Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

161 viewsSplitter C2-C12: Darda - General Survey

Splitter C2-C12: Darda - General Survey

Uploaded by

Gavin Shen1. The document describes Darda splitting cylinders used for hydraulic rock and concrete splitting.

2. The cylinders come in various sizes with splitting forces ranging from 1,913 kN to 4,048 kN.

3. They are operated using hydraulic pump units that can be powered by air, gasoline, electric, or diesel motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 2008 Saturn DiagramasDocument45 pages2008 Saturn DiagramasAUTOMOTRIZ TIPO SPCA75% (4)

- MF 6190Document674 pagesMF 6190hanganu constantin100% (1)

- E47 Repair Manual PDFDocument56 pagesE47 Repair Manual PDFcamohunter71100% (1)

- ThermoKing Yanmar Overhaul Manual TK353ModelRD1Document53 pagesThermoKing Yanmar Overhaul Manual TK353ModelRD1liudnas0091% (11)

- Allrounder 420 C: Golden EditionDocument6 pagesAllrounder 420 C: Golden EditionEdwinQuintiNo ratings yet

- DW13261207 PDFDocument136 pagesDW13261207 PDFp_janko100% (1)

- Bobcat Battery Reference GuideDocument2 pagesBobcat Battery Reference GuideFrancisco Godoy Kutzbach67% (3)

- Darda SplittersDocument1 pageDarda SplittersAsad AijazNo ratings yet

- Deck SlabDocument3 pagesDeck SlabPurnima SinghNo ratings yet

- Product CatalogueDocument2 pagesProduct CatalogueBharath YemireddyNo ratings yet

- Trider Scheda Tecnica ENDocument2 pagesTrider Scheda Tecnica ENHFNo ratings yet

- Multiplas V Series SpecsDocument1 pageMultiplas V Series SpecsEmmanuel PachecoNo ratings yet

- Drill Log: Hole No: T17BDocument6 pagesDrill Log: Hole No: T17Bbahlawan 19No ratings yet

- SD Wire Mesh - Brochure - ENDocument2 pagesSD Wire Mesh - Brochure - ENAltug TasNo ratings yet

- Headed Bars For Shear Reinforcement - July 2018 PDFDocument4 pagesHeaded Bars For Shear Reinforcement - July 2018 PDFKevin ArNo ratings yet

- 188888Document1 page188888Sumit PatelNo ratings yet

- Chain Tongs: WrenchesDocument1 pageChain Tongs: WrenchesAgus HaryadieNo ratings yet

- Spesifikasi Teknis Steel Sheet Pile: U TypeDocument1 pageSpesifikasi Teknis Steel Sheet Pile: U TypebagusNo ratings yet

- MS 021 Grooved Red Painted BDocument52 pagesMS 021 Grooved Red Painted BRagul0042No ratings yet

- Dilatoflex KP High PressureDocument1 pageDilatoflex KP High PressureJo KingsNo ratings yet

- Scheda Tecnica: Etpv Anchor Anchor For Hollow Base MaterialsDocument1 pageScheda Tecnica: Etpv Anchor Anchor For Hollow Base MaterialsKasia GosławskaNo ratings yet

- Heavy Lift Swivel Hoist Rings: HR-1000 UNC ThreadsDocument1 pageHeavy Lift Swivel Hoist Rings: HR-1000 UNC ThreadsAlex RotsNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- LLG Low Locknut Load Return: Innovative Hydraulic SolutionsDocument1 pageLLG Low Locknut Load Return: Innovative Hydraulic SolutionsSanti CheewabantherngNo ratings yet

- Articoliallegato1 Ita91630 Product Specification DURGLASSDocument3 pagesArticoliallegato1 Ita91630 Product Specification DURGLASSMarco Dos Santos NevesNo ratings yet

- Engine Mechanical Hal 6Document1 pageEngine Mechanical Hal 6budi dNo ratings yet

- 3 SkidsteerDocument22 pages3 Skidsteerhamza rezguiNo ratings yet

- Metric Hex BoltsDocument2 pagesMetric Hex BoltsCelestine OzokechiNo ratings yet

- SHIELD Steel Piping Catalogue v16 18Document48 pagesSHIELD Steel Piping Catalogue v16 18ZeeshanNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- PT Gaya Baru Energi: Drill Pipe Inspection Tally SheetDocument1 pagePT Gaya Baru Energi: Drill Pipe Inspection Tally SheetRobert TirtaNo ratings yet

- Anchor Bolt Base Plate Max FXcompDocument9 pagesAnchor Bolt Base Plate Max FXcomppandianNo ratings yet

- Weekly Web Sling Inspection ChecklistDocument2 pagesWeekly Web Sling Inspection Checklistnababul37No ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- 4272 01 500 215 Triple PlateDocument2 pages4272 01 500 215 Triple PlateElieNo ratings yet

- Steel Sun and Planet GearDocument1 pageSteel Sun and Planet GearAmarnathNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- Type HD Hard / Soft ClipDocument2 pagesType HD Hard / Soft ClippaulpopNo ratings yet

- Balok Beton Bertulang - Hitung Tonase Tulangan, Luas Bekisting, Volume Beton - Phase 2Document14 pagesBalok Beton Bertulang - Hitung Tonase Tulangan, Luas Bekisting, Volume Beton - Phase 2Umar FadliNo ratings yet

- Cutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdureDocument6 pagesCutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdurepcatruongNo ratings yet

- CatPage341 - 342 Cam CouplingsDocument2 pagesCatPage341 - 342 Cam CouplingsEnoch TwumasiNo ratings yet

- BS4 Channel Dimensions PDFDocument1 pageBS4 Channel Dimensions PDFwaynectwNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- Tai Mex by Tederic D SeriesDocument13 pagesTai Mex by Tederic D SeriesPHYONEGRIPNo ratings yet

- Shield Pipes Fittings PDFDocument36 pagesShield Pipes Fittings PDFilieoniciuc50% (2)

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- Industrial Roof Ventilators BlowerDocument5 pagesIndustrial Roof Ventilators Blowerศตวรรษ ฉิมวัยNo ratings yet

- 02a. Log BorDocument18 pages02a. Log BorSam WitNo ratings yet

- Engine Mechanical Part1 (To p44)Document1 pageEngine Mechanical Part1 (To p44)budi dNo ratings yet

- 1) Details of Geotech Investigation of Badapur To Churaibari Section of NH-37 & NH-8 in The State of Assam.Document9 pages1) Details of Geotech Investigation of Badapur To Churaibari Section of NH-37 & NH-8 in The State of Assam.SANDEEP GAWANDENo ratings yet

- Heavy Duty Impact Wrenches: Powerful, Compact Tools For Demanding ApplicationsDocument4 pagesHeavy Duty Impact Wrenches: Powerful, Compact Tools For Demanding Applicationsjoker63000No ratings yet

- PuleyDocument7 pagesPuleyTrường PhạmNo ratings yet

- QT-DC 4.875 X 2.250 XT39 SpiralDocument1 pageQT-DC 4.875 X 2.250 XT39 SpiralAmin AminNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- OneSteel Hot Rolled PropertiesDocument22 pagesOneSteel Hot Rolled PropertiesRajeev SharanNo ratings yet

- Dokumen - Tips Interpolasi Dan EkstrapolasiDocument1 pageDokumen - Tips Interpolasi Dan EkstrapolasielhamNo ratings yet

- Technical Data: Truck-Mounted Concrete Pump S 39 SXDocument2 pagesTechnical Data: Truck-Mounted Concrete Pump S 39 SXBe-do PharaohsNo ratings yet

- HDD Calculation For Gas PipelineDocument3 pagesHDD Calculation For Gas Pipelinesamotavijaypal26No ratings yet

- Ficha Tecnica Grua Grover GRT625Document24 pagesFicha Tecnica Grua Grover GRT625Beatriz PinedoNo ratings yet

- Pop Nut PDFDocument48 pagesPop Nut PDFJavier A. ValenzuelaNo ratings yet

- BBS For Pier Cap & Pedestal P7Document1 pageBBS For Pier Cap & Pedestal P7SAYAN SARKARNo ratings yet

- Tapered Flange Channels: H (MM) B (MM) T (MM) T (MM) R (MM) R (MM) B (MM) D (MM) K (MM) S (%) A (CM) e (MM)Document5 pagesTapered Flange Channels: H (MM) B (MM) T (MM) T (MM) R (MM) R (MM) B (MM) D (MM) K (MM) S (%) A (CM) e (MM)ariffNo ratings yet

- Borlog DDocument1 pageBorlog Drifqi bambangNo ratings yet

- Borlog ADocument1 pageBorlog Arifqi bambangNo ratings yet

- Crossmax Elite 29 2017 REARDocument2 pagesCrossmax Elite 29 2017 REARlcesserNo ratings yet

- Air Conditioner: Aesthetics and ErgonomicsDocument13 pagesAir Conditioner: Aesthetics and ErgonomicsRadhey PatankarNo ratings yet

- DECALSDocument2 pagesDECALSLUIS FERNANDO JOAQUINNo ratings yet

- 2021 MG Hector Plus Accessories List - OfficialDocument65 pages2021 MG Hector Plus Accessories List - OfficialRushLaneNo ratings yet

- Deutz Fahr Agrotron K100 Tractor Parts Catalogue ManualDocument21 pagesDeutz Fahr Agrotron K100 Tractor Parts Catalogue ManuallaopaodunNo ratings yet

- SUSPENSION CONTROL - ACTIVE HEIGHT CONTROL SUSPENSION - C1763 Abnormal Pump Motor Oil Pressure 2010Document5 pagesSUSPENSION CONTROL - ACTIVE HEIGHT CONTROL SUSPENSION - C1763 Abnormal Pump Motor Oil Pressure 2010awan wijayantoNo ratings yet

- Instruction Manual For Cylinder Set (124 CC) : Exclusively For Our Twin Spark Super Head +RDocument5 pagesInstruction Manual For Cylinder Set (124 CC) : Exclusively For Our Twin Spark Super Head +RMoto ExpertNo ratings yet

- VTO2514B Eng 02 1982413Document2 pagesVTO2514B Eng 02 1982413AyhamNo ratings yet

- CBD15W CBD18W CBD20WDocument2 pagesCBD15W CBD18W CBD20WFelix StancioiuNo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorDocument3 pages303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorCARLOS LIMADANo ratings yet

- Calibracion de Valvulas Toyota 6V Hi Lux 1GRDocument19 pagesCalibracion de Valvulas Toyota 6V Hi Lux 1GRcpaolinodNo ratings yet

- Cooling System: Description and OperationDocument26 pagesCooling System: Description and Operationrodolfodiaz100% (1)

- Articulated Haulers / F Series Models: Description Part No. Qty First Service 250 H 500 H 1000 H 2000 H NotesDocument4 pagesArticulated Haulers / F Series Models: Description Part No. Qty First Service 250 H 500 H 1000 H 2000 H NotesHugo Alejandro Bello ParraNo ratings yet

- 250 HMI 475 SpecsDocument3 pages250 HMI 475 SpecsProyectil De Proyecto100% (1)

- Load Control ValvesDocument18 pagesLoad Control ValvesMusa ArysNo ratings yet

- Vdru02 01GBDocument1,312 pagesVdru02 01GBmaNo ratings yet

- Bobcat E19Document1 pageBobcat E19Goran MatovicNo ratings yet

- Pneumatic Valve Types & Working PrincipleDocument2 pagesPneumatic Valve Types & Working PrincipleAbdul Mohid SheikhNo ratings yet

- Front Fender Front Apron (Assy) : Body Panel Replacement BP-5Document2 pagesFront Fender Front Apron (Assy) : Body Panel Replacement BP-5Komatsu Perkins HitachiNo ratings yet

- cbr24 9150Document11 pagescbr24 9150arman esmaeilpoorNo ratings yet

- Durma MS Series Mechanical ShearDocument7 pagesDurma MS Series Mechanical ShearKiril IvchevNo ratings yet

- CentraDocument51 pagesCentrakumarNo ratings yet

- Catálogo EIXO ZFDocument27 pagesCatálogo EIXO ZFOdirley JonesNo ratings yet

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pages2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozNo ratings yet

Splitter C2-C12: Darda - General Survey

Splitter C2-C12: Darda - General Survey

Uploaded by

Gavin Shen0 ratings0% found this document useful (0 votes)

161 views2 pages1. The document describes Darda splitting cylinders used for hydraulic rock and concrete splitting.

2. The cylinders come in various sizes with splitting forces ranging from 1,913 kN to 4,048 kN.

3. They are operated using hydraulic pump units that can be powered by air, gasoline, electric, or diesel motors.

Original Description:

Darda-C2-C12-Product-info

Original Title

Darda-C2-C12-Product-info

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document describes Darda splitting cylinders used for hydraulic rock and concrete splitting.

2. The cylinders come in various sizes with splitting forces ranging from 1,913 kN to 4,048 kN.

3. They are operated using hydraulic pump units that can be powered by air, gasoline, electric, or diesel motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

161 views2 pagesSplitter C2-C12: Darda - General Survey

Splitter C2-C12: Darda - General Survey

Uploaded by

Gavin Shen1. The document describes Darda splitting cylinders used for hydraulic rock and concrete splitting.

2. The cylinders come in various sizes with splitting forces ranging from 1,913 kN to 4,048 kN.

3. They are operated using hydraulic pump units that can be powered by air, gasoline, electric, or diesel motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

DARDA - splitting cylinder

Darda - general survey SPLITTER C2-C12

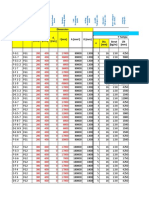

Splitting cylinders

Type Wedge

set

Required

drill hole

Minimal

drill hole

Splitting-

distance

Splitting force

theoretical

Splitting force

effective

Weight ² Length

splitting

Length

wedge

Order-No

Hydraulic rock and concrete splitters

Control valve diameter depth cylinder set

mm mm mm kN to kN to kg mm mm

C2S N 31 - 32 270 9 3490 355 1913 195 17 745 150 8381 0402 10

C4S N 35 - 36 430 10 4524 461 2256 230 21 995 250 8381 0405 25 • Splitting force up to

C4S WL 35 - 38 540 14 3267 333 1864 190 22 1145 400 8381 0405 40 413 tons (4048 kn)

C9 N 45 - 48 410 18 - 53 ¹ 2995 305 1962 200 22 1020 230 8381 0409 00

C9 L 48 - 50 580 18 - 53 ¹ 2995 305 1962 200 23 1190 400 8381 0409 40 • Dust free

C12 N 45 - 48 610 19 - 60 ¹ 6061 618 3507 358 31 1290 380 8381 0412 38

C12 L 45 - 48 680 15 - 44 ¹ 8082 824 4048 413 32 1360 450 8381 0412 45

• Quiet performance

C12 W 45 - 48 550 24 - 80 ¹ 4849 494 3150 321 31 1250 320 8381 0412 50

• Also applicable at places

¹ With one enlarging counter wedge and one special enlarging counter wedge ² without hydraulic hoses and SV coupeling

of difficult access

Cylinder • Vibration free

Hydraulic pump units (portable)

• Easy handling

Type Type of motor Weight Length Width Height Pump capacity Pump capacity Volume Order-No

kg lbs mm inch mm inch mm inch low pressure high pressure of oil tank

l/min gal/min l/min gal/min l gal (USA) • Easy to transport

AP2 Air motor ¹ 40 88 600 23,6 398 15,7 426 16,8 5,0 1,32 1,6 0,42 5,0 1,32 8381 0503 54

Piston rod BP2 Gasoline motor 40 88 600 23,6 398 15,7 426 16,8 5,0 1,32 1,6 0,42 5,0 1,32 8381 0503 39 • Splits in seconds

EP2 Electric motor 400 V 40 88 600 23,6 398 15,7 426 16,8 5,0 1,32 1,6 0,42 5,0 1,32 8381 0503 47

EP2 Electric motor 230 V 50 110 600 23,6 398 15,7 426 16,8 5,0 1,32 1,6 0,42 5,0 1,32 8381 0503 51 • Controlled splitting

D4 Diesel motor 137 301 1180 46,4 720 28,4 730 28,8 5,4 1,42 5,4 1,42 10,0 2,64 8381 0502 40

1

max. 0,7Mpa (7bar), Air consumption: 47-195m³/h

• Dimensionally accurate

working

Hydraulic hoses Enlarging counter wedges Pressure shells

Type Length Suitable Order-No Type Enlarging Special enlarging Suitable Required Minimal Order-No

for counter wedges counter wedges for drill hole drill hole

m cylinders Order-No Order-No diameter depth

S1 10 1 8381 0504 02 C4N 3390 0141 03 – mm mm

S1 20 1 8381 0504 03 C9N 3390 0246 11 3390 0246 21 C9N 100 410 3390 0357 00

S2 10 2 8381 0504 10 C9L 3390 0246 31 3390 0246 51 C 12 N/W 100 610 3390 0429 00

Front head S2 20 2 8381 0504 11 C 12 N 3390 0236 00 3390 0280 00

S3 20 3 8381 0504 29 C 12 L 3390 0236 21 3390 0280 21

1

Distance between cylinder and pump unit C 12 W 3390 0236 11 3390 0280 11

Special lubricant

Quantity / Tin Order-No

0,50 kg 3391 0985 10

1,00 kg 3391 0942 10

25,00 kg 3391 0980 10

Counterwedges

Wedge

Our distributor:

P_8381_e_291014 Alterations reserved

Darda GmbH

Im Tal 1, D-78176 Blumberg

Fon + 49 (0) 77 02 / 43 91 - 0

Fax + 49 (0) 77 02 / 43 91 - 12

info@darda.de

www.darda.de

The powerful and economic way to split rock and demolish concrete

Hydraulic rock and concrete splitters Advantages Technical Details

provide a powerful and extremely

cost-effective alternative to other Economical A complete DARDA rock and concrete Hydraulic pump unit Enlarging counter wedges

conventional demolition techniques. Blasting usually requires work stoppages splitter compromises 3 components: Electric, air, diesel or gasoline motors can If you need to enlarge the crack already

Hydraulic splitting means controlled and the installation of protective walls and 1. one or several splitting cylinders be used to drive the high-pressure pump made, simply remove the counter wedges

splitting, and this method eliminates other safety equipment. This costs both time 2. one hydraulic pump unit units. The system pressure has been limited initially used and replace with enlarging

shock waves, vibrations, dust and noise and money. With DARDA high-performance 3. one set of high- and low-pressure hoses to 50 MPa (500 bar) by a pressure counter wedges. The crack can now be

that large impact tools usually produce. rock and concrete splitters, blasting is not limiting valve. Both mobile and portable widened further, allowing heavy duty iron

DARDA rock and concrete splitters have longer necessary. Therefore, there is no Hydraulic splitting cylinder pump units are available. Depending on bars and other reinforcements to be cut.

been used with a great sucess in over 80 potential danger to the workforce or The hydraulic splitting cylinder consists of a the pump model, up to 5 splitting

countries for the past 40 years. The high passers-by, and other work in th immediate control valve, a cylinder, a front head and cyclinders can be run simultaneously.

quality, reliability and durability of the surroundings can continue unaffected. a wedge set (1 wedge and 2 counter

equipment is unsurpassed. wedges). The entire cylinder is made of Hydraulic hoses

Safe highest quality aluminium and steel so that High- and low pressure hoses connect

How the splitter works Hydraulic splitting means controlled demo- although the equipment is light, it is still the splitter to the pump unit. If several

Conventional demolition techniques lition. The entire force developed is always extremely durable. The counter wedges are splitters are to be connected, a distri- Pressure shells

destroy rock and concrete by using an under full control. There is no danger of also coated with a hard metal (carbide) butor part is attached to the end of the In a small diameter drill hole, the high

external force. However, because of flying debris, vibrations or even explosions. layer in a specially developed hardening 10 m hose. splitting force acts on a very small area,

their compressive strength, these process. This makes them more resistant to exerting extreme surface pressure. In the

materials are highly resistant to impact Environmental-friendly very high pressure and forces. case of heavily steel- reinforced concrete

forces. For optimum results, one should When using the DARDA hydraulic splitting and under the most unfavorable condi-

adopt a splitting technique that works technique, there are unpleasant side effects Main applications Type of splitting cylinder C 2 S C 4S C 9 C 12 tions, attempts at splitting may merely

from the inside of the material, because like vibrations and dust. Even noise emission compact the concrete, leaving an oval

Multitude of applications Demolition of concrete and reinforced concrete

rock an concrete have a lower tensile is extremely low, which means that, all in hole. Only short cracks develop around

There are different types of splitting Demolition of nonreinforced and lightly reinforced concrete

strength. The DARDA hydraulic splitters all, this demolition technique is particularly the hole and the reinforcing rods remain

cylinders available for a variety of Demolition of reinforced concrete

were developed to do this and work environmental-friendly. That is why the unaffected. In such cases, two large,

applications. Demolition work in closed spaces and places that are of difficult access (e.g. in elevator shafts)

according to a safe and proven wedge DARDA splitter is indispansable in densely heavy-gauge pressure shells provide the

Demolition work in extremely cramped spaces

principle: populated areas or inside buildings. necessary remedy. These are introduced

Demolition work in extremely cramped spaces

into a 100 mm diameter core hole and

Cutting concrete piles

Durable enclose the wedge set of the splitting

Demolition of factory chimneys

Thanks to the extremely robust design, the cylinder. The splitting force is now

Secondary splitting of concrete slabs (e.g. preparing concrete for recycling)

DARDA rock and concrete splitter can applied over a large area, resulting in a

Underwater demolition

withstand even the toughest conditions. precise split and forcing the steel rods

Demolition of rock

Its durability is quite exceptional. apart more effectively.

Rock demolition (e.g. in trenching or splitting rock for a cellar extension)

Therefore, next to no maintenance is Secondary splitting of large boulders

required. Yet another cost-saving factor. Tunnelling

Enlarging work in underground mining

Autonomy Secondary splitting

DARDA splitters and pump units are easy to Pipe jacking/microtunnelling

transport. Operators no longer depend on Production of blocks in the natural stone industry

Special lubricant

heavy machinery, e.g. excavators, for their Marble

During the splitting process the wedge set

transport to the demolition site. Granite

is exposed to extremely high forces.

Therefore, even the smallest workplace is Sandstone

This requires that the inner wedge and

no longer a poblem. cylinder is most suitable cylinder is suitable counter wedge surfaces be frequently

lubricated. Tests carried out over an

Easy to use extended period of time proved beyond

The splitters are extremely easy to operate. C2S C4S C9 C 12 doubt that only our special lubricant is

The lightweight design enables an operator capable of significantly reducing the

First of all, a hole is drilled to a speci- to work on a splitting job single-handedly. extreme friction. Owing to that, the use of

fied diameter and dept using an Even unskilled workers can learn to use the DARDA lubricating paste guarantees the

ordinary rock drill. Then the wedge set is DARDA splitter in a very short time. highest splitting performance which is 20

inserted into the hole with the wedge in to 50% higher than if conventional

a retraced position. The hydraulic Controlled demolition lubricants are used.

pressure then forces the wedge between DARDA hydraulic rock and concrete splitters

the two counter wedges, pressing them enable you to work with a precision that

against the walls of the drilled hole. cannot be achieved when using conventional

The effective splitting force of up to demolition methods. The desired direction of

413 tons or 4048 kN breaks concrete the split and size of material to be removed

and rock from the inside, breaking can be determined beforehand. The portion

thinner iron rods at the same time. of a structure that ought to remain intact is

not affected by the splitting process.

You might also like

- 2008 Saturn DiagramasDocument45 pages2008 Saturn DiagramasAUTOMOTRIZ TIPO SPCA75% (4)

- MF 6190Document674 pagesMF 6190hanganu constantin100% (1)

- E47 Repair Manual PDFDocument56 pagesE47 Repair Manual PDFcamohunter71100% (1)

- ThermoKing Yanmar Overhaul Manual TK353ModelRD1Document53 pagesThermoKing Yanmar Overhaul Manual TK353ModelRD1liudnas0091% (11)

- Allrounder 420 C: Golden EditionDocument6 pagesAllrounder 420 C: Golden EditionEdwinQuintiNo ratings yet

- DW13261207 PDFDocument136 pagesDW13261207 PDFp_janko100% (1)

- Bobcat Battery Reference GuideDocument2 pagesBobcat Battery Reference GuideFrancisco Godoy Kutzbach67% (3)

- Darda SplittersDocument1 pageDarda SplittersAsad AijazNo ratings yet

- Deck SlabDocument3 pagesDeck SlabPurnima SinghNo ratings yet

- Product CatalogueDocument2 pagesProduct CatalogueBharath YemireddyNo ratings yet

- Trider Scheda Tecnica ENDocument2 pagesTrider Scheda Tecnica ENHFNo ratings yet

- Multiplas V Series SpecsDocument1 pageMultiplas V Series SpecsEmmanuel PachecoNo ratings yet

- Drill Log: Hole No: T17BDocument6 pagesDrill Log: Hole No: T17Bbahlawan 19No ratings yet

- SD Wire Mesh - Brochure - ENDocument2 pagesSD Wire Mesh - Brochure - ENAltug TasNo ratings yet

- Headed Bars For Shear Reinforcement - July 2018 PDFDocument4 pagesHeaded Bars For Shear Reinforcement - July 2018 PDFKevin ArNo ratings yet

- 188888Document1 page188888Sumit PatelNo ratings yet

- Chain Tongs: WrenchesDocument1 pageChain Tongs: WrenchesAgus HaryadieNo ratings yet

- Spesifikasi Teknis Steel Sheet Pile: U TypeDocument1 pageSpesifikasi Teknis Steel Sheet Pile: U TypebagusNo ratings yet

- MS 021 Grooved Red Painted BDocument52 pagesMS 021 Grooved Red Painted BRagul0042No ratings yet

- Dilatoflex KP High PressureDocument1 pageDilatoflex KP High PressureJo KingsNo ratings yet

- Scheda Tecnica: Etpv Anchor Anchor For Hollow Base MaterialsDocument1 pageScheda Tecnica: Etpv Anchor Anchor For Hollow Base MaterialsKasia GosławskaNo ratings yet

- Heavy Lift Swivel Hoist Rings: HR-1000 UNC ThreadsDocument1 pageHeavy Lift Swivel Hoist Rings: HR-1000 UNC ThreadsAlex RotsNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- LLG Low Locknut Load Return: Innovative Hydraulic SolutionsDocument1 pageLLG Low Locknut Load Return: Innovative Hydraulic SolutionsSanti CheewabantherngNo ratings yet

- Articoliallegato1 Ita91630 Product Specification DURGLASSDocument3 pagesArticoliallegato1 Ita91630 Product Specification DURGLASSMarco Dos Santos NevesNo ratings yet

- Engine Mechanical Hal 6Document1 pageEngine Mechanical Hal 6budi dNo ratings yet

- 3 SkidsteerDocument22 pages3 Skidsteerhamza rezguiNo ratings yet

- Metric Hex BoltsDocument2 pagesMetric Hex BoltsCelestine OzokechiNo ratings yet

- SHIELD Steel Piping Catalogue v16 18Document48 pagesSHIELD Steel Piping Catalogue v16 18ZeeshanNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- PT Gaya Baru Energi: Drill Pipe Inspection Tally SheetDocument1 pagePT Gaya Baru Energi: Drill Pipe Inspection Tally SheetRobert TirtaNo ratings yet

- Anchor Bolt Base Plate Max FXcompDocument9 pagesAnchor Bolt Base Plate Max FXcomppandianNo ratings yet

- Weekly Web Sling Inspection ChecklistDocument2 pagesWeekly Web Sling Inspection Checklistnababul37No ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- 4272 01 500 215 Triple PlateDocument2 pages4272 01 500 215 Triple PlateElieNo ratings yet

- Steel Sun and Planet GearDocument1 pageSteel Sun and Planet GearAmarnathNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- Type HD Hard / Soft ClipDocument2 pagesType HD Hard / Soft ClippaulpopNo ratings yet

- Balok Beton Bertulang - Hitung Tonase Tulangan, Luas Bekisting, Volume Beton - Phase 2Document14 pagesBalok Beton Bertulang - Hitung Tonase Tulangan, Luas Bekisting, Volume Beton - Phase 2Umar FadliNo ratings yet

- Cutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdureDocument6 pagesCutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdurepcatruongNo ratings yet

- CatPage341 - 342 Cam CouplingsDocument2 pagesCatPage341 - 342 Cam CouplingsEnoch TwumasiNo ratings yet

- BS4 Channel Dimensions PDFDocument1 pageBS4 Channel Dimensions PDFwaynectwNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- Tai Mex by Tederic D SeriesDocument13 pagesTai Mex by Tederic D SeriesPHYONEGRIPNo ratings yet

- Shield Pipes Fittings PDFDocument36 pagesShield Pipes Fittings PDFilieoniciuc50% (2)

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- Industrial Roof Ventilators BlowerDocument5 pagesIndustrial Roof Ventilators Blowerศตวรรษ ฉิมวัยNo ratings yet

- 02a. Log BorDocument18 pages02a. Log BorSam WitNo ratings yet

- Engine Mechanical Part1 (To p44)Document1 pageEngine Mechanical Part1 (To p44)budi dNo ratings yet

- 1) Details of Geotech Investigation of Badapur To Churaibari Section of NH-37 & NH-8 in The State of Assam.Document9 pages1) Details of Geotech Investigation of Badapur To Churaibari Section of NH-37 & NH-8 in The State of Assam.SANDEEP GAWANDENo ratings yet

- Heavy Duty Impact Wrenches: Powerful, Compact Tools For Demanding ApplicationsDocument4 pagesHeavy Duty Impact Wrenches: Powerful, Compact Tools For Demanding Applicationsjoker63000No ratings yet

- PuleyDocument7 pagesPuleyTrường PhạmNo ratings yet

- QT-DC 4.875 X 2.250 XT39 SpiralDocument1 pageQT-DC 4.875 X 2.250 XT39 SpiralAmin AminNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- OneSteel Hot Rolled PropertiesDocument22 pagesOneSteel Hot Rolled PropertiesRajeev SharanNo ratings yet

- Dokumen - Tips Interpolasi Dan EkstrapolasiDocument1 pageDokumen - Tips Interpolasi Dan EkstrapolasielhamNo ratings yet

- Technical Data: Truck-Mounted Concrete Pump S 39 SXDocument2 pagesTechnical Data: Truck-Mounted Concrete Pump S 39 SXBe-do PharaohsNo ratings yet

- HDD Calculation For Gas PipelineDocument3 pagesHDD Calculation For Gas Pipelinesamotavijaypal26No ratings yet

- Ficha Tecnica Grua Grover GRT625Document24 pagesFicha Tecnica Grua Grover GRT625Beatriz PinedoNo ratings yet

- Pop Nut PDFDocument48 pagesPop Nut PDFJavier A. ValenzuelaNo ratings yet

- BBS For Pier Cap & Pedestal P7Document1 pageBBS For Pier Cap & Pedestal P7SAYAN SARKARNo ratings yet

- Tapered Flange Channels: H (MM) B (MM) T (MM) T (MM) R (MM) R (MM) B (MM) D (MM) K (MM) S (%) A (CM) e (MM)Document5 pagesTapered Flange Channels: H (MM) B (MM) T (MM) T (MM) R (MM) R (MM) B (MM) D (MM) K (MM) S (%) A (CM) e (MM)ariffNo ratings yet

- Borlog DDocument1 pageBorlog Drifqi bambangNo ratings yet

- Borlog ADocument1 pageBorlog Arifqi bambangNo ratings yet

- Crossmax Elite 29 2017 REARDocument2 pagesCrossmax Elite 29 2017 REARlcesserNo ratings yet

- Air Conditioner: Aesthetics and ErgonomicsDocument13 pagesAir Conditioner: Aesthetics and ErgonomicsRadhey PatankarNo ratings yet

- DECALSDocument2 pagesDECALSLUIS FERNANDO JOAQUINNo ratings yet

- 2021 MG Hector Plus Accessories List - OfficialDocument65 pages2021 MG Hector Plus Accessories List - OfficialRushLaneNo ratings yet

- Deutz Fahr Agrotron K100 Tractor Parts Catalogue ManualDocument21 pagesDeutz Fahr Agrotron K100 Tractor Parts Catalogue ManuallaopaodunNo ratings yet

- SUSPENSION CONTROL - ACTIVE HEIGHT CONTROL SUSPENSION - C1763 Abnormal Pump Motor Oil Pressure 2010Document5 pagesSUSPENSION CONTROL - ACTIVE HEIGHT CONTROL SUSPENSION - C1763 Abnormal Pump Motor Oil Pressure 2010awan wijayantoNo ratings yet

- Instruction Manual For Cylinder Set (124 CC) : Exclusively For Our Twin Spark Super Head +RDocument5 pagesInstruction Manual For Cylinder Set (124 CC) : Exclusively For Our Twin Spark Super Head +RMoto ExpertNo ratings yet

- VTO2514B Eng 02 1982413Document2 pagesVTO2514B Eng 02 1982413AyhamNo ratings yet

- CBD15W CBD18W CBD20WDocument2 pagesCBD15W CBD18W CBD20WFelix StancioiuNo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorDocument3 pages303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorCARLOS LIMADANo ratings yet

- Calibracion de Valvulas Toyota 6V Hi Lux 1GRDocument19 pagesCalibracion de Valvulas Toyota 6V Hi Lux 1GRcpaolinodNo ratings yet

- Cooling System: Description and OperationDocument26 pagesCooling System: Description and Operationrodolfodiaz100% (1)

- Articulated Haulers / F Series Models: Description Part No. Qty First Service 250 H 500 H 1000 H 2000 H NotesDocument4 pagesArticulated Haulers / F Series Models: Description Part No. Qty First Service 250 H 500 H 1000 H 2000 H NotesHugo Alejandro Bello ParraNo ratings yet

- 250 HMI 475 SpecsDocument3 pages250 HMI 475 SpecsProyectil De Proyecto100% (1)

- Load Control ValvesDocument18 pagesLoad Control ValvesMusa ArysNo ratings yet

- Vdru02 01GBDocument1,312 pagesVdru02 01GBmaNo ratings yet

- Bobcat E19Document1 pageBobcat E19Goran MatovicNo ratings yet

- Pneumatic Valve Types & Working PrincipleDocument2 pagesPneumatic Valve Types & Working PrincipleAbdul Mohid SheikhNo ratings yet

- Front Fender Front Apron (Assy) : Body Panel Replacement BP-5Document2 pagesFront Fender Front Apron (Assy) : Body Panel Replacement BP-5Komatsu Perkins HitachiNo ratings yet

- cbr24 9150Document11 pagescbr24 9150arman esmaeilpoorNo ratings yet

- Durma MS Series Mechanical ShearDocument7 pagesDurma MS Series Mechanical ShearKiril IvchevNo ratings yet

- CentraDocument51 pagesCentrakumarNo ratings yet

- Catálogo EIXO ZFDocument27 pagesCatálogo EIXO ZFOdirley JonesNo ratings yet

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pages2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozNo ratings yet