Professional Documents

Culture Documents

HP/LP Bypass Automation: Function Description

HP/LP Bypass Automation: Function Description

Uploaded by

Mohit GohilCopyright:

Available Formats

You might also like

- Closed Cooling Water System (Sample)Document37 pagesClosed Cooling Water System (Sample)shahida100% (2)

- Bypass ControllerDocument4 pagesBypass Controllernjc6151100% (2)

- AV6+ BypassGeneralDescriptionDocument14 pagesAV6+ BypassGeneralDescriptionGaurav ChauhanNo ratings yet

- HP-LP Bypass System AdvantagesDocument3 pagesHP-LP Bypass System Advantageskaruna346100% (1)

- HP-Bypass and LP BypassDocument3 pagesHP-Bypass and LP Bypassdinesh7136100% (2)

- Turbine Bypass SystemsDocument10 pagesTurbine Bypass SystemsZaqPoilm100% (1)

- Seal Oil PresentationDocument10 pagesSeal Oil Presentationjeromejoe100% (1)

- Sliding Pressure Control BasicsDocument4 pagesSliding Pressure Control BasicsUdhayakumar VenkataramanNo ratings yet

- HP LP Bypass System: Ravi Pal SinghDocument36 pagesHP LP Bypass System: Ravi Pal SinghMinh Hoang NguyenNo ratings yet

- DEH PresentationDocument37 pagesDEH PresentationPRAMOD KUMAR NANDA100% (2)

- Lube Oil SystemDocument4 pagesLube Oil SystempawangwlNo ratings yet

- HP Bypass SystemDocument21 pagesHP Bypass SystemShameer Majeed100% (1)

- Thermal Plant Control Instrumentation IIDocument29 pagesThermal Plant Control Instrumentation IIpradeep1987cool100% (1)

- De Super HeaterDocument27 pagesDe Super HeaterShivam Mannan MishraNo ratings yet

- Turbine Stress Evaluator: 17 February 2018 PMI Revision 00 1Document23 pagesTurbine Stress Evaluator: 17 February 2018 PMI Revision 00 1NILESHNo ratings yet

- HP Feed WaterDocument13 pagesHP Feed WaterAxlejunz Dublin RondinaNo ratings yet

- Introduction To Steam Seal System of 800Mw Kudgi TurbineDocument10 pagesIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800100% (2)

- Auto Loops TVNLDocument144 pagesAuto Loops TVNLRajeevAgrawal100% (1)

- Governing 11Document35 pagesGoverning 11rahul100% (2)

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- HindalcoDocument28 pagesHindalcoSiddhant Satpathy100% (1)

- Turbine Bypass System - HORADocument11 pagesTurbine Bypass System - HORAhozipek100% (2)

- Turbine Governing SystemDocument77 pagesTurbine Governing SystemGrishma Warke100% (2)

- HPBPDocument14 pagesHPBPrnumesh1100% (1)

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- Schemes TalcherDocument206 pagesSchemes TalcherSam100% (1)

- Turbine Control and Efficiency ImporovementDocument6 pagesTurbine Control and Efficiency ImporovementUdhayakumar Venkataraman100% (2)

- Bhel Steam Turbine Description-1Document2 pagesBhel Steam Turbine Description-1Srinivasa Rao Pallela100% (1)

- Seal Oil and Hydrogen SystemDocument34 pagesSeal Oil and Hydrogen Systemashish_ntpc100% (1)

- Automatic Turbine Runup System Gyanendra Sharma NPTI DelhiDocument32 pagesAutomatic Turbine Runup System Gyanendra Sharma NPTI DelhiNPTI100% (3)

- C&I Part of SCDocument28 pagesC&I Part of SCSam100% (3)

- Protection and InterlocksDocument47 pagesProtection and InterlocksRavi kant Ghatoye100% (1)

- Auto Control Loops PresentationDocument106 pagesAuto Control Loops PresentationMohammad Ibnul Hossain100% (1)

- Steam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestDocument10 pagesSteam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestAakash Ranjan100% (2)

- Npti 20072010Document19 pagesNpti 20072010Sai SwaroopNo ratings yet

- Feed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam AccumulatorsDocument74 pagesFeed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam Accumulatorsbanukiran sambojuNo ratings yet

- Generator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Document32 pagesGenerator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Praveen Jagadev100% (4)

- CRH Drain Pot LevelDocument30 pagesCRH Drain Pot LevelBibhash SinghNo ratings yet

- Ing The Starting Device To Zero: M.S. Pr. 35-40 Ksc. HRH Pr. 12-14 Ksc. M.S. and HRH Tempr. - 320 To 3500C)Document3 pagesIng The Starting Device To Zero: M.S. Pr. 35-40 Ksc. HRH Pr. 12-14 Ksc. M.S. and HRH Tempr. - 320 To 3500C)Sourav SahaNo ratings yet

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pages020-SOP of H2 CYLINDER Room ChargingsambhuNo ratings yet

- Ammonia Dosing at The Electrostatic Precipitator (ESP) Inlet Is A Technique Used For Reducing The Emission of Fine Particulate Matter, Particularly in Coal-Fired Power Plants and Industrial ProcessesDocument3 pagesAmmonia Dosing at The Electrostatic Precipitator (ESP) Inlet Is A Technique Used For Reducing The Emission of Fine Particulate Matter, Particularly in Coal-Fired Power Plants and Industrial ProcessesYadbir singhNo ratings yet

- 20mw Operation ManualDocument55 pages20mw Operation Manualaakash srivastavaNo ratings yet

- Turbine and AuxiliariesDocument65 pagesTurbine and AuxiliariesSwadhin Kumar Das100% (3)

- 660 MW Vs 500 MWDocument7 pages660 MW Vs 500 MWKrishnan SanthanarajNo ratings yet

- Safety Valve Floating MrthodDocument4 pagesSafety Valve Floating MrthodSanjay Chakraborty100% (1)

- BHEL Turbine Start-UpDocument17 pagesBHEL Turbine Start-UpSelvakumar SubramanianNo ratings yet

- Soot BlowersDocument264 pagesSoot BlowersNitin Sen100% (1)

- C&I WriteupDocument137 pagesC&I WriteupSayan AichNo ratings yet

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984100% (1)

- Write Up On LPBP SystemDocument9 pagesWrite Up On LPBP SystemKhushboo PandeyNo ratings yet

- Delay in Opening of LP Bypass ValveDocument94 pagesDelay in Opening of LP Bypass ValveCharu ChhabraNo ratings yet

- HPBP DrawingDocument1 pageHPBP DrawingLakshmi NarayanNo ratings yet

- Bhel LP-HP Bypass OrderDocument32 pagesBhel LP-HP Bypass OrderGiriDharanNo ratings yet

- Technical Feedback EhtcDocument9 pagesTechnical Feedback EhtcPrashant Kumar ChoudharyNo ratings yet

- Closed Feed Water HeatersDocument56 pagesClosed Feed Water HeatersAnudeep ChittluriNo ratings yet

- Lecture On ATRS & Speed-Load ControlDocument44 pagesLecture On ATRS & Speed-Load Control06nikhil100% (3)

- Steam Turbine Governing Systems OverviewDocument11 pagesSteam Turbine Governing Systems Overviewdrmsrmurty83% (6)

- HP & LP Bypass System - Steam Turbine Power PlantDocument4 pagesHP & LP Bypass System - Steam Turbine Power Plantamer_arauf100% (14)

- Sachin Governing System or DEHDocument38 pagesSachin Governing System or DEHNaveen100% (1)

- Manual Steering EngDocument24 pagesManual Steering Engghiocel apinteiNo ratings yet

- QAP For Branch Pipe With NozzleDocument2 pagesQAP For Branch Pipe With NozzleMohit GohilNo ratings yet

- Leave Balance Feb 2022Document2 pagesLeave Balance Feb 2022Mohit GohilNo ratings yet

- Minimum Disclosure Norms For Colleges of Higher Education: Shantilal Shah Engineering College, BhavnagarDocument17 pagesMinimum Disclosure Norms For Colleges of Higher Education: Shantilal Shah Engineering College, BhavnagarMohit GohilNo ratings yet

- Bhensala Rutvik Email: Contact No: 9016151418: Archean Chemical Industries Private LTDDocument3 pagesBhensala Rutvik Email: Contact No: 9016151418: Archean Chemical Industries Private LTDMohit GohilNo ratings yet

- Prandtl's Boundary Layer TheoryDocument6 pagesPrandtl's Boundary Layer TheoryMohit GohilNo ratings yet

- Shantilal Shah Engineering College, BhavnagarDocument2 pagesShantilal Shah Engineering College, BhavnagarMohit GohilNo ratings yet

- OK.2019.Switchyard LayoutPGDC+Qs 16Document28 pagesOK.2019.Switchyard LayoutPGDC+Qs 16Mohit GohilNo ratings yet

- Final Demo Natural ResourcesDocument16 pagesFinal Demo Natural ResourcesStephany Mae CanoyNo ratings yet

- Study List and TT Yr 4 GR 3Document5 pagesStudy List and TT Yr 4 GR 3marks2muchNo ratings yet

- 11aug2023131058 Esiareport VDP, Thy, Mt&Pzugss1108Document275 pages11aug2023131058 Esiareport VDP, Thy, Mt&Pzugss1108akhilaggarwalNo ratings yet

- 2 D ℜ= 2.0 log 3.7 D + 2.51 ℜ + 1 = 0: ∆ P=f Lρ V Ρ Vd μ ε f fDocument5 pages2 D ℜ= 2.0 log 3.7 D + 2.51 ℜ + 1 = 0: ∆ P=f Lρ V Ρ Vd μ ε f ftennerNo ratings yet

- Brain Gut Connection: Anil K. RajvanshiDocument2 pagesBrain Gut Connection: Anil K. RajvanshijulfukarNo ratings yet

- Aphasia in Left HandersDocument2 pagesAphasia in Left Handerskeihoina keihoinaNo ratings yet

- Castillo2020 Bayesian Predictive Optimization of Multiple and Profile Responses Systems in IndustryDocument18 pagesCastillo2020 Bayesian Predictive Optimization of Multiple and Profile Responses Systems in IndustryAngel GarciaNo ratings yet

- Psychology Mid-TermDocument6 pagesPsychology Mid-TermSyed Aman BukhariNo ratings yet

- 0001Document7 pages0001ag_f53No ratings yet

- Seal of Good Local GovernanceDocument46 pagesSeal of Good Local GovernanceKyza Mae AlcontinNo ratings yet

- Term 2 ProjectfinalDocument19 pagesTerm 2 ProjectfinalRahul RoopchandNo ratings yet

- Solvent Promoted Self HealingDocument3 pagesSolvent Promoted Self HealingVansala GanesanNo ratings yet

- Admmodule s11 12ps Iiib 12Document11 pagesAdmmodule s11 12ps Iiib 12Lebz RicaramNo ratings yet

- Rashtrasant Tukadoji Maharaj Nagpur UniversityDocument1 pageRashtrasant Tukadoji Maharaj Nagpur UniversityAkash RautNo ratings yet

- Holt California Algebra 1 Homework and Practice Workbook AnswersDocument5 pagesHolt California Algebra 1 Homework and Practice Workbook Answersafmtcbjca100% (1)

- CHANGES TO BLOOMs TAXONOMYDocument23 pagesCHANGES TO BLOOMs TAXONOMYMi Yu KeyNo ratings yet

- Fermentation: Bio Lab ManualDocument11 pagesFermentation: Bio Lab Manualthegp12No ratings yet

- Tooling Guide For High Reliability Electrical Systems Rev. 11 Ver. 1Document202 pagesTooling Guide For High Reliability Electrical Systems Rev. 11 Ver. 1AndersonNo ratings yet

- 3D Seismic Survey FOR Ratawi Oil Field Area in Southern IraqDocument39 pages3D Seismic Survey FOR Ratawi Oil Field Area in Southern IraqAkhilaNo ratings yet

- Behaviorist and Learning Aspects of PersonalityDocument24 pagesBehaviorist and Learning Aspects of Personalitydurubelsan02No ratings yet

- Gri Adis 2022Document79 pagesGri Adis 2022amellgothiqueNo ratings yet

- Iqbal's Concept of KhudiDocument4 pagesIqbal's Concept of KhudiJay Dee11No ratings yet

- Carta 2003Document112 pagesCarta 2003Oliver SANCHEZNo ratings yet

- How To Use This Module: Module 6: Developing A Business PlanDocument17 pagesHow To Use This Module: Module 6: Developing A Business PlanYejira KionNo ratings yet

- Non-Verbal Communication in SpainDocument20 pagesNon-Verbal Communication in SpainDarina PiskunovaNo ratings yet

- DTL Summer Training ReportDocument63 pagesDTL Summer Training ReportARYAN ANo ratings yet

- Construction Project Management 101 - ChecklistDocument5 pagesConstruction Project Management 101 - ChecklistUsman ShahidNo ratings yet

- Converter, Inverter, Brake: Skiip 23Nab126V1Document4 pagesConverter, Inverter, Brake: Skiip 23Nab126V1Danish ShahNo ratings yet

- An Assignment ON Differential Scale: Submitted To:-. Submitted By:-Jr. LecturerDocument3 pagesAn Assignment ON Differential Scale: Submitted To:-. Submitted By:-Jr. LecturerPriyaNo ratings yet

- 1 Question Bank For Unit 1Document11 pages1 Question Bank For Unit 1Ajay KareNo ratings yet

HP/LP Bypass Automation: Function Description

HP/LP Bypass Automation: Function Description

Uploaded by

Mohit GohilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HP/LP Bypass Automation: Function Description

HP/LP Bypass Automation: Function Description

Uploaded by

Mohit GohilCopyright:

Available Formats

CCI AG Switzerland

Im Link 11 Function description

P.O. Box 65

CH-8404 Winterthur

TELEFON ++41-(0)52-264 95 00

TELEFAX ++41-(0)52-264 95 01

HP/LP Bypass Automation

HP HP HP HP BPE1 BPE2

1. Introduction PS PS PS PT TT TT

30 years experience with Sulzer Bypass

Systems, including controls and safety (Option)

functions, show that the bypass-controller is Signal Conditioning

neither a integrated part of the boiler Operator

Safety

controls nor the turbine controls. The Sulzer Setpoint Generation

function Control

bypass system is rather an independent Interface

system which serves the operational Test Valve Positioners

requirements of the complete plant (i.e.

boiler and turbine). The number of active

signals between the bypass controller and

other systems is small. Much more important

is a bypass controller which fulfils exactly BP1 BP2 BPE1BPE2 BD1 BD2

the requirements of the bypass operation and Figure 1 HP-Bypass controller (2 lines)

allows the easy implementation of safety including safety function

functions or other quick opening or quick

closing functions. The life conserving

operation of the heavily stressed valves and With a few standardized interface signals the

pipework, especially by accurate steam Sulzer bypass controller can be tied easily

desuperheating in all operating modes and into an overall plant automation. The duty of

transients, poses a special challenge for the the HP bypass controller can be summarized

Sulzer bypass controller. for the different operating conditions as

follows:

2. HP bypass controller • Boiler start up

The Sulzer HP bypass controller is an The controller has to control and increase

integrated system with the functions signal the boiler steam pressure according to the

conditioning, control and valve positioning steam production of the boiler. The bypass

(Figure 1). The type of operator interface has to divert the steam flow to the reheater,

can be tailored to the needs of the individual thus ensuring a proper steam flow through

plant. The below described functions for superheater and reheater. The bypass

start up as well as for shut down are fully controller has to control the temperature of

automated. the steam to the reheater whenever steam is

flowing through the bypass.

• Turbine start up

The HP bypass controller has to control the

steam pressure until the boiler master

controller can take over the pressure control.

640/30.04.04/Ri D1_HDNDe 1/4

• Load operation 2.1 Pressure control

The bypass is closed but the controller is Figure 3 shows in more detail the structure

ready to prevent excessive live steam of the pressure controller and the pressure

pressure or excessive pressure gradients. setpoint generator. The different functions

• Turbine load rejection/trip

and operating modes of the pressure

controller are represented again in the start

The controller opens the bypass valves, if up diagram of Figure 4.

necessary with the help of the quick opening

devices, in order to prevent excessive live At the begin of a cold start the minimum

steam pressure and controls the pressure opening (Ymin) is active. It ensures

until the turbine picks up load again. immediately after ignition an open path and

• Safety Function therefore a steam flow through the

superheater and reheater.

Regulations of various countries allow the

use of the HP Bypass valves as safety valves When there is enough steam production to

for the HP part of the boiler without any reach a predetermined minimum pressure

additional conventional safety valves on the (pmin) the controller begins to control the

HP side. for this the HP Bypass has to be live steam pressure by opening the bypass

equipped with a hardwarewise fully valves.

independent safety system. Functionally this

system is fully integrated into the bypass When the valve positions reach a

controller to ensure smooth transients predetermined value Ym (determined by the

between safety and control function. desired steam flow during boiler start up) the

setpoint generator begins to increase the

Main Steam Line

pressure setpoint in accordance with the

HP Turbine

PT PS PS PS steam production of the boiler, but with a

1/3 limited maximum gradient.

Safety

System

YT

OP! BPE1 BD1 Setpoint PT

BP1

Generator Pressure

OP! YT BPE2 BD2 Controller

Pressure BP2

Controller Rate Limiter

C Ym

TT Temperature RTL M

Controller A SCO M

X A

X

TT

Reheater

S

Cold Reheat Line C YT

PS

PT Pressure Transmitter C C Ymin

TT Temperature Transmitter

YT Position Transmitter Pmin p

PS Pressure Switch

start up follow

Figure 2 HP-Bypass System with Safety Function

(two line system)

Basic control diagram

Operating modes: pressure control (fixed pr. Ps)

start up

Figure 2 shows the main elements of a two follow (Bypass closed)

line HP bypass with the main control C fixed value S set value

functions:

Figure 3 HP-Bypass pressure controller

• pressure controller

• temperature controller

• injection water isolation valve control

• safety function

640/30.04.04/Ri D1_HDNDe 2/4

Pressure/Load/Flow

%

factor for the heavily stressed walls of the

100 valves and piping.

80 3. LP bypass controller

Ymin Pmin Start up press. follow

contr.

60

The Sulzer LP bypass controller is an

40 integrated system with the functions signal

SH

conditioning, control and valve positioning

Pressure

20 Turbine

Load

(Figure 5). The type of operator interface

Steam

Flow can be tailored to the needs of the individual

Time plant. With a few standardized interface

Valve position

signals the Sulzer bypass controller can be

% tied easily into an overall plant automation.

100

Although independent in operation from the

50

Ym HP bypass controller the LP bypass

Ymin

controller must operate in conjunction with

Time

the HP Bypass system and allow the excess

steam flow which is not admitted to the

Figure 4 Cold start up with HP-Bypass

turbine to pass to the condenser.

Once the target pressure for starting the

turbine (psynch) is reached, the setpoint PT RH RH

PT PT TT

generator switches to (fixed) pressure

control. As the turbine starts to accept steam

the bypass will start to close until the turbine

consumes all the steam produced by the (Option)

boiler and the bypass is fully closed. Signal Conditioning

As soon as the bypass is closed the pressure Setpoint Generation Operator

setpoint tracks the actual pressure plus a Control

Interface

threshold dp which keeps the bypass closed

(follow mode). The maximum gradient of the Valve Positioners

pressure setpoint is still limited. If the life

steam pressure exceeds this gradient, the

bypass will start to open and the controller

returns to pressure control mode. The

pressure is controlled by the bypass until LPI1 LPI2 LP1 LP2 LPE1 LPE2

normal operation has been restored and the

bypass is closed again. Figure 5 LP-Bypass controller (2 lines)

2.2 Temperature control

3.1 Pressure Control

Regarding temperature control it should be

mentioned here only that accurate control of The duty of the LP bypass pressure

the steam temperature under all operating controller for the different operating modes

conditions requires a controller well matched can be summarized as follows:

to the wide range of operating conditions of

a HP bypass (low load, quick opening at full

load, etc.). Accurate control of the

temperature under all this operating

conditions is an important life conserving

640/30.04.04/Ri D1_HDNDe 3/4

• Boiler start up If power operated reheater safety valves are

The controller has to control the steam provided (e.g. Sulzer MSV valves),

pressure in the reheater system. The coordinated operation of the reheater safety

injection controller has, when ever the LP valves with the LP bypass can further

bypass is open, to control the desuperheating improve plant operation for the case of

of the steam so that it can be accepted by the turbine trip or load rejection at high load.

condenser. The Sulzer LP bypass controller can provide

the necessary signals for operation of the

• Load operation reheater safety valves.

The bypass is closed but the controller 3.2 Injection water control

monitors the reheat steam pressure in order

to open and control the pressure whenever Because the steam conditions after the LP

an unacceptable pressure increase is bypass desuperheater are usually near or at

monitored. saturation condition, the temperature after

the desuperheater cannot be used as control

• Condenser protection signal. The necessary injection water flow

Whenever the condenser is not able to accept and valve position of the injection valve

the steam or the injection water system is must therefore be calculated from the steam

unavailable, the controller has to close the flow and steam conditions. The steam flow

bypass through a separate safe channel in is in turn a function of the steam conditions

order to protect the condenser. and the valve position of the bypass valve.

The LP bypass controller provides the

HP Turbine

necessary computing functions to perform

this calculations and uses the calculated

Reheater

injection water demand as setpoint for the

water flow controller.

LP-Bypass

PT TT isolating valves

1st stage pr. Cond.

PT protection

PT T RH

F LP-Bypass

control valves

Setpoint Pressure YT

generator Controller

T RH YT

P RH P RH C

FT

C

FT

PT

Condenser

Figure 6 LP-Bypass system (2 lines)

Basic control diagram

During load operation the first stage pressure

of the turbine serves as load signal for the

setpoint generator which generates a load

dependent (sliding) pressure setpoint.

With large bypass valves, their flow capacity

at high reheater pressure can exceed the

absorption capacity of the condenser. For

such cases the steam flow to the condenser

must be limited by the bypass controller.

640/30.04.04/Ri D1_HDNDe 4/4

Functional description

Function description HP Bypass control

1. Overview (Diagram D)

The HP-Bypass Controller consists of the following parts

Pressure setpoint generation (Diagrams DA/RA)

Pressure controller (Diagram DB/TB)

Temperature controller (Diagram DC)

Spraywater isolation control (diagram DF)

2. Pressure setpoint generation

2.1 Startup

2.1.1 Mode Selection (Diagram RA)

The “startup mode” is set by the operator or by the signal “Boiler fire on” from the

DCS. When the “startup mode” is selected, the setpoint generator can be in three

different operating conditions:

• min pressure

• pressure ramp

• restart

The “min pressure” is active whenever the main steam pressure is below “Pmin”.

The “pressure ramp” is active when the main steam pressure is above “Pmin” and

below “Psync”.

The “restart” is active when the pressure is above “Pmin” and the BP valve is closed.

The signal “start sequence” is generated when the operating “min pressure” or

“pressure ramp” is on.

The “startup mode” is deselected as soon as the pressure reaches “Psync” and the BP

valve is open. The “startup mode” is also deselected when the signal “HP Turbine

loaded” is active or when the pressure controller is switched to manual.

The “fixed pressure mode” is active when the “startup mode”, the “follow mode “ and

the “shut down mode” is not active.

The “follow mode” is active when the BP valve is closed and the DEH signal “HP

Turbine loaded” is on or the DCS signal “Boiler fire on” is off . or when the. Further

the “Follow mode” is on when BP controller is in manual.

0640/06.12.04 Bi HP_Bypass.doc 1/5

Rev. 0

Functional description

2.1.2 Setpoint Generator (Diagram DA)

At startup, with no pressure in the boiler the setpoint generator is in the “min pressure”

condition. The pressure setpoint “Ps actual” is then set at pressure value “Pmin”. And

the pressure controller open the BP valve to a minimum position value “Ymin” (see: 3.

Pressure Controller).

As soon as the main steam pressure is above “Pmin” the “pressure ramp” condition is

activated. The pressure setpoint “Ps demand” is increased, whenever the BP valve

position “Yset” exceed the position value “Ym”. The increase of the pressure setpoint

is limited by the gradient limiter and only positive pressure gradient are allowed

during “pressure ramp” operation, decrease of the pressure setpoint “Ps actual” is not

permitted in this operation mode.

As soon as the main steam pressure reaches “Psync” the “startup mode” is deselected

and the “fixed pressure mode” is activated. The pressure setpoint “Ps demand” is set at

the current last pressure setpoint “Ps actual”. In “fixed pressure mode” the “Pressure

setpoint” can be adjusted by the operator.

When the “HP turbine loaded” the BP valve will close automatically due to pressure

drop. As soon the BP valve is closed the setpoint generator will switch over to “follow

mode” (see: 2.2 Load Operation). In this mode pressure setpoint “Ps actual” will

follow main steam pressure.

In case of pressurized boiler at startup the “restart” condition is selected while the BP

valve is closed. In the “restart” condition the pressure setpoint “Ps actual” is following

the main steam pressure but only negative pressure gradients are allowed. As soon as

the boiler pressure starts to increase the bypass valve will start to open. When the BP

valve open the setpoint generator will go to “pressure ramp” condition if the pressure

is still below “Psync” or to “fixed pressure mode” if the pressure at startup is already

above “Psync”.

P re s s u r e / L o a d / F lo w

100 % S ta rt S e q u e n c e .

Turbine on

M in P re s s u re F ix e d

80 % P re s s Ram p P r e s s u re . F o llo w

60 %

40 % P sync S H -P r e s s u r e P S H

T u r b in e L o a d

20 %

S t e a m F lo w

P m in

F ire o n T im e

T u rb in e lo a d e d

B P v a lv e

100 %

Y BP

50 %

Ym

Y m in

T im e

0640/06.12.04 Bi HP_Bypass.doc 2/5

Rev. 0

Functional description

2.2 Load Operation (Diagram /DA/RA)

During load operation, i.e. when the HP turbine is taking over all the produced steam,

the bypass valves are closed. The “follow mode” is activated.

In the “follow mode” the pressure setpoint “Ps actual” is following the actual main

steam pressure. The maximum pressure gradient is limited, depending on the actual

main steam pressure. A differential pressure “dP” is added to the pressure setpoint “Ps

actual” to keep the BP valve closed (see: 3. Pressure Controller).

If the main steam pressure is increasing above the Bypass controller setpoint “Ps

actual + dP” the BP valve starts to open. The setpoint generator is switched over to

“fixed Pressure mode”.

D e s ig n P re s s u re (P m a x + d P m a x )

P re s s .

M a x . P re s s u re (P m a x )

B yp a s s fa s t o p e n in g

(P s a c tu a l + d P m a x )

B yp a s s C o n tro lle r S e tp o in t

(P s a c tu a l + d P )

P re s s u re s e tp o in t

(P s a c tu a l)

M o d ifie d S lid in g P re s s u re

Load

2.3 Shut down

2.3.1 Mode selection (Diagram RA)

When a plant shutdown is planned the “Shut down mode” can be selected by the

operator. The “Shut down mode” can only be selected when the DEH signal “HP

Turbine loaded” is active and the BP controller is on auto. As soon as the DEH signal

“HP Turbine loaded” is deactivated the “Shut down mode” is deselected and the

setpoint generator change to “fixed pressure mode”.

When the boiler shuts down, the DCS signal “Boiler fire on” is deactivated, the BP

valve will close and the setpoint generator is switched to “follow mode”

0640/06.12.04 Bi HP_Bypass.doc 3/5

Rev. 0

Functional description

2.3.2 Setpoint Generator (Diagram DA)

At “Shut down mode” the pressure setpoint “Ps actual” is following the main steam

pressure but only negative gradients are allowed. As soon as the boiler pressure starts

to increase the BP valve start to open.

After the “Shut down mode” is deselected the setpoint generator is on “fixed pressure

mode”. At “fixed pressure mode” the setpoint generator controls the actual pressure.

As soon the boiler shuts down the BP valve is closing and the pressure generator is

switched to “follow mode”. In “follow mode” the pressure setpoint will again follow

the actual main steam pressure.

P re s s u re / L o a d / F lo w

100 %

F o llo w Shut

F ix e d

m ode down

p re s s u re F o llo w m o d e

80 % m ode

P r e s s .-S e tp o in t

60 %

M a in S te a m P r e s s u r e

40 %

S te a m F lo w

20 % T u r b in e L o a d

T u rb in e o ff F ire o ff T im e

B P v a lv e

100 %

Y BP

50 %

3. Pressure Controller (Diagram DB)

The pressure controller is receiving the actual main steam pressure signal and the

pressure setpoint “Ps actual” from the setpoint generator. It is generating the BP valve

position demand signal.

The pressure controller has one M/A station to control the BP valve.

At signals “BP open “ the BP valve will open to 100%. During this signal controller is

set manual and follow the valve position. After the signal the controller set automatic

At signal “BP close trip” the BP valve will be closed by the close command signal to

to the valve. The controller is set to manual.

0640/06.12.04 Bi HP_Bypass.doc 4/5

Rev. 0

Functional description

In “follow mode” when the “dP on” is active a differential pressure is added to the

pressure setpoint “Ps actual” to keep BP valve close.

At “startup mode” when the “min pressure” condition is active the BP valve are

opened to a minimum position “Ymin”. The “Ymin on“ is deselcted when position is

above the minimum position “Ymin”.

4. Fast open / close logic (Diagram TB)

The “BP open” command for the BP valve is generated from DEH signals “Turbine

trip” or “Generator switch trip” or when the main steam pressure has reached the

quick opening pressure threshold “dp max” above the pressure setpoint “Ps actual”.

The “BP open” is blocked when pressure is below the pressure “Pfo” and the “startup

sequence” is active or when the “BP close trip “ is active.

The “BP close trip” command is generated when the BP outlet temperature exeed the

pressure “Tmax”.

5. Temperature control (Diagram DC)

The temperature controller is receiving the actual signal “HP-BP outlet temperature”

from the transmitter and the “Temp setpoint“ set by the operator. The controller is

generating the spraywater valve position demand signal.

The feed forward signal is generated from “Main steam pressure” and BP valve

position and is added to the valve position demand signal. With the adjustable value

“wpl” the feed forward signal can be adapted.

The temperature controller has one M/A station to control the sprayvalve BPE valve.

The temperature controller is set automatic mode as soon the BP valve is open.

When the BP valve closes the spraywater valve closes also, and the temperature

controller is set to manual.

6. Spraywater isolation valve control (Diagram DF)

The spraywater isolation valve is open as soon the BP valve is open. When the BP

valve is closed the spraywater isolation valve is closed again.

0640/06.12.04 Bi HP_Bypass.doc 5/5

Rev. 0

Functional description

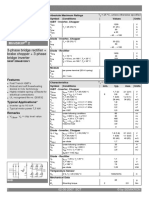

Parameter list HP Bypass control

Function DWG Unity Denom. Default Definition/Description

Minimum pressure /DA [Mpa] Pmin 1 Min. range of pressure set point

Maximum pressure /DA [Mpa] Pmax 20 Max. range of pressure set point

Syncronisation /RA [Mpa] Psync 8 Minimum pressure, at which

pressure turbine can be started and

syncronised

Fast opening release /TB [Mpa] Pfo 15 General release for fast opening

pressure

Pressure gradient /DA [Mpa] P1 5 Fixed point 1 for Gradient

/DA [Mpa] P2 6 Fixed point 2 for Gradient

/DA [Mpa/min] GRD1 0.4 Gradient 1 f(P1)

/DA [Mpa/min] GRD2 1.2 Gradient 2 f(P2)

/DA [Mpa/min] GRD3 0.2 Gradient 3

Gradient in „min pressure“

/DA [Mpa/min] GRD4 0.2 Gradient 4

Gradient in „pressure ramp“

/DA [Mpa/min] GRD5 0.4 Gradient 4

Gradient in„restart“

/DA [Mpa/min] GRD6 0.6 Gradient 4

Gradient in ”shut down”

Fast opening /TB [Mpa] dp max 0.5 Control deviation fast opening

P steam high

Follow up /DB [Mpa] dP 0.5 Additional dP to the setpoint to

produces a neg. control deviation

to keep the valve closed

Minimum opening /DB [%] Ymin 10 Is set at „start up“

Medium opening /DA [%] Ym 30 Equilibrium in „pressure ramp“

at constant steam procuction

Feedforward /DC [-] wpl 0.5 Feed forward signal

0640/06.12.04 Bi HP_Para.doc 1/1

Rev. 0

Functional description

Function description LP Bypass control

1. Overview (Diagram D)

The LP-Bypass Controller consists of the following parts

Pressure setpoint generation (Diagrams DG)

Pressure controller (Diagram DH)

Condenser protection (Diagram DM)

Temperature controller (Diagram DK1/DK2)

Spraywater isolation control (Diagram DL)

2. Pressure setpoint generation (Diagram DG)

In the “min pressure” operation the turbine is not on load. The pressure setpoint “Ps

RHH actual” is set to the pressure “Pmin”. The minimum pressure setpoint can also be

increased by the operator if an higher setpoint is required.

At “load pressure” operation the pressure setpoint “Ps RHH actual” is generated from

the transmitter signal “Turbine 1st stage pressure”. The pressure setpoint “Ps RHH

actual” changes in function of the turbine load of the unit.

P re s s u re / L o a d / F lo w

100 %

80 % M in P re s s u re L o a d P re s s u re

60 %

40 % H o t re h e a t p re s s

P m in T u r b in e L o a d

20 %

S te a m F lo w

F ire o n T im e

T u rb in e lo a d e d

B P v a lv e

100 %

Y LBP

50 %

T im e

0640/06.12.04 Bi LP_Bypass.doc 1/3

Rev. 0

Functional description

3. Pressure controller (Diagram DH)

The pressure controller is receiving the actual hot reheat steam pressure signal (1 out

of 2 selection of two transmitter signals) and the pressure setpoint “Ps RHH actual”

from the setpoint generator. It is generating the LBP valves position demand signal.

Each LBP valve has one M/A station.

At signal “LBP close trip” from condenser protection the LBP valves will be closed by

the close command to the valves and the controller is set to manual.

The PI controller is set to manual when both LBP valves are set to manual. The

controller then is tracking the max valve position.

The maximal LBP valve opening is limited by the steam flow to the condensator. As

soon the “LBP steam flow” the LBP valve start to close.

4. Condenser protection (Diagram /DM)

The “LBP close trip” command for the LBP valve is generated from condenser

protection switches. Each one of the following criteria are activating the “LBP close

trip” command:

- Condenser press. high (2 out of 3)

- Condenser temp. high

- Condenser level high

- LBP spraywater pressure low.

5. Temperature controller (Diagram /DK1/DK2)

The temperature controller is receiving the actual signal Fw “LBP spraywater flow”

from the transmitter. The spraywater setpoint Fws is calculated out of the steam

pressure, steam temperature and LBP valve position . The controller is generating the

spraywater valve position demand signal.

The temperature controller has one M/A station to control the sprayvalve LP-BPE

valve.

The temperature controller is set to automatic mode as soon the LBP valve is open.

When the LBP valve is closed the spraywater valve is also closed, the controller is set

to manual.

6. Spraywater isolation valve control (Diagram DL)

0640/06.12.04 Bi LP_Bypass.doc 2/3

Rev. 0

Functional description

The spraywater isolation valve is open as soon the LBP valve is open. When the LBP

valve is closed the spraywater isolation valve is closed again.

0640/06.12.04 Bi LP_Bypass.doc 3/3

Rev. 0

Functional description

Parameter list LP Bypass control

Function DWG Unity Denom. Default Definition/Description

Pressure setpoint /DG [Mpa] Pmin 0.2 Min. range of pressure set point

/DG [Mpa] Pmax 5 Max. range of pressure set point

/DG [MPa] P1 0 Fixed point 1 for Setpoint

/DG [MPa] P2 20 Fixed point 2 for Setpoint

/DG [MPa] Ps1 0 Setpoint 1 Ps = f(P1st)

/DG [MPa] Ps2 5 Setpoint 2 Ps = f(P1st)

Calculation of /DK [m3/h] kvs kv at 100% valve stroke

Spraywater /DK [KJ/Kg] Ew Enthalpy spraywater

/DK [KJ/Kg] Ek Enthalpy steam after LBP

0640/06.12.04 Bi LP_Para.doc 1/1

Rev. 0

You might also like

- Closed Cooling Water System (Sample)Document37 pagesClosed Cooling Water System (Sample)shahida100% (2)

- Bypass ControllerDocument4 pagesBypass Controllernjc6151100% (2)

- AV6+ BypassGeneralDescriptionDocument14 pagesAV6+ BypassGeneralDescriptionGaurav ChauhanNo ratings yet

- HP-LP Bypass System AdvantagesDocument3 pagesHP-LP Bypass System Advantageskaruna346100% (1)

- HP-Bypass and LP BypassDocument3 pagesHP-Bypass and LP Bypassdinesh7136100% (2)

- Turbine Bypass SystemsDocument10 pagesTurbine Bypass SystemsZaqPoilm100% (1)

- Seal Oil PresentationDocument10 pagesSeal Oil Presentationjeromejoe100% (1)

- Sliding Pressure Control BasicsDocument4 pagesSliding Pressure Control BasicsUdhayakumar VenkataramanNo ratings yet

- HP LP Bypass System: Ravi Pal SinghDocument36 pagesHP LP Bypass System: Ravi Pal SinghMinh Hoang NguyenNo ratings yet

- DEH PresentationDocument37 pagesDEH PresentationPRAMOD KUMAR NANDA100% (2)

- Lube Oil SystemDocument4 pagesLube Oil SystempawangwlNo ratings yet

- HP Bypass SystemDocument21 pagesHP Bypass SystemShameer Majeed100% (1)

- Thermal Plant Control Instrumentation IIDocument29 pagesThermal Plant Control Instrumentation IIpradeep1987cool100% (1)

- De Super HeaterDocument27 pagesDe Super HeaterShivam Mannan MishraNo ratings yet

- Turbine Stress Evaluator: 17 February 2018 PMI Revision 00 1Document23 pagesTurbine Stress Evaluator: 17 February 2018 PMI Revision 00 1NILESHNo ratings yet

- HP Feed WaterDocument13 pagesHP Feed WaterAxlejunz Dublin RondinaNo ratings yet

- Introduction To Steam Seal System of 800Mw Kudgi TurbineDocument10 pagesIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800100% (2)

- Auto Loops TVNLDocument144 pagesAuto Loops TVNLRajeevAgrawal100% (1)

- Governing 11Document35 pagesGoverning 11rahul100% (2)

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- HindalcoDocument28 pagesHindalcoSiddhant Satpathy100% (1)

- Turbine Bypass System - HORADocument11 pagesTurbine Bypass System - HORAhozipek100% (2)

- Turbine Governing SystemDocument77 pagesTurbine Governing SystemGrishma Warke100% (2)

- HPBPDocument14 pagesHPBPrnumesh1100% (1)

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- Schemes TalcherDocument206 pagesSchemes TalcherSam100% (1)

- Turbine Control and Efficiency ImporovementDocument6 pagesTurbine Control and Efficiency ImporovementUdhayakumar Venkataraman100% (2)

- Bhel Steam Turbine Description-1Document2 pagesBhel Steam Turbine Description-1Srinivasa Rao Pallela100% (1)

- Seal Oil and Hydrogen SystemDocument34 pagesSeal Oil and Hydrogen Systemashish_ntpc100% (1)

- Automatic Turbine Runup System Gyanendra Sharma NPTI DelhiDocument32 pagesAutomatic Turbine Runup System Gyanendra Sharma NPTI DelhiNPTI100% (3)

- C&I Part of SCDocument28 pagesC&I Part of SCSam100% (3)

- Protection and InterlocksDocument47 pagesProtection and InterlocksRavi kant Ghatoye100% (1)

- Auto Control Loops PresentationDocument106 pagesAuto Control Loops PresentationMohammad Ibnul Hossain100% (1)

- Steam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestDocument10 pagesSteam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestAakash Ranjan100% (2)

- Npti 20072010Document19 pagesNpti 20072010Sai SwaroopNo ratings yet

- Feed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam AccumulatorsDocument74 pagesFeed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam Accumulatorsbanukiran sambojuNo ratings yet

- Generator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Document32 pagesGenerator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Praveen Jagadev100% (4)

- CRH Drain Pot LevelDocument30 pagesCRH Drain Pot LevelBibhash SinghNo ratings yet

- Ing The Starting Device To Zero: M.S. Pr. 35-40 Ksc. HRH Pr. 12-14 Ksc. M.S. and HRH Tempr. - 320 To 3500C)Document3 pagesIng The Starting Device To Zero: M.S. Pr. 35-40 Ksc. HRH Pr. 12-14 Ksc. M.S. and HRH Tempr. - 320 To 3500C)Sourav SahaNo ratings yet

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pages020-SOP of H2 CYLINDER Room ChargingsambhuNo ratings yet

- Ammonia Dosing at The Electrostatic Precipitator (ESP) Inlet Is A Technique Used For Reducing The Emission of Fine Particulate Matter, Particularly in Coal-Fired Power Plants and Industrial ProcessesDocument3 pagesAmmonia Dosing at The Electrostatic Precipitator (ESP) Inlet Is A Technique Used For Reducing The Emission of Fine Particulate Matter, Particularly in Coal-Fired Power Plants and Industrial ProcessesYadbir singhNo ratings yet

- 20mw Operation ManualDocument55 pages20mw Operation Manualaakash srivastavaNo ratings yet

- Turbine and AuxiliariesDocument65 pagesTurbine and AuxiliariesSwadhin Kumar Das100% (3)

- 660 MW Vs 500 MWDocument7 pages660 MW Vs 500 MWKrishnan SanthanarajNo ratings yet

- Safety Valve Floating MrthodDocument4 pagesSafety Valve Floating MrthodSanjay Chakraborty100% (1)

- BHEL Turbine Start-UpDocument17 pagesBHEL Turbine Start-UpSelvakumar SubramanianNo ratings yet

- Soot BlowersDocument264 pagesSoot BlowersNitin Sen100% (1)

- C&I WriteupDocument137 pagesC&I WriteupSayan AichNo ratings yet

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984100% (1)

- Write Up On LPBP SystemDocument9 pagesWrite Up On LPBP SystemKhushboo PandeyNo ratings yet

- Delay in Opening of LP Bypass ValveDocument94 pagesDelay in Opening of LP Bypass ValveCharu ChhabraNo ratings yet

- HPBP DrawingDocument1 pageHPBP DrawingLakshmi NarayanNo ratings yet

- Bhel LP-HP Bypass OrderDocument32 pagesBhel LP-HP Bypass OrderGiriDharanNo ratings yet

- Technical Feedback EhtcDocument9 pagesTechnical Feedback EhtcPrashant Kumar ChoudharyNo ratings yet

- Closed Feed Water HeatersDocument56 pagesClosed Feed Water HeatersAnudeep ChittluriNo ratings yet

- Lecture On ATRS & Speed-Load ControlDocument44 pagesLecture On ATRS & Speed-Load Control06nikhil100% (3)

- Steam Turbine Governing Systems OverviewDocument11 pagesSteam Turbine Governing Systems Overviewdrmsrmurty83% (6)

- HP & LP Bypass System - Steam Turbine Power PlantDocument4 pagesHP & LP Bypass System - Steam Turbine Power Plantamer_arauf100% (14)

- Sachin Governing System or DEHDocument38 pagesSachin Governing System or DEHNaveen100% (1)

- Manual Steering EngDocument24 pagesManual Steering Engghiocel apinteiNo ratings yet

- QAP For Branch Pipe With NozzleDocument2 pagesQAP For Branch Pipe With NozzleMohit GohilNo ratings yet

- Leave Balance Feb 2022Document2 pagesLeave Balance Feb 2022Mohit GohilNo ratings yet

- Minimum Disclosure Norms For Colleges of Higher Education: Shantilal Shah Engineering College, BhavnagarDocument17 pagesMinimum Disclosure Norms For Colleges of Higher Education: Shantilal Shah Engineering College, BhavnagarMohit GohilNo ratings yet

- Bhensala Rutvik Email: Contact No: 9016151418: Archean Chemical Industries Private LTDDocument3 pagesBhensala Rutvik Email: Contact No: 9016151418: Archean Chemical Industries Private LTDMohit GohilNo ratings yet

- Prandtl's Boundary Layer TheoryDocument6 pagesPrandtl's Boundary Layer TheoryMohit GohilNo ratings yet

- Shantilal Shah Engineering College, BhavnagarDocument2 pagesShantilal Shah Engineering College, BhavnagarMohit GohilNo ratings yet

- OK.2019.Switchyard LayoutPGDC+Qs 16Document28 pagesOK.2019.Switchyard LayoutPGDC+Qs 16Mohit GohilNo ratings yet

- Final Demo Natural ResourcesDocument16 pagesFinal Demo Natural ResourcesStephany Mae CanoyNo ratings yet

- Study List and TT Yr 4 GR 3Document5 pagesStudy List and TT Yr 4 GR 3marks2muchNo ratings yet

- 11aug2023131058 Esiareport VDP, Thy, Mt&Pzugss1108Document275 pages11aug2023131058 Esiareport VDP, Thy, Mt&Pzugss1108akhilaggarwalNo ratings yet

- 2 D ℜ= 2.0 log 3.7 D + 2.51 ℜ + 1 = 0: ∆ P=f Lρ V Ρ Vd μ ε f fDocument5 pages2 D ℜ= 2.0 log 3.7 D + 2.51 ℜ + 1 = 0: ∆ P=f Lρ V Ρ Vd μ ε f ftennerNo ratings yet

- Brain Gut Connection: Anil K. RajvanshiDocument2 pagesBrain Gut Connection: Anil K. RajvanshijulfukarNo ratings yet

- Aphasia in Left HandersDocument2 pagesAphasia in Left Handerskeihoina keihoinaNo ratings yet

- Castillo2020 Bayesian Predictive Optimization of Multiple and Profile Responses Systems in IndustryDocument18 pagesCastillo2020 Bayesian Predictive Optimization of Multiple and Profile Responses Systems in IndustryAngel GarciaNo ratings yet

- Psychology Mid-TermDocument6 pagesPsychology Mid-TermSyed Aman BukhariNo ratings yet

- 0001Document7 pages0001ag_f53No ratings yet

- Seal of Good Local GovernanceDocument46 pagesSeal of Good Local GovernanceKyza Mae AlcontinNo ratings yet

- Term 2 ProjectfinalDocument19 pagesTerm 2 ProjectfinalRahul RoopchandNo ratings yet

- Solvent Promoted Self HealingDocument3 pagesSolvent Promoted Self HealingVansala GanesanNo ratings yet

- Admmodule s11 12ps Iiib 12Document11 pagesAdmmodule s11 12ps Iiib 12Lebz RicaramNo ratings yet

- Rashtrasant Tukadoji Maharaj Nagpur UniversityDocument1 pageRashtrasant Tukadoji Maharaj Nagpur UniversityAkash RautNo ratings yet

- Holt California Algebra 1 Homework and Practice Workbook AnswersDocument5 pagesHolt California Algebra 1 Homework and Practice Workbook Answersafmtcbjca100% (1)

- CHANGES TO BLOOMs TAXONOMYDocument23 pagesCHANGES TO BLOOMs TAXONOMYMi Yu KeyNo ratings yet

- Fermentation: Bio Lab ManualDocument11 pagesFermentation: Bio Lab Manualthegp12No ratings yet

- Tooling Guide For High Reliability Electrical Systems Rev. 11 Ver. 1Document202 pagesTooling Guide For High Reliability Electrical Systems Rev. 11 Ver. 1AndersonNo ratings yet

- 3D Seismic Survey FOR Ratawi Oil Field Area in Southern IraqDocument39 pages3D Seismic Survey FOR Ratawi Oil Field Area in Southern IraqAkhilaNo ratings yet

- Behaviorist and Learning Aspects of PersonalityDocument24 pagesBehaviorist and Learning Aspects of Personalitydurubelsan02No ratings yet

- Gri Adis 2022Document79 pagesGri Adis 2022amellgothiqueNo ratings yet

- Iqbal's Concept of KhudiDocument4 pagesIqbal's Concept of KhudiJay Dee11No ratings yet

- Carta 2003Document112 pagesCarta 2003Oliver SANCHEZNo ratings yet

- How To Use This Module: Module 6: Developing A Business PlanDocument17 pagesHow To Use This Module: Module 6: Developing A Business PlanYejira KionNo ratings yet

- Non-Verbal Communication in SpainDocument20 pagesNon-Verbal Communication in SpainDarina PiskunovaNo ratings yet

- DTL Summer Training ReportDocument63 pagesDTL Summer Training ReportARYAN ANo ratings yet

- Construction Project Management 101 - ChecklistDocument5 pagesConstruction Project Management 101 - ChecklistUsman ShahidNo ratings yet

- Converter, Inverter, Brake: Skiip 23Nab126V1Document4 pagesConverter, Inverter, Brake: Skiip 23Nab126V1Danish ShahNo ratings yet

- An Assignment ON Differential Scale: Submitted To:-. Submitted By:-Jr. LecturerDocument3 pagesAn Assignment ON Differential Scale: Submitted To:-. Submitted By:-Jr. LecturerPriyaNo ratings yet

- 1 Question Bank For Unit 1Document11 pages1 Question Bank For Unit 1Ajay KareNo ratings yet