Professional Documents

Culture Documents

Draft STR CK-407 Revision 4

Draft STR CK-407 Revision 4

Uploaded by

btcwbcrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Draft STR CK-407 Revision 4

Draft STR CK-407 Revision 4

Uploaded by

btcwbcrCopyright:

Available Formats

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev.

-

Page 1 of 47

Ver 1.0 August, 2020 04)

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

SCHEDULE OF TECHNICAL REQUIREMENTS FOR AIR

SUSPENSION CONTROL EQUIPEMENTS FOR AIR SPRING

ASSEMBLY SYSTEM WITH ICF/LHB TYPE BOGIE

S. No. Month / Year of Revision / Page No. Reason for

issue Amendment Amendment

As per the

1. July 2007 Revision 1 2

amendment slip

As per the

2. December 2008 Revision 2 2

amendment slip

To include the ISO

Revision 2/ Doc. No. QO-D-7.1-

3 October, 2016 5

Amendment 1 11 in Para no. 1 of

Scope

As per Amendment

4 June, 2018 Revision 3 ----

Slip

Revision Enforcement date

September

5 3/Amendment 4 refixed as

2018

1 15.04.2019.

6 August 2020 Revision 4

Issued By

Carriage Directorate

Research Designs and Standards Organisation

Manak Nagar Lucknow-226011.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 2 of 47

Ver 1.0 August, 2020 04)

CONTENTS

Description Page No.

I FOREWORD 3

SECTION-A

II Air Spring Control Equipments

1. Scope 4

2. Operating Conditions 4

3. Environmental Condition 5-6

4. Scope of Supply 6

5. Particular Requirements 6-9

6. Technical Requirements 9-12

7. Submission of Offer 11-12

8. Guarantee 12

9. Proto type testing 12-13

10. Installation, Commissioning & Maintenance 13

11. Inspection and Testing 13-15

12. Painting 15

13. Marking 15

14. Packing 15

15.Tolerance 16

16. General 16

17. Annexure – A 17 – 29

18. Annexure – 1 30 – 32

19. Annexure – 2 33 - 44

20.SECTION-B 45-47

III Referred Specification & Drawings

III.A Drawings (Enclosed)

1. SKETCH-K1049 Alt.1:Space Envelope for Leveling Valve

2. SKETCH-K1050 Alt.3:Instalation Lever Assembly with Ball And Socket Ends

3. SKETCH-K1051:Space Envelope for Duplex Check Valve

4. SKETCH-K1054: Hose Connection for Air Spring Suspension Bogies.

5. Drain Cock Assembly RDSO SKETCH-98003

6. Isolating Cock(OLP type) 20mm bore as SKETCH- 97002

7. Check Valve as RDSO SKETCH – 98112

8. Two Way Dirt Collector as RDSO SKETCH-1 – 97005

9. Details Two Way Dirt Collector as RDSO SKETCH-2 – 97005

III.B Specification & Drawings (Not Enclosed)

1. RDSO specification No. 02-ABR-02 (Air Brake)

2. ICF drawing of reservoirs

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 3 of 47

Ver 1.0 August, 2020 04)

FOREWORD

1. This Schedule of Technical Requirements (STR) is issued under fixed serial No. C-

K407.The number K4 indicates the year of adoption/revision.

2. This Schedule of Technical Requirements (STR) is issued as third Fourth revision to

the earlier specification no. C-K407 of 2004.

3. The purchaser will be at liberty to buy any part / component or all from this

specification.

4. This Schedule of Technical Requirements (STR) will be read along with RDSO

specification No.02-ABR-02 (Latest amendment).In case of any conflict, the

requirements given in this specification shall be final.

5. Date of enforcement of this STR of Air Suspension Control Equipements will be

……….

****************************************

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 4 of 47

Ver 1.0 August, 2020 04)

SCHEDULE OF TECHNICAL REQUIRMENTS OF

AIR SUSPENSION CONTROL EQUIPEMENTS FOR MAINLINE COACHES AND EMU/DMU

TYPE COACHES

SECTION-A

1. SCOPE:

1.1 This schedule section covers lays down the technical requirements for the design and

supply of control equipment for pneumatic suspension for use in existing two axle

bogies of EMU/DMU/MEMU/Mainline/Conventional ICF Type Bogies/Rajdhani/ LHB

type coaches and any other type of Bogies for which RDSO approves applicability of

this STR of Indian Railways having air-suspension. Scope of supply shall generally

be as per clause-4 of this specification. However if the supplier feels that certain

additional items are necessary for improved working performance of the system, he

may quote for the same. In any case, purchaser will be at liberty to buy all or part

material from the offer.

1.2 All the provisions contained in RDSO’s ISO procedures laid down in Document No.

QO-D-7.1-11 dated 19.07.2016 QO-D-8.1-11 dated 08.05.2019 or latest (titled

“Vendor-Changes in approved status”) and subsequent versions/amendments

thereof, shall be binding and applicable on the successful vendor/vendors in the

contracts floated by Railways to maintain quality of products supplied to Railways.

2. OPERATING CONDITIONS & FUNCTIONAL REQUIREMENT:

2.1 For Main Line/ Rajdhani & LHB Coaches :

2.1.1 Each coach fitted with air spring assemblies would have a feed pipe and one brake

pipe. Normally up to twenty six coaches form a train. These coaches would have a

maximum speed of up to 160 kmph and negotiate curves upto a minimum radius of

175 meters and carry payload of upto 30 t. Maximum operating speed and radius of

curve which is negotiated by various types of coaches of IR are as under:

Types of coaches Maximum Minimum radius of Maximum

operating curve (negotiated Gross load

speed by coaches)

EMU/DMU fitted with ICF 110 Kmph 152.4 meter 81.2 t

bogies. (The annual kilometer

earning of these coaches is

approximately 2,00,000 (2

lakhs).

Mainline/Rajdhani 130 Kmph 152.4 meter 65.0 t

conventional type ICF

coaches fitted with

conventional ICF type

Bogies.

LHB coaches fitted with FIAT 160 Kmph 152.4 meter 65.0 t

Bogies

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 5 of 47

Ver 1.0 August, 2020 04)

2.1.2 Compressed air supply to the air spring assemblies shall be maintained through a

compressor provided in the Locomotive. Provision of air-drying drier does may

not exist/function in some of the compressed air supply system of some

Locomotives/motor coaches. The pneumatic circuit of air spring assembly

system is connected to the Feed pipe.

2.1.3 Each coach shall be fitted with four air spring assemblies (two per bogie) and each air

spring assembly shall be controlled by an independent leveling valve (4-point control

system). Two air springs of the same bogie shall be connected through a duplex

check valve set to act at a pressure differential of 1.5+ 0.12 Kg/cm² as per

requirement.

2.1.4 To maintain continuous supply of compressed air to the air spring assembly system,

an 150 liter auxiliary air reservoir has been provided.

2.1.5 Track-ballast during train operation may occasionally hit air spring assembly and

control equipments.

2.2 For EMU / DMU & MEMU coaches

2.2.1 Each set of EMU / DMU & MEMU coaches fitted with air spring assemblies would

consist of one power car/ motor coach and two or three trailer coaches. Two to four

of such sets would normally form a train. These coaches would have a maximum

speed of 110 kmph and will be required to negotiate curves upto a minimum radius of

152.4 meters carrying a payload of upto 36t. The annual kilometer earning of these

coaches is approximately 2,00,000 (2 lakhs).

2.2.2 Compressed air supply to the air spring assemblies shall be maintained through a

compressor provided in the motor coach/power car. The compressor charges the

Main Reservoir pipe/ Feed pipe at 6 Kg/cm². Provision of air-drying may not exist in

the compressed air supply system. Pneumatic circuit of air spring assembly system is

connected to the Main Reservoir / Feed pipe.

2.3 For All Type Of Stock:

2.3.1 This para shifted to para 2.1.3 of this STR.

2.3.2 This para shifted to para 2.1.4 of this STR.

2.3.3 This para shifted to para 2.1.5 of this STR.

3 ENVIRONMENTAL CONDITIONS:

3.1 The control equipment for air suspension fitted in coaches described above shall be

subjected to following environmental conditions:

Max. Temperature under sun : 60ºC.

Ambient temperature : 0º to 45ºC in shade.

Average relative humidity : 70% to 90%, 100% on several days.

Rainfall : Fairly heavy, maximum being 200mm in

24 hours, typical to the coastal areas.

Atmosphere : Dusty for several months of the year.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 6 of 47

Ver 1.0 August, 2020 04)

3.2 The control equipment for Air spring assembly system may also come in contact with

the following, during coach maintenance operation:

Chemical products (like cleaning compound of coach cleaning)

Cotton waste smeared with oil and paint etc.

Disinfectants.

Oils & lubricants used in coach bogies.

4 SCOPE OF SUPPLY:

4.1 The air suspension system for which control equipment is required shall be 4-point

control system.

4.2 The scope of supply shall cover the following items to suit air springs and their

characteristic. Technical requirements of these items are given in Clause-6.

SN Item Description Quantity per

coach

1 Leveling valve 4

2 Installation lever 4

3 Duplex check valve with 1.50.12 Kg/cm² pressure setting 2

4 Main pressure tank (Auxiliary reservoir) 150 liters capacity 1

with ½” drain cock.

5 Air reservoir(Additional reservoir) of 20 dm3 (20 liters) 4

capacity with ½” drain valve . OR

40 dm3 (40 liters) capacity with ½” drain valve

6 Check valve (non return valve)20 mm bore with 3mm 1

choke

7 Two way centrifugal dirt collector (20mm bore) 1

8 Isolating cock (OLP type) 20mm bore

i) For main supply line pressure isolation 1

ii) For bogie pressure isolation 2

9 Hose connections 4

Note: (i) Purchaser can purchase suitable fittings and hardwares in deviation of item

no. 8 under clause 4.2 from the sources developed by RDSO/RCF/ICF/MCF as per their

requirement based on the type of joint (single ferrule/double ferrule/Flange joint) used in

pneumatic suspension. Item no 8 & 9 of Para 4.2 are to be purchased from

RDSO/ICF/RCF/MCF registered sources for similar items (isolating cock/ferrule fittings for

item 8 , hose pipe/connection for item 9). These item may be manufactured by the vendor

with prior approval of Carriage Directorate, if it is found that sufficient registered sources for

similar items (isolating cock,hose pipe/connection) are not available in vendor directory of

ICF/MCF/RCF/RDSO.

(ii) Any other item, which in the view of the supplier is considered essential for operation or

enhances the performance of the system, may also be offered.

(iii) In case of FIAT bogies, additional reservoir is not required (item no. 05).

5 PROCEDURE PARTICULAR REQUIREMENTS FOR VENDOR REGISTRATION:

5.1 Manufacturers Vendors willing to supply air suspension control equipment for the use

of Indian Railways shall register themselves with Research Designs and Standards

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 7 of 47

Ver 1.0 August, 2020 04)

Organization, Ministry of Railways, Lucknow-226011 (RDSO) and should be ISO

approved. All relevant documents like Vendor Approval guidelines & Application

form, latest version of all specifications and drawings are provided on RDSO

websites. The firm shall follow the latest vendor approval guidelines for

registration with RDSO.

The firm should possess ISO: 9001 certificate for his works address, covering

the items for which he seeks registration with RDSO.

5.2 The manufacturer shall have adequate facilities infrastructure for manufacturing,

testing and quality control requirements as stipulated in Section-B of this STR for the

manufacture and testing of pneumatic suspension control system conforming to

drawings approved by RDSO. This will be verified by the RDSO official at the time of

registration.

5.3 This para shifted to section B of this STR.

5.3.1 This para shifted to section B of this STR.

5.3.2 This para shifted to section B of this STR.

5.3.3 This para shifted to section B of this STR.

5.3.4 This para shifted to section B of this STR.

5.3.5 This para shifted to section B of this STR.

5.3.6 This para shifted to section B of this STR.

5.3.7 This para shifted to section B of this STR.

5.3.8 This para shifted to section B of this STR.

5.3.9 This para shifted to section B of this STR.

5.4 Special Conditions:

a) Since pneumatic suspension control equipments are a safety related

suspension element, in-service trials shall be necessary before full clearance

is given for supply for inclusion of name of firm in ‘List of RDSO vendors

for developmental orders’ for manufacture and supply of Air suspension

control equipments.

b) The control equipments shall be subjected to in-service trials on a minimum of

ten coach sets for one year on IR’s system. For this purpose, one time trial

order for more than ten coach sets shall be given to such vendor to monitor

the service performance of equipment supplied by their firm.

c) In case of any failure during service trials attributable to poor

design,manufacturings process or material, the service trials shall be repeated

with modified/updated design, manufacturing process or material after

successful type testing afresh by RDSO official at firm premises. The vendor

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 8 of 47

Ver 1.0 August, 2020 04)

has to submit the fresh drawing and modified QAP for approval. . RDSO shall

decide the cause of failure after investigation in this regard.

d) After completion of service trial period, sample of the control equipments shall

be subjected to the tests laid down at para 6 (Section-A) of this specification.

In case the values obtained during these tests are beyond permissible limits,

the air spring control equipments design shall be deemed to have failed the

service trials.

e) After satisfactory performance of the service trials & successful test as para

(d), the pneumatic suspension control equipments design may be considered

for regular service on Indian Railways and firm may be given status of ‘RDSO

Vendor for Developmental order’.

f) A Vendor shall be considered eligible for upgradation to status of ‘Approved

Vendor’ on completing successful supply of a minimum of 100 coach sets of

the particular type of pneumatic suspension control equipments as per latest

ISO guideline of RDSO.

g) Manufacturers shall be provided “Developmental” status on successful

completion of service trials as defined in clause 5.4.b above. A Vendor shall

be considered eligible for upgradation as “Approved Vendor” on completing

successful supply of a minimum of 100 coach sets of pneumatic suspension

control equipments along with the fulfillment of conditions mention in latest

apex ISO document of RDSO for “Vendor- Changes in approved status”

(document no. QO-D-7.1-11 ).

The proto type test shall be witnessed by authorized representative of

RDSO at firm premises at the time of design approval of the vendor at

their own test facility.

Any additional test if considered necessary shall also be arranged by vendor

free of cost. All necessary arrangement for witnessing the proto type test of

pneumatic suspension control equipments at firm’s premises shall be done by

the vendor. RDSO reserves the right to witness the type test again if change

in approved design/ drawings are carried out which are likely to alter design /

performance characteristics of the pneumatic suspension control equipments.

h) In case design of critical component is changed, fresh proto test and service

trial shall be required. However, service trial can be dispensed with by RDSO

considering the reasons for change and extent of modification.

i) After proto type tests of a particular design are approved by RDSO, vendors

shall ensure that pneumatic suspension control equipments to the particular

specification are supplied with components manufactured from the sources as

indicated at the time of design approval and used for type testing.

j) In case, source of any component of pneumatic suspension control

equipments is changed or any additional source is introduced, the firm shall

get approval of modified QAP from RDSO before manufacturing and supply of

pneumatic suspension control equipments. The vendor should provide the

detailed information of the source changed/ additional source introduced

along with the documentary evidences for the record of this office. Firm shall

validate the source in all respect i.e material, manufacturing process, quality

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 9 of 47

Ver 1.0 August, 2020 04)

control and inspection & testing etc. to confirm to originally approved design

and process. Compliance to all obligations including guarantee/warrantee (as

per para.8 of section 8) shall remain the responsibility of vendor.

5.5 Service trial quantity

As per the requirement of Indian Railways, RDSO at its discretion with approval of

competent authority can increase the trial quantity of pneumatic suspension control

equipments of particular vendor based on the satisfactory performance of pneumatic

suspension control equipments supplied earlier against developmental orders for

service trials.

6 TECHNICAL REQUIREMENTS:

6.1 GENERAL REQUIREMENT:

6.1.1 All the valves and linkages offered shall be of proven design, easy to install, operate

and maintain.

6.1.2 All pneumatic suspension control equipments shall be able to work under pressure

between 1.0 Kg/cm2 to 10.0 Kg/cm2 and withstand an applied frequency of up to 10

Hz during run.

6.1.3 Any special requirements given in the drawings will over ride this STR.

6.2 LEVELLING VALVE:

6.2.1 Leveling valve shall regulate the supply of air to the air springs so as to maintain pre-

defined height at all variable loads.

6.2.2 Outer dimension of leveling valve and its pipe connection ports shall as per space

envelope shown in RDSO SKETCH-K1049 Alt. 1.

6.2.3 Leveling valve shall have such a setting that under dynamic load variations of the

coach running, insignificant consumption of air takes place.

6.2.4 Effective length of its lever shall be 160mm.

6.2.5 Design of leveling valve and its characteristics shall be approved by RDSO.

6.2.6 The leveling valve should function as per this specifications properly with installation

lever located on either side of the valve body.

6.2.7 The test procedure of leveling valve shall be strictly as test set up enclosed as

specified in Annexure – 1.

6.2.8 The dead band angle of leveling valve shall not be greater than 1 0 20’ on either

direction.

6.2.9 The charging and discharging time for 20 liters reservoir shall be as per the proforma

given in test record sheet enclosed as Annexure – 1.

6.2.10 All internal parts of levelling valve should be made of stainless steel.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 10 of 47

Ver 1.0 August, 2020 04)

6.3 INSTALLATION LEVER:

6.3.1 Design of installation lever shall be as per RDSO SKETCH-K1050 Alt 3.

6.3.2 Installation lever shall have ball and socket joint at both the ends. It shall position

locking system at both the ends to avoid unnecessary rotation of the lever.

6.3.3 When connected to leveling valve lever; top and bottom ball and socket joints of

installation lever shall enable a free simultaneous or independent movement of the

order of upto 80 mm lateral and 15 mm (minimum) longitudinal of the assembly at top

articulation with reference to the bottom fixed articulation.

6.3.4 The material of ball and socket joint and also Turn Buckle and threaded trunnion rod

shall be of corrosion resistant steel duly approved by RDSO. The ball and socket joint

shall be case hardened up to 1 mm depth.

OR

The material of ball and socket joint and also Turn Buckle and threaded trunnion rod

shall be of corrosion resistant steel duly approved by RDSO. Ball and socket joint

should be separated by injection moulded rubber to prevent wear.

6.3.5 The screws nuts and lock nuts shall be of high tensile steel of M10 x 60 at both ends.

6.3.6 Material of Installation lever body shall be Stainless Steel AISI 304.

6.4 DUPLEX CHECK VALVE (RELIEF VALVE):

6.4.1 Duplex check valve shall be provided between the air springs on same bogie and

shall permit flow of air in either direction whenever pressure differential go beyond 1.5

0.12 Kg/cm².

6.4.2 Duplex check valve design shall suit the space envelope and pipe connections &

fixing arrangement shown in RDSO SKETCH- K1051.

6.4.3 The test procedure for Duplex Check Valve shall be strictly as per Annexure-2

6.4.4 The test setup for Duplex Check valve is as per fig. enclosed in Annexure-2.

6.5 MAIN PRESSURE TANK (AUXILIARY RESERVOIR ) WITH DRAIN VALVE:

6.5.1 Main pressure tank should be of 150 dm³ (150 litres) capacity.

6.5.2 Design of 150 lit. pressure tank shall be as per ICF Drawing No. ICF/STD – 3-5-066

(latest alteration).

6.5.3 Drain cock assembly shall be as per RDSO SKETCH- 98003.

6.6 20 OR 40 dm3 (20 OR 40 LITRES) ADDITIONAL AIR RESERVOIR:

6.6.1 Air reservoir for additional air volume of air spring shall be 20 dm 3 or 40 dm3 (20

litres OR 40 litres) capacity.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 11 of 47

Ver 1.0 August, 2020 04)

6.6.2 Design of 20 dm3 reservoir will be as per ICF Drawing No. ICF/SK3-0-5-008 (latest

alteration) with drain valve (for EMU/DMU bogies).

6.6.3 Design of 40 dm3 reservoir will be as per ICF Drawing No. LWGSCWAC-0-5-003

(latest alteration) with drain valve (for main line ICF bogies).

6.7 CHECK VALVE (NON RETURN VALVE):

6.7.1 The check valve shall be as per RDSO SKETCH- 98112.

6.7.2 Except drawing/sketch all clauses of appendix-I (clause 5.0, 6.0 & 7.0) of RDSO

specification 02-ABR-02 shall be followed.

6.8 TWO WAY DIRT COLLECTOR:

6.8.1 The two way dirt collector shell be as per RDSO SKETCH- 97005.

6.8.2 Except Drawing/sketch all clauses of appendix-E (clause 6.0, 7.0 & 8.0) of RDSO

specification 02-ABR-02 shall be followed.

6.9 ISOLATING COCK:

6.9.1 Isolating cock (OLP type) (20mm bore) as per RDSO SKETCH-97002.

6.9.2 Except Drawing/sketch all clauses of appendix-I (clause 6.0, 7.0 & 8.0) of RDSO

specification 02-ABR-02 shall be followed.

6.9.3 Isolating cock with ferrule fittings may also be purchased/supplied. Isolating cock are

to be purchased from RDSO/ICF/RCF/MCF registered sources for similar items

(isolating cock/ ferrule fittings).

6.10 HOSE CONNECTIONS:

6.10.1 The hose connection shall be as per RDSO SKETCH-K1054.

6.10.2 Hose connections are to be purchased from RDSO/ICF/RCF/MCF registered

sources for similar items (hose pipe/connection).

7 SUBMISSION OF OFFERS TECHNICAL DOCUMENTS: (FOR FIRMS SEEKING

RDSO's APPROVAL)

7.1 Firms Vendors desirous of seeking approval from RDSO for supply of material as

per this STR, shall submit their proposal accompanied by the documents containing

the following information to RDSO:

7.1.1 Test report on the proposed equipments based on the tests conducted and results

compiled by manufacture to indicate the characteristics of the tested equipments.

7.1.2 Dimensional drawings of the equipments.

7.1.3 Characteristics of the offered equipments.

7.1.4 Weight of offered equipments.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 12 of 47

Ver 1.0 August, 2020 04)

7.1.5 Whether proposed equipments are being used by any other rail-road system? If yes,

details regarding quantity, type of stock, maximum operating speed, type of service,

average annual running kilometers, life cycle obtained by the user rail-road and

maintenance cycle followed by them.

7.1.6 Details of deviation from the STR.

7.1.7 Content of indigenous and imported items in offered equipment.

7.1.8 Expected life cycle in operating and environmental conditions enumerated in clauses

2 & 3 of section-A of this STR.

7.1.9 Authorization certificate / License etc. from the original manufacturer permitting

supply / manufacture of the offered equipment. (For proposals from other than the

original manufacturers).

7.1.10 A write-up giving broadly the maintenance requirements on time/distance basis along

with the facilities that would be needed for proper maintenance/upkeep of the offered

equipment.

7.1.11 A detailed write-up giving the details of "Quality Assurance System" being followed

for manufacture of the offered items; and

7.1.12 Details of manufacturing and testing facilities available with the manufacturer.

7.2 The information as received above shall be used for preliminary evaluation of the

firm's capability in meeting with the requirements of this STR.

7.3 After preliminary evaluation, the premises of the firm may also be visited by RDSO’s

officials for on-the-spot assessment of the firm's capability.

7.4 RDSO reserves complete right of granting approval or otherwise to a firm.

8 GUARANTEE:

8.1 Equipments supplied by the firms shall be guaranteed for satisfactory performance for

a minimum period of 24 months from the date of actual commission in bogies or 30

months from the date of supply. Satisfactory performance for this purpose means that

complete equipment or any of its part shall neither show any kind of deterioration

which is likely to render it unserviceable nor loose its characteristics as stipulated in

this STR, during the guarantee period for reasons attributable to

manufacturing/design defects.

8.2 In the event of 'non-satisfactory performance' of any of the items as indicated above,

supplier will have to replace the same at his own expense without levying any cost

involved in transportation, handling and replacement of such items on the Purchaser.

9 PROTOTYPE INSPECTION:

9.1 Vendor shall offer at least three sets prototype pneumatic suspension control

equipments of particular type, for which they are seeking registration in RDSO, for

necessary inspection and testing as paras 11,Annexure A,Annexure-1,Annexure-2

of this STR.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 13 of 47

Ver 1.0 August, 2020 04)

9.2 The Prototype inspection of pneumatic suspension control equipments shall be

carried out by Carriage Directorate of RDSO or their nominee at manufacturing

premises of firm. The manufacturer shall provide material, tool and any other

assistance without any extra charges which may consider necessary for any test

/examination and dimensional check.

9.3 After prototype clearance, the pneumatic suspension control equipments shall

be subjected to field trial as per Para 5.4 (b) of Section A of this STR.

10 INSTALLATION, COMMISSIONING & MAINTENANCE:

10.1 On placement of order, supplier whose equipment will be purchased for the "First

Time" for installation on the coaches, shall have to depute his representative at his

own expense to associate with the purchaser in installation and commissioning of the

equipment on first five coaches. He shall also depute his representative during

maintenance schedules undertaken on his equipment as per maintenance booklet

supplied by him.

10.2 With every order for supply of air spring control equipments to approved supplier; the

supplier shall have to supply two maintenance booklets (hard copy) and one copy on

pen drive and one copy on Compact Disc (MS-Office compatible).

10.3 Maintenance booklet supplied by the supplier shall cover the following aspects in

detail:

10.3.1 Specification of the pneumatics control equipment.

10.3.2 Drawing and specification of all gauges required for maintenance.

10.3.3 Working principle based on the actual construction.

10.3.4 Constructional details giving sketches, drawings and photographs etc. identifying

various items and their part numbers etc. for easy identification.

10.3.5 Procedure for dismantling using sequential steps with the help of sketches etc.

10.3.6 Procedure for assembly, using sequential steps with the help of sketches etc.

10.3.7 Jigs, tools, other materials and details of special set-ups etc., necessary for items

4&5 above.

10.3.8 Testing procedures and facilities required along with their details.

10.3.9 Comprehensive details containing legible sectional views of defects normally

observed or may happen in equipollents with clear remarks whether the defect is

reject able or non-reject able.

10.3.10 List of other defects and their remedies.

10.3.11 Periodicity for various maintenance activities on time and distance basis.

10.3.12 Do's and Don'ts for maintenance officials.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 14 of 47

Ver 1.0 August, 2020 04)

11 PURCHASE INSPECTION AND TESTING:

11.1 GENERAL REQUIREMENTS:

11.1.1 During initial approval of a firm by RDSO (Clause 7.3) and later on when approval

has been granted, RDSO for purpose of ensuring quality of purchased product may

carry out periodic quality audit, inspection and testing of the equipment at the

premises of the manufacturer / supplier.

11.1.2 Purchase inspection shall be done at the premises of the manufacturer / supplier by

the representative of the Research Design and Standard Organization or an agency

authorized by RDSO and supplier shall have to arrange for the following and

associate with the same:

11.1.2.1 Access to all records considered relevant for such activity by inspecting officials.

11.1.2.2 Questioning of relevant personnel engaged in production, testing and quality

checking activities etc. or related issues.

11.1.2.3 Testing of few samples of items already produced by the firm to ascertain the

technical characteristics given in this STR.

11.1.2.4 Any other check considered necessary by the inspecting party.

11.1.2.5 Test bench for hydraulic test of reservoirs having facility to conduct test on minimum

five reservoirs at a time.

11.1.2.6 The inspecting official will carry out purchase inspection as per updated check list

sheet approved by RDSO. The general format of inspection checklist is attached at

Annexure-“A” of this STR.

11.2 INSPENSION AND TESTING OF LEVELLING VALVE, DUPLEX CHECK VALVE,

INSTALLATION LEVER & HOSE CONNECTION.

11.2.1 Inspection of all control equipments shall be carried out as per approved drawings.

However, in cases where vendors source some items from RDSO/MCF/ICF/RCF

approved registered sources duly inspected by Quality Assurance Department of

RDSO or RITES, inspection of already inspected items will not undertaken and such

items shall be accepted against copy of Inspection Certificate issued by inspecting

agency.

11.2.2 5% of lot or 10 nos. each item, whichever is more, shall be picked up randomly for

dimension & other specified inspection as given above in clause 11.2.1 of this STR.

11.2.3 In case anyone picked up samples fails manufacture/supplier may offer rectifying the

defects. However, in such cases, double the quantity of samples shall be picked up

and check for dimension and other specified testing. In case any one samples again

fails the entire lot shall be rejected.

11.3 INSPECTION AND TESTING OF MAIN RESERVOIR TANK (150 dm3), AIR

RESERVOIR (20 dm3 OR 40 dm3) CHECK VALVE, TWO-WAY DIRT COLLECTOR,

ISOLATING COCK AND HOSE CONNECTIONS.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 15 of 47

Ver 1.0 August, 2020 04)

S.N. Item Make Ref.

1 Main Pressure Approved Dimensional check as per ICF drawing no.

tank (150 dm3) Registered ICF/STD – 3-5-066 (latest alteration).

sources of

RDSO/ICF/

RCF/MCF

2 Air Reservoir -Do- Dimensional check as per ICF Drawing No.

(20dm3 OR ICF/SK3-0-5-008 (latest alteration)

40dm3) OR LWGSCWAC-0-5-003 (latest alteration)

3 Check valve Approved Dimensional check as per RDSO SKETCH-

Registered 98112

sources of RDSO Inspection as per technical requirement

ICF/ RCF/MCF clause 6.7 of this STR

4 Two way dirt -Do- Dimensional check as per RDSO

collector SKETCH- 97005

Inspection as per technical requirement

clause 6.8 of this STR

5 Isolating cock RDSO/ICF/RCF/ Dimensional check as per RDSO SKETCH-

MCF registered 97002

source for similar Inspection as per technical requirement

items (isolating clause 6.9 of this STR

cock/ferrule

fittings)

6 Hose RDSO/ICF/RCF/ Dimensional check as per RDSO SKETCH-

connections MCF registered K1054

source for similar Inspection as per technical requirement

items (hose clause 6.10 of this STR

pipe/connections)

12 PAINTING:

12.1 Leveling valve, Duplex check valve and Installation lever internal & external part shall

be given anticorrosion treatment. External surface, excluding the flange shall be

painted with Red enamel paint or red anodized.

12.2 Hose connection head shall be given anticorrosive treatment and painted with Red

enamel paint.

13 MARKING:

Every item of control equipment shall be legibly marked by using punching or casting

etc. to indicate the following:

1) Manufacturer's initials.

2) Month and year of manufacture.

3) Identification mark, i.e. Part No. and Batch No. etc.

14 PACKING:

14.1 All the ports of valve and cock shall be suitably covered with protection caps to

prevent ingress of foreign matter during handling and storage.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 16 of 47

Ver 1.0 August, 2020 04)

14.2 All pneumatic suspension control equipment shall be suitably packed to protect

against any damages during transit and handling by transport to the destination.

15 TOLERANCE:

Tolerance in different dimensions of pneumatic suspension control equipments

should be mentioned in drawing as under-

Fractions Decimals Angles

X.0 + 2 X.X + 1.0 X.XX + 0.50 X.XXX + 0.250 + 3.0 0

Dimension tolerance of pneumatics suspension control equipments for other than

specified dimension should be as per IS 2102 (part 1) (medium).

16 GENERAL:

16.1 RDSO may draw samples for quality check to test any property mentioned in this

specification at it’s discretion. The vendor shall arrange testing of these samples at a

reputed outside laboratory as decided between RDSO and the vendor. The testing

charges should be borne by the vendor.

16.2 RDSO reserve the right to modify any clause of this STR as per requirement of Indian

Railways.

16.3 Additional information if required may be obtained from the office of the Director

General (Carriage), RDSO, Manak Nagar, Lucknow – 226011.

*****************

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 17 of 47

Ver 1.0 August, 2020 04)

ANNEXURE - A

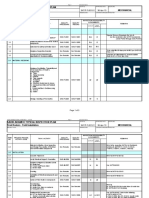

CHECKLIST SHEET FOR INSPECTION OF PNEUMATIC CONTROL EQUIPMENTS

As per inspection and testing Clause no. 6.0

1.0 INSPECTION FORMAT OF INSTALLATION LEVER

S.No. Particulars Unit Specified Observations

1 Finish Smooth

2 Cut Nil

3 Burrs/Flash Nil

4 Rust/Corrosion Not allowed

5 Weld/Paint Marks Not allowed

6 Flatness/Parallelism

7 Thread mm M10x1.5 RH

8 Thread mm M10x1.5 LH

9 Overall Length mm 290-360

10 Hex. Rod Length mm 170

11 Hole Diameter mm 10

12 Effective bolt length mm 60

STATUS: Accepted / Not Accepted

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 18 of 47

Ver 1.0 August, 2020 04)

2.0 INSPECTION FORMAT OF LEVELLING VALVE

S.No. Particulars Unit Specified Observations

1 Diameter of mm As per approved drawing

hole in leveling

valve handle.

2 Center mm 50

Distance of

mounting holes

3 Square Size mm As per approved drawing

4 Mounting Hole mm Ø9.5

Diameter

5 Overall mm As per approved drawing

dimension

6 Threading ¾ “ BSPT

7 Handle mm As per approved drawing

Thickness

8 Handle Width mm 20

9 Position mm As per approved drawing

10 Handle mm 160

Effective

Length

Pressure Test: Sample checked at 10 Kg/cm2 and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Painting: Red Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 19 of 47

Ver 1.0 August, 2020 04)

3.0 INSPECTION FORMAT OF DUPLEX CHECK VALVE

S.No. Particulars Unit Specified Observations

1 Height mm As per approved drawing

2 Width mm As per approved drawing

3 Base to hole mm 61

center line

4 Tapped hole to mm As per approved drawing

hole center line

5 Depth mm As per approved drawing

6 Port Threading ¾” BSPT

7 Square size mm As per approved drawing

8 Square size mm As per approved drawing

9 Center Mm 60

distance of

mounting holes

10 Mounting hole mm 11.5

dia.

Pressure Test: Sample checked at 10 Kg/cm2 and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Painting: Red Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 20 of 47

Ver 1.0 August, 2020 04)

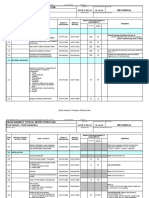

4.0 INSPECTION FORMAT OF MAIN PRESSURE TANK (150 lit.)

S.No. Particulars Unit Specified Observations

1 Overall Length mm 817 +3 /-0

2 Length over mm 545 ± 1.0

barrel

3 Plate width mm 75 ± 1.0

4 Plate to plate mm 415 ± 1.0

length

5 Outside dia. of mm Ø530+3.0 / -0

reservoir

6 Tapped holes 1/2” B.S.P. & 1” B.S.P.

dimension

7 Length of pad mm 500 ± 1.0

8 Centre mm 400 ± 1.0

Distance of

holes

Pressure Test: Hydraulic test at 16 Kg/cm2 for min. 10 minutes and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 21 of 47

Ver 1.0 August, 2020 04)

5.0 INSPECTION FORMAT OF TWO WAY DIRT COLLECTOR

S.No. Particulars Unit Specified Observations

1 Top to bottom mm 201 +0 / -2.0

distance.

2 Flange to flange mm 182 ± 0.5

distance

3 Mounting Hole mm Ø 13.5 ± 0.2

diameter

4 Center distance mm 70 ± 0.2

of hole

5 Flange mm 15 ± 0.25

thickness

6 Air hole mm Ø 20 + 1.5/-0.0

Pressure Test: Sample checked at 10 Kg/cm2 and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Painting: Red Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 22 of 47

Ver 1.0 August, 2020 04)

6.0 INSPECTION FORMAT OF AIR RESERVOIR (20 lit.)

S. Particulars Unit Specified Observation

No

01. Overall mm 605 +0 / -

Length 5

02. Shell mm Ø220 +0 /

Diameter -2

03. End Cover mm Ø210 ±

Diameter 0.5

04. Threaded --- PIPE

Hole THREAD

ISO 7-

Rp1/2

05. Threaded ---- PIPE

Hole THREAD

ISO 7-

Rp1/2

06. Length of mm 100 ± 1.0

Pad

07 Centre mm 340 ± 1.0

distance of

hole

08 Centre mm 280 ± 1.0

distance of

hole

Pressure Test: Hydraulic test at 16 Kg/cm2 for min 10 minutes and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 23 of 47

Ver 1.0 August, 2020 04)

7.0 INSPECTION FORMAT OF AIR RESERVOIR (40 lit.)

S. Particulars Unit Specified Observation

No

01. Overall mm 600 ±1.0

Length

02. Shell mm Ø302 ±1.0

Diameter

03. End Cover mm Ø302 ±1.0

Diameter

04. Threaded --- 1/2”

Hole B.S.P.T

05. Threaded ---- 1-1/4”

Hole B.S.P.T.

06. Length of mm 135 ± 0.25

Pad

07 Centre mm 350 ± 1.0

distance of

hole

08 Centre mm 380 ±1.0

distance of

hole

Pressure Test: Hydraulic test at 16 Kg/cm2 for min 10 minutes and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 24 of 47

Ver 1.0 August, 2020 04)

8.0 INSPECTION FORMAT OF CHECK VALVE (NRV)

S.No. Particulars Unit Specified Observations

1 Flange to flange mm 100 ± 0.50

distance

2 Top to center mm 100 (Max.)

distance

3 Flange thickness mm 15 ± 0.25

4 Flange width mm 52 (Min.)

5 Mounting Hole mm Ø 13.5 ± 0.25

diameter

6 Hole diameter of mm Ø 19 ± 0.1

air vent.

7 Center distance mm Ø 70 ± 0.2

of holes

8 Flange length mm 96(Min.)

Pressure Test: Sample checked at 10 Kg/cm2 and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Painting: Red Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 25 of 47

Ver 1.0 August, 2020 04)

9.0 INSPECTION FORMAT OF ISOLATING COCK

S.No. Particulars Unit Specified Observations

1 Flange to flange mm 85 ± 0.1

distance

2 Top to center mm Max. 80

distance

3 Flange mm 15 ± 0.5

thickness

4 Centerline to mm 125 ± 1.0

handle end

5 Mounting hole mm Ø 13.5 ± 0.25

diameter

6 Center distance mm 70 ± 0.4

of holes

Pressure Test: Sample checked at 10 Kg/cm2 and no leakage observed.

Physical Condition: OK / Not OK

Marking: Done / Not Done

Painting: Red Done / Not Done

Remark: Found OK / Not OK.

Status: Accepted / Not Accepted.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 26 of 47

Ver 1.0 August, 2020 04)

10.0 Inspection Format of Drain Valve

Sr. Particulars Unit Specified Observation

No

01. Overall Length mm As per

approved

drawing

02. Hexagon Head mm As per

approved

drawing

03. Length mm As per

approved

drawing

04. Thread - As per

approved

drawing

Presssure Test: Sample checked at 10 Kg/cm2 and no leakage observed.

Physical Condition: OK/Not Ok.

Status: Accepted/Not Accepted

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 27 of 47

Ver 1.0 August, 2020 04)

11.0 Inspection Format of Hose Connection

S. Particulars Unit Specified Observation

No

01. Overall mm 550+ 2

Length

02. Thread - ¾ “ BSP

03. Thread - ¾ “ BSP

Physical Condition: OK/Not Ok.

Remarks: Found OK/Not OK

Status: Accepted/Not Accepted

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 28 of 47

Ver 1.0 August, 2020 04)

12.0 Pressure Differential Test on DCV

S.No. DCV’s Single Direction Reverse Direction Remarks

No. P1(Bar) P2(Bar) Differential P1(Bar) P2(Bar) Differential

1.5 1.5

1. 4.0 4.0

6.0 6.0

1.5 1.5

2. 4.0 4.0

6.0 6.0

1.5 1.5

3. 4.0 4.0

6.0 6.0

1.5 1.5

4. 4.0 4.0

6.0 6.0

1.5 1.5

5. 4.0 4.0

6.0 6.0

1.5 1.5

6. 4.0 4.0

6.0 6.0

Note: Pressure differential should be 1.5 0.12 Kg/cm².

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 29 of 47

Ver 1.0 August, 2020 04)

13.0 Characteristic Test Of Levelling Valve

DB Angle Charging (2 to 6 bar) Discharging (6 to 2

S.No. Levelling (1.330- bar)

Valve No. 0.670) At 40 At 100 At 4 0

At 100

(15 to 45 (4 to 14 (33 to 93 (5 to 25

sec.) sec.) sec.) sec.)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 30 of 47

Ver 1.0 August, 2020 04)

ANNEXURE-1

TEST SET UP

Install the valve in the test rack as shown in fig.1.

All cocks IC-1, 1C-2, IC-3, & IC-4 should be closed.

Adjust the air inlet pr. to 10 kg/cm2 as shown in pressure gauge (P-1) by opening cock

IC-1.

Adjust the handle at 0 degree as shown in angle protector.

LEAKAGE TEST

Apply soap water all over the body, cap etc. of leveling valve.

There should not be any leakages.

Open cock IC-2. There should not any flow in flow indicator.

Move the lever upto 0.50. there should not be any leakage and any flow throw the flow

indicator. Record no leakage.

Similarly move the lever down to 0.5 0. There should not be any leakage.

FUNCTION TEST

1) Initial charging and discharging of air

Open cock IC-3 and move the handle from 0 deg. to + 0.5 deg. Interval. Note at what

angle air flow start through flow indicator. This should be approximately +(1020’).

Same procedure to be followed for discharge also. It will be approximately -(1020’)

degree.

2) Normal charging and discharging

Gradually increase the angle of handle clockwise to +100 as shown in the angle

protector. Check the time taken for the pressure shown on pressure gauge P-2 to rise

from 2 to 6 kg/cm2. Record the time in the test record sheet, which should be 9 + 5

secs

Gradually move the handle to -100 as shown in the angle protector. Check the time

taken for the pressure shown on pressure gauge P-2 to fall from 6 to 2 kg/cm2.

Record the time in the test record sheet which should be 15 + 10 secs

Gradually increase the angle of handle clockwise to +4 0 as shown in the angle

protector. Check the time taken for the pressure shown on pressure gauge P-2 to rise

from 2 to 6 kg/cm2. Record the time in the test record sheet which should be 30 + 15

secs

Gradually move the handle to -40 as shown in the angle protector. Check the time

taken for the pressure shown on pressure gauge P-2 to fall from 6 to 2 kg/cm2.

Record the time in the test record sheet which should be 63 + 30 secs

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 31 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 32 of 47

Ver 1.0 August, 2020 04)

TEST RECORD SHEET FOR LEVELLING VALVE (Test Pressure 10 bar)

Leakage Test

Parameter Standard Observed

1. Apply soap water to Body No Leak

/Cap

2. Move the lever to + ½ deg. No Leak, No rise of Float

Function: A (Test for Dead Band)

Initial Charging Standard Observed

/Discharging Degree of rotation Degree of rotation

Charging (When flow of air + (1 20’)

takes place by rotation of

lever in the forward

direction)

Discharging (When flow of - (1 20’)

air takes place by rotation

of lever in the reverse

direction)

Function: B

Initial Charging Standard Time (seconds) Observed Time (seconds)

/Discharging

With rotation of lever in 95

forward direction at +10

deg, time taken for change

in pressure from 2 kg/cm2

to 6 kg/cm2

With rotation of lever in 15 10

reverse direction at -10

deg, time taken for change

in pressure from 6 kg/cm2

to 2 kg/cm2

With rotation of lever in 30 15

forward direction at +4 deg,

time taken for change in

pressure from 2 kg/cm2 to 6

kg/cm2

With rotation of lever in 63 30

reverse direction at -4 deg,

time taken for change in

pressure from 6 kg/cm2 to 2

kg/cm2

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 33 of 47

Ver 1.0 August, 2020 04)

ANNEXURE-2

TEST SET UP

Install the duplex check valve in the test rack as shown in fig.2. ensure clean and dry air

supply to the manifold as indicated. Close all cocks before starting the test. Open cock IC-

1. Regulate the air pressure on gauge to read 3 bar.

LEAKAGE TEST

Using soap solution check for any leakage at the joints. No leak permitted.

FUNCTION TEST 1

Set pressure reducing valve PR to 0 bar.

Open cocks IC-1 and IC-2.

Slowly increase pressure at pressure reducing valve PR and watch pressure gauge M

(having least count 0.05 bar). Air must escape from cock IC-2 when the pressure reaches

the set value of 1.5 bar.

Slowly reduce the pressure at pressure reducing valve PR and watch pressure gauge M

(having least count 0.05 bar). Air should stop escaping from cock IC-2 when the pressure

reaches the set value of 1.5 bar.

Close cock IC-1.

Set the pressure reducing valve PR to 4 bar and 6 bar respectively and repeat the test

procedure same as above to check valve opening and closing when the differential

pressure reaches around 1.5 bar.

To carry out function Test 2, install the duplex check valve in the test set up according to fig. ‘

b’ of fig 2.(Reverse direction of air flow)

FUNCTION TEST 2

Set pressure reducing valve PR to 0 bar.

Open cocks IC-1 and IC-2.

Slowly increase pressure at pressure reducing valve PR and watch pressure gauge M. Air

must escape from cock IC-2 when the pressure reaches the set value of 1.5 bar.

Slowly reduce the pressure at pressure reducing valve PR and watch pressure gauge M.

Air should escape from cock IC-2 when the pressure reaches the set value of 1.5 bar.

Close cock IC-1.

END OF TEST

Close IC-1. Vent the duplex check valve.

Close cock IC-2.

Remove duplex check valve from test set up.

Marked “Tested” stickers on the duplex check valve, which have passed.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 34 of 47

Ver 1.0 August, 2020 04)

( Fig.-2)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 35 of 47

Ver 1.0 August, 2020 04)

TEST RECORD SHEET FOR DUPLEX CHECK VALVE (Test Pressure 10 bar)

1) Air flow in forward direction (P-1 to P-2)

Sr. No. Observed Observed Differential Remarks

pressure at pressure at pressure (bar)

P-1(bar) P-2(bar)

1 1.5

2 4.0

3 6.0

2) Air flow in reverse direction (P-2 to P-1)

Sr. No. Observed Observed Differential Remarks

pressure at pressure at pressure (bar)

P-1(bar) P-2(bar)

1 1.5

2 4.0

3 6.0

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 36 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 37 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 38 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 39 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 40 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 41 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 42 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 43 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 44 of 47

Ver 1.0 August, 2020 04)

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 45 of 47

Ver 1.0 August, 2020 04)

SECTION-B

INFRASTRUCTURE & TESTING FACILITIES REQUIRED FOR MANUFACTURE OF AIR

SUSPENSION CONTROL EQUIPMENTS.

1.0 SCOPE

1.1. This Section covers the infrastructural requirements for manufacture and supply of

Air Suspension Control Equipments for air spring fitted BG ICF, LHB, Hybrid and

Double Decker mainline coaches & MEMU/DEMU having ICF and LHB type bogies

on Indian Railways.

2.0 REQUIREMENTS

2.1 All vendors seeking registration with RDSO shall comply all requirements mentioned

below.

3.0 PLANT, MACHINERY AND INFRASTRUCTURE REQUIREMENTS

3.1 The Manufacturer shall have adequate space and covered area with cemented floor

to accommodate the following and for smooth logistics:

a) Damp-free place for storage of raw materials.

b) Adequate manufacturing area.

c) Finishing, Assembly and Inspection area.

d) Storing and dispatch of finished products.

3.2 The Manufacturer shall have at least following machines/facility of suitable capacity:

a) CNC Center (Turning): Min. 01 Nos.

b) VMC Milling Machine: Min. 01 Nos.

c) Drilling Machine: Min. 01 Nos.

d) Cutting Machine: Min. 01 Nos.

e) Lathe Machine: Min. 01 Nos.

f) Grinding Machine: Min. 01 Nos.

g) Welding Machine: Min. 1 Nos.

h) Air compressor: Min. 01 Nos.

i) If any of M&P mentioned above is not required, the vendor shall

establish in place of non-requirement of the specified M&P and also

establish that process followed by the vendor is better.

4.0 TESTING FACILITIES

4.1 The Manufacturer shall have at least following testing equipment/facility with

controlled temperature and humidity:

a) Test Bench for Functional Testing of Air suspension control equipments : Min.

01 Nos.

b) Digital Vernier Caliper (500mm): Min. 01 Nos.

c) Dial Gauge: Min. 01 Nos.

d) Micrometer( inside/ outside/Depth/Disk): Min. 01 each Nos.

e) Measuring tapes (3 mtr): Min. 01 Nos.

f) Thread Plug Gauge: Min. 02 Sets

g) Steel Scale: Min. 02 Nos.

h) Digital Weigh scale (20 Kg): Min. 01 Nos.

i) Stop watch: Min. 01 Nos.

j) Any other essential measuring equipments for dimensional & function test.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 46 of 47

Ver 1.0 August, 2020 04)

5.0 QUALITY CONTROL REQUIREMENTS

5.1 The firm should have acquired ISO:9000 series certification for the product for which

an approval is sought.

5.2 The Vendor shall have a well-documented ‘Internal Quality Assurance System’ to

ensure sustained quality of product being manufactured. The Quality Assurance

System’ shall generally cover the following: -

5.2.1 System to ensure that correct raw material is being used.

5.2.2 System to ensure that components having manufacturing defects are identified and

destroyed so that such components are not used during assembly of air spring.

5.2.3 System to ensure that bought out components are strictly as per requirements laid

down in the STR / drawing.

5.2.4 System to maintain strict control of dimensions and workmanship of components and

assembled product.

5.2.5 System to test and establish that the Air Suspension Control Equipments

manufactured by the firm meets all the requirements laid down in STR / drawing.

5.2.6 System of periodical calibration of equipments/gauges to ensure accuracy of product.

5.2.7 System to ensure cleaning & removal of dust/rust and moisture by dry air.

5.2.8 System to ensure that Air Suspension Control Equipments is properly packed to

meet the requirement of Clause-13 of this STR.

5.2.9 System to ensure traceability at least up to guarantee period.

5.3 Quality manual of the firm for ISO:9000 should clearly indicate at any stage the

control over manufacturing and testing of the railway product.

5.4 The firm should submit the Quality Assurance Plan (QAP) as per RDSO ISO doc no.

CG-G-7.1-2.

5.5 The firm must ensure that proper analysis is being done on regular basis to study the

rejections at various internal stages and it is well documented.

5.6 The firm should ensure that latest version all the relevant specifications, IS Standards

are available with the firm.

5.7 System for calibration of testing & measuring equipment.

6.0 DOCUMENTATION

Firm shall maintain the following documents/ records:

6.1 A well-documented Quality Plan.

6.2 Incoming raw material register with Test Certificates references of suppliers and

internal test results.

6.3 Stage inspection results including finished products results.

6.4 Records of internal rejection and its analysis vis-à-vis action plan.

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

Ref: CG-WI-4.2.1-1 Date / Month of issue: Specification No. C-K407 (Rev. -

Page 47 of 47

Ver 1.0 August, 2020 04)

6.5 Records of final products inspection by external agencies (like RDSO/Railways), Non-

Conformity Reports and case analysis as well as action taken thereof.

6.6 There should exist a system of documentation in respect of rejection at customer end,

warranty replacement and in service performance.

6.7 Records of raw material received and supplies made to Railways against the raw

material. Incoming raw material with TC reference of supplier as well as internal

test/audit checking from outside agency.

6.8 The details regarding Stage inspection and test result.

********************

Signature

Name & Prepared by: Checked By: Approved By:

Designation Sameer Kumar /SSE/Design Praveen Kumar/DD/VDG Shobhit Pratap Singh /JD/VDG

You might also like

- Om Part BDocument328 pagesOm Part BBoeingNo ratings yet

- SI-WI-8.1-3 Ver 2.1 Work Instruction For Vendor ApprovalDocument14 pagesSI-WI-8.1-3 Ver 2.1 Work Instruction For Vendor ApprovalVKGNo ratings yet

- Government of India Ministry of Railways: DraftDocument26 pagesGovernment of India Ministry of Railways: DraftraveenNo ratings yet

- IRS R-19-93 Part II (Rev-5) Final DraftDocument41 pagesIRS R-19-93 Part II (Rev-5) Final Draftkkmehrotra328No ratings yet

- Draft Spec RDSO-CG-18003 For AMDBS 200kmphDocument37 pagesDraft Spec RDSO-CG-18003 For AMDBS 200kmphMS kunalNo ratings yet

- AED HDBK 2010Document132 pagesAED HDBK 2010Suresh RajagopalNo ratings yet

- Indian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoDocument14 pagesIndian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoMohitrajranikashyapNo ratings yet

- STR For FIBADocument26 pagesSTR For FIBAkohli9150% (2)

- C-508 Rev 2 - Draft PDFDocument37 pagesC-508 Rev 2 - Draft PDFPravinNo ratings yet

- Coil Spring For Fiat BogieDocument99 pagesCoil Spring For Fiat BogieBhabasankar SamantaNo ratings yet

- 5-0605A (CMM RG-380E - GH Series)Document36 pages5-0605A (CMM RG-380E - GH Series)AripudinNo ratings yet

- Draft Spec RDSO-2011-CG-04 Rev - 2Document36 pagesDraft Spec RDSO-2011-CG-04 Rev - 2Gopal DixitNo ratings yet

- FS 3210 - FS-Gas Flow ComputerDocument6 pagesFS 3210 - FS-Gas Flow ComputerBinu ManiNo ratings yet

- Indian Railways: Ref: CG-WI-4.2-1-1 Ver.-1.0 Page 1 of 12 Date of Issue: June, 2020Document12 pagesIndian Railways: Ref: CG-WI-4.2-1-1 Ver.-1.0 Page 1 of 12 Date of Issue: June, 2020Kathirasan Ramalingam100% (1)

- NDE Procedures RT, MPI, DPT, HARDNESS, HEAT TREATMENTDocument67 pagesNDE Procedures RT, MPI, DPT, HARDNESS, HEAT TREATMENTmuslim100% (1)

- EASBAS355620036ENR2Document14 pagesEASBAS355620036ENR2Raymond ZamoraNo ratings yet

- RDSO 2008 CG-04 (Rev.-5) - Final Draft - Final PDFDocument31 pagesRDSO 2008 CG-04 (Rev.-5) - Final Draft - Final PDFNeeraj Bansal100% (1)

- C-K607 (Rev.1) - Final PDFDocument11 pagesC-K607 (Rev.1) - Final PDFMadhwesh Katti100% (2)

- GF-OGF4-J-SP-1009 - Specification For Pipe Supports - Rev 0 - AFCDocument20 pagesGF-OGF4-J-SP-1009 - Specification For Pipe Supports - Rev 0 - AFCRami KsidaNo ratings yet

- GRP Procedure PDFDocument42 pagesGRP Procedure PDFJITHIN KRISHNAN MNo ratings yet

- Flight Operations ManualDocument229 pagesFlight Operations ManualSurya Varma100% (1)

- Technicalspecification 2021 06 02 03 - 30 - 01Document76 pagesTechnicalspecification 2021 06 02 03 - 30 - 01muhammadaljabbarsyahNo ratings yet

- Rules: For The Classification and Construction of Sea-Going ShipsDocument282 pagesRules: For The Classification and Construction of Sea-Going Shipsacademo misirNo ratings yet

- Rules For The Classification and Construction of Sea-Going Ships Part VII Machinery Installations 2-020101-124-E-7Document103 pagesRules For The Classification and Construction of Sea-Going Ships Part VII Machinery Installations 2-020101-124-E-7academo misirNo ratings yet

- Avionics Shop Manual: Uncontrolled DocumentDocument53 pagesAvionics Shop Manual: Uncontrolled DocumentWallyNo ratings yet

- (4210-GP-13-01) Prosedur CSMS - Rev JDocument38 pages(4210-GP-13-01) Prosedur CSMS - Rev JSisy100% (1)

- SP 07 Sop Customer PropertyDocument13 pagesSP 07 Sop Customer PropertyLoemban S Jody100% (1)

- C-K406 Rev3 DraftDocument34 pagesC-K406 Rev3 Draftpunyavathi kNo ratings yet

- RDSO 2008 CG-04 (Rev.-3) Final DraftDocument26 pagesRDSO 2008 CG-04 (Rev.-3) Final DraftRojalin KhatuaNo ratings yet

- Rg-380E/44 H Series Main Aircraft Battery Component Maintenance ManualDocument36 pagesRg-380E/44 H Series Main Aircraft Battery Component Maintenance Manualekonugroho1293No ratings yet

- GF-OGF4-J-SP-1008 - Material Specification For Piping and Valves - Rev 1 - CODE AFCDocument159 pagesGF-OGF4-J-SP-1008 - Material Specification For Piping and Valves - Rev 1 - CODE AFCRami Ksida100% (1)

- Piping Design CriteriaDocument15 pagesPiping Design CriteriaSubash Chandrabose50% (2)

- GF-OGF4-J-SP-1007 - Specification For Piping & Pipeline Flexibility Analysis - Rev 0 - AFCDocument26 pagesGF-OGF4-J-SP-1007 - Specification For Piping & Pipeline Flexibility Analysis - Rev 0 - AFCRami KsidaNo ratings yet

- Flooring Spec No RDSO-2017-CG-05 For Rubberized FlooringDocument15 pagesFlooring Spec No RDSO-2017-CG-05 For Rubberized FlooringIshanNo ratings yet

- Process Design Basis Rev ADocument49 pagesProcess Design Basis Rev Agharsallah mounaNo ratings yet

- Brake Disc Stdz. Draft Spec UploadingDocument14 pagesBrake Disc Stdz. Draft Spec UploadingAditya PratapNo ratings yet

- Parts and Chapters: 28 February 2002 17 April 2014 17 April 2014Document7 pagesParts and Chapters: 28 February 2002 17 April 2014 17 April 2014Shariful Mamun RanimNo ratings yet

- Standard Support GS RFCC Cilacap 2013Document269 pagesStandard Support GS RFCC Cilacap 2013Arief KarebetNo ratings yet

- Metro ManualDocument52 pagesMetro ManualManicaNo ratings yet

- Piping Fabrication and ErectionDocument24 pagesPiping Fabrication and ErectionbaurzhannNo ratings yet

- Draft C-8527 Rev.1 Amend2Document23 pagesDraft C-8527 Rev.1 Amend2Shivendra KumarNo ratings yet

- STR-ISEJ - Final - 19 - 09 - 2022Document10 pagesSTR-ISEJ - Final - 19 - 09 - 2022Preeti goswamiNo ratings yet

- GF-WPK-J-CA-2001 - WP-K Calculation Note For Piping Stress Analysis - Rev 1 - RDocument32 pagesGF-WPK-J-CA-2001 - WP-K Calculation Note For Piping Stress Analysis - Rev 1 - RRami KsidaNo ratings yet

- SmokeDocument27 pagesSmokeJeetendra Singh ChauhanNo ratings yet

- GF-OGF4-P-SP-1007 Page 1 of 24: Pchibv CommentDocument24 pagesGF-OGF4-P-SP-1007 Page 1 of 24: Pchibv CommentBilel MahjoubNo ratings yet

- 01 Samss 016 - 00001Document14 pages01 Samss 016 - 00001Thansil ThangalNo ratings yet

- SDocument23 pagesSCleber Albertino De Souza SouzaNo ratings yet

- CK-407Rev 3Document34 pagesCK-407Rev 3Ahmad Khubaib AdnanNo ratings yet

- Satip F 001 01Document3 pagesSatip F 001 01ahmadNo ratings yet

- Document Wta 501 2 PDFDocument37 pagesDocument Wta 501 2 PDFTibin ThomasNo ratings yet

- FOI ManualDocument201 pagesFOI Manualconfirm@No ratings yet

- Revision-A1: Oman Tank Terminal Company (Ottco)Document5 pagesRevision-A1: Oman Tank Terminal Company (Ottco)ANIL PLAMOOTTILNo ratings yet

- Saudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalDocument3 pagesSaudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalOmer aliNo ratings yet

- DHC3 Flight ManualDocument140 pagesDHC3 Flight ManualGreg HowardNo ratings yet

- Technical Specification 1601291135Document84 pagesTechnical Specification 1601291135Prashanth ChinthallapallyNo ratings yet

- ADCO Caravan SpecificationDocument19 pagesADCO Caravan Specificationvenkatesh waranNo ratings yet

- Section 1 - General: CAR Series Issue No. and Date Subject Most Recent Amendment No. Date of AmendmentDocument26 pagesSection 1 - General: CAR Series Issue No. and Date Subject Most Recent Amendment No. Date of AmendmentShashi SahNo ratings yet

- Satip F 001 01Document3 pagesSatip F 001 01Ansar Ali VemmullyNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Rdso Summer Training ProgramDocument4 pagesRdso Summer Training ProgramvlucknowNo ratings yet

- A Training Report ON Brake System in Diesel Locomotives RDSO Lucknow in Partial Fulfillment of Bachelor of Technology in Mechanical Engineering (2019-20)Document27 pagesA Training Report ON Brake System in Diesel Locomotives RDSO Lucknow in Partial Fulfillment of Bachelor of Technology in Mechanical Engineering (2019-20)Køñåřk ĞűpțäNo ratings yet

- RDSO 2008 CG 06 Rev-1Document15 pagesRDSO 2008 CG 06 Rev-1Shiv PandeyNo ratings yet

- Government of IndiaDocument4 pagesGovernment of Indiavishnu kumar VyasNo ratings yet

- Organization and Objectives of Mechanical Department - 0Document10 pagesOrganization and Objectives of Mechanical Department - 0Jaikanthan DasarathaNo ratings yet

- FINAL Handout - 48 CBRR PDFDocument115 pagesFINAL Handout - 48 CBRR PDFsksingh03No ratings yet

- NCR 2x25Document4 pagesNCR 2x25Pankaj MauryaNo ratings yet

- 62nd Esc Meeting Final PresentationDocument81 pages62nd Esc Meeting Final Presentationjaykachave.scoe.mechNo ratings yet

- Rdso Specification OF Permanently Lubricated Hdpe DuctDocument20 pagesRdso Specification OF Permanently Lubricated Hdpe Ductrichard issaNo ratings yet

- Revised Draft SCH of 1400HP DEMU - MP-MISC-157 - Rev-05 - July-2021 - DT 14-7-2021Document58 pagesRevised Draft SCH of 1400HP DEMU - MP-MISC-157 - Rev-05 - July-2021 - DT 14-7-2021Pradnyesh PrabhuNo ratings yet

- Ms 369Document2 pagesMs 369Ritesh SrivastavaNo ratings yet

- 04 - Part A - TrackDocument112 pages04 - Part A - TrackSurya LalithaNo ratings yet

- Spec 133 WAG7 RGB 09012018Document42 pagesSpec 133 WAG7 RGB 09012018essen999No ratings yet

- POH Programme 2024-25 TargetsDocument26 pagesPOH Programme 2024-25 TargetsJeetendra Singh ChauhanNo ratings yet

- Preamble For SBOQDocument5 pagesPreamble For SBOQsanthosh kumar t mNo ratings yet

- Rdso, TPPDocument17 pagesRdso, TPPAl OkNo ratings yet

- Guide Book For Training of IRSE ProbationersDocument30 pagesGuide Book For Training of IRSE ProbationersSuyenthan SathishNo ratings yet

- Uclt Siding & PolDocument36 pagesUclt Siding & PolSSE TRD JabalpurNo ratings yet

- Mod in RDSO Drgs Incorporate in The Tender Documents Letter To ADocument21 pagesMod in RDSO Drgs Incorporate in The Tender Documents Letter To Adipak100% (1)

- 7 2021-02-17 Letter To RDSO For Air Spring and FIBA Modifications SignedDocument10 pages7 2021-02-17 Letter To RDSO For Air Spring and FIBA Modifications Signedsibaranjandash2007No ratings yet