Professional Documents

Culture Documents

AC 04006 Reliability CAAV A2009E

AC 04006 Reliability CAAV A2009E

Uploaded by

Thanh Hao LuongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC 04006 Reliability CAAV A2009E

AC 04006 Reliability CAAV A2009E

Uploaded by

Thanh Hao LuongCopyright:

Available Formats

CIVIL AVIATION AUTHORITY ADVISORY CIRCULAR

OF VIETNAM

AC 04-006

MAINTENANCE CONTROL BY RELIABILITY METHODS

SECTION 1 POLICY & GENERAL INFORMATION

1.1 PURPOSE

A. This advisory circular outlines practices acceptable to CAAV with regard to development,

management and approval of aircraft maintenance reliabilty control programs using the

aircraft manufacturer’s maintenance planning document which establish the criteria for

classifying maintenance processes.

B. It also provides information and guidance The aircraft maintenance reliability program is a

which may be used to design or develop a subsection of an approved aircraft maintenance

maintenance program that utilizes program.

reliability control methods.

1.2 STATUS OF THIS AC

This AC is an original issuance.

1.3 BACKGROUND

1.3.1 HARD-TIME

A. The first generation of formal air operator maintenance programs was based on the belief

that each functional part of a transport aircraft needed periodic disassembly inspection.

B. Time limitations were established for servicing, checks and inspections, and the entire

aircraft was periodically disassembled, overhauled, and reassembled in an effort to maintain

the highest level of safety.

z This is the origin of the first primary maintenance process discussed in this publication and referred

to as "Hard-Time."

1.3.2 ON-CONDITION

A. As the industry grew, matured, and adopted more complex aircraft, literal application of the

"Hard-Time" primary maintenance process became obsolete.

z The industry came to realize that each component and part did not require scheduled overhaul on a

fixed time basis, and a second primary maintenance process evolved, referred to as "On-

Condition."

z Advisory Circulars are intended to priovide advice and guidance to illustrate a means, but not necessarily the only means, of

complying with the Regulations, or to explain certain regulatory requirements by providing informative, interpretative and

explanatory material.

z Where an AC is referred to in a ‘Note’ below the regulation, the AC remains as guidance material,

z ACs should always be read in conjunction with the referenced regulations.

Issue Date: 31 October 2009

2 AC 04-006: MAINTENANCE RELIABILIY

B. This concept is assigned to components on which a determination of continued

airworthiness can be made by visual inspections, measurements, tests or other means

without disassembly, inspection or overhaul.

1.3.3 RELIABILITY CONTROL

Control of these programs was previously accomplished by individual approval of the hard- time

or on-condition check periods for the aircraft, engines, and components.

z The procedures used to adjust these periods were awkward and burdensome, often inhibiting

logical adjustment.

z This method of control was oriented toward mechanical performance rather than to predicting

failure wear out points, as was the case in the previous methods.

z The new method was entitled "reliability control" because its major emphasis was toward

maintaining failure rates below a predetermined value; i.e., an acceptable level of reliability.

1.3.4 CONDITION MONITORING

A. The analytical nature of reliability control disclosed and emphasized the existence of

components and systems that did not respond to the hard-time or on-condition processes.

B. This led to a third process whereby no services or inspections are scheduled to determine

integrity or serviceability.

z In this process, the mechanical performance is monitored and analyzed, but limits or mandatory

action are not prescribed. This process is entitled "Condition-Monitoring."

1.4 APPLICABILITY

The guidance provided in this advisory circular This AC is also applicable to the personnel and

is applicable to operators of aircraft that are organizations that are involved in the implemen-

required to be maintained under an tation and administration of the maintenance

maintenance program approved by CAAV. program.

1.5 RELATED REGULATIONS

This advisory circular provides guidance regarding airworthiness reliability that is applicable to

compliance with—

z Part 4, Continuing Airworthiness.

z Part 5, Approved Airworthiness Organizations

z Part 12, AOC Certification and Administration

1.6 RELATED PUBLICATIONS

The following publications also contain pertinent technical background regarding reliability

programs—

z CAAV Airworthiness Inspector Manual

The CAAV airworthiness inspectorates can pro-

z Maintenance Control by Reliability Methods, vide access to these reference documents.

AC 120-17, United States Federal Aviation

Administration

1.7 ACRONYMS & DEFINITIONS

1.7.1 ACRONYMS & ABBREVIATIONS

The following acronyms and abbreviations are used in this document.

Issue Date: 31 October 2009

AC 04-006: MAINTENANCE RELIABILITY 3

1) CM = Condition Monitoring

2) HT = Hard Time

3) MPD = Maintenance Planning Document

4) MSG = Maintenance Steering Guide

5) MRB = Maintenance Review Board

6) OC = On-Condition

1.7.2 DEFINITIONS

The following definitions are used in this document—

1) Operator. An airline with maintenance programme controlled by a reliability programme.

2) Service Provider. An operator contracting out an approved maintenance programme

controlled by a reliability programme to another operator.

SECTION 2 GENERAL INFORMATION & GUIDANCE

2.1 ACCEPTABLE LEVEL OF RELIABILITY

A. The Reliability Control Program focuses on maintaining failure rates below a predetermined

value; i.e., an acceptable level of reliability.

B. The maintenance philosophy, consideration of operational and environmental factors, record

keeping systems, the extent and scope of the operator's application of reliability control, are

reflected and defined in his own reliability program document.

2.2 COMPONENTS OF A MAINTENANCE PROGRAM

A. There are four general categories of an All four categories may be controlled by a com-

operator's maintenance program— posite program, or each may be handled individ-

ually.

1) Systems and components;

2) Propulsion systems and components;

3) Aircraft and propulsion system checks and inspections; and

4) Structural inspection and/or /overhaul.

B. The program can encompass a select group of items from a category without affecting other

controls for the remaining items of that category.

z For example, the basic engine might be maintained by a program that does not include its

accessories. The accessories could be on another program or they could be under traditional

operations specifications control

2.3 STATISTICAL ANALSIS

A. Statistical analysis is most effective in its application to systems and components because

the occurrence of failures can be readily reduced to meaningful statistics.

z Alert rates used in the analysis, graphic charts (or equivalent displays) show areas in need of

corrective action.

z Conversely, statistical analysis of inspection findings or other abnormalities related to aircraft/

engine check and inspection periods requires judgmental analysis.

Issue Date: 31 October 2009

4 AC 04-006: MAINTENANCE RELIABILIY

B. Programs encompassing aircraft/engine check or inspection intervals might consider

numerical indicators, but sampling inspection and discrepancy analysis would be of more

benefit.

SECTION 3 PRIMARY MAINTENANCE PROCESSES

3.1 GENERAL

A. The three primary maintenance processes utilized by maintenance programs are—

1) Hard-time;

2) On-condition; and

3) Condition-monitoring.

B. Each program should include specific The detailed requirements for the condition-

definitions of the processes it uses and how monitoring process are included in the aircraft

they are applied. manufacturer’s maintenance planning document

(for example, MSG-2).

3.1.1 HARD-TIME (HT)

A. This is a preventive primary maintenance process.

B. It requires that an appliance or part be periodically overhauled in accordance with the AOC

holder’s maintenance manual or that it be removed from service.

3.1.2 ON-CONDITION (OC)

A. This is a preventive primary maintenance process.

B. It requires that an appliance or part be periodically inspected or checked against some

appropriate physical standard to determine whether it can continue in service.

C. The purpose of the standard is to remove the unit from service before failure during normal

operation occurs.

3.1.3 CONDITION-MONITORING (CM)

A. This is a maintenance process for items that have neither "Hard-Time" nor "On-Condition"

maintenance as their primary maintenance process.

B. CM is accomplished by appropriate means The detailed requirements for the condition-

available to an operator for finding and monitoring process are included in the aircraft

solving problem areas. nanufacturer’s MPD (MSG-2 and MSG-3)

C. Complex (multicell) units may be subject to

control by two or even all three of the primary processes.

D. The predominant process will determine its classification.

z For example, the B-747 Modular Package - Stabilizer Control has CM assigned as its primary

maintenance process by the MRB report, but a leakage check, which is a conventional OC task, is

also specified.

3.2 EXAMPLE COMBINING ALL THREE PROCESSES

A. The basic engine has characteristics that involve all three primary maintenance processes.

B. Programs that control engine major The overhaul standards are specified by over-

overhaul intervals consider the engine as a haul manuals or other publications that do not

hard-time unit. identify individual processes as such.

Issue Date: 31 October 2009

AC 04-006: MAINTENANCE RELIABILITY 5

C. Programs controlling shop maintenance to a "conditional" standard (restoration, etc.,) may

classify the engine as on-condition or as condition-monitoring depending on the

characteristics of the program.

D. The applicable maintenance processes and their intervals should be designated in (or

referenced by) the program document, MSG-2 and -3,. discusses the analysis method for

assigning maintenance processes.

E. This method was used in the MRB activity This analytical method, in conjunction with ser-

for the engines of the wide-bodied jets. vice experience, can be applied to earlier

engines.

SECTION 4 RELIABILITY CONTROL SYSTEMS

A. The maintenance reliability program must reflect the application of the following control

systems—

1) Data collection;

2) Data analysis;

3) Corrective action;

4) Performance standards;

5) Data display and report;

6) Maintenance interval adjustment and process change; and

7) Program revision.

B. These systems explain the framework which the operator can use to develop his particular

reliability program.

4.1 DATA COLLECTION SYSTEM

A. This system should include—

z A specific flow of information;

z Identification of data sources; and

z Procedures for transmission of data, such as the use of forms and computer runs.

B. Responsibilities within the operator's organization must be established for each step of data

development and processing.

C. Typical sources of performance information includes—

1) Pilot reports; z All of these sources do not need be included in the

2) In-flight engine performance data; program

z This listing does not prohibit the use of other

3) Mechanical interruptions/delays; sources of information.

4) Engine shutdowns;

5) Unscheduled removals;

6) Confirmed failures;

7) Functional checks;

8) Bench checks;

9) Shop findings;

Issue Date: 31 October 2009

6 AC 04-006: MAINTENANCE RELIABILIY

10) Sampling inspections;

11) Inspection writeups; and

12) Service difficulty reports

4.2 DATA ANALYSIS SYSTEM

A. Data analysis is the process of evaluating mechanical performance data to identify

characteristics indicating a need for—

z Program adjustmen;

z Revision of maintenance practices;

z Hardware improvement (modification)

B. The initial step in analysis is the comparison of the data to a standard representing

acceptable performance.

z The standard may be a running average, tabulations of removal rates for past periods, graphs,

charts, or any means of depicting a "norm."

4.2.1 PROGRAMS INCORPORATING STATISTICAL PERFORMANCE STANDARDS

A. These programs are generally known at “alert type programs.”

B. Reliability programs previously developed, These programs incorporate performance stan-

utilize parameters for reliability analysis dards which define acceptable performance.

such as delays per 100 departures for an

aircraft system.

z When compared with a running graphical or tabular display of current performance these programs

depict trends as well as show out-of-limits conditions.

C. The system performance data is usually reinforced by component removal or confirmed

failure data.

z The condition-monitoring process can be readily accommodated by this type of program.

4.2.2 PROGRAMS USING OTHER ANALYSIS STANDARDS

A. These programs are generally known as “non-alert type programs.”

B. Data that is compiled to assist in the day-to-day operation of the maintenance program may

be effectively used as a basis for continuous mechanical performance analysis.

z Mechanical interruption summaries, flight log review, engine monitoring reports, incident reports,

engine and component analysis reports are examples of the types of information suitable for this

monitoring method.

z For this arrangement to be effective, the number and range of inputs must be sufficient to provide a

basis for analysis equivalent to the statistical standard programs.

C. The operator's organization must have the Actuarial analysis should be periodically con-

capability of summarizing the data to arrive ducted to ensure that current process classifica-

at meaningful conclusions. tions are correct.

SECTION 5 CORRECTIVE ACTION

The objective of data analysis is to—

1) Recognize the need for corrective action;

2) Establish what corrective action is needed; and

Issue Date: 31 October 2009

AC 04-006: MAINTENANCE RELIABILITY 7

3) Determine the effectiveness of that action.

5.1 CORRECTIVE ACTION SYSTEM

A. The actions to be taken are a reflection of z The system must include notification to the

the analysis and should be positive enough organizational element responsible for taking the

to effectively restore performance to an action.

acceptable level within a reasonable time. z The system should provide periodic feedback until

such time as performance has reached an

B. The mechanics of the corrective action acceptable level.

system normally encompass methods that

have been established for the overall

maintenance program such as—

z Work forms

z Special inspection procedures

z Engineering orders

z Technical standards

C. Special provisions should be included for critical failures; such as failures in which loss of the

function or secondary effects of the failure impair the airworthiness of the aircraft.

5.2 STATISTICAL PERFORMANCE STANDARDS SYSTEM

A. The basis for the statistical standard is a performance measurement expressed numerically

in terms of—

1) System or component failures;

2) Pilot reports;

3) Delays or some other event (bracketed by hours of aircraft operation, number of

landings, operating cycles; or

4) Other exposure measurement..

B. The development of control limits or alert Some applications use the average or base line

values is usually based on accepted method.

statistical methods such as standard

deviation or the poisson distribution.

C. The standard should be adjustable with reference to the operator's experience and should

reflect seasonal and environmental considerations.

D. The program should include procedures for The program should also include monitoring

periodic review of, and either upward or procedures for new aircraft until sufficient oper-

downward adjustment of, the standards as ating experience is available for computing per-

indicated. formance standards.

SECTION 6 DATA DISPLAY & REPORT SYSTEM

6.1 REPORTS FOR ALERT TYPE PROGRAM

A. Programs incorporating statistical performance standards (alert type programs) should

develop a monthly report, with appropriate data displays, summarizing the previous month's

activity.

B. The report should—

Issue Date: 31 October 2009

8 AC 04-006: MAINTENANCE RELIABILIY

1) Cover all aircraft systems controlled by the program in sufficient depth to enable the

CAAV and other recipients of the report to evaluate the effectiveness of the total

maintenance program;

2) Highlight systems which have exceeded the established performance standards and

discuss what action has been taken or planned;

3) Explain changes which have been made or are planned in the aircraft maintenance

program, including changes—

(a) In maintenance and inspection intervals; and

(b) From one maintenance process to another.

4) Discuss continuing over-alert conditions carried forward from previous reports; and

5) Report the progress of corrective action programs.

6.2 REPORTS FOR NON-ALERT TYPE PROGRAM

A. Programs using other analytical standards These reports may be in the form of computer

should consolidate or summarize printouts, summaries, or any intelligible form.

significant reports used in controlling their

program to provide for evaluation of its

effectiveness.

B. A typical program of this type reports the following information—

1) Mechanical Interruption Summary (MIS);

2) Mechanical Reliability Reports (MRR);

3) Listing of all maintenance processes and interval assignments (Master specifications);

4) Weekly updates;

5) Daily Repetitive Item Listing (by aircraft);

6) Monthly Component Premature Removal Report (includes removal rate);

7) Monthly Engine Shutdown and Removal Report;

8) Quarterly Engine Reliability Analysis Report;

9) Engine Threshold Adjustment Report;

10) Worksheets for maintenance process and interval changes;

11) Maintenance interval adjustment and process change system.

SECTION 7 ADJUSTMENTS & REVISIONS

7.1 MAINTENANCE INTERVAL ADJUSTMENTS

A. Maintenance interval adjustments should Special procedures for escalating systems or

not interfere with ongoing corrective components whose current performance

actions. exceeds control limits should be provided.

B. Typical considerations for adjusting hard-

time and on-condition intervals include—

1) Sampling; All the factors listed here do not have to be con-

2) Actuarial studies; sidered for each case

Issue Date: 31 October 2009

AC 04-006: MAINTENANCE RELIABILITY 9

3) Unit performance;

4) Inspector or shop findings;

5) Pilot reports.

C. Methods for adjusting aircraft/engine check intervals should be included if the program

controls these intervals and sampling criteria should be specified.

D. The system should include—

1) Procedures for initial classification of maintenance processes (HT-OC-CM) and for

changes from one process to another;

2) Authority and procedures for changing maintenance specifications; and

3) Related documents to reflect the interval adjustment or primary process change.

7.2 PROGRAM REVISION SYSTEM

A. The program should include a procedure This revision procedure should identify organi-

for revision which is compatible with CAAV zational elements involved in the revision pro-

approvals. cess and their authority.

B. The program areas requiring formal CAAV

approval include any changes to the program that involve—

1) Any of the program control systems;

2) Adding or deleting components/systems;

3) Adding or deleting aircraft types;

4) All procedural and organizational changes concerning administration of the program.

7.3 PROGRAM ADMINISTRATION

A. Administration of reliability programs (as discussed in this circular) requires a specific

organizational structure within the operator's maintenance organization.

z Participants of the reliability program andministration team should be drawn from appropriate

elements of the organization and should be authorized to act on behalf of their elements.

z The highest maintenance official or his designee should participate in the administration of the

program. He should serve as the final authority for major activities and for the program.

B. The reliability program administration team may vary from one operator to another.

C. It may have a technical board that analyses z The two boards can be combined if this better

performance deteriorations and shop serves the needs of the particular operator.

findings to make determinations that may z The board type of administration should entail

be acted on by an administrative board. meetings scheduled for some specified interval and

should provide for assembling a board at any time a

D. In the absence of a formal administration decision is needed.

team, operators with sufficient

organizational capability should include a strong engineering function to administer their

program by assigning appropriate responsibilities to specific elements of the operator's

organization.

E. It is important to know that the effective These procedures should be incorporated in

management of the established procedures appropriate sections of the operator's manual

of operating each system is essential to the system.

success of the program.

Issue Date: 31 October 2009

10 AC 04-006: MAINTENANCE RELIABILIY

F. Forms should be used, as necessary, to facilitate and document recurring transactions that

involve several elements such as—

1) Changes from one maintenance process to another;

2) Analysis of substandard system or component mechanical performance;

3) Shop disassembly analysis for condition-monitoring purposes or overhaul frequency

adjustment.; and

4) Sampling inspection for aircraft check or inspection adjustment.

SECTION 8 RELIABILITY PROGRAM DOCUMENT

A. The operator should develop a document describing the application of reliability control

methods.

B. This document should include at least the following—

1) General description of the program;

2) Organizational structure, duties and responsibilities;

3) Description of the individual systems;

4) Derivation of performance standards (if used);

5) Changes to the program including designation of changes requiring CAAV approval;

6) Copy and explanation of all forms peculiar to the system; and

7) Revision control and certification of revisions to the document.

C. The document should—

1) Describe the workings of all systems in sufficient detail to provide for proper operation of

the program.

2) The details for how the three maintenance processes are applied.

3) Describe the monthly report and any other reports relative to the program, and include

samples of these reports with instructions for their use;

4) Identify the organizational element(s) Copies of pertinent reports shall be provided to

responsible for publishing reports and CAAV.

the distribution of those reports; and

5) Include definitions of significant terms used in the program with particular emphasis on

definitions of the three maintenance processes.

SECTION 9 PROGRAM APPROVAL

9.1 INITIAL APPROVAL

A. The program document and related data should be submitted to CAAV with a formal cover

letter.

B. CAAV approval will be specified in the operations specifications issued to the operator.

9.2 REVISION APPROVAL

A. Amendments to the reliability program shall be subjected to a review, evaluation and

approval process before incorporation.

Issue Date: 31 October 2009

AC 04-006: MAINTENANCE RELIABILITY 11

B. It is important to take in consideration the impact of the proposed amendments on the overall

organization manual system.

End of Advisory Circular

Issue Date: 31 October 2009

12 AC 04-006: MAINTENANCE RELIABILIY

This Page Intentionally Left Blank

Issue Date: 31 October 2009

You might also like

- FAA - Form 337Document2 pagesFAA - Form 337ElLoko MartinesNo ratings yet

- FAA Order 8900.1 CHG 218Document5 pagesFAA Order 8900.1 CHG 218Muhammad Ashraful KabirNo ratings yet

- AC 05001 AMO Certification CAAV B20151Document24 pagesAC 05001 AMO Certification CAAV B20151Thanh Hao LuongNo ratings yet

- Final Report With ChangesDocument38 pagesFinal Report With ChangesAkash Kumar75% (4)

- Topic 2Document24 pagesTopic 2Kiven M. GeonzonNo ratings yet

- Ac 05002 Amo Manual Caav A2009Document48 pagesAc 05002 Amo Manual Caav A2009Thanh Hao LuongNo ratings yet

- Regulation 1321 2014 On The Continuing Airworthiness of Aircraft en PDFDocument194 pagesRegulation 1321 2014 On The Continuing Airworthiness of Aircraft en PDFmechNo ratings yet

- NPA Part-M GADocument20 pagesNPA Part-M GAAnanda MandalNo ratings yet

- Part M Presentation For AOC OperatorsDocument306 pagesPart M Presentation For AOC OperatorsKostasNo ratings yet

- 21 Air ConditioningDocument20 pages21 Air ConditioningK Praveen RaoNo ratings yet

- A320 Avionics Level 1 PDF FreeDocument270 pagesA320 Avionics Level 1 PDF FreeAmiel Simon AureNo ratings yet

- TTC Boeing 737CDocument4 pagesTTC Boeing 737CGuntur EkoNo ratings yet

- Awnot 065 Awrg 4Document21 pagesAwnot 065 Awrg 4HussainAhmedNo ratings yet

- Easa-Part-M - Last EditionDocument325 pagesEasa-Part-M - Last EditionMUHANDES UKRAINENo ratings yet

- B 747 FPDocument11 pagesB 747 FPFayez Shakil AhmedNo ratings yet

- Car 147Document50 pagesCar 147Sudheesh Sudhakaran NairNo ratings yet

- Car-M Subpart DDocument29 pagesCar-M Subpart Dpandurang nalawadeNo ratings yet

- Lsr12 HFACS PresentationDocument7 pagesLsr12 HFACS PresentationIonChiaburuNo ratings yet

- Table of ContentsDocument27 pagesTable of ContentsDipendra SenNo ratings yet

- DOCUMENTATIONDocument47 pagesDOCUMENTATIONRicell James Adriano100% (1)

- LHD 241 CAME Checklist Part CAMODocument32 pagesLHD 241 CAME Checklist Part CAMOS.A.M AkramuzzamanNo ratings yet

- GMMDocument228 pagesGMMCristhian342No ratings yet

- PART-147 Approved Training Organisations: Q.C.M. Revision No.: 1 Date: 01 March 2012Document74 pagesPART-147 Approved Training Organisations: Q.C.M. Revision No.: 1 Date: 01 March 2012mahmud517No ratings yet

- SARI Part 66-Issue 1-15december2012Document177 pagesSARI Part 66-Issue 1-15december2012Pawan Kumar KarwalNo ratings yet

- Demo Systems PDL 30100 Manual Rev CDocument26 pagesDemo Systems PDL 30100 Manual Rev CEvandro Oliveira100% (1)

- Combined Airworthiness Organisation Manual TemplateDocument131 pagesCombined Airworthiness Organisation Manual TemplateHadeer Muhammad Abdelhady100% (1)

- Easa Part M Consolidated DocumentDocument371 pagesEasa Part M Consolidated DocumentRogerNo ratings yet

- Reportable Occurence CAAM 2019 PDFDocument21 pagesReportable Occurence CAAM 2019 PDFAmbas NelusNo ratings yet

- CAA-AC-AWS011A - Maintenance Control ManualDocument4 pagesCAA-AC-AWS011A - Maintenance Control ManualPaschalNo ratings yet

- Curso SupsDocument9 pagesCurso SupsJUBILLANo ratings yet

- CAR - 147 Approved Maintenance Training Organisation (Type Training)Document57 pagesCAR - 147 Approved Maintenance Training Organisation (Type Training)Jebin Kumar K JNo ratings yet

- 7 CAAT-AIR-GM03 Guidance-Material-for-Foreign-Approved-Maintenance-Organization - I3R0 - 30oct2019 PDFDocument59 pages7 CAAT-AIR-GM03 Guidance-Material-for-Foreign-Approved-Maintenance-Organization - I3R0 - 30oct2019 PDFJindarat KasemsooksakulNo ratings yet

- AC 120-49 Amdt 0Document31 pagesAC 120-49 Amdt 0matalangNo ratings yet

- Receiving Inspections Power Point 10-22-16Document52 pagesReceiving Inspections Power Point 10-22-16Darby MorganNo ratings yet

- De-Anti Icing of Aircraft On The Ground-Technical Information FormDocument48 pagesDe-Anti Icing of Aircraft On The Ground-Technical Information FormMurat DemirbaşNo ratings yet

- A123281 Aircraft Random Vibration Test CriteriaDocument13 pagesA123281 Aircraft Random Vibration Test CriteriarobNo ratings yet

- CRJ Mmel Rev.19 13 May 10Document264 pagesCRJ Mmel Rev.19 13 May 10Enrique Gómez EscrihuelaNo ratings yet

- L SeriesDocument141 pagesL SeriesKshitiz RastogiNo ratings yet

- UsjsjsDocument8 pagesUsjsjsKirito SeiyaNo ratings yet

- Capability List SAATDocument344 pagesCapability List SAATMohsen PeykaranNo ratings yet

- EMB SS Catalog PDFDocument21 pagesEMB SS Catalog PDFRenatoNo ratings yet

- 24 Electrcial PowerDocument32 pages24 Electrcial PowerK Praveen RaoNo ratings yet

- Maint Philsp N Devlp ProgrDocument47 pagesMaint Philsp N Devlp Progrhatach100% (1)

- AVICSYNC Operation ManualDocument29 pagesAVICSYNC Operation ManualLynne Black0% (1)

- ICAO DOC 9870 App PDFDocument10 pagesICAO DOC 9870 App PDFpasargad135106No ratings yet

- ETSO-C127a CS-ETSO 0Document6 pagesETSO-C127a CS-ETSO 0Anurag MishraNo ratings yet

- Demonstration of 6-24 Months ExperienceDocument17 pagesDemonstration of 6-24 Months Experiencerameshneupane100% (1)

- Session 7 Part M CAMO FinalDocument86 pagesSession 7 Part M CAMO FinalSerzeb KamranNo ratings yet

- AC 20-154 Incoming InspectionDocument24 pagesAC 20-154 Incoming Inspectionyvesandrade100% (1)

- 11b Critical Task FPLDocument34 pages11b Critical Task FPLVerickNo ratings yet

- Easa Independent Inspection PDFDocument2 pagesEasa Independent Inspection PDF张海林No ratings yet

- A00006WIDocument8 pagesA00006WISantosa Edy WibowoNo ratings yet

- Airplane Health ManagementDocument4 pagesAirplane Health ManagementScotNo ratings yet

- Aero Engine Services: Pt. Nusantara Turbin Dan PropulsiDocument17 pagesAero Engine Services: Pt. Nusantara Turbin Dan PropulsiMeingkarNo ratings yet

- FadeccccDocument69 pagesFadeccccsugihnuNo ratings yet

- Nepal Civil Aviation Regulation Part 66 ManualDocument194 pagesNepal Civil Aviation Regulation Part 66 ManualAbhishek Man ShresthaNo ratings yet

- Sms+With+Template PotxDocument247 pagesSms+With+Template PotxLEAI FAYE CARUNGCONGNo ratings yet

- 1 Suspected Unapprove PartDocument27 pages1 Suspected Unapprove PartNDT GMF100% (1)

- EASA Part 145 Certifying Staff and Support Staff Audit EASA.145.a.35 R0Document11 pagesEASA Part 145 Certifying Staff and Support Staff Audit EASA.145.a.35 R0Javier Melchor JimenezNo ratings yet

- ATA 32 Landing GearDocument3 pagesATA 32 Landing GearhmtuanbkNo ratings yet

- EASA Part CAMO Safety Human Factor Training Requirements Initial - 3 Days PDFDocument6 pagesEASA Part CAMO Safety Human Factor Training Requirements Initial - 3 Days PDFcarbonNo ratings yet

- Ac 05002 Amo Manual Caav A2009Document48 pagesAc 05002 Amo Manual Caav A2009Thanh Hao LuongNo ratings yet

- AC 04002 Special CofA CAAV A2009EDocument8 pagesAC 04002 Special CofA CAAV A2009EThanh Hao LuongNo ratings yet

- AC 02001 Registration CAAV A2009Document8 pagesAC 02001 Registration CAAV A2009Thanh Hao LuongNo ratings yet

- An Introduction and Guide To Successfully Implementing A LIMS (Laboratory Information Management System)Document9 pagesAn Introduction and Guide To Successfully Implementing A LIMS (Laboratory Information Management System)notonectal100% (1)

- Maintenance Plan Base On RCMDocument4 pagesMaintenance Plan Base On RCMSisawad XayyasithNo ratings yet

- Humanitarian AidDocument6 pagesHumanitarian AidHumair KhanNo ratings yet

- A Practical MTBF Estimate For PCB Design Considering Component and Non-Component FailuresDocument7 pagesA Practical MTBF Estimate For PCB Design Considering Component and Non-Component FailuresAnthonyNo ratings yet

- D02-D03 Reliasoft Weibull++ 8Document150 pagesD02-D03 Reliasoft Weibull++ 8ArieWBNo ratings yet

- Ruckus Vs Aruba Oct2012Document5 pagesRuckus Vs Aruba Oct2012Atul DeshpandeNo ratings yet

- Easy Laser E710 E720ShaftBrochureDocument8 pagesEasy Laser E710 E720ShaftBrochuretmmehtaNo ratings yet

- MTECH2017 INTERNATIONAL CONFERENCE ON MATERIALS: Corrosion, Heat Treatment, Testing and TribologyDocument8 pagesMTECH2017 INTERNATIONAL CONFERENCE ON MATERIALS: Corrosion, Heat Treatment, Testing and TribologyMatija SakomanNo ratings yet

- NOrsock Standard R-002Document186 pagesNOrsock Standard R-002Popovici AlexandruNo ratings yet

- Kilpi - Sourcing of Availability Services (2008)Document188 pagesKilpi - Sourcing of Availability Services (2008)cd.davechNo ratings yet

- CEN-CLCTC10 WG02Sec00051DC PDFDocument36 pagesCEN-CLCTC10 WG02Sec00051DC PDFRubenNo ratings yet

- Dirak CatalogDocument407 pagesDirak CatalogAshvin KunnathelNo ratings yet

- CMRP Quiz 2Document3 pagesCMRP Quiz 2FERRELIN100% (2)

- OMAE2018 ProgramDocument124 pagesOMAE2018 ProgramTahsin TezdoganNo ratings yet

- Thesis Topics in Cloud ComputingDocument8 pagesThesis Topics in Cloud Computingiapesmiig100% (2)

- Fmea Failure Mode and Effect Analysis: PT. MTS IndonesiaDocument44 pagesFmea Failure Mode and Effect Analysis: PT. MTS IndonesiaFransisco SimamoraNo ratings yet

- Fmea Failure Mode Effects AnalysisDocument93 pagesFmea Failure Mode Effects AnalysisCHANDUNo ratings yet

- Presenting On "Power System Planning Tools": Swami Keshvanand Intitute of Technology and Management & Gramothan, JaipurDocument13 pagesPresenting On "Power System Planning Tools": Swami Keshvanand Intitute of Technology and Management & Gramothan, JaipurHimanshu SoniNo ratings yet

- Paulo Gomes: Personal DetailsDocument2 pagesPaulo Gomes: Personal DetailsCertified Rabbits LoverNo ratings yet

- Chapter 1 - Introduction To AISDocument60 pagesChapter 1 - Introduction To AISAlfy FarhanNo ratings yet

- Reusing Screws and Bolts Is A Safety Risk and Decreases Fan ReliabilityDocument3 pagesReusing Screws and Bolts Is A Safety Risk and Decreases Fan ReliabilityThanaraj SanmughamNo ratings yet

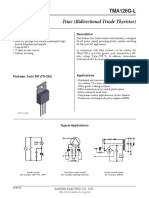

- Triac (Bidirectional Triode Thyristor) : TMA126G-LDocument10 pagesTriac (Bidirectional Triode Thyristor) : TMA126G-LPedro RodriguezNo ratings yet

- Geotechnical & Structural InstrumentationDocument36 pagesGeotechnical & Structural InstrumentationManikandanNo ratings yet

- Turret Punch Press EM Series: Punching TechnologyDocument12 pagesTurret Punch Press EM Series: Punching TechnologyParvezNo ratings yet

- AutoMoor SP Ver1 1 PDFDocument24 pagesAutoMoor SP Ver1 1 PDFAgung Sugiwanto100% (1)

- GA 30+-90 / GA 37-90 VSD: Oil-Injected Rotary Screw CompressorsDocument2 pagesGA 30+-90 / GA 37-90 VSD: Oil-Injected Rotary Screw Compressorsjackyt09No ratings yet

- Aw139 Customer Advisory Board MeetingDocument121 pagesAw139 Customer Advisory Board MeetingJames Edward100% (3)