Professional Documents

Culture Documents

Frank Whittle 1945

Frank Whittle 1945

Uploaded by

DUVAN FELIPE MUNOZ GARCIACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frank Whittle 1945

Frank Whittle 1945

Uploaded by

DUVAN FELIPE MUNOZ GARCIACopyright:

Available Formats

288 THE E N G INEE R OoT.

12, 1945

•

The President of the Air Council was a. party

The Whittle Jet Propulsion Gas Turbine* to the agreement which r esulted in the forma-

tion of Power Jets, and the Air Ministry was a.

shareholder from the start in that a proportion

By Air Commodore F. WHITTLE, C.B.E ., R.A.F., M.A. , Hon. M.I . Mech. E .t of the shares alloted to me was held in trust for

the D epartment.

No. I During the negotiations leading to the forma·

tion of Power J ets, I was working on the designs

INTRODUCTION AND GENERAL OUTLINE a Flight Cadet at the R.A.F. College, Cranwell. of an experimental engine. Messrs. 0. T. Falk

Each term we had to write a science thesis, and Partners placed an order with the British

HE main argument against the gas turbine

T was that the maximum temperatures per-

missible with materials available, or likely to

and in my fourth term I chose for my subject

the future development of aircraft. Amongst

Thomson-Houston Company, Ltd., for engi.

neering and design work in accordance with my

other things, I discussed the possibilities of jet requirements in advance of the formation of

be available, was such that the ratio of positive the new company. Power Jets placed the order

to negative work in the constant-pressure cycle propulsion and of gas turbines ; but it was not

until ·eighteen months later, when on an for the manufacture of the engine (except t he

could not be great enough to allow of a reason- combustion chamber, instruments, and some

able margin of useful work to be obtained, after instructors' course at the Central Flying School,

Wittering, that I conceived the idea of using a accessories), with the British Thomson-Houston

a llowing for the losses in the turbine and com- Company in June, 1936.

pressor. There seemed to be a curious tendency gas turbine for jet propulsion. I applied for

my first patent in January, 1930. The principal The engine was to b e a simple jet propulsion

to take it for granted that the low efficiencies gas turbine having a single-stage centrifugal

of turbines and compressors commonly cited drawing of the patent specification as filed is

reproduced in Fig. 1. It may be seen that I compressor with bilateral intakes, driven by a.

• were inevitable. I did not share the prevalent single-stage turbine directly coupled. Com-

pessimism because I was convinced that big tried to include the propulsive duct, or

" athodyd," as it has since been called, but this bustion was to take place in a single combustion

improvements in these efficiencies were possible, chamber through which the working fluid

had been anticipated at least twice, so the upper

ftG. l . drawing and relevant descriptive matter had passed from the compressor to the turbine.

to be deleted from the specification. We were going beyond all previous engineer-

The idea was submitted to the Air Ministry, ing experience in each of the major organs. We

but was turned down on the ground that as it were aiming at a pressure ratio of about 4/ 1 in

a single-stage centrifugal blower when at the

time, so far as we knew, a ratio of 2t/1 had not

7

c ..~ . D

been exceeded. We were aiming at a breathing

capacity in proportion to size substantially

~

1\

\

\V

NOZZl E THROAT

lliS'~ABS., 1,938 FT. PE R SEC

~

flG. 2., g ))-8 SQ. IN .

......

~

B c -

~

.

~

.....a

I

J

\

MAIN NOZZl E

~UTH

EF

...«

~

• 1

' .... I'..A

........

......_

G

I

100 lio )CO 400 ~ lo 600 7lo elo

-"

0

VOLUME-CV. FT.

S WAI N Se ..

f tc• 0 Sea. level cycle .

SW"'f N Se.

Assumptions :-Coml?ressor efficiency, 70 per cen t.

\0 Turbme efficiency , 70 p er cent.

Axia.l velocit y a.t turbine exhaust, 1020ft. FIG. 3- .Assembly of the F irst 111odel of E xp eriTMntat

p er second. Engine

E fficiency of final expansion, 90 p er cent.

Weight of air, 26 lb. per second.

Weight of fuel, 0 · 3635lb. p er second . greater than had previously been attempted.

y = 1 · 4 for comp ression = 1· 379 for ex - The combustion intensity we aimed to achieve t

•

pa.ns10n.

Kp = 0 · 24 for compression = 0 · 26 for was far beyond anything previously attempted. I

combustion an d el.."P&n sion. Finally, we had to get over 3000 S.H.P. out of a

Static thrust, 1240 lb. a single-s tage turbine wheel of about 16lin.

FIG. 2- The Pressure- Volume D iagram, D esign A ssump- outside diamet er, and to do it with high

\0 tiotl8, &,c. , on which the Initial Design of the efficiency.

E xperimental Engine was Based At first, our intention was to do the job stage

$ W AI,.. Se.

by stage that is, to make a compressor and

was a gas turbine the practical difficulties in the t est it ; then to add a combustion chamber to

The upper drawing-t he thermo-propulsive duct--had way of the development were too great. the compressor; then to test a turbine alone;

to be deleted from the specification During 1930 I tried to interest various firms and finally to build an engine but we very

FIG. ! - Reproduction of Drawings Illustrating B riti,sh in the scheme, but m et with no success ; for soon realised that this was likely to be a. long

Patent No . 341,206,flled January 16th, 1930 the most part they thought the same way as and costly pro ess and we decided to go for a

u.nd, in the application of jet propulsion to the Air Ministry. It is probably also true that in complet e engine right away.

aircraft, I realised that there were certain their view the prevalent industrial depression This first engine was b ased on a design for

favourable factors not present in other applica- made it anything but a favourable moment for flight, but was n ot intended for flight ; and

tions, namely : - expensive ideas of this sort. though it was designed to b j very light by normal

Nothing very much happened for a few engineering standards, we did not put forth

( 1) The fact that the low temperatures at years. I gave up hope of ever getting the idea special efforts to make it as light as possible.

high altitudes made possible a greater ratio to the practical stage, but continued to do paper I was fairly confident in the compressor a.nd

of positive to negative work for a given work at intervals, until, in May, 1935, when I turbine elements, but felt rather out of my depth

maximum cycle temperature. was at Cambridge as an engineer officer taking with the combustion problem, and so (in 1936)

(2) A certain proportion of the com- the Tripos Course, I was approached by two I visited the British Industries F air with a

pression could be obtained at high efficiency ex-R .A.F. officers (Mr. R. D. Williams and view to enlisting the aid of one of the oil burner

by the ram effect of forward speed, thereby Mr. J. C. B. Tinling}, who suggested that they firms, but the requirements I specified were

raising the average efficiency of the whole should try to get something started. Though I considered to b e far too stringent by most of

compression process. had allowed the original patent to lapse them until I m et Mr. Laidlaw, ofLaidlaw, Drew

(3) The expansion taking place in the through failure to pay the renewal fee, and and Co. Though he recognised that we were

turbine element of such an engine was only though I regarded thein as extremely opti- aiming at something far in advance of previous

that which was necessary to drive the com- m istic, I agreed to co-operate. I thought that experience in this field he considered the target

pressor ; and therefore only part of the there was just a bare chance that something possible of atta inment, and so it was with his

expansion process was subject to turbine might come of it. help that we attacked the combustion problem.

losses. We eventually succeeded in coming to an While the engine was in course of design and

Outline.- ! first started thinking about this arrangement with a firm of investment bankers manufacture, we carried out a number of com-

general subject in 1928, in my fourth term as (Messrs. 0. T. Falk and Partners}, which led to bustion el..'Periments on the premises of the

the formation of Power J et s. Ltd., in March , British Thomson -Houston Company, with

• First James Clay ton Lecture. Institution of 1936. Before Power Jets was formed, 0. T. apparatus supplied by Laidlaw, Drew and Co.,

Mechanical Engineers, October 6th. Abstract.

t Special Duty List, R.A.F., attached to Power Jets Falk and Partners obtained the opinion of a until we considered that we had enough informs.·

(Research and Development), Ltd. , Whetstone, Leicester. consulting engineer (Mr. M. L. Bramson), who tion to design a combustion chamber. P ower

The statements and opinions expressed herein are the gave a wholly favourable report. The initial Jets therefore placed the contract for the design

personal views of th& lo ct~er, and ar_e .not to b e t ake? sum subscribed was £2000, and with this we

as in any way re~resentmg the opm10ns. of the A1r and manufacture of the combustion chamber

Ministry or the Min1stry of Aircraft Product10n. cheerfully went ahead. with Laidlaw, Drew and Co.

OcT. 12, 1945 THE ENGINEER 289

By this time the Tripos Examinations at impeller as manufacturing limitations would assembly which contained one of the two water

Cambridge were over, and the Air Ministry permit, in order to keep the blade loading as jackets for the turbine cooling could not be

he.d agreed that I should stay for a post- low as possible. In particular, it was hoped split in the diametral plane. These considera-

graduate year. This was really a device to that by keeping the pitch-chord ratio of the tions governed the rotor design.

enable me to continue work on the engine, and rotating guide vanes small we should avoid Testing .-As already mentioned, the testing of

so a considerable proportion of my time was stalling at the intake, as I believed then-and the engine under its own power began on April

spent at the British Thomson-Houston Com- still believe that this is one of the main sources 12th, 1937. The very :first attempt to start

pany's works in Rugby. of loss in centrifugal compressors. was successful, in that the engine ran under its

Testing of the engine commenced on April No diffuser blades were fitted to the blower own power, but it accelerated out of control

12th, 1937, and continued intermittently until casing at :first. Two stages of diffusion were up to about half its designed full speed. This

August 23rd. These early tests made it clear aimed at. The intention was to obtain partial happened several times, and altogether it was a

that the combustion problem was by no means diffusion in the bladeless vortex space between very alarming business, so much so that in the

solved, and that the compressor performance the impeller tips and the scroll, and to convert early days the individuals in the vicinity did

was far below expectations. Nevertheless, they more running than the engine.

were sufficiently encouraging to show that we The starting procedure was as follows :- The

were on the right track. engine was motored at about 1000 r.p.m. and

THE DESIGN AND TESTING OF THE

EXPERIMENTAL ENGINE

IWODiltJ the pilot jet (which injected an atomised spray)

was switched on and ignited by means of a.

11

1I

,----''

(--- _, PILOT JET sparking plug and hand magneto. The motor-

The Design and Testing of the First Model: ing speed was then raised to about 3000 r.p.m.,

Design.-The first engine was designed with PILOT JET

CONTROL

R

u and the main control opened slowly. The engine

a specific target in mind. It was a very optimis- '• fUEL PUMP would then accelerate under its own power ;

tic one, but, nevertheless, it formed the starting but, as I say, not always under control. The

point and is worth r ecording. The aim was to explanation of the first few uncontrolled accele-

propel a very " clean " little aeroplane of about rations was simple when we found it, and may

2000 lb. " all up '' weight at a speed of 600 t~AIN

be understood by reference to the diagram of

CONTROl

.......... the early fuel system, shown in Fig. 5. If the

(MEI\CENCY

1\ELIEF VAlVE 8Y·PASS spill line from the burner was not full of fuel

:,OWAI,.. S C o

the needle valve of the burner would be forced

into the fully open position when the fuel

FIG. 5 The Fuel System Used in the Early T uts of the pump ran. We were frequently breaking the

First 111odel of the Experimental Engine fuel line and doing various motoring tests, so

that often, unknown to us, there was a " lake "

of fuel in the combustion chamber. Other

most of the remaining kinetic energy into pres- uncontrolled accelerations were caused by the

sure in the " honeycomb " di.ffuser through sudden opening of the burner needle valve after

00

which the air passed from the compressor scroll initial sticking ; by loss of temper in the burner

1 HC CNGI,..t(.A •

to the combustion chamber. spring through overheating, &c. Fortunately,

FIG. 4 - T e.<Jt Assembly of F irst Model of Experimental

The turbine nozzle arrangement was very none of these uncontrolled accelerations took

Engine unorthodox, as no nozzle blades were used. The the engine beyond about 9000 r.p.m.

idea was that most of the expansion took place No trouble was ever experienced in starting

in the convergent-divergent entry to the nozzle except when the ignition failed through cracked

m.p.h., at a height _of the order of 70,000ft. This scroll which was shaped to cause the discharge electrodes, or when mistakes were made in the

speed was estimated to correspond to that of of the gases through its annular mouth with assembly of the fuel lines.

minimum drag at that height, i.e., this high constant axial velocity, the whirl velocity The overheating of the burner already referred

speed was also the most economical speed for corresponding to that of a free vortex, i.e., to was a serious problem, and as a result of it a.

the height. It was estimated that a net thrust constant angular momentum. This nozzle fairly drastic change in the combustion system

at this height of lll lb. would be required. design was the source of considerable contro- was made. We changed over to downstream

The size of engine corre.,poncling to the data versy, and though I am not very proud of it inj ection. Five runs were then made with this

was considered to be the smallest in which the

necessary accuracy of m ..chining could be

obtained without excessive manufacturing costs.

The design assumptions and leading particu-

lars are given in Table I, and the pressure-

volume cycle shown in Fig. 2.

TABLE I.-Leading Particulars of First Edition of

Experimental Engine

Dimensions are in inches.

Compreseor impeller-

Tip diameteT . . . . . . . .. 19

Tip width ... ... ... .,. 2

Outer diameter of eye ... 10·75

Inner diameter of eye 5·5

Number of blades ... 30

Materia l . .. .. . .. . Hiduroinium RR 56

Compressor ce.sing-

Inner diameter of scroll . . . 31

:Material .. . .. . .. . .. . Hiduminium RR 55,

DTD. 133 B

Turbine-a-

Mean diameter of blo.des... 14

Blade length .. . .. . .. . 2 · 4

Material of blades ... .. . Firth-Vickers Stayblade

Material of disc ... ... ... Firth-Vickers Stayblade

Blade chord .. . .. . .. . 0 · 8

Number of blades ... .. . 66

Maximum speed-

R evolutions p er minute ... 17,750

Figs. 3, 4, and 5 illustrate various features of FIG. 6 First M odel of the First Experimental Eng~ne

the design, which are further amplified in

Figs. 6, 7, 8, and 9.

The assumption of 80 p er cent. adia,b atic now, I thought it a good idea at the time. It is system up to maximum speeds of about 8500

efficiency for a centrifugal compressor running of considerable interest in retrospect, because r.p.m., but the combustion was so bad that this

at a tip speed of l470ft. per second was very it became evident later than I had not succeeded speed could not Le exceeded. Any further

optimistic indeed, and received a good deal of in conveying to others what I had in mind. opening of the control seemed to result only in

criticism, but I felt confident that we could Air tests were made on a half-scale model of the burning of more fuel aft of the turbine.

design to avoid many of the losses which were this nozzle, and though very rough they seemed Many attempts to improie the combustion

occurring in all centrifugal compressors of to show that it would behave approximately as were made by a series of modifications to the

which I had knowledge at the time. The general expected. combustion chamber, and some improvement

view was that we should be fortunate if we got The design of the rotor assembly needed was achieved-we managed to get up to a speed

65 per cent. adiabatic efficiency. much careful thought. It was considered of 11,000 r.p.m. for 10 min. This series of runs

We went for the double-sided compresso_r necessary to use unbored forgings for both the ended when the compressor impeller fouled the

because we wanted to get the greatest possible turbine wheel and compressor impeller, also to casing after running for 4 min. at 12,000 r.p.m.

breathing capacity in proportion to size. I also use an overhung turbine rotor, as it was thought The d.a.mage to the compressor and impeller

counted on this featW'e to give a reduced pro- that the provision of a satisfactory bearing casing was only slight, but as it had now become

portion of skin friction losses. support on the exhaust side of the turbine clear that the delivery pressure from the com-

We aimed at having as many blades on the would be very difficult. The bearing housing pressor was much below expectations, we

290 THE ENGINEER OcT. 12, 1945

decided to fit diffuser blades in an effort t o the burner now b eing insulated against over- to the national standards bodjes in Britain.

improve tho blower performance before further heating b y using a fuel-cooling arrangement. America, and Canada, so that what is termed

testing. " 'o th n managed to attain a speed Combustion appeared to be improved, and for an" A . B. C." standard will be speedily approved.

of 13,000 r.p.m., but tho compressor perform- the first time no part of the casings reached Mutual under ~ tanding was reached on specifica-

ance still left much to be desired. Moreover, the glow heat at speeds of up to 12,000 r.p.m. tions for sma11 screws and various scr ews and

combustion had deteriorated, and as this was Tes ting was now suspended for the following threads u ed in the optical and scientific in. tru-

believed to be due to th e nature of the flow reasons :- First, because the speed restriction ment trades, and on buttress thread forms.

from the compressor scroll to the combustion of 12,000 r.p.m. made it necessary to :find a new Considerable progress was made in gathering

chamber, many modifications to improve this site for running at higher speeds, and, secondly, data on high-duty studs in light alloys, but a

great deal more exploratory work is, it is felt,

r equired. Drawing practice and its tmi:fication

wero discussed, and it was agreed that thi:-:

subject be actively pursued. Pipe threads wore

dealt with and an invitation to the British and

Canadian representatives to continue discnR-

sions of this subject at the November meeting~:~

of the American Petroleum Institute were

given. On the question of limits and fits, a

furth er meeting with the British delegates will

be held in N ew York before the return of the

delegates. Suggestions were forthcoming on

precision and gauging m ethods, with a view to

the co-ordination of future practice. Propo. ed

specifications for screw threads and connections

for gas cylinders were presented. On the wholo.

thic; third Conference exemplified the spirit of

collaboration which prevails among the engi -

neering profc. sions of the thrE"e EngliRh·Spf'aking

countries.

FIG. 7-Rotor Assembly of First Experimental Engine

flow were made, but without no ticeable improve- becau::;e it was decided to make major modifica- Institution Programmes

ment. There wa::~ evidence of a flow reversal t ions to the general a rrangement.

in the elbow, bnl, we did not realise how sever e The t est s so far had been very disappointing, Pn.oGRAMM:ES for the session 1945-46 have now

this was until (in one test late in the series) but there were m any encouraging features. We been issued by the fo 1lowing institutions and

:fltlmes were seen through a small hole which had demonstrated that there was no particular societies : -

•

had been drilled in the nE"ck of the blower difficulty in starting or in control. There was INSTITUTE OF MARINE ENGINEERS

casing scroll. a lso plenty of evidence which suggested that November 13th, 1945 : " Development in Tur-

A ser ies of rapid modifications to the diffuser the whole scheme was well worth developing, bine Blading," by J. G. Monypenny.

though it had become obvious that much harrl D ecember 11th: '· Deck Machinery, with

work lay ahead. Particular Reference to Latest Developments," by

' ' ' OIA Tho principal defects of that par ticn lnr T. Brown.

anangement were shown to be:- January 8th, 1946 : " Elements of Propulsive

(1) Poor compressor efficiency. Efficiency," by F. H. Todd, B.Sc., Ph.D., M.I.N.A.

February 12th : '· The Development of the

(2) Excessive prehcating of the air to the Opposed-Piston Marine Oil Engine, with Special

r ear intake, owing to the disposition and tem- Reference to Engine Dynamics," by \V. Ker \Yi1 on,

pt-rature of the combustion chamber. D .Sc., Ph .D., 'W h. Ex.

(3) Very unsatisfactory combustion. March 12th: "Strain Gauges," by Dr. F.

( 4) Excessive frictional loss in the n n- Aughtie.

orthodox turbine nozzle scroll. April 9th : " Engine-Room Lay-Out, with

Special Reference to Pipe W ork," by Lient.-Colonel

No reading of sufficient r eliability had bePn G. Rochfort, M.C., D.S.O.

obtained from which any estimat e of the effi- Apr il 30th : " Lubricating Oils a.nd their

ciency of the turbine could be macle, but it Charactel'istics," by C. Lawrie nnd Colonel S. J. M.

eemed practically certain that it wa,:-: wc.>ll bPlow Auld.

FIG . 8-The Uncotwentional BLadeless Turbine Nozzle thA-t ft,RRUm <'<l in the design. May 14th : " Air Preheater D esign, Construction,

, 'rroll in the Fir.9t M odel of the El·perimental Engine and Maintenance, " by \V. Crawford Hume.

('T'o be continued) September lOth : The President's Address.

system of the blower, combu:"tion cha mber and October 8th : " Vacuum Refrigeration," by \\'.

the flow path between the compre::;sor scroll and Sa.mpson .

the combus tion chamber was made, most of November 12th : " R esistance Welding in Engi-

them with little improvement, but subse- neering Construction," by S. Hunter Gordon.

quently wA ~mcceeded in reaching a speed of Standardisation of Screw

ROYAL AERONAUTICAL SOCIETY

13,600 r.p.m. with the blower fitted with a

modified . et of d iffu. er b lades. Threads Oc:tober l th, 1945 : " Aircraft Engine Oil Cool·

At this poin t in t.lH' tc>sts t he chit'f <"nginE"Pr ing," by F. Nixon , B . c., M.I.A.E., F.R.Ae. .

THE Conference on the Unification of Engi- Novembor l st : " A Critical Review of German

neering 'tandardc; held in Ottawa, and referred Long-Range Ro('k(}t Development," by W. G. A.

to in one of las t week's J ournal notes, adjourned Perring, F.R.Ae.S.

on October 7th after a two weeks' session. The Novembor 15th: Fit·st Briti ~ h Empire Lootw·e,

British delegate ' will visi t various industrial " Australian and Empire Air Transport," by \\' .

centres in Canada and the United States, and Hudson Fysh, D.F.C.

are expected to leave on their return journey November 29th : " Aspec ts of German ,\ ot·o-

nautical D evelopment," by \V. J. Stern.

lator t his month. It can be stat ed that the December l lth : " Meteorology a.ml H igh·

fundamental clifferences between British and Altitude Aviation," by Professor Dobson, F.RS.

American screw thread forms, which caused December 19th : " Atomic Disintegration," by

tremendous production and supply difficulties P rofossor N. Feather, Ph.D., F.R.S.

during tho war period, were resolved to the

point at which the delegates were prepared to

return to their respective countries with a speci-

fication of a basic thread form that will provide 0VEHSEAS 'J'RADE STATISTICS.-Publication of

a unified standard for all countries employing tlio Board of Trade's monthly trade accounts will

the inch syst em. The basic form, it is stated, bo resumed in the normal form beginning with

retains t he best features of the present forms J a.nuary, 1946. They will give particulars of all our

and, at the same time, a series of associated principal imports, e"-'}>Orts, and re-exports, with n.

considerable amount of information on trade with

diameters and pitches have been worked out individual countrios. Accounts relating to Crea.t

which, it is believed, will simplify existing Britain's overseas trade in the first half of 19 t>

practice and yet provide an adequate range of ha.vo already been published, and the Boat·d of

FIG. 9 -Tile "Honeycomb" DiffUJJer uaed in~the First choice for all requirements. I t is also felt that Trade will publish detailed trade accounts for tho

Model of the Experiment<Jl Engine first nine months of 1945 and furthor accounts fot·

the proposed change would involve the minimum

of the British Thomson-Houston Company amount of departure from existing practice the whole year. In addition, a. monthly summary

consistent with the obtaining of a common (on tho lines of those issued during 1940) will he

considered it unwise to run at speeds higher published showing the July and August figures for

than 12,000 r .p.m. in the open factory, and this standard for gener al-purpo e threads to the each group distinguished in the overseas trad~

was the speed limit for the remaining testR of inch system of measurement. Agreement was statistics ; fUI·ther summaries will be publishod for·

t he :first model. also r eached on Acme aBd sub-Acme threads, October and for Novembor. The July and August.

A return t o upHtream injection was mad&, and the agreed specification will be submit.ted summary will be publiRhed timing t.his month.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Plumbing System (Fire Fighting System)Document67 pagesPlumbing System (Fire Fighting System)RadoNoun100% (7)

- LNG ShipDocument4 pagesLNG ShipAkademiks29No ratings yet

- EPRI - Renewable Energy Technology Guide 2012Document856 pagesEPRI - Renewable Energy Technology Guide 2012sulemankhalid100% (1)

- 11.2. Nitrogen Oxides: 11.2.1. Kinetics of NO FormationDocument20 pages11.2. Nitrogen Oxides: 11.2.1. Kinetics of NO FormationDUVAN FELIPE MUNOZ GARCIANo ratings yet

- 15.5. Variables That Affect Diesel Engine Performance, Efficiency, and EmissionsDocument10 pages15.5. Variables That Affect Diesel Engine Performance, Efficiency, and EmissionsDUVAN FELIPE MUNOZ GARCIANo ratings yet

- 10.5. Ignition Delay: 10.5.1. Definition and DiscussionDocument14 pages10.5. Ignition Delay: 10.5.1. Definition and DiscussionDUVAN FELIPE MUNOZ GARCIANo ratings yet

- 15.3. Operating Variables That Affect Si Engine Performance, Efficiency, and EmissionsDocument21 pages15.3. Operating Variables That Affect Si Engine Performance, Efficiency, and EmissionsDUVAN FELIPE MUNOZ GARCIANo ratings yet

- 3D Blade Analysis v1.0Document12 pages3D Blade Analysis v1.0DUVAN FELIPE MUNOZ GARCIANo ratings yet

- Euler Equation v1.2Document19 pagesEuler Equation v1.2DUVAN FELIPE MUNOZ GARCIANo ratings yet

- BPHEDocument19 pagesBPHEjaskaran singhNo ratings yet

- Air Conditioning System Control: 5.1 Face and Bypass DampersDocument10 pagesAir Conditioning System Control: 5.1 Face and Bypass DampersMostafa AwadNo ratings yet

- Aer Conditionat Multisplit LG Unitati Interne Ceiling Concealed Duct Type Pliant Date TehniceDocument6 pagesAer Conditionat Multisplit LG Unitati Interne Ceiling Concealed Duct Type Pliant Date TehniceKyaw San OoNo ratings yet

- Turbo Machines Question BankDocument9 pagesTurbo Machines Question BankSHASHI Kumar100% (1)

- Turbine SafetyDocument54 pagesTurbine SafetyAkashNo ratings yet

- 2.3 CLSS Control ValveDocument17 pages2.3 CLSS Control ValveSatria Fajri100% (6)

- Types of BoilersDocument17 pagesTypes of Boilersbhautikpatel0% (2)

- PvsystDocument5 pagesPvsystHunain AKNo ratings yet

- Article-On Waste To EnergyDocument4 pagesArticle-On Waste To EnergyUsman HasnainNo ratings yet

- KKS Designation System KKS Designation SystemDocument19 pagesKKS Designation System KKS Designation Systemdexter schmithNo ratings yet

- Assignment 2Document2 pagesAssignment 2Prinkesh MauryaNo ratings yet

- CarburetorDocument19 pagesCarburetorSelazinap LptNo ratings yet

- Solar PumpDocument18 pagesSolar PumpDhaval Bhayani78% (18)

- Bp3000 Piusi Datasheet Fuel 01.21 enDocument2 pagesBp3000 Piusi Datasheet Fuel 01.21 enAndre FilipeNo ratings yet

- PS600 CS-F3-7: Solar Surface Pump SystemDocument3 pagesPS600 CS-F3-7: Solar Surface Pump SystemAgustynho MagimbaNo ratings yet

- Mack Insurance Surveyors & Loss Assessors (P) LTD.: Insured - Vodfone-Idea Private LimtedDocument2 pagesMack Insurance Surveyors & Loss Assessors (P) LTD.: Insured - Vodfone-Idea Private LimtedMuthiah ManiNo ratings yet

- I.C For Exit ExamDocument117 pagesI.C For Exit ExamNur JemsNo ratings yet

- ESD LogicDocument2 pagesESD LogicEmamokeNo ratings yet

- Equipment at HPSDocument60 pagesEquipment at HPSSam100% (1)

- Spesifikasi Incinerator 22 Desember 2019Document9 pagesSpesifikasi Incinerator 22 Desember 2019Dara Lextiany PutriNo ratings yet

- DWV Series: Power RatingDocument2 pagesDWV Series: Power Ratingquangtruc106No ratings yet

- ME180 Preliminary Report Pagbilao Power StationDocument15 pagesME180 Preliminary Report Pagbilao Power StationMark Christian LiwagNo ratings yet

- Wind Energy Course SEE614 First LectureDocument18 pagesWind Energy Course SEE614 First LectureShatakshi JainNo ratings yet

- NJ9226E 208-230 V 60 HZ 1Document4 pagesNJ9226E 208-230 V 60 HZ 1Leonardo GiarolaNo ratings yet

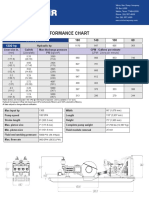

- White Star Quatro 1300HP Performance ChartDocument1 pageWhite Star Quatro 1300HP Performance ChartMo SafNo ratings yet

- Process and Carbon Footprint Analyses of The Allam Cycle Power Plant Integrated With An Air Separation UnitDocument16 pagesProcess and Carbon Footprint Analyses of The Allam Cycle Power Plant Integrated With An Air Separation UnitАндрей ФNo ratings yet

- List of Vendor 16,11,91Document48 pagesList of Vendor 16,11,91abbassNo ratings yet