Professional Documents

Culture Documents

AFL - Installation OPGW - Quick Reference Guide

AFL - Installation OPGW - Quick Reference Guide

Uploaded by

Paweł TylusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AFL - Installation OPGW - Quick Reference Guide

AFL - Installation OPGW - Quick Reference Guide

Uploaded by

Paweł TylusCopyright:

Available Formats

INSTALLING OPGW—QUICK REFERENCE GUIDE

This Quick Reference Guide is intended to provide highlights of OPGW installation instructions needed in the field.

AFL provides detailed installation instructions on proper techniques for installing OPGW cable. Please review the

document (WI-0298 Rev 1) before proceeding with installation. To receive the detailed OPGW installation

instructions, please email sales@AFLglobal.com.

Stringing Setup

STRINGING BLOCK

PULLING

OPGW CABLE

LINE

100’ 100’

PULLING

ANTI-ROTATIONAL

PAYOUT TENSIONER MACHINE

DEVICE

REEL

300’ DISTANCE TO STRINGING EQUIPMENT FROM 300’

15’

TOWER IS THREE TIMES BLOCK HEIGHT

Figure 1—Typical Stringing Setup

Table 1—Recommended Values for Safe OPGW Installation

PARAMETER VALUE

70 x OPGW diameter

Minimum Bull Wheel Diameter

For larger diameter OPGW cables where 70 x OD exceeds 60" (~1.5 m), a 60" (~1.5 m) bull wheel may be used. Please consult AFL in such cases.

40 x OD of OPGW

Stringing Sheave (Root) Diameter Based on a sheave through angle of 45° and maximum stringing tension (at tensioner) of 20% of the rated strength of the OPGW.

NOTE: Refer to Table 2 for additional information on minimum diameters of the stringing blocks for other conditions.

After Installation (Static): 15 x OD of OPGW

Minimum Cable Bending Radius During Installation (Dynamic): 20 x OD of OPGW

NOTE: Based on actual OPGW size, etc., care must be taken when bending the OPGW to avoid kinking the strands and damaging the

optical fibers contained within the central pipe.

20% of the Rated Breaking Strength of OPGW

Maximum Stringing Tension The stringing tension is always measured at the tensioner side. In general, the maximum stringing tension should be a half of the maximum

sagging tension and never should exceed 20% RBS of the OPGW.

Pulling Speed 60 meters (195 feet) per minute OR 3.6 km (2.2 miles ) per hour

Minimum Distance from Puller and

3:1 Ratio

Tensioner to the Stringing Block

Storage -50°C to +85°C (-58°F to +185°F)

Temperature

Installation -30°C to +85°C (-22°F to +185°F)

Ranges

Operating -40°C to +85°C (-40°F to +185°F)

(800) 235-3423 • (864) 433-0333 • www.AFLglobal.com 2.7.19

Stringing Setup (cont.)

“Radius Blocks,” “Banana Blocks” or “Array Travelers” as shown below in Figures 2A-C are strictly prohibited during the installation of OPGW.

The decreased surface area in contact with the OPGW is sufficient to damage the OPGW at typical stringing tensions.

A B C

Figures 2A-C—These types of array installation blocks should NOT be used to string OPGW.

Stringing Block

OPGW

δ

Tower

Stringing Plane θ/2 θ/2

Figure 3—Stringing angles and sheave size diagram

Table 2—Sheave Sizes for Different Stringing Angles

STRINGING OR LINE ANGLE SHEAVE SIZE (x OPGW OD)

Bull Wheel Diameter 70x

First and Last Structures 40x

Θ < 20° Stringing Angle 30x

20° < Θ < 45° Stringing Angle 40x

Tangent Structures 45° < Θ < 60° Stringing Angle 50x

60° < Θ < 90° Stringing Angle 60x

90° < Θ Stringing Angle No Go

* Refer to Appendix 1 in full AFL OPGW Installation Instructions for additional

sheave information.

Figure 4—Tying a support rope to the sheave keeps it

suspended to the stringing block.

(800) 235-3423 • (864) 433-0333 • www.AFLglobal.com 2.7.19

Table 3—Recommended Values for Handling OPGW

PARAMETER VALUE

Upon receiving the shipment, the purchaser should conduct an acceptance inspection. A cable acceptance inspection should include several

Inspection of Reels simple and inexpensive steps including but not limited to the following: Visual Inspection for Damage During Shipment, Inspection of Reel Tags,

and Optical Attenuation Inspection.

Handling of Cable Reels When moving cable reels, care should be taken to ensure that material handling equipment does not come into contact with the cable surface.

Short-term Storage For short-term storage, which is defined loosely as four months or less, steel or wood reels are suitable.

Long-term Storage When long-term storage is a possibility or anticipated (i.e., spare reels), steel reels should be used.

OPGW: 15 x OD of OPGW

Stainless Steel Tube: 45 x OD of stainless steel tube

Minimum Permanent Bending Radius

Plastic Buffer Tubes: 3 in. (8 cm)

Optical Fibers: 1.5 in. (3.8 cm)

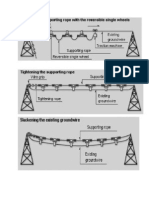

Shall be controlled corresponding to the swinging angle of the OPGW stringing plane to help prevent the cable from riding out of the traveler

or excessive twisting during installation.

Swinging Angle of Stringing Block

The cable should travel through the lowest part of the groove.

At angle structures, this is done by tying a support rope to the sheave to keep it suspended as shown in Figure 4.

Reeving Method

The OPGW must be reeved (threaded) through the bull-wheel tensioner properly. Left hand lay

OPGW (typical USA) is reeved from right to left, as shown in Figure 5. Right hand lay OPGW (typical

International), is reeved from left to right. A thorough explanation of the reeving process can be

found in the latest revision of IEEE Std 524. This arrangement is necessary to avoid any tendency to

loosen the outer layer of strands and to avoid induced torque during installation.

Figure 5—Left Hand Lay Reeving direction

Dead Ending and Clipping In

In general, the rule for hardware use is the following:

• Single Suspension to be used at structures with line

angles between 0 and 30 degrees.

• Double Suspension to be used at structures with

line angles between 30 and 60 degrees.

• Double Dead End to be used at structures with line

angles over 60 degrees.

Dead ends can be used starting from line angles of 30

degrees in lieu of double suspensions. Figure 6—OPGW Dead end (Bolted Type) Figure 7—OPGW Suspension Unit

In order to diminish the probability of motion-induced

damages and creep rate change, AFL recommends that

tensioning and anchoring of the OPGW to the structure

and removal of the stringing blocks be completed no

later than 48 hours after pulling in the cable.

Vibration Dampers

If vibration dampers are required for this span, these should be placed on the OPGW immediately after clipping in. Dampers may not be required at

every structure; their locations will be specified by the utility or AFL.

(800) 235-3423 • (864) 433-0333 • www.AFLglobal.com 2.7.19

Gripping Devices

A temporary grip is installed on the OPGW for tensioning. The grip must be designed to fit the cable. AFL can provide a come-along, sometimes called

a pocketbook grip, that can be attached anywhere along the length of an OPGW. Figure 9 illustrates a satisfactory come-along design. Some types of

gripping devices that might induce crushing damage the OPGW such as Chicago grip or Kito grip are strictly prohibited to use for OPGW, as shown in

Figures 10A and 10B.

Kito Grip (prohibited) Chicago grip (prohibited)

Figure 9—Come-along (Pocketbook Grip) Figures 10A and 10B—Types of prohibited grips used to tension OPGW.

Anti-Rotational Device (ARD)

ROTATING

ROTATING SWIVEL SWIVEL

PULLINGPULLING0.15 m 0.150.30

m m 0.30 m 4.6 m 4.6 m 0.30 m 0.30

0.30mm 0.30 m 4.6 m 4.6 m 0.30 m 0.30

0.30mm 0.30 m

6” 1’ 1’

6” 1’ 1’ 1’ 1’ 1’ 1’ 1’ 1’ 1’ 1’

LINE LINE 15’ 15’ 15’ 15’

OPGW OPGW

KELLEM KELLEM

GRIP GRIP APPLYLAYER

APPLY HEAVY HEAVY LAYER APPLYLAYER

APPLY HEAVY HEAVY LAYER

OF ELECTRICAL

OF ELECTRICAL TAPE TAPE OF ELECTRICAL

OF ELECTRICAL TAPE TAPE

APPLYLAYER

APPLY HEAVY HEAVY LAYER

OF ELECTRICAL

OF ELECTRICAL TAPE TAPE8’ 8’ 8’ 8’ 8’ 8’

2.44 m 2.44 m 2.44 m 2.44 m 2.44 m 2.44 m

The use of an Anti-Rotational Device depends largely upon the construction of the PUNCH

PUNCH LOK LOK CLAMPS

CLAMPS

optical ground wire. Such a device is used to prevent the OPGW from twisting while being

pulled. Variations of these devices have been successfully used. Please consult AFL for any OPGW OPGW

inquiries regarding a particular form of anti-rotation device.

For cables with helically stranded stainless steel tubes, an anti-rotational device may or may

not be required. To confirm whether one is needed for your particular application, contact

7/8” WIRE

7/8”

ROPE

WIRE ROPE

AFL. When in doubt, the conservative approach is to conduct the installation with the use

of an anti-rotational device. For cables constructed with an un-stranded stainless steel tube

in the center of the cable or single layer cables, an anti-rotational device is always a

requirement. 1-1/2”

1-1/2” OD ODREINFORCED

STEEL STEEL REINFORCED

HYDRAULIC

HYDRAULIC HOSE HOSE

(800) 235-3423 • (864) 433-0333 • www.AFLglobal.com 2.7.19

You might also like

- Stringing Method StatementDocument18 pagesStringing Method StatementAbhish Raj83% (6)

- Installation of Overhead Transmission LinesDocument55 pagesInstallation of Overhead Transmission LinesSheik Ali (QA/QC Manager Coastal)67% (6)

- 3 2 Rigging of Transmission Line Towers PDFDocument5 pages3 2 Rigging of Transmission Line Towers PDFsauravkafle1No ratings yet

- Bill of Quantity Proyek Pembangunan Gardu Induk 150 KV Bati - Bati + Incomer Sutt 150 KV (Cempaka - Pelaihari) RekapitulasiDocument7 pagesBill of Quantity Proyek Pembangunan Gardu Induk 150 KV Bati - Bati + Incomer Sutt 150 KV (Cempaka - Pelaihari) RekapitulasiYanuar Putra100% (1)

- FBSB Company Profile 2018Document13 pagesFBSB Company Profile 2018arslankhan20akNo ratings yet

- Installation Manual For OPGW CableDocument19 pagesInstallation Manual For OPGW Cablecsudha100% (2)

- Sketch of Basic Stringing Work For 500 KV Transmission Line Jawa 1 CCP ProjectDocument1 pageSketch of Basic Stringing Work For 500 KV Transmission Line Jawa 1 CCP ProjectJatmiko Purwo Saputro100% (3)

- Method of Installation For Overhead Transmission Line Conductors & OpgwDocument17 pagesMethod of Installation For Overhead Transmission Line Conductors & OpgwInba RajNo ratings yet

- Pre Installationfor Opgw 48 FDocument5 pagesPre Installationfor Opgw 48 FMayank PorwalNo ratings yet

- OPGW Installation ManualDocument23 pagesOPGW Installation Manualspark_187No ratings yet

- Conductor Installation Manual-MegatroDocument5 pagesConductor Installation Manual-MegatromanafNo ratings yet

- Opgw StringingDocument3 pagesOpgw StringingNiraj SinhaNo ratings yet

- StringingDocument4 pagesStringingFe Fatima NavarreteNo ratings yet

- Underground Pipes Mapping Survey (XYZ - Reduct - MS)Document18 pagesUnderground Pipes Mapping Survey (XYZ - Reduct - MS)Batu GajahNo ratings yet

- Field Work Procedure: 8. 8.1 Pre Hand ChecksDocument7 pagesField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- En 50155 (Ferrovia)Document3 pagesEn 50155 (Ferrovia)Roni Marcos OliveiraNo ratings yet

- LineDocument4 pagesLineShaharyar WaliullahNo ratings yet

- OPGW Installation Manual v2 6 12Document15 pagesOPGW Installation Manual v2 6 12gaurang1111No ratings yet

- Guying StandardDocument36 pagesGuying Standarddwas1314No ratings yet

- Distribution Conductor StringingDocument21 pagesDistribution Conductor Stringingmadhava_srinivasan174No ratings yet

- Itp Opgw Fat PDFDocument5 pagesItp Opgw Fat PDFPrabhakar Sv100% (1)

- Opgw Installation ManualDocument12 pagesOpgw Installation ManualSiva PNo ratings yet

- MOS Soil Investigation WorksDocument3 pagesMOS Soil Investigation WorksIzza HalimNo ratings yet

- NSC-400-CE-3230-Transmission Line Checklist MasterlistsDocument2 pagesNSC-400-CE-3230-Transmission Line Checklist MasterlistsElisco Pher SalmasanNo ratings yet

- Scope of Railway ManagementDocument14 pagesScope of Railway ManagementSourav NathNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- 53 - SOP For Cable Laying Termination in SwitchyardDocument8 pages53 - SOP For Cable Laying Termination in SwitchyardVipin SinghNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended PracticesCarlos PlaceresNo ratings yet

- Transmission Line Construction February 2023Document12 pagesTransmission Line Construction February 2023ccalosa29No ratings yet

- Method Statement For HV Cables Laying at Multi Storey Car Park Building at BWTC ComplexDocument9 pagesMethod Statement For HV Cables Laying at Multi Storey Car Park Building at BWTC Complexfibin haneefaNo ratings yet

- ITP-OPGW - Type Test PDFDocument4 pagesITP-OPGW - Type Test PDFPrabhakar SvNo ratings yet

- Coaxial Cable InglesDocument7 pagesCoaxial Cable InglesGianmarco Yllanes LamaNo ratings yet

- 3M Cable Joints Terminations PDFDocument116 pages3M Cable Joints Terminations PDFananNo ratings yet

- StringingDocument5 pagesStringingsrinu240000100% (1)

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- EotDocument16 pagesEotMayuresh GoregaonkarNo ratings yet

- FabHotels Invoice 5MN5O8Document1 pageFabHotels Invoice 5MN5O8fixoran553No ratings yet

- Tps OHLDocument88 pagesTps OHLNaseem AhmedNo ratings yet

- Form Qw-482Document3 pagesForm Qw-482Leon PerinangoNo ratings yet

- 1.0. Methodology For Survey WorksDocument2 pages1.0. Methodology For Survey WorksharshaNo ratings yet

- JMC Format For Transmission Line StriningDocument7 pagesJMC Format For Transmission Line StriningSanjay Rout0% (1)

- NewDocument77 pagesNewVarun ShahNo ratings yet

- 2GW OPGW - Live Line Installation Elsewedy (Compatibility Mode)Document20 pages2GW OPGW - Live Line Installation Elsewedy (Compatibility Mode)Dela Akoto100% (1)

- Drum Schedule Format For Conductor Stringing in Transmission LineDocument36 pagesDrum Schedule Format For Conductor Stringing in Transmission LinesAuRaBhNo ratings yet

- Aerial Fiber Optic Cable OverviewDocument7 pagesAerial Fiber Optic Cable OverviewSted KingNo ratings yet

- Contractor's Inspection Checklist - UPLOADDocument1 pageContractor's Inspection Checklist - UPLOADMATENo ratings yet

- Communications Backbone CablingDocument3 pagesCommunications Backbone CablingHumaid ShaikhNo ratings yet

- CKE - Itp.01.28.00.2012 Form For Line Continuity and Phase Sequence TestDocument1 pageCKE - Itp.01.28.00.2012 Form For Line Continuity and Phase Sequence TestNUR FATEHA MOHAMMED100% (1)

- Feeder System Installation Procedure - MOPDocument19 pagesFeeder System Installation Procedure - MOPSandeep singh100% (1)

- PSK Checklist New Elec E01 - 18 HT CablingDocument1 pagePSK Checklist New Elec E01 - 18 HT CablingBAHARUDIN BURAHNo ratings yet

- Work Method Statement For 69kV Live Line Crosssing in PVI and VIIIDocument10 pagesWork Method Statement For 69kV Live Line Crosssing in PVI and VIIITwin BullsNo ratings yet

- Technical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit Breakers NPS001 - 009Document29 pagesTechnical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit Breakers NPS001 - 009Indika Withanage100% (1)

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- 3C3 Product Catalog 2019Document8 pages3C3 Product Catalog 2019sunil kumarNo ratings yet

- Final Work Instructions - Electrical ErectionDocument116 pagesFinal Work Instructions - Electrical ErectionBuggy App100% (2)

- Installation Checklist LARPAZEEDocument7 pagesInstallation Checklist LARPAZEEDimgba ProgressNo ratings yet

- CMRL PS Ohe 01 2017 PDFDocument72 pagesCMRL PS Ohe 01 2017 PDFrajimuruganNo ratings yet

- QAP Plan Elect.Document2 pagesQAP Plan Elect.insap_dineshNo ratings yet

- Method Statement For Installation of Cable Tray/Trunking/LadderDocument5 pagesMethod Statement For Installation of Cable Tray/Trunking/LadderSandeep Kumar50% (2)

- Standard Technique - Underground Cable InstallationDocument61 pagesStandard Technique - Underground Cable InstallationFibin Haneefa100% (1)

- Appendix F OPGW Installation Manual: AFL Telecommunications Technical ResponseDocument15 pagesAppendix F OPGW Installation Manual: AFL Telecommunications Technical ResponseramsesNo ratings yet

- OPGWInstallation InstructionsDocument15 pagesOPGWInstallation InstructionsjorgemachigueNo ratings yet

- Montaje OpgwDocument105 pagesMontaje OpgwRicardo PerlaciosNo ratings yet

- Installation PracticeDocument16 pagesInstallation PracticeramsesiNo ratings yet

- PMRDA BOQ Inquiry With ScopeDocument8 pagesPMRDA BOQ Inquiry With ScopeAkd DeshmukhNo ratings yet

- Aluminum Clad Central Steel Tube DesignDocument2 pagesAluminum Clad Central Steel Tube Designhemantgupta226No ratings yet

- Power Sector in Bangladesh 12Document12 pagesPower Sector in Bangladesh 12Akib zavedNo ratings yet

- Opgw - 24g652-Ast-177 (69.8 - 256.7)Document9 pagesOpgw - 24g652-Ast-177 (69.8 - 256.7)pedro torresNo ratings yet

- 4.3.1. Specific Method Description For Stringing The Towers - Rev 2Document73 pages4.3.1. Specific Method Description For Stringing The Towers - Rev 2sasa milosevicNo ratings yet

- Overhead Line SolutionsDocument8 pagesOverhead Line SolutionsDomingo O Chavez PeñaNo ratings yet

- AXY Series - Suspension Set ADSS Long SpanDocument3 pagesAXY Series - Suspension Set ADSS Long SpanhcindustryNo ratings yet

- Price Schedule Ishurdi-RooppurDocument10 pagesPrice Schedule Ishurdi-RooppurRahul ShyamNo ratings yet

- Fiber Optic Installation and MaintenanceDocument5 pagesFiber Optic Installation and MaintenanceGhayas Ud-din Dar100% (2)

- Saudi Electricity Company: Revision 01 Aug 16, 2015Document10 pagesSaudi Electricity Company: Revision 01 Aug 16, 2015Prabhakar SvNo ratings yet

- Presentacion de Taihan Electric Wire Co Ltd.Document47 pagesPresentacion de Taihan Electric Wire Co Ltd.santiago foriguaNo ratings yet

- Adnan Nawaz CVDocument4 pagesAdnan Nawaz CVNawa LibanNo ratings yet

- OPGWDocument6 pagesOPGWanushkabhardwajNo ratings yet

- Calculation of 750kV Transmission Line Parameters Based On ATP-EMTP SimulationDocument4 pagesCalculation of 750kV Transmission Line Parameters Based On ATP-EMTP SimulationYeissonSanabriaNo ratings yet

- Selecting OPGW FOR APPLICATIONDocument6 pagesSelecting OPGW FOR APPLICATIONARCC2030No ratings yet

- Optical Ground WireDocument14 pagesOptical Ground Wireshubham jaiswalNo ratings yet

- KEPPRES No 22 TAHUN 1993 Penyakit Yang Timbul Karena Hubungan KerjaDocument5 pagesKEPPRES No 22 TAHUN 1993 Penyakit Yang Timbul Karena Hubungan KerjaMuhammad Alif Ardy YansyahNo ratings yet

- Fiber Optics Const Manual CO-107147Document8 pagesFiber Optics Const Manual CO-107147Ahmad TaheriNo ratings yet

- Pages From OPGW Joint Box Spec-85439Document2 pagesPages From OPGW Joint Box Spec-85439DejanNo ratings yet

- 0.9. OPGW - Technical SpecificationDocument20 pages0.9. OPGW - Technical Specificationgiorgis072No ratings yet

- Power Cable D319eDocument8 pagesPower Cable D319erocket-vtNo ratings yet

- GRE - EEC.S.00.XX.A.00000.16.002.00 OHT-LineDocument98 pagesGRE - EEC.S.00.XX.A.00000.16.002.00 OHT-LineCeciliaNo ratings yet

- Nofn Pilot Project AT Paravada Mandal VisakhapatnamDocument10 pagesNofn Pilot Project AT Paravada Mandal VisakhapatnamMpls NocbgNo ratings yet

- Asl TLDocument9 pagesAsl TLNirmal WiresNo ratings yet

- Method For Calculating OPGW Optical Cable Short Circuit Current Heat Effect by Using Improved Synthetic MethodDocument25 pagesMethod For Calculating OPGW Optical Cable Short Circuit Current Heat Effect by Using Improved Synthetic MethodHugh cabNo ratings yet

- Aluma CoreDocument1 pageAluma Corelewislia1991No ratings yet