Professional Documents

Culture Documents

CT Coveyed Perforating

CT Coveyed Perforating

Uploaded by

Adel Ahmed AlkhaligyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CT Coveyed Perforating

CT Coveyed Perforating

Uploaded by

Adel Ahmed AlkhaligyCopyright:

Available Formats

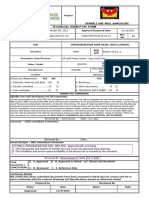

Recommended Practice: Perforating Page 1 of 4

Alaska Drilling and Wells

Recommended Practice: CT Conveyed Perforating

Authority: CTD Manager Custodian: Drilling Representative

Document

Drilling and Wells

Drilling and Wells – CTD Control

Scope: Document Control

Operations Administrator

Specialist

:

Issue Date: December 1997 Issuing Dept: Drilling and Wells

Revision Date: June 01, 2002 Control Tier: Tier U

Next Review Date: June 01, 2005

1.0 Purpose/Scope

Cemented CTD liners are perforated using coil conveyed carrier guns. Typically, 2-7/8” liners

will be perforated using 2” diameter hollow carriers, while 2-3/8” liners are perforated with 1-

11/16” carrier guns. The perforating is done in an over balanced condition in clean flo-pro mud

utilizing a pressure activated firing head.

2.0 Definitions

PBTD – plug back depth

CNL/GR – compensated neutron/gr (log)

3.0 General Requirements

N/A

4.0 Key Responsibilities

N/A

5.0 Procedure/Process

SCOPE AND BACKGROUND

Because all rig personnel will be in the vicinity of explosives, a comprehensive safety meeting

should be held prior to any perforating operation and during the operation as personnel or

objectives change. These meetings should include the following items:

1. Identify all people on site, introduce the Perforating Specialist, and discuss pick up, make up,

and lay down procedures.

2. Rough handling of guns could result in poor performance of the gun system. The guns are

fired using percussion detonators, not electrical detonators, and radio silence is not needed.

No welding or open flame is permitted around the guns.

3. Keep non-essential personnel away while assembling guns. Establish personnel assignments.

The cellar is to be kept clear whenever guns are above ground level, both going in and out of

the hole. Rig entrances should be posted with appropriate warning signs during perforating

operations.

4. Gun assembly will be done with the rig crew and with the Perforating Specialist’s assistance

and supervision. Exercise caution when removing thread protectors and installing lifting

subs. Trapped pressure precautions will be used when breaking out guns. Use appropriate

Control Tier: 4 – ADW Revision Date: 06/01/02

Document Number: UPS-US-AK-ADW-CTD-HSE-DOC-00023-4 Print Date: 08/13/02

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE

CONTROLLED VERSION OF THIS DOCUMENT CAN BE FOUND AT http://alaska.bpweb.bp.com/ems

Recommended Practice: Perforating Page 2 of 4

handling equipment: dog collar, slips, and elevators. The Perforating Specialist will provide

lifting subs.

5. H2S risk from the well and from the guns.

6. Well control issues.

7. Establish safe pump pressures and rates. Identify all hazards going in the hole. Liner tops,

tight spots, windows, dog legs, PBTD, and so forth. Determine connection from firing head

to BHA and the correct ball size and type to be used. Verify that disconnect ball sizes are

compatible with firing head ball size.

PRE-JOB PLANNING AND GUIDELINES

At the start of each well, contact the perforating service company with an estimate of interval,

gun and charge type. Once the well is at TD, determine final perf picks, and give the service

company the latitude of meeting the picks plus or minus a few feet. If cased hole logs show

significant depth discrepancies, or the liner does not reach TD, be prepared to remove guns from

the “bottom” end to eliminate incurring substantial gun reconfiguration down time. For

deviations from normal operations, planning may be required weeks or even months before the

operation commences. Discuss contingencies as early as possible. Also:

1. The service company will provide a detailed tool string diagram. All equipment will be

strapped and calipered.

2. Drifting the work string is recommended to ensure the passage of the largest disconnect ball.

3. Clean fluids are a must. 1% or 2% KCL should be used. The pits should be cleaned while

displacing to KCL water prior to cementing. Cement or other debris could cause the firing

ball to remain off seat. It is possible that junk or debris landing on seat, combined with high

pump rates could accidentally fire the guns.

BHA

Bullnose

Hollow carrier guns (loaded and blank)

Safety spacer (to keep live guns below floor when installing firing head)

Firing head

Lower hyd disconnect

Work string as required

Upper hyd disconnect

Check valve

Non-rotating joint

CTC

Be certain to pick up enough work string to prevent tagging the liner top with the work string

before the guns contact PBTD. An extra 100’ or so is recommended.

STEP-BY-STEP PROCEDURE

1. Load pipe shed with guns after initial safety meeting . Compare the gun layout to original

picks and to the guns themselves. Have a safety joint prepared with a TIW valve and blank

firing head for rapid deployment for possible well control contingencies.

2. Hold another safety meeting with crew prior to discuss gun make up. Post the cellar off

limits. Pick up guns. Use correct dog collar, slips, elevators, and lift subs. Use fishable

lifting subs with “GS’ profiles while making up guns.

Make up the firing head.

Control Tier: 4 – ADW Revision Date: 06/01/02

Document Number: UPS-US-AK-ADW-CTD-HSE-DOC-00023-4 Print Date: 08/13/02

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE

CONTROLLED VERSION OF THIS DOCUMENT CAN BE FOUND AT http://alaska.bpweb.bp.com/ems

Recommended Practice: Perforating Page 3 of 4

3. Make up the disconnect. Drop the firing head ball through the disconnect before making it

up to ensure ball passes and will not operate the disconnect.

4. Run the work string. Note that all starts and stops with the pipe be smooth, do not set slips

while moving.

5. Pick up injector and make up disconnect to coil.

6. Make up injector and trip in hole. Circulation must be kept at minimum rate. Set pump

pressure trip to a value below firing head threshold. The perforating Specialist must be

present, and rate/pressure limits must be discussed. Trip in hole at normal speeds. Slow

down when entering and once inside liner, usually to 50 FPM or less.

7. Tag bottom lightly. Compare coil depth PBTD with that obtained from the cased hole

CNL/GR log. The “corrected” tag is used for depth control. Determine bottom at “pick up”

weight while slowly pulling off bottom. Pull up hole to place the guns on depth. Note:

Depth corrections/ bottom shot location can be made with up or down pipe movements, as

long as consistency is maintained.

8. Pump 5-10 bbls clean flo-pro into coil to replace that circulated up hole above firing head.

Drop ball. The reel position may have to be adjusted. Once ball is loaded, pressure up to

200-300 psi minimum and open reel valve to launch ball. Return guns to correct depth

Bring the pumps on line as per recommendation of Perforating Specialist. Listen for ball

inside reel house to verify launch. Note circulation rate and pressure.

9. At eight to ten barrels from calculated volume decrease rate to 0.5 to 0.75 BPM. When ball

goes on seat, RIH a few feet, then begin to POOH slowly. If possible, have the coil moving

very slowly up hole as guns fire to reduce the chance of debris or differential sticking.

Closely monitor coil pressure build up, followed by an abrupt drop off as guns fire. Firing

head is typically set to fire at 3000 pounds differential pressure. If the coil is not already in

motiong, be prepared to POOH immediately after guns fire. Circulation rate and pressure

should be different from that observed prior to shearing the firing head.

10. Trip out of hole at no more than 50 FPM while inside liner. The hole can be filled across the

top or down the coil. Closely monitor hole fill to avoid swabbing in well. Max safe pull

should be determined.

11. Pull injector, break out disconnect and stand back. Stand back work string. Stop with guns

below ground level and hold safety meeting. Flag cellar. Continue out of hole.

12. Break out disconnect. Remove firing head. Assume the guns have not fired until visual

verification is made. Trapped pressure can be encountered in any of the blank guns or

connectors. Only the Perforating Specialists should be present while laying down guns.

Have a safety joint prepared with a TIW valve and blank firing head for rapid deployment for

possible well control contingencies. Continue to monitor the fluid level in the well. Check

guns for misfires and abnormal swelling.

13. Remove the guns from pipe shed.

CONTINGENCIES

The ball may not seat after pumping the calculated displacement volume. It is possible that the

ball is trapped in the coil or that debris is blocking the ball seat. The contingencies for this are

as follows: (1) Pump another CT volume; (2) Pump another ball; (3) Pump at max

pressure/rate to create differential across seat to shear firing head. If guns will not fire, discuss

other contingencies with Anchorage drilling team before POOH. When pumping at max

rate/pressure, it may be very difficult to determine if guns have fired by pressure indications

alone.

Control Tier: 4 – ADW Revision Date: 06/01/02

Document Number: UPS-US-AK-ADW-CTD-HSE-DOC-00023-4 Print Date: 08/13/02

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE

CONTROLLED VERSION OF THIS DOCUMENT CAN BE FOUND AT http://alaska.bpweb.bp.com/ems

Recommended Practice: Perforating Page 4 of 4

6.0 Key Documents/Tools/References

Revision Log

Revision Date Approving Custodian/ Revision Details

Authority Author

December 1997 Original Issue

March 31, 1999 Drilling Manager John McMullen

June 01, 2002 Mark Stanley Gary Goodrich Updated to reflect current practices

<< Revision date >> << Approving << Author’s << Brief Description of Revision

Authority’s Name >> Name >> >>

(or, see attached e-mail )

Approving Authority signature Date

Control Tier: 4 – ADW Revision Date: 06/01/02

Document Number: UPS-US-AK-ADW-CTD-HSE-DOC-00023-4 Print Date: 08/13/02

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE

CONTROLLED VERSION OF THIS DOCUMENT CAN BE FOUND AT http://alaska.bpweb.bp.com/ems

You might also like

- Sub 01 012Document21 pagesSub 01 012ARYA JENA100% (1)

- Dynatech T56 Repair Capabilities ListDocument6 pagesDynatech T56 Repair Capabilities ListrizkyNo ratings yet

- Extended Length Perforating With CTDocument19 pagesExtended Length Perforating With CTMuhammad ShahrukhNo ratings yet

- Stabil Drill BrochureDocument27 pagesStabil Drill Brochuretrinhtu7No ratings yet

- WCP SopDocument71 pagesWCP SopDIEUDONNE MBAIKETENo ratings yet

- CT Intervention On Snake WellsDocument8 pagesCT Intervention On Snake WellsRamanamurthy PalliNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Perforation: Omega 2013Document73 pagesPerforation: Omega 2013Igbereyivwe TejiriNo ratings yet

- TDF DISPAROS HLBDocument88 pagesTDF DISPAROS HLBDanielStiglitzNo ratings yet

- Perforating SafetyDocument2 pagesPerforating SafetyMahmoud AbdelDayemNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Tubing-Conveyed PerforatingDocument2 pagesTubing-Conveyed PerforatingAhmed GharbiNo ratings yet

- Maxfire Electronic Firing Systems: Conveyance and Triggering OptionsDocument7 pagesMaxfire Electronic Firing Systems: Conveyance and Triggering OptionsGabriel GonzalezNo ratings yet

- Tools-Components Stimgun PDFDocument4 pagesTools-Components Stimgun PDFLuis Alfonso EstebanNo ratings yet

- EP Dyna EnergeticsDocument2 pagesEP Dyna Energeticssmithyry2014No ratings yet

- Case Hole PDFDocument11 pagesCase Hole PDFyazidNo ratings yet

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- Da13 DDR N1 14000104 191 0Document3 pagesDa13 DDR N1 14000104 191 0Hamed NazariNo ratings yet

- Completion (Natural Flow)Document3 pagesCompletion (Natural Flow)Mohammed Ali YoussefNo ratings yet

- GEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFDocument12 pagesGEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFSusin LimNo ratings yet

- LTK 70 01 003Document2 pagesLTK 70 01 003romeoleonNo ratings yet

- How To Drill A Usable HoleDocument30 pagesHow To Drill A Usable HoleMohamed Ahmed Aly100% (1)

- DPU Tubing Punch: Slickline Services Integrated Cased-Hole Services DPU ServicesDocument2 pagesDPU Tubing Punch: Slickline Services Integrated Cased-Hole Services DPU ServicesOleg MalkovNo ratings yet

- Rotary Bottom Hole Assembly: at The End of This Lecture, YOU Should Be Able ToDocument19 pagesRotary Bottom Hole Assembly: at The End of This Lecture, YOU Should Be Able Toburak kamaliNo ratings yet

- Chapter 3. Shale Shakers: Principle of OperationDocument34 pagesChapter 3. Shale Shakers: Principle of Operationkaleem ullah janNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- NLOG GS PUB 1483 Final Drilling ReportDocument120 pagesNLOG GS PUB 1483 Final Drilling ReportLuis David Concha CastilloNo ratings yet

- Da13 DDR N1 13991122 149 0Document3 pagesDa13 DDR N1 13991122 149 0Hamed NazariNo ratings yet

- Propellant Technology FAQ'S and RecommendationsDocument8 pagesPropellant Technology FAQ'S and RecommendationsCuenta InformacionNo ratings yet

- (Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During PerforatingDocument8 pages(Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During Perforatingjlbarretoa100% (1)

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- Whip Stock Procedure OMO 142Document15 pagesWhip Stock Procedure OMO 142Mino MinoNo ratings yet

- Cement Plugs Brochure PDFDocument4 pagesCement Plugs Brochure PDFveromesaNo ratings yet

- Kahraman C-181 (ST-1)Document3 pagesKahraman C-181 (ST-1)Islam AtifNo ratings yet

- Chapter 7perforationDocument81 pagesChapter 7perforationKarwan Ibrahim100% (1)

- CemNET Client PresentationDocument37 pagesCemNET Client PresentationLenin DiazNo ratings yet

- Dull Grading TriDocument15 pagesDull Grading TriCamilo SanchezNo ratings yet

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDocument2 pagesSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreNo ratings yet

- Cavins Double Action Tubing PumpDocument2 pagesCavins Double Action Tubing PumpHassan KhalidNo ratings yet

- HSE Perforation CTDocument21 pagesHSE Perforation CTOchulor IsaacNo ratings yet

- AEC DynamicsNewDocument42 pagesAEC DynamicsNewMuhammad Hamdy100% (1)

- General Overview of PerforatingDocument40 pagesGeneral Overview of PerforatingMahmoud RadwanNo ratings yet

- Programa Completo Completacion InicialDocument23 pagesPrograma Completo Completacion InicialAlejandro JaramilloNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Gas Lift ProductsDocument86 pagesGas Lift ProductshaudvNo ratings yet

- Rotary Cutters PDFDocument3 pagesRotary Cutters PDFAlleyson AkinNo ratings yet

- FINAL DP # 5 - 9 5-8 Casing TallyDocument5 pagesFINAL DP # 5 - 9 5-8 Casing TallydavoodazNo ratings yet

- How To PerforateDocument48 pagesHow To PerforateMostafa MAHMOUD KORTAMNo ratings yet

- SPE 81536 An Improved Method of Slickline PerforatingDocument4 pagesSPE 81536 An Improved Method of Slickline PerforatingAung Htet LingNo ratings yet

- Bod Serebrykovskaya-1 4341918 01Document67 pagesBod Serebrykovskaya-1 4341918 01Amlk MartinezNo ratings yet

- GAME PLAN RTTS RBP Wellhead WorkDocument1 pageGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaNo ratings yet

- 05 Trip Sheet - IPM - QuartzDocument7 pages05 Trip Sheet - IPM - QuartzRebarNo ratings yet

- Bit RecordDocument1 pageBit RecordstevebeardsleyNo ratings yet

- MudLog NEB-85 Scale 200 (130-5325 FT) - April 25th 2018Document30 pagesMudLog NEB-85 Scale 200 (130-5325 FT) - April 25th 2018parama drillingNo ratings yet

- Cementing Job Model 001Document6 pagesCementing Job Model 001islam atifNo ratings yet

- JarPro Jarring Analysis SoftwareDocument4 pagesJarPro Jarring Analysis Softwareeleceron7919No ratings yet

- Sand Pump Bailer - Flapper TypeDocument2 pagesSand Pump Bailer - Flapper TypeDias IrsaNo ratings yet

- Module 9 - Managed Pressure OperationsDocument20 pagesModule 9 - Managed Pressure Operationschristianleal123No ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- Well Control in CTD OperationsDocument6 pagesWell Control in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

- Window Milling - Mechanical Whipstock - Mill Single StringDocument5 pagesWindow Milling - Mechanical Whipstock - Mill Single StringAdel Ahmed AlkhaligyNo ratings yet

- Stuck Pipe in CTD OperationsDocument5 pagesStuck Pipe in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

- Plugbak Sidetracks - Open HoleDocument5 pagesPlugbak Sidetracks - Open HoleAdel Ahmed AlkhaligyNo ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Window Milling - Cement WhipstockDocument9 pagesWindow Milling - Cement WhipstockAdel Ahmed AlkhaligyNo ratings yet

- Alaska Drilling and Wells Recommended Practice: Lost CirculationDocument4 pagesAlaska Drilling and Wells Recommended Practice: Lost CirculationAdel Ahmed AlkhaligyNo ratings yet

- Stuck Pipe in CTD OperationsDocument5 pagesStuck Pipe in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- Off-Bottom Drilling PracticesDocument3 pagesOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNo ratings yet

- 1 - Water and Gas Coning-AHEDocument78 pages1 - Water and Gas Coning-AHEAdel Ahmed AlkhaligyNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- Logging While DrillingDocument37 pagesLogging While DrillingAdel Ahmed AlkhaligyNo ratings yet

- An Introductory Handbook On WDG4G Diesel Locomotive - FinalDocument208 pagesAn Introductory Handbook On WDG4G Diesel Locomotive - FinalVinay SharmaNo ratings yet

- ESSTOPIC-2.2-WORKBOOKDocument12 pagesESSTOPIC-2.2-WORKBOOKKalina DUDZIAKNo ratings yet

- Aug 55 XDocument15 pagesAug 55 XLoz LizNo ratings yet

- Surge Protection Technical Background and BasicsDocument22 pagesSurge Protection Technical Background and BasicsZainNo ratings yet

- Testing of InsulatorsDocument5 pagesTesting of InsulatorsEzekiel IyamuNo ratings yet

- Ensc 211 Bsabe 2 Midterm ExamDocument1 pageEnsc 211 Bsabe 2 Midterm Examfaithmark ceriacoNo ratings yet

- Hydrocracker Revamp Lifts Product FlexibilityDocument6 pagesHydrocracker Revamp Lifts Product FlexibilityJeffrey Ryan LindmarkNo ratings yet

- Diesel Power Plant Proposal, DUMAOPDocument44 pagesDiesel Power Plant Proposal, DUMAOPRyan DumaopNo ratings yet

- GN300 - DatasheetDocument2 pagesGN300 - DatasheetMinh Chí NguyễnNo ratings yet

- Table For RTD Pt100 (IEC 60751) : - 200 °C To 850 °CDocument1 pageTable For RTD Pt100 (IEC 60751) : - 200 °C To 850 °CRafael Bispo De Souza NetoNo ratings yet

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocument2 pagesToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix VelasquezNo ratings yet

- Experiment No - Measurement of ResistanceDocument5 pagesExperiment No - Measurement of ResistanceAppu ParoorNo ratings yet

- Mor 0002Document3 pagesMor 0002Trường Bửu TrầnNo ratings yet

- Tesla's Battery Supply Chain - A Growing ConcernDocument24 pagesTesla's Battery Supply Chain - A Growing ConcernbeyzakeklikNo ratings yet

- Spider Crane Inspection ReportDocument6 pagesSpider Crane Inspection ReportBishoo ShenoudaNo ratings yet

- Tourism Impact Mitigation: Sustainable Tourism & Hospitality Assessment & DevelopmentDocument8 pagesTourism Impact Mitigation: Sustainable Tourism & Hospitality Assessment & DevelopmentJUN GERONANo ratings yet

- Corporate Profile - ReNew PowerDocument3 pagesCorporate Profile - ReNew PowerYash SamarthNo ratings yet

- MCCB-With Microprocessor Release MTX2.0Document1 pageMCCB-With Microprocessor Release MTX2.0Prashanth RajuNo ratings yet

- HALOTRONIC ManualDocument2 pagesHALOTRONIC ManualgermiNo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsDocument14 pagesSTOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsAHMED AMIRANo ratings yet

- HYOSUNG Wind Turbine System: Wind Energy Business DivisionDocument6 pagesHYOSUNG Wind Turbine System: Wind Energy Business DivisionE. Javier Fernandez RodriguezNo ratings yet

- LIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedDocument25 pagesLIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedshafeeqadeptNo ratings yet

- ElectrationDocument5 pagesElectrationVaronika KourNo ratings yet

- PPE Exit Exam ReviewerDocument48 pagesPPE Exit Exam ReviewerJamiel CatapangNo ratings yet

- Mechanical Design of Transmission LineDocument35 pagesMechanical Design of Transmission LineMikias YimerNo ratings yet

- 9 Stereo MSC 4Document60 pages9 Stereo MSC 4Gowtham LecturesNo ratings yet

- CSP0000535-01.Large Drawings 5of5Document25 pagesCSP0000535-01.Large Drawings 5of5SSK las. BambasNo ratings yet

- Balikpapan Industrial Expo (Bex) 2023: November 2023Document4 pagesBalikpapan Industrial Expo (Bex) 2023: November 2023S Riskiyanto100% (1)