Professional Documents

Culture Documents

Gascalc 5.0: Calculation Reference

Gascalc 5.0: Calculation Reference

Uploaded by

Masood Alam FarooquiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gascalc 5.0: Calculation Reference

Gascalc 5.0: Calculation Reference

Uploaded by

Masood Alam FarooquiCopyright:

Available Formats

GASCalc™ 5.

0 Calculation Reference

Pipe Hydraulic Diameter

Home

Background Information

Equations

Example Calculation

General Calculation Procedures

Notes & Considerations

Screen Description

See Also

General Calculation Procedures

To calculate the various values associated with the pipe hydraulic diameter calculation, complete the following steps:

! Select the Hydraulic Diameter menu item from the Pipe menu list. The Pipe Hydraulic Diameter

calculation screen will be displayed.

! Select the Clear command button to set all of the values to an empty (null) value.

! Select an appropriate method from the Calculation Method data list.

! Click on the red label associated with the item to be calculated (the unknown) until the label is underlined.

! Select the desired dimensional units for all of the data items.

! Enter a value for all known data items.

! Select the Calculate command button.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 1 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Example Calculation

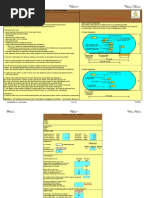

Calculate the inside diameter value associated with an average outside diameter value of 6.625 Inches [170

Millimeter], for a polyethylene pipe with a dimension ratio of 11.5 using the Plastic Pipe Institute DR based method.

To perform the calculation, complete the following steps.

! Select the Hydraulic Diameter menu item from the Pipe menu list. The Pipe Hydraulic Diameter

calculation screen will be displayed.

! Select the Clear command button.

! From the Calculation Method list, select PPI Outside Diameter Controlled Pipe Using DR.

! In the Pipe Data section:

! Click on the Inside Diameter label until it is underlined.

! For the Average Outside Diameter, enter 6.625 Inches [170 Millimeter].

! For the Dimension Ratio, enter 11.5.

! Select the Calculate command button.

Results - The results should be similar to the following:

Inside Diameter: 5.404 Inches [138.661 Millimeter]

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 2 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Screen Description

The various values associated with the hydraulic or inside diameter of a pipe segment may be calculated using the

Pipe Hydraulic Diameter calculation routine. To perform a calculation, select the Hydraulic Diameter menu item

from the Pipe menu list. The Pipe Hydraulic Diameter calculation screen will be displayed. The features associated

with the screen are described as follows.

Data Items

Average Outside Diameter - A data list used to enter, select, or display the average outside diameter of the pipe

segment. If the value is known, either select an item from the list, enter a value by typing it into the data field., or

select the ? command button to select a size using the Pipe Selection screen. Ensure the value is expressed in terms

of the selected dimensional unit. This item is only displayed for certain calculation methods.

Calculation Method - A drop-down list used to select which method is to be used to perform the calculation. Select

an item from the list. The unknown value should be recalculated if the method is changed.

Dimension Ratio - A data field used to enter or display the dimension ratio (DR) commonly used to designate the

wall thickness for plastic material pipe segments. If the value is known, enter a value by typing it into the data field.

This value is dimensionless. This item is only displayed for certain calculation methods.

Inside Diameter - A data field used to enter or display the inside (hydraulic) diameter of the pipe segment. If the

value is known, enter a value by typing it into the data field. Ensure the value is expressed in terms of the assigned

dimensional unit.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 3 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Maximum Wall Thickness - A data field used to enter or display the maximum wall thickness of the pipe. If the

value is known, enter a value by typing it into the data field. Ensure the value is expressed in terms of the assigned

dimensional unit. If the outside diameter is set by selecting a size from the diameter list, the Wall Thickness value

will automatically be set to the wall thickness value listed in the Pipe Property Table. The outside diameter value

must be manually entered (not selected) if the wall thickness is manually entered. This item is only displayed for

certain calculation methods.

Minimum Outside Diameter - A data list used to enter, select, or display the minimum outside diameter of the pipe

segment. If the value is known, either select an item from the list, enter a value by typing it into the data field, or

select the ? command button to select a size using the Pipe Selection screen. Ensure the value is expressed in terms

of the selected dimensional unit. This item is only displayed for certain calculation methods.

Minimum Wall Thickness - A data field used to enter or display the minimum wall thickness of the pipe. If the

value is known, enter a value by typing it into the data field. Ensure the value is expressed in terms of the assigned

dimensional unit. If the outside diameter is set by selecting a size from the diameter list, the Wall Thickness value

will automatically be set to the wall thickness value listed in the Pipe Property Table. The outside diameter value

must be manually entered (not selected) if the wall thickness is manually entered. This item is only displayed for

certain calculation methods.

Outside Diameter - A data list used to enter, select, or display the outside diameter of the pipe segment. If the value

is known, either select an item from the list, enter a value by typing it into the data field, or select the ? command

button to select a size using the Pipe Selection screen. Ensure the value is expressed in terms of the selected

dimensional unit. This item is only displayed for certain calculation methods.

Wall Thickness - A data field used to enter or display the wall thickness of the pipe. If the value is known, enter a

value by typing it into the data field. Ensure the value is expressed in terms of the assigned dimensional unit. If the

outside diameter is set by selecting a size from the Outside Diameter list, the Wall Thickness value will automatically

be set to the wall thickness value listed in the Pipe Property Table. The outside diameter value must be manually

entered (not selected) if the wall thickness is manually entered. This item is only displayed for certain calculation

methods.

Command Buttons

? - A command button used to display a data selection screen for the associated item. Use the various data lists on

the screen to select a value, then select the Apply command button to assign the selected value and return to the

calculation screen.

i - A command button used to display information about the associated item. The contents of the information screen

generally reflects the various data values contained in the associated Property Table. Select the Close command

button to return to the calculation screen.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 4 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Calculate - A command button used to calculate the value of the unknown (underlined) parameter.

Cancel - A command button used to close the screen without saving any changes.

Clear - A command button used to set all of the data items to blank (null) values.

Close - A command button used to close the screen and save the current data values.

Help - A command button used to display this Calculation Reference.

Notes - A command button used to display the Calculation Notes editor screen for the current calculation.

Open - A command button used to open a previously saved calculation file. When selected, the File Selection screen

will be displayed. Enter or select the desired File name, then select the Open command button.

Print - A command button used to print the contents of the calculation screen. When selected, the Print Settings

screen will be displayed. Make any desired changes to the printer settings, then select the Print command button.

Save - A command button used to save the contents of the calculation screen to a calculation file. When selected,

the File Selection screen will be displayed. Enter or select the desired File name, then select the Save command

button.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 5 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Notes & Considerations

! The Calculation Notes editor screen allows the User to add a specific title and/or notes to the current calculation

values.

! The red colored labels indicate which items may be calculated. An underlined label identifies it as the item for

which the value is unknown. Only one item at a time may be selected to be calculated, the remaining items must be

known. To identify which item to calculate, click on the label associated with the desired item until the label is

underlined.

! When the pipe outside diameter value is set by selecting a size/type code from the diameter list, the outside

diameter and wall thickness values are read from the Pipe Property Table. These values may or may not be

appropriate for the selected calculation method. The appropriate values may need to be manually entered, as required

by the calculation method.

! The values calculated by this method are only valid for circular pipe.

! To specify the number of digits to display to the right of the decimal indicator, double-click in the associated data

field. The Decimal Specifications screen will be displayed. Enter or select the desired number of digits, then select

the Apply command button to save and apply any changes.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 6 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Background Information

In liquid flow, the pipe may or may not be full during flow conditions. The liquid may only partially fill the pipe. One

property of a gas is that it completely fills the space that it is contained in. In gas flow, because of this property, the

pipe is always “full”. The hydraulic diameter will always be equal to the inside diameter of the pipe.

The basic approach to calculating the inside diameter of a pipe segment is fairly straight forward - the wall thickness

is subtracted twice from the outside diameter. Even so, there are several methods that are used in the industry to

determine the hydraulic or inside diameter of a pipe segment. Each method more or less uses the basic relationship

between the outside diameter, wall thickness, and inside diameter. However each has a unique approach to

determining the appropriate outside diameter and wall thickness value to be used in the calculation.

The customary method of calculating the inside diameter uses the nominal (normal) outside diameter and wall

thickness values to calculate the inside diameter. For steel pipe, these are the normal or standard values that appear

in most industry or manufacturer pipe dimension tables. For example, for an 8 Inch steel pipe with a wall thickness

of 0.156 Inches. The inside diameter would be calculated using 8.625 Inches for the outside diameter and 0.156

Inches for the wall thickness. For plastic pipe, the outside diameter would represent the normal or standard values

that appear in most industry or manufacturer pipe dimension tables, and the wall thickness would likely represent

the average values that appear in most industry or manufacturer pipe dimension tables.

The conservative method of calculating the inside diameter uses an outside diameter value which represents the

minimum outside diameter, and a wall thickness value which represents the maximum wall thickness listed in the

industry or manufacturer pipe dimension tables. Using these values will result in the smallest (most conservative)

inside diameter value that could be possible for the pipe segment. The minimum outside diameter and maximum wall

thickness values are determined by subtracting or adding the appropriate manufacturing tolerance to the nominal or

normal respective values. For example, if the normal outside diameter is reported to be 3.500 Inches with a

manufacturing tolerance of +0.008 and -0.008 Inches, the minimum outside diameter would be 3.492 Inches. If the

normal wall thickness value is reported to be 0.307 Inches with a manufacturing tolerance of +0.035 and -0.000

Inches, the maximum wall thickness would be 0.377 Inches.

The Plastic Pipe Institute (PPI) methods use equations and values defined in that reference. In general each uses

outside diameter, dimensional ratios, and wall thickness values reported in industry or manufacturer’s pipe dimension

tables.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 7 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Equations

GASCalc provides several methods to calculate the Hydraulic (inside) diameter of a pipe segment. The equations

associated with each method are described on the following pages.

Outside Diameter & Wall Thickness - Customary

As implemented by GASCalc, the “customary” inside diameter value is computed using the following equation.

Reference 2

Outside Diameter & Wall Thickness - Conservative

As implemented by GASCalc, the “conservative” inside diameter value is computed using the following equation.

Reference 2

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 8 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

Plastic Pipe Institute - Wall Thickness

As implemented by GASCalc, the “average” inside diameter value using the PPI wall thickness based method is

computed using the following equation.

Reference 1

Plastic Pipe Institute - Dimension Ratio

As implemented by GASCalc, the “average” inside diameter value using the PPI DR based method is computed using

the following equation.

Reference 1

References

1. Plastic Pipe Institute, Handbook Of Polyethylene Pipe, Second Edition, 2008.

2. None - Derived.

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 9 of 10

GASCalc™ 5.0 Calculation Reference

Pipe Hydraulic Diameter

Home

See Also

Hoop Stress Calculation Reference

Thermal Expansion Calculation Reference

Bradley B Bean PE ENGINEERING & SOFTWARE

Revision - 005, Copyright 2015, All Rights Reserved.

Page 10 of 10

You might also like

- SPPID - 01 (Tutorial) PDFDocument11 pagesSPPID - 01 (Tutorial) PDFchristinaNo ratings yet

- Measuring Internal Combustion Engine In-Cylinder Pressure With LabviewDocument2 pagesMeasuring Internal Combustion Engine In-Cylinder Pressure With LabviewJose Luis RattiaNo ratings yet

- Instrucalc IIDocument27 pagesInstrucalc IINorberto Soto100% (1)

- Pipesim DesignDocument57 pagesPipesim DesignPutri Diofita WNo ratings yet

- Practical Gas Lift ManualDocument26 pagesPractical Gas Lift ManualJorge Alberto Quiza Polania83% (6)

- API 12j SizingDocument8 pagesAPI 12j SizingsegunoyesNo ratings yet

- Key Performance Indicators For Gas Distribution Network SystemDocument2 pagesKey Performance Indicators For Gas Distribution Network SystemMasood Alam Farooqui100% (1)

- Ufg Study of BangladeshDocument12 pagesUfg Study of BangladeshMasood Alam FarooquiNo ratings yet

- BTM 940Document28 pagesBTM 940arlgmuserNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument12 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument12 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceApril TrevinoNo ratings yet

- CalcpdesignDocument13 pagesCalcpdesignAldo Hernan CortesNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument11 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument15 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument11 pagesGascalc 5.0: Calculation ReferenceApril TrevinoNo ratings yet

- Calc MAOPDocument11 pagesCalc MAOPMasood Alam Farooqui100% (2)

- Calc Hoop StressDocument11 pagesCalc Hoop StressApril Trevino100% (1)

- Gascalc 5.0: Calculation ReferenceDocument46 pagesGascalc 5.0: Calculation ReferenceCésar Sandoval100% (1)

- Gascalc 5.0: Calculation ReferenceDocument21 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- CalcmonitorDocument43 pagesCalcmonitorMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument44 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Calc Pipe FlowDocument46 pagesCalc Pipe FlowAldo Hernan CortesNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument17 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- CalcpipeflowDocument53 pagesCalcpipeflowAldo Hernan Cortes100% (1)

- Gascalc 5.0: Calculation ReferenceDocument15 pagesGascalc 5.0: Calculation ReferenceApril TrevinoNo ratings yet

- Match DevDocument9 pagesMatch DevMasood Alam FarooquiNo ratings yet

- Calc Blow DownDocument14 pagesCalc Blow DownMasood Alam Farooqui100% (1)

- What's New in PVElite 2016Document18 pagesWhat's New in PVElite 2016msmrizhwanNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument11 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Instrucal IIIDocument46 pagesInstrucal IIINorberto Soto100% (1)

- Calc QCompareDocument11 pagesCalc QCompareMasood Alam FarooquiNo ratings yet

- Wellplan Opticem ManualDocument21 pagesWellplan Opticem ManualtibismtxNo ratings yet

- CalcvalveDocument16 pagesCalcvalveAldo Hernan CortesNo ratings yet

- Instrucalc ManualDocument18 pagesInstrucalc ManualRangga Taufiqurahman100% (1)

- Instrucalc IDocument18 pagesInstrucalc INorberto Soto100% (1)

- Gascalc 5.0: ReferenceDocument8 pagesGascalc 5.0: Referencekarioke mohaNo ratings yet

- Calc VolumeDocument11 pagesCalc VolumeAldo Hernan CortesNo ratings yet

- PressureDocument5 pagesPressureSMBEAUTYNo ratings yet

- CalcreynoldsDocument13 pagesCalcreynoldsAldo Hernan CortesNo ratings yet

- Calc VelocityDocument14 pagesCalc VelocityAldo Hernan CortesNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- Instrucalc ViDocument25 pagesInstrucalc ViNorberto Soto100% (1)

- PipephaseDocument32 pagesPipephaseZadeh NormanNo ratings yet

- Appendix B Test Control Using Labview: Panel PalettesDocument8 pagesAppendix B Test Control Using Labview: Panel PalettesamokhtaNo ratings yet

- Geothermal System Cost EstimatorDocument44 pagesGeothermal System Cost EstimatorblizanacNo ratings yet

- Self Guided Demo - Aspen Shell and Tube Exchanger V8.8Document45 pagesSelf Guided Demo - Aspen Shell and Tube Exchanger V8.8HarySetiyawanNo ratings yet

- Result ANADocument15 pagesResult ANAVinod Mehara MNo ratings yet

- Elite Software - HeaventDocument5 pagesElite Software - Heaventsyedkaleem55No ratings yet

- Elite Software - HeaventDocument5 pagesElite Software - Heaventsyedkaleem55No ratings yet

- Elite Software - HeaventDocument5 pagesElite Software - Heaventsyedkaleem55No ratings yet

- Elite Software - HeaventDocument5 pagesElite Software - Heaventsyedkaleem55No ratings yet

- Elite Software - HeaventDocument5 pagesElite Software - Heaventsyedkaleem55No ratings yet

- Elite Software - HeaventDocument5 pagesElite Software - Heaventsyedkaleem55No ratings yet

- DX8 01 GetStartedDocument32 pagesDX8 01 GetStartedPradeep Kumar Reddy BNo ratings yet

- TD 167Document33 pagesTD 167Przemysław PastuchaNo ratings yet

- 24508-51 - V-Cone Sizing User Guide - 1.4Document8 pages24508-51 - V-Cone Sizing User Guide - 1.4binhogatoNo ratings yet

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingFrom EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingNo ratings yet

- SetpathDocument6 pagesSetpathMasood Alam FarooquiNo ratings yet

- Match DevDocument9 pagesMatch DevMasood Alam FarooquiNo ratings yet

- Calc Blow DownDocument14 pagesCalc Blow DownMasood Alam Farooqui100% (1)

- CalcmonitorDocument43 pagesCalcmonitorMasood Alam FarooquiNo ratings yet

- Calcregrlf 2 CutDocument50 pagesCalcregrlf 2 CutMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument17 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- Calc QCompareDocument11 pagesCalc QCompareMasood Alam FarooquiNo ratings yet

- Calc MAOPDocument11 pagesCalc MAOPMasood Alam Farooqui100% (2)

- Calc ThermDocument11 pagesCalc ThermMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- Close Interval SurveyDocument2 pagesClose Interval SurveyMasood Alam FarooquiNo ratings yet

- Sindh SWMS NIT-4RFPContractorofDMCMalir PDFDocument121 pagesSindh SWMS NIT-4RFPContractorofDMCMalir PDFMasood Alam FarooquiNo ratings yet

- On Key Performance IndicatorsDocument23 pagesOn Key Performance IndicatorsMasood Alam FarooquiNo ratings yet

- Learn ArabicDocument50 pagesLearn ArabicMasood Alam FarooquiNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument10 pagesGascalc 5.0: Calculation ReferenceMasood Alam FarooquiNo ratings yet

- 49 CFR Ch. I (10-1-04 Edition) 192.10: 192.10 Outer Continental Shelf Pipe-LinesDocument1 page49 CFR Ch. I (10-1-04 Edition) 192.10: 192.10 Outer Continental Shelf Pipe-LinesMasood Alam FarooquiNo ratings yet

- Purchase Kesc Pak Steel FJ FC CNG Power Large I Ndustri Es Sal e Remai Ni NG Purchase For Sal eDocument1 pagePurchase Kesc Pak Steel FJ FC CNG Power Large I Ndustri Es Sal e Remai Ni NG Purchase For Sal eMasood Alam FarooquiNo ratings yet

- How Dangerous AreDocument5 pagesHow Dangerous AreMasood Alam FarooquiNo ratings yet

- A Mad ManDocument7 pagesA Mad ManMasood Alam FarooquiNo ratings yet

- Federal Board (FBISE) Affiliated Institutions at SSC and HSSC Level AbroadDocument3 pagesFederal Board (FBISE) Affiliated Institutions at SSC and HSSC Level AbroadMasood Alam FarooquiNo ratings yet

- Specification For Seamless Red Brass Pipe, Standard SizesDocument8 pagesSpecification For Seamless Red Brass Pipe, Standard SizesVCNo ratings yet

- Stainless Steel Cold Rolled en StandardsDocument4 pagesStainless Steel Cold Rolled en StandardsMichael DavidNo ratings yet

- 0 G-Dok EN LOWDocument124 pages0 G-Dok EN LOWlinuskotteNo ratings yet

- Guide To Standards and Tolerances 2015 PDFDocument70 pagesGuide To Standards and Tolerances 2015 PDFSathishNo ratings yet

- M&I 04-Dimensional Chains Stack Up2017 V02uncovDocument20 pagesM&I 04-Dimensional Chains Stack Up2017 V02uncovMritunjay SharmaNo ratings yet

- Seam DesignDocument29 pagesSeam Designcsc001No ratings yet

- Fitter Iii Semester Question - New 1-4 PDFDocument11 pagesFitter Iii Semester Question - New 1-4 PDFGangadharam MademNo ratings yet

- 1HD-T 2Document37 pages1HD-T 2HERMAWAN100% (2)

- BS en 438-9-2010Document18 pagesBS en 438-9-2010Abey VettoorNo ratings yet

- Practice Problems 2021 ModifiedDocument9 pagesPractice Problems 2021 ModifiedmbamjoshiNo ratings yet

- BS3134-2 (Roller BRG)Document12 pagesBS3134-2 (Roller BRG)Ravindra PawarNo ratings yet

- Hall Sensors: Ordering Codes, Packaging, Handling: Edition Sept. 12, 2001 6200-249-2EDocument24 pagesHall Sensors: Ordering Codes, Packaging, Handling: Edition Sept. 12, 2001 6200-249-2EbabazadeNo ratings yet

- Gis-F6 2021Document16 pagesGis-F6 2021Ashraf Ismail HassenNo ratings yet

- BS8110Document14 pagesBS8110thusharajcl50% (2)

- Is 3739 1987Document13 pagesIs 3739 1987Kiran KumarNo ratings yet

- Hidraulicki CilindriDocument64 pagesHidraulicki CilindriKovačević DarkoNo ratings yet

- 07 - Bearings and BushingsDocument87 pages07 - Bearings and BushingsMr ShrekNo ratings yet

- TUBACEX Power Generation 10Document12 pagesTUBACEX Power Generation 10walitedisonNo ratings yet

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument21 pagesCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroNo ratings yet

- Leitz PMM-C Line: Version 2015-5Document12 pagesLeitz PMM-C Line: Version 2015-5kimikononNo ratings yet

- 3-Limits Fits and TolerancesDocument22 pages3-Limits Fits and TolerancesAbhay Sharma100% (1)

- Preferred Fits and Tolerances (Metric) - AmesDocument2 pagesPreferred Fits and Tolerances (Metric) - AmesvikasgahlyanNo ratings yet

- Welded Precision Steel Tubes Technical Information RoundDocument1 pageWelded Precision Steel Tubes Technical Information RoundsalimmalmaliNo ratings yet

- Rao 1982Document9 pagesRao 1982mechdualNo ratings yet

- Astm D3308 PtefDocument4 pagesAstm D3308 PtefIsabella RomeroNo ratings yet

- What Is MSA?Document4 pagesWhat Is MSA?Adrian FinichiuNo ratings yet

- Gauges and Gauge DesignDocument12 pagesGauges and Gauge DesignAmir JodeyriNo ratings yet

- Honeywell Sensing Potentiometers 380 Rv4 485 53c 385 Datasheet 32301266 A enDocument47 pagesHoneywell Sensing Potentiometers 380 Rv4 485 53c 385 Datasheet 32301266 A enJose CaballeroNo ratings yet