Professional Documents

Culture Documents

Pressure Thrust: Pathway Engineering Bulletin N/A 0 1 of 2 N/A DLE N/A 7/14/2008

Pressure Thrust: Pathway Engineering Bulletin N/A 0 1 of 2 N/A DLE N/A 7/14/2008

Uploaded by

adfafad gfadfOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Thrust: Pathway Engineering Bulletin N/A 0 1 of 2 N/A DLE N/A 7/14/2008

Pressure Thrust: Pathway Engineering Bulletin N/A 0 1 of 2 N/A DLE N/A 7/14/2008

Uploaded by

adfafad gfadfCopyright:

Available Formats

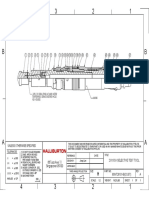

PATHWAY ENGINEERING DRAWING NO.

REV SHEET

BULLETIN N/A 0 1 OF 2

CUSTOMER BY QUOTE/JOB/NO DATE

N/A DLE N/A 7/14/2008

PRESSURE THRUST

INTRODUCTION - Pressure thrust is a natural result of using an

UNRESTRAINED expansion joint. When this type of joint is used

properly, it is the most flexible, cheapest and easiest type of joint to

use. However, extra engineering time and construction cost must

be expended in the design and construction of the pipe line. If the

joint is not properly engineered, a major failure could occur. Table

1 provides the pressure thrust force that will be developed at Fig. 1

various sizes and pressures.

The reason for the bulging can be explained by taking a section

through the tin can, see Figure 2 & 3. The pressure will react

Nom Pipe Pressure Thrust (Pt)

against the wall of the tin can radially and also at the ends.

Pipe ID 15 150 300 450

Size Area Lb Lb Lb Lb

(in) (in2) (lbs) (Lbs) (Lbs) (Lbs)

1 .86 13 130 260 389

2 3.36 50 503 1,007 1,510

4 12.7 191 1,910 3,819 5,729

6 28.9 433 4,333 8,667 13,000

8 50.0 750 7,504 15,008 22,512

10 78.8 1,183 11,828 23,656 35,484

12 113 1,696 16,964 33,929 50,894 HOOPS STRESS LONGITUDINAL STRESS

16 183 2,740 27,398 54,796 82,194 Fig. 2 Fig. 3

20 291 4,366 43,656 87,312 130,968

24 425 6,368 63,684 127,367 191,051 αC = P • R αL = P • R

32 767 11,505 115,049 230,097 345,146 t 2•t

36 976 14,639 146,386 292,772 439,158

48 1753 26,302 263,018 526,035 789,053 The general formulas for each of the resulting stresses are provided

under the appropriate figure. It is seen that the longitudinal stress

60 2757 41,358 413,578 827,157 …

(αL) will generally be one half of the circumferential stress. For

PRESSURE THRUST vs DIAMETER

this reason, the longitudinal stress is often over looked. Normally

Table 1

all loads cancel each other.

NOMENCLATURE

Aeff ......... Bellows effective area, in2.

When an UNRESTRAINED expansion joint is introduced into the

Pt ........... Longitudinal pressure thrust force due to pressure, lb.

system, it is similar to introducing a spring into the tin can, see

IDpip ....... Pipe inside diameter, in.

figure 4.

P ............ Design pressure of the line, psi

Pc ........... Force required to compress or extend the bellows

element plus any additional friction forces due to guides

etc, lbs.

Rpip ........ Pipe radius, in.

tpip .......... Pipe wall thickness, in.

αC .......... Circumferential stress due to pressure, psi.

αL .......... Longitudinal stress due to pressure, lb. Fig. 4

DISCUSSION - In order to explain pressure thrust and it’s effects,

it is first necessary to understand the relationship between pressure The pressure thrust force (Pc) acting at the ends of the can will not

and force. When pressure is applied to a closed container, the be restrained by the spring. The spring will start to spread apart

pressure will act against all surfaces to develop a force on that until it is pulled completely apart, see figure 5.

surface. This concept can be illustrated by imagining a tin can

being pressurized, see figure 1. It is easy to see that as the pressure

is increased, the can will begin to bulge in the middle and also at

the ends.

Piping Solutions Group: Senior Operations LLC, Pathway Div:

P.O. Box 10 2400 Longhorn Industrial Dr

Pine Valley, Ca. 91962 New Braunfals, Texas 37830

(619) 473-8248 (830) 629-8080

PATHWAY ENGINEERING DRAWING NO. REV SHEET

BULLETIN N/A 0 2 OF 2

CUSTOMER BY QUOTE/JOB/NO DATE

N/A DLE N/A 7/14/2008

Fig. 5

In order to prevent this from happening a main anchor strong

enough to hold the line together must be installed on both ends of

the expansion joint, see figure 6.

Fig 9.

Also, a very small amount of the force will develop at the bellows

itself, see figure 9, and be transmitted down the pipe in

compression. For this reason, pipelines with UNRESTRAINED

expansion joints operate in compression instead of tension and

require additional guiding for compression stability. The standards

Fig. 6

of EJMA contain guidelines for guiding UNRESTRAINED expansion

joints. The actual compressive pressure thrust force created by a

In a piping system, see Figure 7, the pressure thrust will develop at

bellows may be calculated by:

the elbows and be transmitted down the pipe line in tension and

cancel with the equal and opposite pressure thrust. However, when

an UNRESTRAINED expansion joint is used, most of the pressure Pb = P • π • (dp2 - IDpip2 ) / 4

thrust develops at the elbows or operating equipment and can not

be transmitted down the pipe and must be restrained by anchors,

see figure 8. CONCLUSION - When using UNRESTRAINED expansion joints,

the main thrust anchors should be designed for a pressure thrust

force equal to:

Aeff = dp2 • / 4

Po = P • Aeff + Pc

The pipeline will be operating under a compressive (tension for

vacuum) force equal to:

Pb = P • π • (dp2 - IDpip2 ) / 4

Fig. 7 The pipeline should be guided in accordance with the EJMA

standards.

This discussion has dealt only with UNRESTRAINED expansion

joints, this type of joint can deflect in any direction (axial, lateral,

angular or torsional). They also have no hardware to transmit the

pressure thrust or system dead weights. There are a number of

joints which can restrain pressure thrust such as tied, hinge,

gimbaled, etc. but when the hardware is added, a degree of freedom

is also eliminated. The standards of EJMA contain a detailed

Fig. 8 discussion of the various styles of expansion joints and their

application and is recommended reading.

Piping Solutions Group: Senior Operations LLC, Pathway Div:

P.O. Box 10 2400 Longhorn Industrial Dr

Pine Valley, Ca. 91962 New Braunfals, Texas 37830

(619) 473-8248 (830) 629-8080

You might also like

- Lift CoreDocument7 pagesLift CoreIsaac Mureithi Maina100% (2)

- Lab1 MEE30004 - Lab1 - 2021 Sem2 - Raw DataDocument7 pagesLab1 MEE30004 - Lab1 - 2021 Sem2 - Raw DataAbidul IslamNo ratings yet

- Work Turned Out by Labour Per Day (Residential) SL No. Particulars of Item Unit Quantity Per Person Per DayDocument5 pagesWork Turned Out by Labour Per Day (Residential) SL No. Particulars of Item Unit Quantity Per Person Per DayVishnu Vardhan Reddy Ogili82% (11)

- Standard Hooks Card-ASTMDocument2 pagesStandard Hooks Card-ASTMAnonymous ANo ratings yet

- Engine Electrical Circuitry (Engine Sensors, Battery, ALT & Starter) - S630Document3 pagesEngine Electrical Circuitry (Engine Sensors, Battery, ALT & Starter) - S630Edmil PabellanoNo ratings yet

- Strength Calculation Sheet For Item No. C-053-12Document297 pagesStrength Calculation Sheet For Item No. C-053-12Urdian Syah100% (1)

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument15 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryAthar YogaNo ratings yet

- Bolts ConnectionDocument3 pagesBolts Connectionrizwanjawaid.meenaNo ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- Flange Leakage v1.0Document5 pagesFlange Leakage v1.0SENTHILNo ratings yet

- Structural Steel Design: Eng Fuad Dhunkal in Civil EngineeringDocument18 pagesStructural Steel Design: Eng Fuad Dhunkal in Civil Engineeringfuaad dhunkaalNo ratings yet

- Pau-T1-02-01 PDFDocument1 pagePau-T1-02-01 PDFKyi LwinNo ratings yet

- Regional Conference and Exhibition On Electricity DistributionDocument8 pagesRegional Conference and Exhibition On Electricity DistributionramsesiNo ratings yet

- C18W10 - Drawing Issue Sheet 008Document6 pagesC18W10 - Drawing Issue Sheet 008Chung Him Joe ChanNo ratings yet

- Nwis Inplace Analysis ReportDocument5 pagesNwis Inplace Analysis ReportPrashanth Talkad RajagopalNo ratings yet

- Nozzle CFD AnalysisDocument6 pagesNozzle CFD AnalysisPett PeeveNo ratings yet

- Static Pressure CalculationsDocument28 pagesStatic Pressure CalculationsAnonymous ixIhrPM2100% (1)

- Thick and Thin ProposalDocument10 pagesThick and Thin Proposalaizat khairiNo ratings yet

- Stress Analysis of Rectangular Boxes Using Fem: D.G. Lokhande, Dr. D. V. BhopeDocument9 pagesStress Analysis of Rectangular Boxes Using Fem: D.G. Lokhande, Dr. D. V. BhopeoliveirassouzaNo ratings yet

- Katalog Bare PDFDocument41 pagesKatalog Bare PDFYuDiNo ratings yet

- Piping Class Spec. - 1c28pe (Lurgi)Document8 pagesPiping Class Spec. - 1c28pe (Lurgi)otezgidenNo ratings yet

- FEA Analysis of Rectangular Pressure Vessel BoxesDocument13 pagesFEA Analysis of Rectangular Pressure Vessel BoxesIJARSCT JournalNo ratings yet

- Spec. No. 7311-DE-041Document1 pageSpec. No. 7311-DE-041HEMANTNo ratings yet

- Numerical Simulation On The Dynamic Response of Buried Pipelines Subjected To Blast Loads by Xu 2013Document5 pagesNumerical Simulation On The Dynamic Response of Buried Pipelines Subjected To Blast Loads by Xu 2013C SzetoNo ratings yet

- Outdim WCP 125 ValeDocument1 pageOutdim WCP 125 Valefcalista1715No ratings yet

- Type 1008 Manual Handwheel Actuator: Bulletin 61.8:1008Document4 pagesType 1008 Manual Handwheel Actuator: Bulletin 61.8:1008Datt NguyenNo ratings yet

- Riveted Joints: SymbolsDocument23 pagesRiveted Joints: SymbolsbobcrystoNo ratings yet

- Pipe Bend RadiusDocument8 pagesPipe Bend RadiusAdagharaNo ratings yet

- Yanmar 4tne84-Eds 0CV10-G48601Document27 pagesYanmar 4tne84-Eds 0CV10-G48601Sergio Urquizo100% (1)

- 3tnv84t Parts BookDocument33 pages3tnv84t Parts BookAnonymous P6xkcz100% (1)

- Piping Class Spec. - 1C9 (Lurgi)Document8 pagesPiping Class Spec. - 1C9 (Lurgi)otezgidenNo ratings yet

- 4TNE98-TBL (Takeuchi)Document27 pages4TNE98-TBL (Takeuchi)MilanNo ratings yet

- Engine & Attaching Parts (Air Cleaner & Muffler) - S130Document2 pagesEngine & Attaching Parts (Air Cleaner & Muffler) - S130Gabriel Pereira SilvaNo ratings yet

- Piping Class Spec. - 1c9pe (Lurgi)Document8 pagesPiping Class Spec. - 1c9pe (Lurgi)otezgidenNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument4 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Dewmark Concrete LoadsDocument2 pagesDewmark Concrete LoadsAfghan Turk DecoratorNo ratings yet

- Daniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FDocument2 pagesDaniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FvtalexNo ratings yet

- Reinforcement Pad CalculationDocument4 pagesReinforcement Pad CalculationMohammad AbdullahNo ratings yet

- 4TNV84T-GGE 20kVADocument40 pages4TNV84T-GGE 20kVAHartech Genset Sby100% (1)

- Stress Concentration Formula Useful For All Notch Shape in A Round Bar (Comparison Between Torsion, Tension and Bending)Document13 pagesStress Concentration Formula Useful For All Notch Shape in A Round Bar (Comparison Between Torsion, Tension and Bending)Pierre NorrisNo ratings yet

- X-Selective Test ToolDocument3 pagesX-Selective Test Toolsong Li100% (3)

- 3259262Document4 pages3259262M Iqbal AdmanNo ratings yet

- WR3Document8 pagesWR3Chris AdaminovicNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- 01 r0 DPL Gi 150 KV Steel Structure Post 18 M Gid 00010Document3 pages01 r0 DPL Gi 150 KV Steel Structure Post 18 M Gid 00010nisaNo ratings yet

- Centrifugal Pump 2009Document8 pagesCentrifugal Pump 2009juan diazNo ratings yet

- 28 Roark Flat PlatesDocument4 pages28 Roark Flat PlatesJorge Silva100% (1)

- Wood Shear Wall With Opening: Input DataDocument3 pagesWood Shear Wall With Opening: Input DatareynoldNo ratings yet

- Air Cleaner (V3300 DI T Kubota) (Tier II) - (S - N 526211001 & Above, 526311001 & Above) - S220Document2 pagesAir Cleaner (V3300 DI T Kubota) (Tier II) - (S - N 526211001 & Above, 526311001 & Above) - S220edNo ratings yet

- "Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramDocument5 pages"Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramNEONo ratings yet

- Engine & Attaching Parts (Radiator Water Exchanger) - (S - N AZNB11001 - AZNB11027) - S570Document3 pagesEngine & Attaching Parts (Radiator Water Exchanger) - (S - N AZNB11001 - AZNB11027) - S570ferneyNo ratings yet

- Metals 10 01056Document16 pagesMetals 10 01056Rizwan TonoyNo ratings yet

- Piping Stress Handbook - by Vi 1Document121 pagesPiping Stress Handbook - by Vi 1Med RjebNo ratings yet

- Piping Stress Handbook - by Victor Helguero - Part 2Document121 pagesPiping Stress Handbook - by Victor Helguero - Part 2namdq-1100% (1)

- Doubly Reinforced Concrete ExcelDocument83 pagesDoubly Reinforced Concrete ExcelShielaSabadoNo ratings yet

- NCHRP w197AppendixDDocument42 pagesNCHRP w197AppendixDBarroso Perez DiegoNo ratings yet

- Unidad Coneccion RWBDocument24 pagesUnidad Coneccion RWBmarcos delgadoNo ratings yet

- Piping Class Spec. - 1C23 (Lurgi)Document5 pagesPiping Class Spec. - 1C23 (Lurgi)otezgidenNo ratings yet

- Drive Train (S - N A3NV11001 - A3NV20687, A3NV20738, A3NW11001 - A3NW12926) - S650Document3 pagesDrive Train (S - N A3NV11001 - A3NV20687, A3NV20738, A3NW11001 - A3NW12926) - S650ferneyNo ratings yet

- Pump Selection Analysis: Calc. by Date CHK'D by Date App'd by DateDocument9 pagesPump Selection Analysis: Calc. by Date CHK'D by Date App'd by Dateorode franklynNo ratings yet

- Ieee On Design and Analysis of Power System Grounding: Effects of The Changes in Std. 80 TheDocument6 pagesIeee On Design and Analysis of Power System Grounding: Effects of The Changes in Std. 80 Thehector stackNo ratings yet

- SFC Key Interlocks & Process Management SystemsDocument5 pagesSFC Key Interlocks & Process Management Systemshector stackNo ratings yet

- Polietileno 100% SolidoDocument4 pagesPolietileno 100% Solidohector stackNo ratings yet

- Nad C42Document68 pagesNad C42hector stackNo ratings yet

- Standard Drawing CompleteDocument60 pagesStandard Drawing CompleteYogesh YadavNo ratings yet

- CLS Aipmt-19-20 XIII Phy Study-Package-2 Level-1 Chapter-9 PDFDocument22 pagesCLS Aipmt-19-20 XIII Phy Study-Package-2 Level-1 Chapter-9 PDFmadhwan khuranaNo ratings yet

- Hydraulic JumpDocument15 pagesHydraulic JumpabbasjadoonNo ratings yet

- Example - Pile Cap DesignDocument4 pagesExample - Pile Cap Designseljak_veseljak100% (1)

- B. English For Enineer (Tenses)Document8 pagesB. English For Enineer (Tenses)Silvie PratiwiNo ratings yet

- ch12.5 Portal Knee ConnectionsDocument112 pagesch12.5 Portal Knee ConnectionsVEDAT ÖZGÜR DÖĞERNo ratings yet

- DuraGal - Design Capacity Tables For Steel Hollow SectionsDocument187 pagesDuraGal - Design Capacity Tables For Steel Hollow SectionsrichardreddinNo ratings yet

- ATC 20 BuildingSafetyEvaluationDocument29 pagesATC 20 BuildingSafetyEvaluationCarlos Arturo GarcíaNo ratings yet

- 42 Efficiency of Pile Group in SandDocument16 pages42 Efficiency of Pile Group in SandYash Raj GairaNo ratings yet

- Spreadsheets To BS 8110: Single Column BaseDocument4 pagesSpreadsheets To BS 8110: Single Column BaseBobby A MathewNo ratings yet

- All 8 Semester Diploma Engineering - 2010 ProbidhanDocument129 pagesAll 8 Semester Diploma Engineering - 2010 ProbidhanShakib Shoumik57% (21)

- Contraction/Control JointsDocument2 pagesContraction/Control Jointsmohannad eliassNo ratings yet

- WorleyParsons Horizontal 2 Phase Separator SizingDocument1 pageWorleyParsons Horizontal 2 Phase Separator SizingDavid Gustavo Duran Tango100% (1)

- Pumping TestDocument34 pagesPumping TestMOHAMAMED BOSS100% (3)

- Syllabus Advanced Reinforced Concrete DesignDocument2 pagesSyllabus Advanced Reinforced Concrete DesignTriet TruongNo ratings yet

- Group 3Document93 pagesGroup 3Prince IbanezNo ratings yet

- Partial Replacement of Coarse Aggregate With Palm Kernel Shell in Concrete IJERTV6IS040098Document4 pagesPartial Replacement of Coarse Aggregate With Palm Kernel Shell in Concrete IJERTV6IS040098aslam sNo ratings yet

- 2018 GSA PM Guide FINALDocument731 pages2018 GSA PM Guide FINALRaymond CarlsonNo ratings yet

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFUday KumarNo ratings yet

- German Atv StandardsDocument16 pagesGerman Atv StandardsMehmet Emre Bastopcu0% (1)

- 파일수평지지력 (Broms)Document8 pages파일수평지지력 (Broms)murthyspandan89No ratings yet

- ASEP Steel HandbookDocument261 pagesASEP Steel HandbookMelgaszarGerry100% (6)

- Final Project (Team)Document5 pagesFinal Project (Team)bintangNo ratings yet

- CIV 2213 - Course OutlineDocument3 pagesCIV 2213 - Course Outlinemunroe wilsonNo ratings yet

- Refractory Support Ring & SeatingDocument12 pagesRefractory Support Ring & SeatingAstle DsouzaNo ratings yet

- Abutment Dhal Khad RockerDocument6 pagesAbutment Dhal Khad RockerAmit KumarNo ratings yet

- NSCP 1992 PDFDocument70 pagesNSCP 1992 PDFanon_181338447100% (1)