Professional Documents

Culture Documents

MM321 Lab 3

MM321 Lab 3

Uploaded by

Roshiv SharmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MM321 Lab 3

MM321 Lab 3

Uploaded by

Roshiv SharmaCopyright:

Available Formats

MM 321 Refrigeration and Air Conditioning

The University of the South Pacific

School of Engineering and Physics

MM 321 – Refrigeration and Air Conditioning

Lab 3: Study of a VCRS with a hermetic compressor, water cooled condenser and evaporator.

Lab Group: data set 1

Student Name: Shanil Sahai, Winji Tamata, Sahil Roshiv Sharma

Student ID#: S11173716, S11119842, S11171799

AIM

The reason for conducting this experiment is to examine the VCRS (Vapor-Compression Refrigeration

System) with a water-cooled condenser, hermetic compressor and evaporator to determine which cycle is

suitable for superheating

INTRODUCTION

This experiment was conducted using a vapor compression refrigeration system basically related hermetic

compressor and water-cooled condenser and evaporator. This paper presents the performance testing of a

refrigeration system for use as experimental apparatus for demonstrating vapour compression refrigeration

cycle for water.

According to Saha B (2012) in vapour compression systems, compressors activate the refrigerant by

compressing it to a higher pressure and higher temperature level after it has produced its refrigeration effect.

The compressed refrigerant transfers its heat to the sink and is condensed to liquid form. This liquid

refrigerant is then throttled to a low-pressure, low temperature vapour to produce refrigerating effect during

evaporation. Vapour compression systems are the most widely adopted refrigeration systems in both

comfort, such as portable air conditioning units, and process air conditioning

Vapor compression refrigeration system is the most popular and universally used system for the production

of low temperature. In this system a working fluid known as refrigerant. It condenses at high temperature

and pressure close to atmospheric condition. It evaporates at low temperature and pressure close to the

system which is to be cooled. During its condensation, it rejects heat to the surrounding and releases its

latent heat to the circulating water or air, i.e., to the atmosphere. The vapor compression refrigeration system

is nowadays used for all purposes. It is generally used for all industrial purposes, from a small domestic

refrigerator to large air conditioning plants.

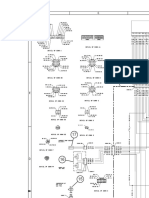

Illustrates schematically the parts which make up the vapor compression refrigeration system for water cool

and condenser.

Lab Report Page 1

MM 321 Refrigeration and Air Conditioning

A hermetic compressor is one in which both compressor and motor are confined in a single outer welded

steel shell. The motor and compressor are directly coupled on the same shaft, with the motor inside the

refrigeration circuit. Brand t (19920. Hermetic compressors are ideal for small refrigeration systems, where

continuous maintenance (replenishing refrigerant and oil charge etc) cannot be ensured. Hence, they are

widely used in domestic refrigerators, room air conditioners etc. Since, the motor is in the refrigerant circuit,

the efficiency of hermetic compressor-based systems is lower as the heat dissipated by the motor and

compressor becomes a part of the system load. Also, material compatibility between the electrical windings,

refrigerant and oil must be ensured. Since the complete system is kept in a welded steel shell, the hermetic

compressors are not meant for servicing. A variation of hermetic compressor is a semi-hermetic compressor,

in which the bolted construction offers limited serviceability.

Moreover, water-cooled condenser uses water as a cooling medium to transfer heat at a higher rate. The

vapor refrigerant transfers heat to the cold circulating water. Slagle, R., (2017). The pressure of the liquid

refrigerant from the condenser has to be reduced so that the liquid refrigerant can vaporize at the desired low

pressure of evaporator. An expansion valve which is also known as throttle valve is a device to reduce the

pressure and temperature of the liquid refrigerant before it is supplied to the evaporator where refrigerant

gets evaporated.

Historically vapor-compression goes back to 1805 where Oliver Evans, an American inventor, described a

closed vapor-compression refrigeration cycle for producing ice (York Compressors, 2010). The first

working vapor-compression refrigeration system was built in 1834 by another American who was living in

the UK, Jacob Jenkins. However, it may be accomplished in a variety of ways over the course of history, but

(VCRS) have become the preferred option thanks to their efficiency and reliability and now days used for

all-purpose refrigeration.

EQUIPMENT

VCRS unit.

Lab Report Page 2

MM 321 Refrigeration and Air Conditioning

METHODOLOGY

First setup of the experiment was the initial inspection to make sure the setup had no issues. The knobs and

dials were set to the correct compressor, evaporator and condenser. For this specific lab, the hermetic

compressor and, water-cooled evaporator and compressor were chosen. After the selection, the front panel

of the unit was opened to check all the valves and to make sure that the ones that are only needed for the

experiment are in use. The panel was closed again, the unit was turned on, and the required temperature of

the cold box was entered into the display. As soon as the display showed that the cold box had reached the

anted temperature the temps inside the box gets verified and using an infrared thermometer, the suction

temperature, the discharge temperature. P1 and P3 were also observed and recorded alongside. The VCRS

unit was run three times in order to obtain three sets of data for groups 1, 2, and 3.

RESULTS

Given data from the experiment for set 1:

Compressor Type: Hermetic

Condenser Type: Water-cooled

Evaporator type: Water-cooled

P1-P4= 300kPa

P2-P3= 900kPa

T1= 23°C

T2= 52°C

Mass flow rate= 8.48g/s

Solution reading form the R-134a for h1, h2, h3=h4, h2s.

h 1=423 kJ /kg

h 2=441 kJ /kg

h 3=h 4=252 kJ /kg

Sample Calculation :

Q L=ṁ(h1−h4 )

Q L=8.48(423−252)=1.45 kW

Q H =ṁ(h 2−h3 )

Q H =8.48(441−252)=1.60 kW

W C =ṁ(h2 −h1)

W C =8.48( 441−223)=152.6 W

Q L 1.45 kW

Cop= = =9.49 %

w c 152.6 W

Table of raw and calculated results:

Values

Lab Report Page 3

MM 321 Refrigeration and Air Conditioning

h1 423 kJ /kg

h2 441 kJ /kg

h 3=h 4 252 kJ /kg

QL 1.45 kW

Qh 1.60 kW

wc 152.6 W

COP 9.49 %

DISCUSSION

A hermetic compressor is a compressor in which both compressor and motor are confined in a single outer

welded steel shell. The motor and compressor are directly coupled on the same shaft, with the motor inside

the refrigeration circuit. Hermetic compressors are ideal for small refrigeration systems, where continuous

maintenance (replenishing refrigerant and oil charge etc.) cannot be ensured. Hence, they are widely used in

domestic refrigerators, room air conditioners etc. The difference between the hermetic and semi-hermetic, is

that the hermetic uses a one-piece welded steel casing that cannot be opened for repair; if the hermetic fails

it is simply replaced with an entire new unit.

Using the temperature and pressures given, the enthalpies of the 4 main processes of the vapor compression

refrigeration system were found from the R134a P-h chart. Upon calculation the cooling capacity of the

water-cooled evaporator was 1.60 Kw and the systems coefficient of performance was 9.49. The input

power by the hermetic compressor was 152.6W.

The results from the previous laboratory exercise shows a clear difference between the two settings. The

results from a semi- hermetic compressor and air-cooled condenser and evaporator were as follows, cooling

capacity of 1.58Kw and compressor power of 1.38Kw while the semi-hermetic compressor was 0.18kw.

Data obtained from the two experiments proves that water cooled system working on a hermetic compressor

has higher coefficient of performance compared to air cooled semi- hermetic system. Thus, water cooled

compressor shows greater cooling capacity then the air-cooled condenser on hermetic compressor requires a

much lower power then the semi-hermetic compressor.

Finally, the most probable factor that causes the water-cooled hermetic compressor system to have a better

COP than the air cooled semi-hermetic system was the difference between how well water absorbs and

dissipates heat compared to air.

CONCLUSION

This experiment mainly focused on water cooling using the vapor compression refrigeration system which

was carried out by a hermetic compressor. After the conclusion of this experiment, it can be stated that the

overall system gives a slightly higher value of COP when compared to the normal refrigeration units. This is

because the compressor did less work when compared to the other components therefore the COP value is

significantly higher. also, the employing of 2 compressors; condensers and evaporators made it possible to

give higher value of COP.

REFERENCE

Lab Report Page 4

MM 321 Refrigeration and Air Conditioning

2021. [online] Available at:

<https://www.researchgate.net/publication/269622386_COOLING_SYSTEM_FOR_HERMETIC_COMPRESSOR>

[Accessed 21 September 2021].

Berg Chilling Systems Inc. 2021. Refrigeration Principles and how a Refrigeration System Works | Berg Chilling

Systems. [online] Available at: <https://berg-group.com/engineered-solutions/the-science-behind-

refrigeration/> [Accessed 21 September 2021].

Achrnews.com. 2021. [online] Available at: <https://www.achrnews.com/articles/103546-methods-for-

compressor-cooling> [Accessed 21 September 2021].

Slagle, R., 2021. How Vapor-Compression Cooling Works | Electronics Cooling. [online] Electronics Cooling.

Available at: <https://www.electronics-cooling.com/2017/07/vapor-compression-cooling-works/> [Accessed

14 September 2021].

Lab Report Page 5

You might also like

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv Sharma0% (1)

- Refrigeration 3Document36 pagesRefrigeration 3May Jade Genzola EsparesNo ratings yet

- Capillary Tubing SizesDocument3 pagesCapillary Tubing Sizesgoodti100% (2)

- DuPont Replacement GuideDocument4 pagesDuPont Replacement GuideKhairul MuzamilNo ratings yet

- MM321 Lab 2Document5 pagesMM321 Lab 2Roshiv SharmaNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- MM321 Lab 1Document5 pagesMM321 Lab 1Roshiv SharmaNo ratings yet

- MM321 Lab 1 Report 2020Document5 pagesMM321 Lab 1 Report 2020JnrNo ratings yet

- PH Number 1Document40 pagesPH Number 1DhduNo ratings yet

- Refrigeration Lab Report: Ali Rida Bachir SID 8104461Document4 pagesRefrigeration Lab Report: Ali Rida Bachir SID 8104461NARE EDMUNDNo ratings yet

- Screenshot 2023-01-11 at 8.11.58 PMDocument15 pagesScreenshot 2023-01-11 at 8.11.58 PMAbdla DoskiNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsSiddhant Vishal ChandNo ratings yet

- Rac Solution Set BDocument12 pagesRac Solution Set BxofigoNo ratings yet

- Refrigeration Comp. LinkedDocument6 pagesRefrigeration Comp. LinkedDin TescoNo ratings yet

- Air Conditioning Lab Final1Document20 pagesAir Conditioning Lab Final1haziqNo ratings yet

- 803 Rac (Me-803) Exp. ManualDocument47 pages803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToNo ratings yet

- Refrigeration SystemDocument30 pagesRefrigeration SystemMay Jade Genzola EsparesNo ratings yet

- GYM-2 Konu 3-Kilidi AçıldıDocument59 pagesGYM-2 Konu 3-Kilidi AçıldıBerkNo ratings yet

- HVACDocument17 pagesHVACashwini_kumar1984No ratings yet

- RevisionDocument19 pagesRevisionmenemNo ratings yet

- Chapter 10: Refrigeration CyclesDocument14 pagesChapter 10: Refrigeration CyclesGhulam AbbasNo ratings yet

- Refrigeracion y Bombas de CalorDocument58 pagesRefrigeracion y Bombas de CalorAnonymous GOKse1EaPNo ratings yet

- Vapor Precooling in A Pulse Tube Liquefier: E.D. Marquardt, Ray Radebaugh, and A.P. PeskinDocument5 pagesVapor Precooling in A Pulse Tube Liquefier: E.D. Marquardt, Ray Radebaugh, and A.P. PeskinANILNo ratings yet

- Lab Heat PumpDocument9 pagesLab Heat PumpShahran IezzatNo ratings yet

- Rankine Cycle PDFDocument41 pagesRankine Cycle PDFAlmeghalawy83% (12)

- 16 Research PaperDocument7 pages16 Research Paperkhaja ziauddinNo ratings yet

- Lab Report 7 1Document6 pagesLab Report 7 1z06585964No ratings yet

- Chapter 5-Compounded Vapor Compression Cyclee-ExamplesDocument65 pagesChapter 5-Compounded Vapor Compression Cyclee-Examplesm_alodat6144100% (1)

- Che325 Tutorial KitDocument10 pagesChe325 Tutorial KitCharles BaileyNo ratings yet

- Vapor-Compression Refrigeration CycleDocument23 pagesVapor-Compression Refrigeration CycleJamshidNo ratings yet

- Jobsheet 5Document12 pagesJobsheet 5g-13551554No ratings yet

- Vapor Compressor SystemDocument9 pagesVapor Compressor SystemMarshal ReaganNo ratings yet

- 4 CH 9Document7 pages4 CH 9Tusshar KNo ratings yet

- EjectorDocument9 pagesEjectorManuel Gallegos CalderónNo ratings yet

- Rey Experiment No. 5 Ref Training UnitDocument13 pagesRey Experiment No. 5 Ref Training UnitrickybobbyNo ratings yet

- Cooling Tower InfoDocument78 pagesCooling Tower Infopitong_manning100% (1)

- University of The West Indies, St. Augustine.: FacultyDocument8 pagesUniversity of The West Indies, St. Augustine.: FacultyCharlotte BNo ratings yet

- The Effect of Eco-Friendly Refrigerants On Performance of Vapor Compression Refrigeration System With Dedicated Mechanical SubcoolinDocument12 pagesThe Effect of Eco-Friendly Refrigerants On Performance of Vapor Compression Refrigeration System With Dedicated Mechanical SubcoolinDr. Akhilesh AroraNo ratings yet

- Energy Optimization of Gasturbine Power Plant With Inlet Air Cooling SystemDocument16 pagesEnergy Optimization of Gasturbine Power Plant With Inlet Air Cooling SystemkorneluNo ratings yet

- Refrigeration: Definitions and Useful InformationDocument18 pagesRefrigeration: Definitions and Useful InformationJeffcaster ComelNo ratings yet

- Energies: An Advanced Exergoeconomic Comparison of CO - Based Transcritical Refrigeration CyclesDocument15 pagesEnergies: An Advanced Exergoeconomic Comparison of CO - Based Transcritical Refrigeration CyclesVicente PérezNo ratings yet

- Optimization of Water-Cooled Chiller System With Load-Based Speed ControlDocument20 pagesOptimization of Water-Cooled Chiller System With Load-Based Speed ControlShalehAhmadNo ratings yet

- Lecture 3 - Refrigeration Basics 3Document23 pagesLecture 3 - Refrigeration Basics 3santiago ValleNo ratings yet

- Chapter IDocument65 pagesChapter IMarcial Jr. MilitanteNo ratings yet

- Performance of Refrigerator Using R-600A As RefrigerantDocument6 pagesPerformance of Refrigerator Using R-600A As RefrigerantAgapito labiagaNo ratings yet

- TAQATI Notes Unit 4 HVACDocument16 pagesTAQATI Notes Unit 4 HVACanwarsubedar.inNo ratings yet

- ME 403 Refrigeration and Air ConditioningDocument19 pagesME 403 Refrigeration and Air Conditioninghamza awanNo ratings yet

- Lecture-02-Thermal Power PlantDocument21 pagesLecture-02-Thermal Power PlantTahir DedefoNo ratings yet

- Ch.2.Regenerative Rankine Cycle With Closed Feed Water HeaterDocument55 pagesCh.2.Regenerative Rankine Cycle With Closed Feed Water Heaterlayanalfar0No ratings yet

- Lecture 02 Thermal Power PlantDocument21 pagesLecture 02 Thermal Power PlantGetu TadesseNo ratings yet

- Lecture-02-Thermal Power PlantDocument21 pagesLecture-02-Thermal Power PlantGetu TadesseNo ratings yet

- Refrigeration Systems Lecture Notes - Batch 7 Bsme-3ADocument7 pagesRefrigeration Systems Lecture Notes - Batch 7 Bsme-3AkhinojidaNo ratings yet

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Document8 pagesDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainNo ratings yet

- TABLE OF CONTENTS E123Document11 pagesTABLE OF CONTENTS E123MohitNo ratings yet

- Rac 1-5 Week Lecture SlidesDocument215 pagesRac 1-5 Week Lecture Slidesmfnzk1980No ratings yet

- Rac Solution Set ADocument7 pagesRac Solution Set AMuhammad AkhtarNo ratings yet

- Refrigeration TutorDocument7 pagesRefrigeration TutorTejas Vibhandik100% (2)

- LS2 - Refrigeration Comp. Linked New PDFDocument6 pagesLS2 - Refrigeration Comp. Linked New PDFdildin01No ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Refrigerarion ImsDocument62 pagesRefrigerarion Imsdeepanshurathore2020No ratings yet

- Chapter Two: Vapor Power CyclesDocument72 pagesChapter Two: Vapor Power CyclesAnything You Could ImagineNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- MM321 Lab 2Document5 pagesMM321 Lab 2Roshiv SharmaNo ratings yet

- MM321 Lab 1Document5 pagesMM321 Lab 1Roshiv SharmaNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument7 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- MM222 Lab 1 (S)Document3 pagesMM222 Lab 1 (S)Roshiv SharmaNo ratings yet

- 95 TOP Refrigeration and Air Conditioning - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsDocument19 pages95 TOP Refrigeration and Air Conditioning - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsNagaraj Muniyandi80% (5)

- Central Ac With Water CoolingDocument13 pagesCentral Ac With Water CoolingNaveenNo ratings yet

- 347Document1 page347Kesavapillai GanesanNo ratings yet

- ME405 Refrigeration and Air Conditioning - Image.Marked PDFDocument3 pagesME405 Refrigeration and Air Conditioning - Image.Marked PDFAbhijith JoseNo ratings yet

- Dehumidifikasi MalaDocument8 pagesDehumidifikasi MalaNirmala SwanNo ratings yet

- 2022 TECUMSEH Compressor General Catalogue 2022Document120 pages2022 TECUMSEH Compressor General Catalogue 2022jonnylimNo ratings yet

- Mec351 - Chapter 1Document97 pagesMec351 - Chapter 1MYlearn HazimiNo ratings yet

- Lecture 30 Thermal Engineering II (22.09.2020)Document36 pagesLecture 30 Thermal Engineering II (22.09.2020)Dr. BIBIN CHIDAMBARANATHANNo ratings yet

- Pcua14-03 Daikin Applied ProductsDocument8 pagesPcua14-03 Daikin Applied ProductsadesNo ratings yet

- Heat Pump and Refrigeration CycleDocument4 pagesHeat Pump and Refrigeration CycleMOHAMAD ASRI YAHAYANo ratings yet

- Catalog PT. WGTDocument22 pagesCatalog PT. WGTRudy AriNo ratings yet

- Refrigeration and CryogenicsDocument55 pagesRefrigeration and Cryogenicsjunhyol100% (1)

- Catalogue Evap-Cond-Cdu - HD 2Document3 pagesCatalogue Evap-Cond-Cdu - HD 2Dimensi LainNo ratings yet

- AC SchematicDocument6 pagesAC SchematicsuwarjitechnicNo ratings yet

- Aircondex Copeland Application QueryDocument66 pagesAircondex Copeland Application Queryangelmejias0% (2)

- Before Installation & Calling ServiceDocument2 pagesBefore Installation & Calling ServiceYssik SelaNo ratings yet

- light commercial compressor技术交流资料20170702Document29 pageslight commercial compressor技术交流资料20170702Ali MoazzamNo ratings yet

- Danfoss Oil TypesDocument1 pageDanfoss Oil TypesTiborNo ratings yet

- Air Conditioner Form PDFDocument12 pagesAir Conditioner Form PDFDungga DunggiNo ratings yet

- SOLKANE Refrigerants-238168 PDFDocument8 pagesSOLKANE Refrigerants-238168 PDFFernando JoseNo ratings yet

- Refrigeration Problem SetsDocument5 pagesRefrigeration Problem SetsNiño Gerard JabagatNo ratings yet

- MCQQQQQQQQQDocument7 pagesMCQQQQQQQQQNaveen PrabhuNo ratings yet

- Libretto Istruzioni Extreme - Extreme Ultra - CompressedDocument7 pagesLibretto Istruzioni Extreme - Extreme Ultra - CompressedagfranchiniNo ratings yet

- SAP Masters Description SAP Product Masters Product Sub Catgeory CodeDocument14 pagesSAP Masters Description SAP Product Masters Product Sub Catgeory CodeanshikaNo ratings yet

- Catalog Sadhana FINAL-kompresDocument16 pagesCatalog Sadhana FINAL-kompresMuhammad JawadNo ratings yet

- Harold Ag & Mobile Products: Your Ag A/C Parts SpecialistDocument5 pagesHarold Ag & Mobile Products: Your Ag A/C Parts SpecialistgoogleheadNo ratings yet

- HACCP Dan Implementasinya Dalam Industri PanganDocument6 pagesHACCP Dan Implementasinya Dalam Industri PanganD'Cilumang 28No ratings yet

- VCR System For Low Temperature Applications: (Cascaded VCRS)Document10 pagesVCR System For Low Temperature Applications: (Cascaded VCRS)Akshay GeraNo ratings yet