Professional Documents

Culture Documents

WhitePaper PBC Lead Screw Efficiency

WhitePaper PBC Lead Screw Efficiency

Uploaded by

Bruno HulsmannOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WhitePaper PBC Lead Screw Efficiency

WhitePaper PBC Lead Screw Efficiency

Uploaded by

Bruno HulsmannCopyright:

Available Formats

WHITE PAPER

Lead Screw Efficiency

Improving the conversion of rotary energy into linear motion

The efficiency of a lead screw refers to how well a screw converts

rotary energy (torque) into linear motion. Lead screw efficiency is a pure

calculated value, and empirical testing is the best method to determine

performance.

tan (helix angle)

Efficiency % = * 100

tan (helix angle + arctan f)

where f is the coefficient of friction

The efficiency of a lead screw is primarily influenced by these factors:

• Lead Distance – i.e. 1mm ~ 25mm (available leads).

• The efficiency is highly dependent upon the lead angle of the screw

thread

• Lead Angle – The angle between the helix of the thread and a line

parallel to the axis of rotation of the screw.

WHITE PAPER: Lead Screw Efficiency PAGE 1

• Friction – Created by the contact area between the screw and the nut.

• Torque – Translating rotary to linear motion.

• Driving the screw to translate the nut.

• Driving the nut to translate the screw.

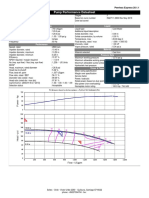

PBC Linear Lead screw Efficiencies

Efficiency Percentages - Metric Screw Diameter Efficiency Percentages - Metric Screw Diameter

Metric Metric

Coating Coating

Leads 6mm 10mm 12mm 16mm Leads 6mm 10mm 12mm 16mm

Coated 39 28 24 19 Coated 81 74 71 65

1 mm 8 mm

Uncoated 30 21 18 14 Uncoated 75 66 62 56

Coated 60 45 40 33 Coated 84 78 75 69

2 mm 10 mm

Uncoated 51 36 31 25 Uncoated 78 71 67 61

Coated 71 61 56 49 Coated 84 80 77 72

4 mm 12 mm

Uncoated 62 52 47 40 Uncoated 81 74 70 64

Coated 76 66 62 55 Coated – 84 81 77

5 mm 16 mm

Uncoated 68 57 53 45 Uncoated – 78 75 70

Coated 77 69 65 58 Coated – 86 85 83

6 mm 25 mm

Uncoated 70 61 56 49 Uncoated – 83 81 77

Inch Efficiency Percentages - IPS Screw Diameter

Coating

Leads

What is Back Driving? 3/16″ 1/4″ 3/8″ 7/16″ 1/2″

Back drive is the result of the load (thrust force) pushing Coated 51 – – – –

axially on the nut to create rotary motion. The resulting 0.05”

Uncoated 41 – – – –

torque is known as “back-driving torque” and is the torque

required to hold a load in position. In a vertical orientation, Coated – – – – 44

back drive can occur by the load (or carriage) alone, 0.10”

Uncoated – – – – 35

causing the carriage to drift down. Vibration and other

external factors can also cause this movement. Generally, Coated – – 66 – –

a lead screw with efficiency greater than 50% will have a 0.20”

Uncoated – – 57 – –

tendency to back drive.

Coated – – – – 65

This can be a disadvantage in applications and may

0.250”

require a form of brake be utilized to support the load Uncoated – – – 56

typically in a vertical orientation. In some cases, back

Coated – 82 – – –

drivability may be desired to allow an object to be moved

0.333”

if needed. Uncoated – 76 – – –

Below is the formula to calculate back drive torque, where: 88 – – – –

Coated

Tb = back drive torque (inch pounds) 0.50”

Uncoated 84 – – – –

Pt = thrust load applied to nut (lbs)

Coated – – – 87 –

SL = lead of screw (inches) 1.00”

Uncoated – – – 82 –

Eƒƒ = all screw efficiency (≈90%)

WHITE PAPER: Lead Screw Efficiency PAGE 2

SL * Pt * Fff

Tb = = 0.143 * L * Pt

2π

Rule of Thumb

Lead Screws typically provide efficiency between 20% - 80%

• Lead Screws that have an efficiency of 50% or greater will back drive.

• When the screw lead is less than 1/3 of the lead screw diameter back

driving will not occur.

Example

• 10mm diameter screw with 2mm lead = 41% Efficiency (<50% will not

back drive)

• 10mm diameter screw with 25mm lead = 83% Efficiency (>50% will

back drive)

Ball screws: Typical Efficiency = 90%

• With a 90% efficiency will back drive.

• This creates the need to provide a form of braking to prevent back Conventional

driving.

lubricants are

How to improve Lead Screw Efficiency?

• Efficiency increases as the screw lead increases.

typically not

• Lead Screw efficiency can be improved by increasing the helix angle of recommended as

a form of lubricant

the thread.

Example

• 10mm diameter screw with 2mm lead = 41% Efficiency. with PTFE lead

• 10mm diameter screw with 25mm lead = 83% Efficiency.

screws and nuts

Lubrication

from PBC Linear.

Conventional lubricants are typically not recommended as a form

of lubricant with PTFE lead screws and nuts from PBC Linear. Using

conventional lubrication can reduce screw coating and nut life. This

is because our proprietary manufacturing process delivers a superior

running surface, which improves performance with reduced pitting and

noise, and extends the life of the nut.

Our lead screws are made from 300 series stainless steel, and the nuts

from polymer. Together, these materials offer outstanding wear and

corrosion resistance. Our lead screws can run maintenance-free because

the polymer nuts are infused with PTFE, offering a continuous form of

lubrication. In addition, our lead screws are available with a PTFE coating,

providing self-lubrication which results in:

• Extended life of both lead screw and nut when compared to un-coated

screws.

• Dry lubrication that will not attract dust & debris.

• A reduction in preventative maintenance vs. non-coated or ball screws.

WHITE PAPER: Lead Screw Efficiency PAGE 3

What happens when a lead screw and nut start making noise? Often, the

first reaction is to apply lubrication to reduce friction and noise, regardless Further Information

of the root cause. Lubrication should be the user’s last resort, with the For questions, contact a PBC Linear

evaluation of motor tuning or alignment of the system being the critical Application Engineer to discuss your

first-steps. In other words, lubrication may be only a “band aid” solution. application. You can contact an engineer

PBC Linear does NOT recommend use of dry film lubricant because: directly by calling 1.800.962.8979 (from

within the USA) or +1.815.389.5600 (from

• The ingredients of the dry film lubricant will degrade the coating on the

outside the USA). If you prefer, e-mail an

screw.

engineer at: appeng@pbclinear.com

• This is a short-term fix with damaging results.

Our lead screws and nuts are intended to be self-lubricating. Coated Version

screws should only be lubricated as a last resort using a recommended This is version 1 of the published white

PTFE-type lubricant such as Uniflor 8981. This lubricant is white in color, paper. © 2021 PBC Linear®, A Division of

and since a very thin film is needed, the screw will have a semi-gloss Pacific Bearing® Company

black appearance when applied. If there is visible white on the screw, too

much lubricant has been applied, allowing dust and debris to stick to the

screw and nut. The customer will need to determine the frequency of

reapplication, based on their preventative maintenance policy.

For more information please download the Lead Screw Technology

catalog, or configure online with the PBC Linear Configurator.

WORLDWIDE HE ADQUARTERS

PBC Linear, A Pacific Bearing Co.

6402 E. Rockton Road, Roscoe, IL 61073 USA

Toll-Free: +1.800.962.8979 sales@pbclinear.com

Office: +1.815.389.5600 www.pbclinear.com

Fax: +1.815.389.5790

EUROPE AN HE ADQUARTERS

PBC Lineartechnik GmbH, A Pacific Bearing Co.

Niermannsweg 11-15, D-40699 Erkrath, Germany

Office: +49.211.416073.10 info@pbclinear.eu

Fax: +49.211.416073.11 www.pbclinear.eu

CHINA HEADQUARTERS

PBC–Moons

168 Mingjia Road, Minhang District, Shanghai 201107

P.R. China

Tel: +86 21 52634688 info@moons.com.cn

Fax: +86 21 52634098 www.moons.com.cn

PBC Linear has a global network of distributors with thousands of locations worldwide.

Visit pbclinear.com to find a distributor near you.

LITTWPBLOG-LSE 0521

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Manual Sbs250 enDocument568 pagesManual Sbs250 enShrey PadiaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Smart Grid Manual Exp.1Document6 pagesSmart Grid Manual Exp.1DineshKanawat100% (1)

- Calculo de Consumos Electricos de Equipos en AmbulanciasDocument4 pagesCalculo de Consumos Electricos de Equipos en AmbulanciasCarlos CastilloNo ratings yet

- Samyung SafetyEquipment SAR9 ServiceManualDocument19 pagesSamyung SafetyEquipment SAR9 ServiceManualGấu BéoNo ratings yet

- Arco Cirúrgico Ge Everview 7500 - MsDocument307 pagesArco Cirúrgico Ge Everview 7500 - MsAnonymous dGFqrw5vO100% (8)

- Exercise A. Pressure Gauge CalibrationDocument4 pagesExercise A. Pressure Gauge CalibrationLuis Fernando BaqueNo ratings yet

- Elastic Modulus RelationshipsDocument2 pagesElastic Modulus Relationshipsaishwarya25singhNo ratings yet

- Q-Win S Se QuickguideDocument22 pagesQ-Win S Se QuickguideAndres DennisNo ratings yet

- Silos Design With Different Aspect RatiosDocument9 pagesSilos Design With Different Aspect Ratiosmrnaeem100% (1)

- Worksheet Science 2 º Unit 5Document20 pagesWorksheet Science 2 º Unit 5Kyo Toey0% (1)

- Oracle Database 12c R2: Administration Workshop Ed 3: DurationDocument6 pagesOracle Database 12c R2: Administration Workshop Ed 3: Durationjackomito100% (1)

- Spacelas Co., LTD: Preliminary!JAN.30,2010Document4 pagesSpacelas Co., LTD: Preliminary!JAN.30,2010James WinsorNo ratings yet

- Data Ontap 8.1.1Document128 pagesData Ontap 8.1.1mikkyphpNo ratings yet

- Classes of FireDocument12 pagesClasses of FireMusharaf Shah100% (2)

- Penawaran Harga COLDSTORAGEDocument1 pagePenawaran Harga COLDSTORAGEChannel Arif0% (1)

- Sany Petroleum: Intelligent EquipmentDocument24 pagesSany Petroleum: Intelligent EquipmentZamfirMarianNo ratings yet

- Design and Analysis of Steel Foot Over Bridge: Presented byDocument28 pagesDesign and Analysis of Steel Foot Over Bridge: Presented byHARIS ALINo ratings yet

- Data Sheet Equipos Sist. Impulsión DieselDocument15 pagesData Sheet Equipos Sist. Impulsión DieselJorge InostrozaNo ratings yet

- SRX HA Deployment GuideDocument35 pagesSRX HA Deployment GuideCraig NetsNo ratings yet

- Solar Water PumpingDocument4 pagesSolar Water PumpingVaibhav Vithoba NaikNo ratings yet

- SATIP-A-113-01 Rev 8 Geotechnical Investigation FinalDocument2 pagesSATIP-A-113-01 Rev 8 Geotechnical Investigation FinalTito GarciaNo ratings yet

- IndexDocument1,018 pagesIndexAjay BansalNo ratings yet

- Full Scale Load Test For BridgeDocument9 pagesFull Scale Load Test For BridgeAlsonChin0% (1)

- Sychronous Type Overview 4 Pole Models: Basic - TypesDocument2 pagesSychronous Type Overview 4 Pole Models: Basic - TypesRichard Leo MoroniNo ratings yet

- Opening Range Breakout Stock Trading Algorithmic ModelDocument7 pagesOpening Range Breakout Stock Trading Algorithmic ModelJames MorenoNo ratings yet

- Pacifica GasDocument20 pagesPacifica GasAnonymous hhdtm8No ratings yet

- Acta Materialia: Dirk Herzog, Vanessa Seyda, Eric Wycisk, Claus EmmelmannDocument22 pagesActa Materialia: Dirk Herzog, Vanessa Seyda, Eric Wycisk, Claus EmmelmannKarteek RaghuNo ratings yet

- Implementation of Vertical Axis Wind TurbineDocument75 pagesImplementation of Vertical Axis Wind TurbineOsama Abd ElkawiNo ratings yet

- FoxcodePlus enDocument29 pagesFoxcodePlus endtriviNo ratings yet