Professional Documents

Culture Documents

CR-10S Pro Inductive Sensor Setup

CR-10S Pro Inductive Sensor Setup

Uploaded by

Felipe MeresCopyright:

Available Formats

You might also like

- Mamiya 645 Light Seal ReplacementDocument4 pagesMamiya 645 Light Seal ReplacementJahanzebHaroonNo ratings yet

- Manual SenseMotion2 LylaDocument87 pagesManual SenseMotion2 LylaAndrew WinterNo ratings yet

- E18+ V6 ManualDocument40 pagesE18+ V6 ManualCorvus100% (3)

- To Achieve 100% 3D Printing Reliability: Our Easy Cheat SheetDocument7 pagesTo Achieve 100% 3D Printing Reliability: Our Easy Cheat Sheetfeere feeer0% (1)

- Auto leveling feaure user guide(Z9V5Pro-PL-08N Sensor)-V2Document8 pagesAuto leveling feaure user guide(Z9V5Pro-PL-08N Sensor)-V2eleniltonRsNo ratings yet

- User Instructions MiraDocument6 pagesUser Instructions MirastefaneduardNo ratings yet

- Hyrel 30M Instructions (Rough Draft)Document2 pagesHyrel 30M Instructions (Rough Draft)Juan Camilo VelasquezNo ratings yet

- Bed Level Test Procedure With Nics FirmwareDocument2 pagesBed Level Test Procedure With Nics FirmwareMarcos Antonio de Souza FilhoNo ratings yet

- Hello Bee Prusa SetupDocument16 pagesHello Bee Prusa SetupwindharmenNo ratings yet

- Brother NV5000 Sewing Machine Instruction ManualDocument44 pagesBrother NV5000 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Fei 430 Nanosem Operating Procedure: 12/17/10 1 of 10 A.GusmanDocument10 pagesFei 430 Nanosem Operating Procedure: 12/17/10 1 of 10 A.GusmanatulkrsharmaNo ratings yet

- Using A Probe Workflow To Square Your X Gantry - grblHAL-1Document7 pagesUsing A Probe Workflow To Square Your X Gantry - grblHAL-1brenelecNo ratings yet

- Print Quality Troubleshooting GuideDocument57 pagesPrint Quality Troubleshooting GuideLeonardo AgnanoNo ratings yet

- White "Magic Key" Buttonholer Accessory Instruction ManualDocument17 pagesWhite "Magic Key" Buttonholer Accessory Instruction ManualiliiexpugnansNo ratings yet

- How To Install Somfy MotorsDocument6 pagesHow To Install Somfy MotorsJuary99No ratings yet

- Marlin Using Manual and Mesh Bed LevelingDocument1 pageMarlin Using Manual and Mesh Bed Levelingmarco.dado2700No ratings yet

- J3DTech Guide To Resin 3D PrintingDocument90 pagesJ3DTech Guide To Resin 3D Printinglfmo77No ratings yet

- Mach TurnDocument4 pagesMach TurnNancy RodriguezNo ratings yet

- Renanim Bed ManualDocument15 pagesRenanim Bed ManualAnnie Ruth OlbesNo ratings yet

- NANO User's ManualDocument7 pagesNANO User's ManualmcmastermurdocNo ratings yet

- WarpingDocument10 pagesWarpingkishor reddyNo ratings yet

- How To Resume From Z AxisDocument2 pagesHow To Resume From Z AxisVinayagam A KNo ratings yet

- Intro To CNC For A Total NoviceDocument11 pagesIntro To CNC For A Total NoviceIshmael AliNo ratings yet

- Bed auto leveling user guideDocument8 pagesBed auto leveling user guideeleniltonRsNo ratings yet

- OBOE GougerDocument2 pagesOBOE GougerCarlos GaldámezNo ratings yet

- How To Resume From Z AxisDocument2 pagesHow To Resume From Z AxisVinayagam A KNo ratings yet

- Auto LevelDocument6 pagesAuto LevelblahaNo ratings yet

- Setting Needle Bar Depth For SWF Embroidery Machines (All Models)Document2 pagesSetting Needle Bar Depth For SWF Embroidery Machines (All Models)Jonathan Lara FandiñoNo ratings yet

- Alineamiento LaserDocument2 pagesAlineamiento LaserpatograndonNo ratings yet

- E3d Nano 3d PrinterDocument11 pagesE3d Nano 3d Printerbunser animationNo ratings yet

- Geeetech Prusa I3 Dual ExtruderDocument56 pagesGeeetech Prusa I3 Dual ExtruderSteve Abonyi100% (1)

- Manual Positector6000 DahecDocument69 pagesManual Positector6000 Dahecjose raulNo ratings yet

- Silkscreening Is Such A Great Happy MediumDocument17 pagesSilkscreening Is Such A Great Happy Mediumjrgene16No ratings yet

- PrusaI3 ProC User ManualDocument56 pagesPrusaI3 ProC User ManualJorge LunaNo ratings yet

- Spider Programs, Step by StepDocument9 pagesSpider Programs, Step by StepHarshana RandheeraNo ratings yet

- Photoshop - Mouthless by Michael OttDocument6 pagesPhotoshop - Mouthless by Michael OttMichael Ott100% (14)

- 329M ManualEnglish 171027Document17 pages329M ManualEnglish 171027Zagiza TuNo ratings yet

- 3D Printing Troubleshooting 34 ProblemsDocument64 pages3D Printing Troubleshooting 34 ProblemsDamir K100% (2)

- Geeetech Prusa I3 Pro&Pro B User ManualDocument46 pagesGeeetech Prusa I3 Pro&Pro B User ManualGeovanny Javier Morocho Choca100% (1)

- HT Series Operation ManualDocument24 pagesHT Series Operation ManualDessire WilliamsNo ratings yet

- Laser Cutter Operation and File Preparation LABDocument6 pagesLaser Cutter Operation and File Preparation LABmohamad eslamiNo ratings yet

- TevoDocument9 pagesTevoJean-m DuguayNo ratings yet

- DMY3dp-001 Automatic Leveling Debug Guide V2Document5 pagesDMY3dp-001 Automatic Leveling Debug Guide V2Saed CattywampusNo ratings yet

- Pro 3600 ManualDocument16 pagesPro 3600 Manualdavidjm88No ratings yet

- S3D Settings PETG EsunDocument4 pagesS3D Settings PETG Esunjose luis martinez martinezNo ratings yet

- Oboe Gouger User GuideDocument3 pagesOboe Gouger User Guidekyanagisawa100% (1)

- Genius Manual-20200818Document114 pagesGenius Manual-20200818Stefano SabatiniNo ratings yet

- Setting The P/C ORIGIN OFFSETDocument4 pagesSetting The P/C ORIGIN OFFSETPablo MafraNo ratings yet

- Ender Xtender XL Installation GuideDocument18 pagesEnder Xtender XL Installation GuideAnonymous w6GMxAPOYBNo ratings yet

- Guidelinesfor Ebeam Litho - DocxDocument5 pagesGuidelinesfor Ebeam Litho - DocxZhang zhenshengNo ratings yet

- Tips To Improve Tablet DrawingDocument9 pagesTips To Improve Tablet DrawingNiranjanNo ratings yet

- 1 3d Printer ProblemsDocument7 pages1 3d Printer ProblemsTAYALSNo ratings yet

- Leica DISTO™ X310: How To UseDocument7 pagesLeica DISTO™ X310: How To UseadenanNo ratings yet

- Dual-Head Machine InstallationDocument5 pagesDual-Head Machine InstallationFreddy GonzalezNo ratings yet

- Drawing Rhino (III)Document22 pagesDrawing Rhino (III)Aldy sabat TindaonNo ratings yet

- L0810348 PDFDocument98 pagesL0810348 PDFhughstimsonNo ratings yet

- Russ Method For Dithering On LaserDocument2 pagesRuss Method For Dithering On LasermarcanstNo ratings yet

- Sidewinder Assembly Manual-ENDocument2 pagesSidewinder Assembly Manual-ENDenis PereiraNo ratings yet

- Elementary Sewing Skills: Do it once, do it wellFrom EverandElementary Sewing Skills: Do it once, do it wellRating: 2 out of 5 stars2/5 (4)

- Sekula Allan 1983 2003 Reading An ArchiveDocument13 pagesSekula Allan 1983 2003 Reading An ArchiveFelipe MeresNo ratings yet

- Shapin 1994 - The Great Civility - Trust, Truth, and Moral OrderDocument21 pagesShapin 1994 - The Great Civility - Trust, Truth, and Moral OrderFelipe MeresNo ratings yet

- Deceitful MediaDocument198 pagesDeceitful MediaFelipe MeresNo ratings yet

- How To Slice STL Models For 3D Printing Using NetfabbDocument3 pagesHow To Slice STL Models For 3D Printing Using NetfabbFelipe MeresNo ratings yet

- CR-10 Enclosure DescriptionDocument4 pagesCR-10 Enclosure DescriptionFelipe MeresNo ratings yet

CR-10S Pro Inductive Sensor Setup

CR-10S Pro Inductive Sensor Setup

Uploaded by

Felipe MeresOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CR-10S Pro Inductive Sensor Setup

CR-10S Pro Inductive Sensor Setup

Uploaded by

Felipe MeresCopyright:

Available Formats

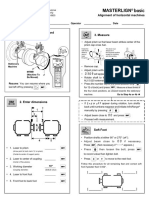

CR-10S Pro

My setup for an inductive sensor with Wham Bam magnetic bed.

The following assumes you have wired in the new inductive sensor already.

Install new sensor and adjust so it is approximately 4mm from the bed with the nozzle 0.2 off

the bed. Raise the gantry 100mm and Press the home button, check the sensor is working by

placing something metallic under it as it starts to lower.

Press home again and make sure the nozzle doesn’t contact the bed.

Start a dummy print and Zero out the Z offset in the print adjust screen. No need to wait for

the print to start, the screen is accessible from the print screen

(This is the way I reset the Z offset. If you don’t do this, the current offset could stick and

might not reset in the homing screen.)

Stop print.

Go to leveling screen.

Check the distance between the nozzle and the bed.

Adjust sensor up to get the nozzle closer to the bed or down to move it away, do this until

you get just over 0.2 gap from nozzle to bed in the homed position.

This may take a couple of goes, try not to move more than 0.5mm at a time. Having the

nozzle a little high is better than low. Re home and use the Z offset to bring nozzle down to

0.2 shim.

Do aux leveling.

Run auto leveling.

On First print after auto levelling adjust Z offset to get good first layer.

After that the only time you should have to adjust your Z offset is for tuning first layers for

different filament.

Hope this makes sense to you and helps.

Patrick Cruse.

You might also like

- Mamiya 645 Light Seal ReplacementDocument4 pagesMamiya 645 Light Seal ReplacementJahanzebHaroonNo ratings yet

- Manual SenseMotion2 LylaDocument87 pagesManual SenseMotion2 LylaAndrew WinterNo ratings yet

- E18+ V6 ManualDocument40 pagesE18+ V6 ManualCorvus100% (3)

- To Achieve 100% 3D Printing Reliability: Our Easy Cheat SheetDocument7 pagesTo Achieve 100% 3D Printing Reliability: Our Easy Cheat Sheetfeere feeer0% (1)

- Auto leveling feaure user guide(Z9V5Pro-PL-08N Sensor)-V2Document8 pagesAuto leveling feaure user guide(Z9V5Pro-PL-08N Sensor)-V2eleniltonRsNo ratings yet

- User Instructions MiraDocument6 pagesUser Instructions MirastefaneduardNo ratings yet

- Hyrel 30M Instructions (Rough Draft)Document2 pagesHyrel 30M Instructions (Rough Draft)Juan Camilo VelasquezNo ratings yet

- Bed Level Test Procedure With Nics FirmwareDocument2 pagesBed Level Test Procedure With Nics FirmwareMarcos Antonio de Souza FilhoNo ratings yet

- Hello Bee Prusa SetupDocument16 pagesHello Bee Prusa SetupwindharmenNo ratings yet

- Brother NV5000 Sewing Machine Instruction ManualDocument44 pagesBrother NV5000 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Fei 430 Nanosem Operating Procedure: 12/17/10 1 of 10 A.GusmanDocument10 pagesFei 430 Nanosem Operating Procedure: 12/17/10 1 of 10 A.GusmanatulkrsharmaNo ratings yet

- Using A Probe Workflow To Square Your X Gantry - grblHAL-1Document7 pagesUsing A Probe Workflow To Square Your X Gantry - grblHAL-1brenelecNo ratings yet

- Print Quality Troubleshooting GuideDocument57 pagesPrint Quality Troubleshooting GuideLeonardo AgnanoNo ratings yet

- White "Magic Key" Buttonholer Accessory Instruction ManualDocument17 pagesWhite "Magic Key" Buttonholer Accessory Instruction ManualiliiexpugnansNo ratings yet

- How To Install Somfy MotorsDocument6 pagesHow To Install Somfy MotorsJuary99No ratings yet

- Marlin Using Manual and Mesh Bed LevelingDocument1 pageMarlin Using Manual and Mesh Bed Levelingmarco.dado2700No ratings yet

- J3DTech Guide To Resin 3D PrintingDocument90 pagesJ3DTech Guide To Resin 3D Printinglfmo77No ratings yet

- Mach TurnDocument4 pagesMach TurnNancy RodriguezNo ratings yet

- Renanim Bed ManualDocument15 pagesRenanim Bed ManualAnnie Ruth OlbesNo ratings yet

- NANO User's ManualDocument7 pagesNANO User's ManualmcmastermurdocNo ratings yet

- WarpingDocument10 pagesWarpingkishor reddyNo ratings yet

- How To Resume From Z AxisDocument2 pagesHow To Resume From Z AxisVinayagam A KNo ratings yet

- Intro To CNC For A Total NoviceDocument11 pagesIntro To CNC For A Total NoviceIshmael AliNo ratings yet

- Bed auto leveling user guideDocument8 pagesBed auto leveling user guideeleniltonRsNo ratings yet

- OBOE GougerDocument2 pagesOBOE GougerCarlos GaldámezNo ratings yet

- How To Resume From Z AxisDocument2 pagesHow To Resume From Z AxisVinayagam A KNo ratings yet

- Auto LevelDocument6 pagesAuto LevelblahaNo ratings yet

- Setting Needle Bar Depth For SWF Embroidery Machines (All Models)Document2 pagesSetting Needle Bar Depth For SWF Embroidery Machines (All Models)Jonathan Lara FandiñoNo ratings yet

- Alineamiento LaserDocument2 pagesAlineamiento LaserpatograndonNo ratings yet

- E3d Nano 3d PrinterDocument11 pagesE3d Nano 3d Printerbunser animationNo ratings yet

- Geeetech Prusa I3 Dual ExtruderDocument56 pagesGeeetech Prusa I3 Dual ExtruderSteve Abonyi100% (1)

- Manual Positector6000 DahecDocument69 pagesManual Positector6000 Dahecjose raulNo ratings yet

- Silkscreening Is Such A Great Happy MediumDocument17 pagesSilkscreening Is Such A Great Happy Mediumjrgene16No ratings yet

- PrusaI3 ProC User ManualDocument56 pagesPrusaI3 ProC User ManualJorge LunaNo ratings yet

- Spider Programs, Step by StepDocument9 pagesSpider Programs, Step by StepHarshana RandheeraNo ratings yet

- Photoshop - Mouthless by Michael OttDocument6 pagesPhotoshop - Mouthless by Michael OttMichael Ott100% (14)

- 329M ManualEnglish 171027Document17 pages329M ManualEnglish 171027Zagiza TuNo ratings yet

- 3D Printing Troubleshooting 34 ProblemsDocument64 pages3D Printing Troubleshooting 34 ProblemsDamir K100% (2)

- Geeetech Prusa I3 Pro&Pro B User ManualDocument46 pagesGeeetech Prusa I3 Pro&Pro B User ManualGeovanny Javier Morocho Choca100% (1)

- HT Series Operation ManualDocument24 pagesHT Series Operation ManualDessire WilliamsNo ratings yet

- Laser Cutter Operation and File Preparation LABDocument6 pagesLaser Cutter Operation and File Preparation LABmohamad eslamiNo ratings yet

- TevoDocument9 pagesTevoJean-m DuguayNo ratings yet

- DMY3dp-001 Automatic Leveling Debug Guide V2Document5 pagesDMY3dp-001 Automatic Leveling Debug Guide V2Saed CattywampusNo ratings yet

- Pro 3600 ManualDocument16 pagesPro 3600 Manualdavidjm88No ratings yet

- S3D Settings PETG EsunDocument4 pagesS3D Settings PETG Esunjose luis martinez martinezNo ratings yet

- Oboe Gouger User GuideDocument3 pagesOboe Gouger User Guidekyanagisawa100% (1)

- Genius Manual-20200818Document114 pagesGenius Manual-20200818Stefano SabatiniNo ratings yet

- Setting The P/C ORIGIN OFFSETDocument4 pagesSetting The P/C ORIGIN OFFSETPablo MafraNo ratings yet

- Ender Xtender XL Installation GuideDocument18 pagesEnder Xtender XL Installation GuideAnonymous w6GMxAPOYBNo ratings yet

- Guidelinesfor Ebeam Litho - DocxDocument5 pagesGuidelinesfor Ebeam Litho - DocxZhang zhenshengNo ratings yet

- Tips To Improve Tablet DrawingDocument9 pagesTips To Improve Tablet DrawingNiranjanNo ratings yet

- 1 3d Printer ProblemsDocument7 pages1 3d Printer ProblemsTAYALSNo ratings yet

- Leica DISTO™ X310: How To UseDocument7 pagesLeica DISTO™ X310: How To UseadenanNo ratings yet

- Dual-Head Machine InstallationDocument5 pagesDual-Head Machine InstallationFreddy GonzalezNo ratings yet

- Drawing Rhino (III)Document22 pagesDrawing Rhino (III)Aldy sabat TindaonNo ratings yet

- L0810348 PDFDocument98 pagesL0810348 PDFhughstimsonNo ratings yet

- Russ Method For Dithering On LaserDocument2 pagesRuss Method For Dithering On LasermarcanstNo ratings yet

- Sidewinder Assembly Manual-ENDocument2 pagesSidewinder Assembly Manual-ENDenis PereiraNo ratings yet

- Elementary Sewing Skills: Do it once, do it wellFrom EverandElementary Sewing Skills: Do it once, do it wellRating: 2 out of 5 stars2/5 (4)

- Sekula Allan 1983 2003 Reading An ArchiveDocument13 pagesSekula Allan 1983 2003 Reading An ArchiveFelipe MeresNo ratings yet

- Shapin 1994 - The Great Civility - Trust, Truth, and Moral OrderDocument21 pagesShapin 1994 - The Great Civility - Trust, Truth, and Moral OrderFelipe MeresNo ratings yet

- Deceitful MediaDocument198 pagesDeceitful MediaFelipe MeresNo ratings yet

- How To Slice STL Models For 3D Printing Using NetfabbDocument3 pagesHow To Slice STL Models For 3D Printing Using NetfabbFelipe MeresNo ratings yet

- CR-10 Enclosure DescriptionDocument4 pagesCR-10 Enclosure DescriptionFelipe MeresNo ratings yet