Professional Documents

Culture Documents

TGN 1 25 Introduction To Fatigue

TGN 1 25 Introduction To Fatigue

Uploaded by

Muhammad ImranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TGN 1 25 Introduction To Fatigue

TGN 1 25 Introduction To Fatigue

Uploaded by

Muhammad ImranCopyright:

Available Formats

›

Note 25 Level 1

36 TheStructuralEngineer Technical

April 2013 Technical Guidance Note

Introduction to fatigue

Introduction ICON W Definition

of fatigue

Fatigue is a phenomenon that is rarely encountered by structural LEGEND

engineers, especially those who work exclusively in the realm of building

structures. It only occurs when an element of a structure is subjected to W Applied practice

cyclical loading over a sustained period. Hence this being a factor in the

design of bridge elements, especially those that are exposed to vehicular

W Further reading

traffic, as that is a form of cyclical loading.

This Technical Guidance Note defines what fatigue is and how its effects

can be countered. Detailed analysis of fatigue is not covered as it is a W Web resources

complex procedure beyond the scope of a Level 1 Guidance Note.

Definition of fatigue

The New Dictionary of Civil Engineering

defines fatigue as ‘the reduction in the S1

Stress

integrity of a structural element due to

repeatedly applying a stress within the S2

elastic limit of the material the element is

S3

made from.’ Continued exposure to fatigue

can result in a brittle failure of an element

from a load that would normally be resisted if

n1 n2 n3

it were static in nature. This occurs because

the integrity of the material is broken Number of cycles to failure

down, which results in a crack that rapidly

propagates as further loads are applied. This

then leads to the element ultimately failing. N Figure 2

S-N Curve While these tests do demonstrate the

capacity of a material, they do not accurately

The concept of fatigue is well known within Fatigue test reflect the conditions that are common in

the field of structural engineering, but in the More scientific methods of testing for actual structures. To correlate between

interests of reinforcing the theories behind fatigue are based on replicating cyclic the ideal sinusoidal approach and the

the analysis of members that are subject loading onto an element within a controlled actual conditions, it is prudent to review

to fatigue, a simple test demonstrates the environment. Loads are applied to the the time-history analysis of the structure

point. By taking a paper clip and bending a element under test within a sinusoidal when it is placed under load, and to discover

section of it repeatedly until it breaks, the pattern. The test continues until failure any sections of the results that match a

resistance to the force applied reduces at occurs or a predetermined number of cycles sinusoidal pattern. This approach is known

every turn, until it eventually breaks due are reached. The results are then plotted as Miner’s Rule and can be summarised thus:

to the brittle failure described previously. on a stress endurance curve (Figure 2).

Some deformation, heat generation and Generically known as an S-N curve, the / Nn n

1

n

2

n

= N1 + N2 + N3 + ... = 1

3

discolouration will be evident at the point vertical axis is the measured stress within

about which the paper clip is being bent. the element while the horizontal axis Where:

Figure 1 shows a paperclip that has been plots the corresponding number of cycles N is the number of cycles to the point of

subjected to fatigue. to failure. failure at an applied stress level within the

structure

n is the number of cycles applied at an

applied stress level within the structure

However, this can be regarded as an over-

simplification as there is no reference made

to the order of the application of loads that

causes the stress to occur. This should

be born in mind when using Miner’s

W Figure 1

Paperclip

subjected to fatigue

Rule to determine the fatigue lifespan of

the structure.

TSE16_36-37.indd 36 22/03/2013 13:40

www.thestructuralengineer.org

37

Structural steel and fatigue

Steel members contain inherent microscopic

flaws. These flaws can open up when a

steel element is exposed to fatigue and

therefore their presence has an impact on Butt weld

a member’s resistance. Steel’s inherent

resistance to fatigue can be assumed to be

approximately half of its ultimate strength.

This applies provided the element is small,

has a polished surface and no significant

stress concentrations. When an element

deviates from these conditions its resistance

to fatigue is reduced. For example, if the E Figure 3

Welded connections

showing flow of stress

surface is not polished then the flaws in the through them Fillet weld

steel would remain. There would also be no

areas of high stress concentration relative

to the size of the element, as would be the mechanism created by the bolts prevents Fatigue impact on design life

case with larger steel members. the element from moving and so the The effect fatigue has on the design life of

friction between the elements resists the structures can be pronounced. Elements

Corrosion and fatigue effects of fatigue. This only applies to designed to withstand the effects of fatigue,

Corrosion must be considered when simple connections as bending moment cannot be expected to do so indefinitely. The

analysing a steel structure for fatigue. It connections have a tension component element will succumb to brittle failure at some

has been proven that due primarily to the within them. Such connections make use of point but it is the responsibility of the designer

increased brittle state of steel caused its resistance to prying, which becomes an to make sure that the point at which this

by corrosion, its resistance to fatigue element that resists fatigue. occurs, is beyond the structure’s design life.

is significantly reduced. Conversely the

deposits generated due to corrosion can Reinforced concrete and fatigue

fill the flaws described previously, which Reinforced concrete elements are less prone Eurocode 0.

partially counter the brittle effect of the to fatigue failure due to the relatively low Applied practice

corrosion. It does this by reducing the stresses present, compared to their steel

propagation of crack growth within the counterparts. Concrete structures that are

material. This is of great importance when subject to high stresses are more liable to BS EN 1993-1-9 Eurocode 3: Design of Steel

designing elements that are exposed to suffer the effects of fatigue, as are those that Structures – Part 1-9: Fatigue

marine environments, which are naturally are exposed to cyclic impact loading. A good

corrosive. example of such structures is road bridges. NA to BS EN 1993-1-9 Eurocode 3: UK

Annex to Design of Steel Structures – Part

Connection type and fatigue Typically the mode of failure consists of 1-9: Fatigue

The type of connection within a steel premature cracking from loads that are

structure has an impact on its resistance to approximately half what the element was

the effects of fatigue. Welded connections designed to resist in the static condition.

Glossary and

react differently to bolted ones. Some Reinforced concrete elements resist

further reading

understanding of how these types of the effects of fatigue through the steel

connection resist fatigue is needed when reinforcement bars within them. According Cyclical loading – repeated actions upon a

designing structures that are subject to this to tests and research carried out on the structure that occur over a long period of time.

form of loading. subject, straight bars have a much greater

resistance than those that are bent. S-N curve – A plot of applied stresses vs.

Welded connections the number of times the stress is applied

Structures that contain a significant amount Prestressed concrete elements are almost prior to failure or when a predetermined

of welded connections are weak against immune to the effects of fatigue if the level number of cycles are reached.

fatigue. This is due to the difficulty in of precompression is such that no cracks

creating the connections, which leads to are generated within the concrete. This Sinusoidal – A mathematical phrase for a

stress concentrations due to poorly applied is due to the fact that the entire concrete curve that describes repetitive oscillation.

welds. The flow of stress passes directly element is resisting stress changes within it

through butt welds and as a result, they are and not just the steel reinforcement, making Further Reading

the most effective weld type in terms of it more efficient. Young W.C., Budynas R.G. and Sadegh A.M.

resisting fatigue. By contrast, fillet welds do (2012) Roark’s Formulas for Stress and Strain

not offer the same level of resistance due to Where prestressed concrete elements do (8th ed.) New York: McGraw Hill

the change in direction of stresses within the have cracks, then the resistance to the

connection (Figure 3). effects of fatigue becomes significant. Eurocode 0.

This is especially the case in exposed Web resources

Bolted connections environments that may result in water

Bolted connections resist fatigue via ingress. This would cause corrosion in the

the friction they provide between the prestressing strands within the concrete and The Institution of Structural Engineers library:

elements fixed through them. The clamping thus reduce their effectiveness. www.istructe.org/resources-centre/library

TSE16_36-37.indd 37 22/03/2013 13:41

You might also like

- Extracts From British Standards For Students of Structural Design PDFDocument2 pagesExtracts From British Standards For Students of Structural Design PDFShannon0% (1)

- TGN - 20-L2-Designing and Detailing of Lintels in Masonry WallsDocument3 pagesTGN - 20-L2-Designing and Detailing of Lintels in Masonry Wallsalberto5791No ratings yet

- Technical Guidance Note (Level 1 No. 6) - Notional Loading (Equivalent Horizontal Forces)Document3 pagesTechnical Guidance Note (Level 1 No. 6) - Notional Loading (Equivalent Horizontal Forces)MohanNo ratings yet

- Service Manual E0S6B-PTA PDFDocument341 pagesService Manual E0S6B-PTA PDFAhmed Kamal100% (3)

- Post Fi X Anchors: Icon LegendDocument2 pagesPost Fi X Anchors: Icon LegendMuhammad ImranNo ratings yet

- Post Fi X Anchors: Icon LegendDocument2 pagesPost Fi X Anchors: Icon LegendMuhammad ImranNo ratings yet

- Concrete Design Guide No5 - How To Calculate Anchorage and Lap Lengths To Eurocode 2Document8 pagesConcrete Design Guide No5 - How To Calculate Anchorage and Lap Lengths To Eurocode 2Gurvir BahraNo ratings yet

- Technical Guidance Note (Level 2, No. 18) - Design of Unreinforced Masonry Retaining Walls - The Institution of Structural EngineersDocument4 pagesTechnical Guidance Note (Level 2, No. 18) - Design of Unreinforced Masonry Retaining Walls - The Institution of Structural Engineersindrajit sodhaNo ratings yet

- Technical Guidance Note (Level 2, No. 9) - Designing A Reinforced Concrete Retaining Wall - The Institution of Structural EngineersDocument4 pagesTechnical Guidance Note (Level 2, No. 9) - Designing A Reinforced Concrete Retaining Wall - The Institution of Structural Engineersindrajit sodhaNo ratings yet

- Flat Slabs: Designing To Eurocode 2Document8 pagesFlat Slabs: Designing To Eurocode 2Ganesh PrabuNo ratings yet

- Concrete Basements, Design and Construction Guide - The Concrete CentreDocument53 pagesConcrete Basements, Design and Construction Guide - The Concrete CentreMickaelGameiro67% (3)

- Chloride PDFDocument26 pagesChloride PDFMuhammad ImranNo ratings yet

- Problems On Coefficients (Naval Architecture)Document3 pagesProblems On Coefficients (Naval Architecture)James67% (3)

- Technical Guidance Note (Level 1, No. 8) - Derivation of Loading To Retaining StructuresDocument3 pagesTechnical Guidance Note (Level 1, No. 8) - Derivation of Loading To Retaining StructuresMohanNo ratings yet

- Derivation of Dead Loads: Icon LegendDocument3 pagesDerivation of Dead Loads: Icon LegendMuhammad Imran100% (1)

- IStructE-001-Principles of Design PDFDocument2 pagesIStructE-001-Principles of Design PDFAlexZaNo ratings yet

- Design of Precast Concrete Oors in Steel-Framed Buildings. Part 3: Disproportionate CollapseDocument3 pagesDesign of Precast Concrete Oors in Steel-Framed Buildings. Part 3: Disproportionate CollapseΤε ΧνηNo ratings yet

- Designing A Concrete Beam: Icon LegendDocument5 pagesDesigning A Concrete Beam: Icon LegendNitish TakalkarNo ratings yet

- Introduction To Piling: Icon LegendDocument2 pagesIntroduction To Piling: Icon LegendVijayNo ratings yet

- Technical Guidance Note-Level-3-No-3-Design Methods of Post Fixed Anchors in ConcreteDocument5 pagesTechnical Guidance Note-Level-3-No-3-Design Methods of Post Fixed Anchors in ConcreteVijayNo ratings yet

- L1 21 How To Avoid Torsion PDFDocument2 pagesL1 21 How To Avoid Torsion PDFdhanya1995100% (1)

- Design of Precast Concrete Oors in Steel-Framed Buildings. Part 2: Beam DesignDocument4 pagesDesign of Precast Concrete Oors in Steel-Framed Buildings. Part 2: Beam DesignΤε ΧνηNo ratings yet

- Design of Precast Concrete Oors in Steel-Framed Buildings. Part 1: Slab DesignDocument5 pagesDesign of Precast Concrete Oors in Steel-Framed Buildings. Part 1: Slab DesignΤε ΧνηNo ratings yet

- Technical Guidance Notes: Level 2, No. 13Document4 pagesTechnical Guidance Notes: Level 2, No. 13Τε ΧνηNo ratings yet

- Designing A Steel Column - IStructEDocument4 pagesDesigning A Steel Column - IStructEVijayNo ratings yet

- No. 6 Fire Design of Concrete Columns and Walls To Eurocode 2Document6 pagesNo. 6 Fire Design of Concrete Columns and Walls To Eurocode 2spid003No ratings yet

- Barrier and Vehicle Loading: Icon LegendDocument3 pagesBarrier and Vehicle Loading: Icon LegendMuhammad Imran100% (1)

- Note 28. Introduction To Extreme Loading ConditionsDocument2 pagesNote 28. Introduction To Extreme Loading ConditionsNabil AttaNo ratings yet

- Visualization of Structures PDFDocument3 pagesVisualization of Structures PDFNitish TakalkarNo ratings yet

- TGN 1 35 Introduction To Structural GlassDocument5 pagesTGN 1 35 Introduction To Structural GlassSiu HinNo ratings yet

- Technical Guidance Notes: Level 2, No. 18Document4 pagesTechnical Guidance Notes: Level 2, No. 18Nitish TakalkarNo ratings yet

- Technical Guidance Note (Level 1, No. 32) - Floor Slab Construction - The Institution of Structural EngineersDocument4 pagesTechnical Guidance Note (Level 1, No. 32) - Floor Slab Construction - The Institution of Structural Engineersindrajit sodhaNo ratings yet

- 16 - Moment Distribution PDFDocument3 pages16 - Moment Distribution PDFkrimchand1825No ratings yet

- JSD Guide To Good Practice Rev 0 PDFDocument18 pagesJSD Guide To Good Practice Rev 0 PDFJakesNo ratings yet

- How To Disproportionate CollapseDocument8 pagesHow To Disproportionate CollapseccapotaNo ratings yet

- Composite and Steel Construction Compendium: Part 2: Shear Connection in Composite BeamsDocument3 pagesComposite and Steel Construction Compendium: Part 2: Shear Connection in Composite BeamsΤε ΧνηNo ratings yet

- List of Technical Guidance Notes (Level 2)Document1 pageList of Technical Guidance Notes (Level 2)Ahmet TukenNo ratings yet

- Model Answer Q1 2016-SecureDocument64 pagesModel Answer Q1 2016-Securegoggings100% (1)

- 100.6 - BD5293 Parapets PDFDocument45 pages100.6 - BD5293 Parapets PDFjageshwariNo ratings yet

- TGN Level 2 Note 9 Designing A Reinforced Concrete Retaining Wall - Oct2016Document4 pagesTGN Level 2 Note 9 Designing A Reinforced Concrete Retaining Wall - Oct2016Lee WhiteheadNo ratings yet

- Biaxial Bending in Columns: Icon LegendDocument2 pagesBiaxial Bending in Columns: Icon LegendGaurav BhendeNo ratings yet

- Introduction To Eurocodes: The Eurocode FamilyDocument8 pagesIntroduction To Eurocodes: The Eurocode FamilySewGuanNo ratings yet

- Material Properties Effect On Deflection PDFDocument15 pagesMaterial Properties Effect On Deflection PDFAndrewNo ratings yet

- EN ISO 3766-1-1999-BS-EN-Construction Drawing-Simplified Representation of Concrete Reinforcement PDFDocument18 pagesEN ISO 3766-1-1999-BS-EN-Construction Drawing-Simplified Representation of Concrete Reinforcement PDFReisWarezNo ratings yet

- NA To BS EN 1991-1-6 - 2005 - UK National Annex To Eurocode 1 - Part 1-6Document10 pagesNA To BS EN 1991-1-6 - 2005 - UK National Annex To Eurocode 1 - Part 1-6Vincent Chin100% (1)

- Model Answer Q1, 2013: Institution of Structural Engineers Chartered Membership ExaminationDocument78 pagesModel Answer Q1, 2013: Institution of Structural Engineers Chartered Membership ExaminationAnonymous 66uWhphVNo ratings yet

- SOFA (Solution For Fastening) : Annex C: Design Methods For AnchoragesDocument39 pagesSOFA (Solution For Fastening) : Annex C: Design Methods For Anchoragesajra_bg0% (1)

- Concrete Bridge Design and Construction Series: No. 12: Management of Concrete BridgesDocument6 pagesConcrete Bridge Design and Construction Series: No. 12: Management of Concrete BridgesJacob GrechNo ratings yet

- ConcreteBasements 1 PDFDocument184 pagesConcreteBasements 1 PDFMaiz NetoNo ratings yet

- NA To BS EN 1993-1-1 2005Document14 pagesNA To BS EN 1993-1-1 2005afiq2697100% (1)

- No. 8 Deflection - The Span-To-effective-Depth Method and EC2Document5 pagesNo. 8 Deflection - The Span-To-effective-Depth Method and EC2spid003No ratings yet

- Eurocode Guides: New BooksDocument6 pagesEurocode Guides: New Bookskoce_todorov100% (1)

- LV 1 Note 10 Principles of Lateral Stability PDFDocument4 pagesLV 1 Note 10 Principles of Lateral Stability PDFArtjom SamsonovNo ratings yet

- BCA - Design Guide On Use of Structural SteelDocument89 pagesBCA - Design Guide On Use of Structural Steelsazkha2100% (1)

- CT5126 FatigueDocument198 pagesCT5126 FatigueJose GalanNo ratings yet

- G - 216 - DMM - Unit 2Document15 pagesG - 216 - DMM - Unit 2Raghu VarmaNo ratings yet

- Topic 2 Flexibilty MethodDocument134 pagesTopic 2 Flexibilty Methodazerai2000No ratings yet

- Moment AmplificationDocument1 pageMoment Amplificationshantanu chowdhuryNo ratings yet

- Laboratory WorksheetDocument7 pagesLaboratory WorksheetmuhdfarisNo ratings yet

- Fatigue Test: Faculty of Mechanical EngineeringDocument9 pagesFatigue Test: Faculty of Mechanical EngineeringAlimin AnniNo ratings yet

- Second Order EffectDocument2 pagesSecond Order Effectshantanu chowdhuryNo ratings yet

- Non-Linear Specialized Module: CAE 1 - Geometrical Non-LinearitiesDocument2 pagesNon-Linear Specialized Module: CAE 1 - Geometrical Non-LinearitiesTAWFIQ RAHMANNo ratings yet

- Simulation of The Response of Glass Window Under Blast LoadDocument7 pagesSimulation of The Response of Glass Window Under Blast LoadomsmursNo ratings yet

- Redundanttruss No.2indeterminatetruss LabsheetDocument4 pagesRedundanttruss No.2indeterminatetruss LabsheetRaziq HanifNo ratings yet

- Book - Structural Masonry Designers ManualDocument508 pagesBook - Structural Masonry Designers ManualMuhammad Imran100% (1)

- Tek 14-08BDocument14 pagesTek 14-08BMuhammad ImranNo ratings yet

- Tek 14-07BDocument18 pagesTek 14-07BMuhammad ImranNo ratings yet

- Technical Guidance Notes: An IntroductionDocument1 pageTechnical Guidance Notes: An IntroductionMuhammad ImranNo ratings yet

- Barrier and Vehicle Loading: Icon LegendDocument3 pagesBarrier and Vehicle Loading: Icon LegendMuhammad Imran100% (1)

- Derivation of Dead Loads: Icon LegendDocument3 pagesDerivation of Dead Loads: Icon LegendMuhammad Imran100% (1)

- CHG 5Document66 pagesCHG 5Muhammad ImranNo ratings yet

- Influence Lines: Version 2 CE IIT, KharagpurDocument11 pagesInfluence Lines: Version 2 CE IIT, KharagpurMuhammad ImranNo ratings yet

- Part 4 Compressive Strength ÐDocument18 pagesPart 4 Compressive Strength ÐMuhammad ImranNo ratings yet

- Sampling Part 1Document10 pagesSampling Part 1Muhammad ImranNo ratings yet

- Self-Compacting Concrete - L BoxDocument14 pagesSelf-Compacting Concrete - L BoxMuhammad ImranNo ratings yet

- Self-Compacting Concrete - SlumpflowDocument14 pagesSelf-Compacting Concrete - SlumpflowMuhammad ImranNo ratings yet

- Testing Fresh Concrete: Part 6: DensityDocument14 pagesTesting Fresh Concrete: Part 6: DensityMuhammad ImranNo ratings yet

- Self-Compacting Concrete - SieveDocument14 pagesSelf-Compacting Concrete - SieveMuhammad ImranNo ratings yet

- Soil Mech Soil Classification UscsDocument18 pagesSoil Mech Soil Classification UscsZach GarciaNo ratings yet

- Unit 5 Tree Lect NotesDocument46 pagesUnit 5 Tree Lect NotesKANIKA CHAUDHARYNo ratings yet

- 4360 2004Document9 pages4360 2004Ivana VujčićNo ratings yet

- Materials For High-Temperature Conversion Process Furnace PartsDocument28 pagesMaterials For High-Temperature Conversion Process Furnace Partsaleeimeran100% (2)

- AC PCC REVISED DRAWING-B&H Approval On 2304Document29 pagesAC PCC REVISED DRAWING-B&H Approval On 2304Rukma Goud ShakkariNo ratings yet

- Mineral Resources Management and The EnviromentDocument313 pagesMineral Resources Management and The Enviromentjunior.geologia100% (1)

- Concrete Pipe, Manhole Section's, or Tile: Standard Method of Test ForDocument6 pagesConcrete Pipe, Manhole Section's, or Tile: Standard Method of Test ForricardojesussardinasalzugarayNo ratings yet

- Memmert Un30 Oven User ManualDocument52 pagesMemmert Un30 Oven User ManualNadun KodikaraNo ratings yet

- EvapEmission PDFDocument8 pagesEvapEmission PDFpivillamilNo ratings yet

- Pradeep Jha June-2019Document13 pagesPradeep Jha June-2019mkpNo ratings yet

- Prius P Hev ManualDocument16 pagesPrius P Hev Manualrey1004No ratings yet

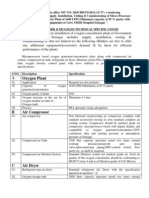

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- CV Rizaljs Indonesia PDFDocument18 pagesCV Rizaljs Indonesia PDFHumairah AnandaNo ratings yet

- Start & Taxi ProceduresDocument12 pagesStart & Taxi ProceduresJoao Vitor RojasNo ratings yet

- EmulsionDocument53 pagesEmulsionSyifaturrahmah Nurfalah67% (3)

- Kernel Internals Student NotesDocument404 pagesKernel Internals Student Notesnaveednad2003556100% (1)

- Data SheetDocument23 pagesData SheetMan TheNo ratings yet

- Volvo Fh12 Sensor CMPDocument4 pagesVolvo Fh12 Sensor CMPRoberto Carlos Montoya SirlupuNo ratings yet

- 3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Document7 pages3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Sri Wahyuni HandayaniNo ratings yet

- MaterialsDocument7 pagesMaterialsJoshua CedillaNo ratings yet

- Time SheetDocument2 pagesTime SheetSuyog JungareNo ratings yet

- ObjectiveDocument19 pagesObjectiveAmmir JusohNo ratings yet

- Manual Unigas Urb4Document28 pagesManual Unigas Urb4Maurice LachaudNo ratings yet

- Explanation TextDocument3 pagesExplanation TextaajunaidiiNo ratings yet

- Thornycroft Tk-60: 4-Cylinders in Line 57 BHP at 3000 R/minDocument2 pagesThornycroft Tk-60: 4-Cylinders in Line 57 BHP at 3000 R/minGilnad WilsonNo ratings yet

- Parts Guide Manual: HD-514 A1RmDocument17 pagesParts Guide Manual: HD-514 A1RmmemetNo ratings yet

- 15CS32 SyllabusDocument2 pages15CS32 SyllabuspramelaNo ratings yet

- SBNHH-1D45C Product SpecificationsDocument4 pagesSBNHH-1D45C Product SpecificationsMauricioNo ratings yet