown. Select shim B to adjust "AL3" obtained

as the difference between "L5" and "L2"

measured in (b).

Difference "A L3": 1.70 - 1.94 mm (0.0669 - 0.0764 in.)

Adjusting shim thickness: 12.90 mm (0.508 in.)

13.15 mm (0.518 in.)

13.40 mm (0.528 in.)

Others ( 0thers)

Apply 0.27 kg/cm2 (3.8 psi, 26 kPa) of pressure to

the boost compensator and measure dimension "L4"

with vernier calipers as shown.

Adjust "L4" by rotating the guide bushing.

Dimension " L C : 9.85 - 9.95 mm (0.3878 - 0.3917 in.)

(g) Remove the attachment measure.

Part No. 95096 - 10030 (NIPPONDENSO)

Downloaded from www.Manualslib.com manuals search engine

FUEL SYSTEM - Injection Pump FU-23

6. INSTALL ADJUSTING LEVER SHAFT TO GOVERNOR a

SHAFT

Install the following parts to the governor cover:

(1) Plate washer

(2) New O-ring

(3) Adjusting lever shaft, O-ring and plate washer

assembly

7. INSTALL GOVERNOR COVER

(a) Install a new gasket to the groove of the governor

cover.

(b) (2L-T)

Connect the adjusting lever shaft to the governor link

and twist the shaft lightly.

(c) (3L)

Install the speed control spring to the adjusting lever

shaft.

(dl (3L)

l nstall the damper spring and spring seat, and connect

the speed control spring to the spring seat.

(e) Using a 5 mm hexagonal wrench, install the governor

cover with the four bolts.

Torque: 85 kg-cm (74 in.-lb, 8.3 N-m)

HINT: Use the bolt which is 35 mm (1.38 in.) length.

(f) (2L-T and w/ HAC)

lnstall the idle speed adjusting screw.

8. INSTALL ADJUSTING LEVER

(a) Place the return spring on the governor cover.

Downloaded from www.Manualslib.com manuals search engine

FU-24 FUEL SYSTEM - Injection Pump

(b) Hook the return spring to the adjusting lever, and

turn and place the adjusting lever on the governor

shaft.

(c) Align the lines of the adjusting lever shaft and adjust-

ing lever.

(dl lnstall the adjusting lever with the nut.

9. INSTALL FUEL CUT SOLENOID

(a) lnstall a new O-ring on the fuel cut solenoid.

(b) lnstall the strainer, valve, spring, a new gasket and the

fuel cut solenoid.

Torque: 225 kg-cm (16 ft-lb, 22 N.m)

(c) lnstall the lead wire to the fuel cut solenoid with the

nut.

(d) l nstall the dust cover to the fuel cut solenoid.

(e) l nstall the lead wire connector to bracket.

(f) Using a 6 rnm hexagonal wrench, install the con-

nector bracket with the bolt.

lo. (2L-T)

INSTALL DASH POT

lnstall a new gasket and the dash pot.

Downloaded from www.Manualslib.com manuals search engine

FUEL SYSTEM - Injection Pump FU-25

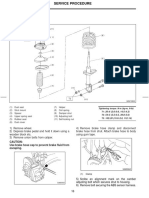

11. (2L-T)

I I Metal Plate

INSTALL THERMO WAX

(a) Using a screwdriver, turn the cold starting lever

counterclockwise approx. 20".

(b) Put a metal plate (thickness of 8.5 - 10 mm (0.335 -

0.384 in.)) between the cold starting lever and

thermo wax plunger.

(c) Install a new O-ring to the pump body.

(dl Using a 5 mm hexagonal wrench, install the thermo

wax with the two bolts.

12. (2L-T)

INSTALL IDLE-UP LEVER

Using a 5 mm hexagonal wrench, install the idle-up lever

with the three bolts.

13. (2L-T Austria)

INSTALL AND CHECK THROTTLE POSITION SENSOR

(a) Using a 5 mm hexagonal wrench, install the throttle

position sensor with the three bolts.

(b) Using an ohmmeter, check that there is continuity

between the terminals VC and E2.

Downloaded from www.Manualslib.com manuals search engine

FU-26 FUEL SYSTEM - lniection Pump

(c) Using an ohmmeter, measure the resistance between

terminals VA and E2.

Resistance: As the opening angle of the adjusting lever

increases, the resistance should continue to decrease.

n 1 14. ( w l Tachometer)

INSTALL PICKUP SENSOR

(a) Install a new O-ring and pickup sensor.

(b) Connect the two lead wires to the connector.

Torque: 210 kg-cm (15 ft-lb, 21 N-m)

15. (w/ A/C)

INSTALL IDLE-UP ACTUATOR

4 7 ~3-2-D

FU2129

16. REMOVE INJECTION PUMP FROM SST (STAND)

SST 09241-76022 and 09245-54010

I 2L-T and w/ HAC 17. PERFORM AIR TIGHT TEST

(a) Install a bolt to the overflow port.

(b) Connect an air hose to the fuel inlet pipe and place

the injection pump into diesel fuel.

NOTICE: On vehicles with the throttle position sensor

(2L-T Austria), be careful not to immerse sensor in diesel

fuel.

(c) Apply 0.5 kg/cm2 ( 7 psi, 49 kPa) of pressure and con-

firm that there are not leaks.

(d) Next check that there are no leaks with 5.0 kg/cm2

(71 psi, 490 kPa) of pressure applied.

18. INSTALL SET KEY OF INJECTION PUMP DRIVE

PULLEY ON DRIVE SHAFT

Downloaded from www.Manualslib.com manuals search engine

You might also like

- MT86 2018 Part BookDocument204 pagesMT86 2018 Part Bookenhbat batsuh100% (2)

- Torques Captiva 2.4Document7 pagesTorques Captiva 2.4rectificamos100% (2)

- Torque Motor KiaDocument54 pagesTorque Motor KiaIvan Montaluisa67% (3)

- Subaru OUTBACK PDFDocument11 pagesSubaru OUTBACK PDFCutiiVitezaNo ratings yet

- Proposal Stone CrusherDocument42 pagesProposal Stone CrusherWawah Hilwah86% (7)

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Elantra 2003 2.0LDocument200 pagesElantra 2003 2.0LMaykol Gonzalez0% (1)

- Kia Rio 2009Document193 pagesKia Rio 2009Miguel Jorge Chavez ChavezNo ratings yet

- Injection Machine MDS-IV - SpecsDocument28 pagesInjection Machine MDS-IV - SpecsEdwin AbingunaNo ratings yet

- Assembly of Injection Pump: FU-16 Fuel SystemDocument6 pagesAssembly of Injection Pump: FU-16 Fuel SystemDavid QuispeNo ratings yet

- 3500 ENGINE Specifications Pistons and RingsDocument5 pages3500 ENGINE Specifications Pistons and RingsVan Phuc ThaiNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- Engine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitDocument86 pagesEngine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitWSMengine WSMengine100% (1)

- Service Data (1998.8 - )Document1 pageService Data (1998.8 - )Jurol MassambaNo ratings yet

- CoroMill 425 92023Document41 pagesCoroMill 425 92023Nelson SanchezNo ratings yet

- Engine t14 t16 Technical DataDocument7 pagesEngine t14 t16 Technical DataJefferson Humbereto Herrera AlfonsoNo ratings yet

- ULM User Information No. 8Document5 pagesULM User Information No. 8khemedra patleNo ratings yet

- Parametros de Desgate de Roletes InferioresDocument2 pagesParametros de Desgate de Roletes InferioresSoares DamascenoNo ratings yet

- C56 SpecsDocument3 pagesC56 SpecsFelipe CINo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Oil Pump Assy (1Az-Fe) : OverhaulDocument2 pagesOil Pump Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- 1106C Lifter GroupDocument1 page1106C Lifter Groupmoh asalanyNo ratings yet

- 2346 Santa Fe D4eaDocument93 pages2346 Santa Fe D4eaJmb BravoNo ratings yet

- Techincal Specifications Shop Manual 2011 REX 550 - ETEC enDocument20 pagesTechincal Specifications Shop Manual 2011 REX 550 - ETEC enSkorost SkorostNo ratings yet

- Folga de VálvulasDocument2 pagesFolga de VálvulasTatiano BrolloNo ratings yet

- Bomba de Aceite-InstalaciónDocument5 pagesBomba de Aceite-InstalaciónOscar CAPSSANo ratings yet

- Tolerancias - Corolla Manual G Box C150 Rm827e21Document1 pageTolerancias - Corolla Manual G Box C150 Rm827e21Renzo GarciaNo ratings yet

- (A) The UNITS Given in This Manual Are Primarily Expressed According To The SI UNIT (International Sys-Tem of Unit), and Alternately Expressed in The Metric System and in The English SystemDocument2 pages(A) The UNITS Given in This Manual Are Primarily Expressed According To The SI UNIT (International Sys-Tem of Unit), and Alternately Expressed in The Metric System and in The English SystemDang Tien PhucNo ratings yet

- Dimensiones Pernos y Bujes 988hDocument8 pagesDimensiones Pernos y Bujes 988hJesús FloresNo ratings yet

- 1106C Cylinder Head ValvesDocument1 page1106C Cylinder Head Valvesmoh asalanyNo ratings yet

- Service Specifications: Author: DateDocument2 pagesService Specifications: Author: DateDang Tien PhucNo ratings yet

- Data Sheet Docol Tube R8 2022-09-20Document2 pagesData Sheet Docol Tube R8 2022-09-20miyoriiosuNo ratings yet

- Prueba Resorte de EmbragueDocument2 pagesPrueba Resorte de Embraguejohan gomezNo ratings yet

- InstallationDocument17 pagesInstallationEdson CRNo ratings yet

- Service Data TableDocument6 pagesService Data Tableelites bigbearNo ratings yet

- Motor D12D - Geral - Especificacoes - Mecanismo de Valvulas, EspecificacoesDocument3 pagesMotor D12D - Geral - Especificacoes - Mecanismo de Valvulas, EspecificacoesAparecidaMarquesNo ratings yet

- Service Specifications: Author: DateDocument2 pagesService Specifications: Author: DateDang Tien PhucNo ratings yet

- Nozzle FEA CalculationDocument64 pagesNozzle FEA CalculationberylqzNo ratings yet

- 2008 Honda CR-V: Engine AssemblyDocument7 pages2008 Honda CR-V: Engine Assemblyfrancisco Alba100% (1)

- Standards and Service Limits: 2005-06 General InformationDocument21 pagesStandards and Service Limits: 2005-06 General Informationvadim vadim100% (1)

- Hyundai Diesel Engine Hd4dd Service ManualDocument20 pagesHyundai Diesel Engine Hd4dd Service Manualbrian100% (52)

- Front Strut: A: RemovalDocument4 pagesFront Strut: A: RemovalmiguelNo ratings yet

- SKI Techl Spec - Engine - 600HOETEC (Line-Up) - Supplement mmr2017-124 enDocument3 pagesSKI Techl Spec - Engine - 600HOETEC (Line-Up) - Supplement mmr2017-124 enSkorost SkorostNo ratings yet

- Scale UpDocument26 pagesScale Upkarteekan144No ratings yet

- Manual Transmission / Transaxle: Service DataDocument3 pagesManual Transmission / Transaxle: Service DataMax K.No ratings yet

- Veracruz 2010Document79 pagesVeracruz 2010Raul ShcksNo ratings yet

- Downloaded From Manuals Search EngineDocument10 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Assembly U241E TransmissionDocument29 pagesAssembly U241E TransmissionFirman SuryaNo ratings yet

- Calibracion 1C EnglishDocument5 pagesCalibracion 1C EnglishJuan BrunoNo ratings yet

- Especificaciones de Camisa S60 2003Document2 pagesEspecificaciones de Camisa S60 2003Leo ContrerasNo ratings yet

- Manual Transmission / Transaxle: Service DataDocument1 pageManual Transmission / Transaxle: Service DataClodoaldo BiassioNo ratings yet

- Escape 2011 2.5LDocument367 pagesEscape 2011 2.5LJuan Jose CalderonNo ratings yet

- Important Electrical Properties of CRGO & Hi - B CRGO GradesDocument6 pagesImportant Electrical Properties of CRGO & Hi - B CRGO GradesaaaaNo ratings yet

- Specification Table: Standards and Service LimitsDocument11 pagesSpecification Table: Standards and Service Limitsvadim vadimNo ratings yet

- 3M L Series Datapage-March2017-V3Document5 pages3M L Series Datapage-March2017-V3Serhan ÜnverNo ratings yet

- Roller Chain Sprokets (Matrin)Document39 pagesRoller Chain Sprokets (Matrin)Divyang MistryNo ratings yet

- BienMo Co Khoa Mot ChieuDocument4 pagesBienMo Co Khoa Mot ChieuDu TrầnNo ratings yet

- Mechanic SystemDocument24 pagesMechanic SystemCristian.E.BNo ratings yet

- Telma F7 Installation On Meritor RS160-180-185 Axle TL103014Document6 pagesTelma F7 Installation On Meritor RS160-180-185 Axle TL103014Odim41No ratings yet

- Machine StructureDocument68 pagesMachine StructureVictor HemzNo ratings yet

- SH-53001-53004 Spring Support S-00-1360-244J Caracteristicas de DiseñoDocument1 pageSH-53001-53004 Spring Support S-00-1360-244J Caracteristicas de DiseñoDAVID SOTONo ratings yet

- Atmega16 (L) : Table 106. Pin Name Mapping (Continued)Document6 pagesAtmega16 (L) : Table 106. Pin Name Mapping (Continued)David QuispeNo ratings yet

- Atmega16 (L) : Programming The EepromDocument6 pagesAtmega16 (L) : Programming The EepromDavid QuispeNo ratings yet

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Components: Downloaded From Manuals Search EngineDocument6 pagesComponents: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesTroubleshooting: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- Datasheet (3) (254-284) - 1-5Document5 pagesDatasheet (3) (254-284) - 1-5David QuispeNo ratings yet

- Fuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDocument6 pagesFuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Assembly of Injection Pump: FU-16 Fuel SystemDocument6 pagesAssembly of Injection Pump: FU-16 Fuel SystemDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Fuel System FU-31 2. Pre-Set Full Load Injection VolumeDocument6 pagesFuel System FU-31 2. Pre-Set Full Load Injection VolumeDavid QuispeNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- Troubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDocument6 pagesTroubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDavid QuispeNo ratings yet

- 2L-T W/ Hac: Downloaded From Manuals Search EngineDocument6 pages2L-T W/ Hac: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Inspection and Repair of Crankshaft: Crank Journal DiameterDocument6 pagesInspection and Repair of Crankshaft: Crank Journal DiameterDavid QuispeNo ratings yet

- System: Differ From The Above Listed ManualDocument6 pagesSystem: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Excessive Fuel Consumption: Downloaded From Manuals Search EngineDocument10 pagesExcessive Fuel Consumption: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Cutout: Downloaded From Manuals Search EngineDocument10 pagesCutout: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Abbreviations Used in Manual,: Downloaded From Manuals Search EngineDocument11 pagesAbbreviations Used in Manual,: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- 4Y Engine: TOYOTA Material Handling CompanyDocument10 pages4Y Engine: TOYOTA Material Handling CompanyDavid QuispeNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDocument66 pagesTrouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument10 pagesDownloaded From Manuals Search EngineDavid Quispe100% (1)

- Ascd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "Document12 pagesAscd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "David QuispeNo ratings yet

- Street Crane Co. LTD: Buffer Positions & Wheel Running SurfacesDocument2 pagesStreet Crane Co. LTD: Buffer Positions & Wheel Running Surfacesmmargarita_15No ratings yet

- Cost Insurance Freight PresentationDocument11 pagesCost Insurance Freight PresentationGumisiriza BrintonNo ratings yet

- Joint Release Waskita Karya Collaborates With Ina On Investment Cooperation For Trans Java Toll Road en 1662522009Document3 pagesJoint Release Waskita Karya Collaborates With Ina On Investment Cooperation For Trans Java Toll Road en 1662522009Justin HalimNo ratings yet

- 2019 Engine G 3.3 MPI LAMBDA II Schematic Diagrams Engine Electrical System Engine Control System Service TipsDocument1 page2019 Engine G 3.3 MPI LAMBDA II Schematic Diagrams Engine Electrical System Engine Control System Service TipsLê LongNo ratings yet

- Recommended Tools & Equipments - Version 1.1Document188 pagesRecommended Tools & Equipments - Version 1.1Seshagiri DeenadayaluNo ratings yet

- Quotation: Container Loca Freight InsuranceDocument5 pagesQuotation: Container Loca Freight InsuranceArmen VardanyanNo ratings yet

- Forklift 2Document17 pagesForklift 2Bilal tahirNo ratings yet

- NTMP2014 1Document1 pageNTMP2014 1HannOtto StoreNo ratings yet

- Railroad-Highway Grade Crosing HandbookDocument266 pagesRailroad-Highway Grade Crosing HandbookppinedabNo ratings yet

- Ceramic TilesDocument48 pagesCeramic TilesHarshil HundiaNo ratings yet

- Product: WarningDocument9 pagesProduct: WarningUldrich TCHOUMOUNo ratings yet

- Kamus Tipe Motor Aktif (Update 18 November 2020)Document113 pagesKamus Tipe Motor Aktif (Update 18 November 2020)Deva Moba100% (1)

- Viwango Vipya Kutembelea Hifadhi Za Taifa Nchini TanzaniaDocument10 pagesViwango Vipya Kutembelea Hifadhi Za Taifa Nchini TanzaniaRama S. MsangiNo ratings yet

- Ameer Hamza: ObjectiveDocument4 pagesAmeer Hamza: ObjectivezafarNo ratings yet

- Cduqph: Dwi Travel JL Ade Irma Suryani GG - Panda VII No.96 Monjok Culik Telp: 085937007199Document1 pageCduqph: Dwi Travel JL Ade Irma Suryani GG - Panda VII No.96 Monjok Culik Telp: 085937007199rizki anugrahNo ratings yet

- Conen 442 Module2 s2021Document65 pagesConen 442 Module2 s2021Wael ElDessoukiNo ratings yet

- Direction: Complete The Following Information. Put A Check Mark ( ) On The Box That Corresponds To Your AnswerDocument3 pagesDirection: Complete The Following Information. Put A Check Mark ( ) On The Box That Corresponds To Your Answerrizumu00100% (1)

- Model Based Urban Traffic Control, Part II Coordinated Model Predictive ControllersDocument22 pagesModel Based Urban Traffic Control, Part II Coordinated Model Predictive Controllers张晗钰No ratings yet

- Digital Transmission Range TR Sensor in Vehicle Repair PDFDocument2 pagesDigital Transmission Range TR Sensor in Vehicle Repair PDFMichael HernandezNo ratings yet

- WIG-206 Never Going Home - Tears in The Sea (OEF) (2021!02!18)Document74 pagesWIG-206 Never Going Home - Tears in The Sea (OEF) (2021!02!18)lonelyshota029No ratings yet

- BWM DataDocument37 pagesBWM DataViceprincipal EurotechNo ratings yet

- The Oriental Insurance Company LimitedDocument3 pagesThe Oriental Insurance Company LimitedMelbinGeorgeNo ratings yet

- Tokyo Subway Ticket 48Document4 pagesTokyo Subway Ticket 48sohilNo ratings yet

- Artificer - MechanicDocument2 pagesArtificer - Mechanicliterallyanythingidontcare1No ratings yet

- Honda CBR600RR 2008 CalendarDocument8 pagesHonda CBR600RR 2008 CalendarRomanNo ratings yet

- Safety Awareness Questionnaire Ver 2.0Document3 pagesSafety Awareness Questionnaire Ver 2.0James Amir100% (1)

- Ad-2 LFPTDocument7 pagesAd-2 LFPTKevin LohierNo ratings yet

- F1250-13 Standard Specification For Stationary UprigDocument5 pagesF1250-13 Standard Specification For Stationary UprigElif SarıoğluNo ratings yet