Professional Documents

Culture Documents

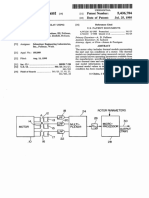

Transistorized Inverter: Instruction Manual (Detailed)

Transistorized Inverter: Instruction Manual (Detailed)

Uploaded by

Alcides AnjosCopyright:

Available Formats

You might also like

- Mitsubishi Freqrol FR A024 Manual PDFDocument167 pagesMitsubishi Freqrol FR A024 Manual PDFndmvillocillo89% (9)

- MP1570A Sonet/Sdh/Pdh/Atm Analyzer Service Manual: Fourth EditionDocument338 pagesMP1570A Sonet/Sdh/Pdh/Atm Analyzer Service Manual: Fourth EditionAnonymous smdEgZN2IeNo ratings yet

- ECG/EKG Interpretation: An Easy Approach to Read a 12-Lead ECG and How to Diagnose and Treat ArrhythmiasFrom EverandECG/EKG Interpretation: An Easy Approach to Read a 12-Lead ECG and How to Diagnose and Treat ArrhythmiasRating: 5 out of 5 stars5/5 (2)

- KN 120-294 Service ManualDocument23 pagesKN 120-294 Service ManualAmir ChakaNo ratings yet

- YDT IDT 2 Operation ManualDocument22 pagesYDT IDT 2 Operation Manualimansantoso23No ratings yet

- ASL, F300 Precision Thermometry Bridge-14-002 Issue 5 Operators Handbook PDFDocument40 pagesASL, F300 Precision Thermometry Bridge-14-002 Issue 5 Operators Handbook PDFLulu Sweet ThingNo ratings yet

- fra500Document257 pagesfra500Lưu TinhNo ratings yet

- Mitsubishi Freqrol FR S500 ManualDocument191 pagesMitsubishi Freqrol FR S500 Manualzodiakastro75No ratings yet

- DP 400Document84 pagesDP 400Quoc VinhNo ratings yet

- Ax 500Document163 pagesAx 500nam thanhNo ratings yet

- JRC JFE-680 Instruct ManualDocument86 pagesJRC JFE-680 Instruct ManualMark Dominic FedericoNo ratings yet

- 120-EchoNav JRC JFE-380 Instruct Manual 1-3-2019Document88 pages120-EchoNav JRC JFE-380 Instruct Manual 1-3-2019Mavi NascarNo ratings yet

- STEREO 230 User Manual 221219 - R12 Rain 1Document20 pagesSTEREO 230 User Manual 221219 - R12 Rain 1aoutedamartinezNo ratings yet

- Rigol: Quick GuideDocument38 pagesRigol: Quick GuideAlbertNo ratings yet

- FD-390 Máy Đo Tim ThaiDocument34 pagesFD-390 Máy Đo Tim ThaiVĩ ĐặngNo ratings yet

- EM730UserManual (V100)Document345 pagesEM730UserManual (V100)Salman SakibNo ratings yet

- Mitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedDocument243 pagesMitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedMROstop.comNo ratings yet

- Rigol DS1054Z UserGuideDocument262 pagesRigol DS1054Z UserGuidenivlarkNo ratings yet

- FR-F800 - Instruction Manual 292550-B (12.15)Document834 pagesFR-F800 - Instruction Manual 292550-B (12.15)Le van hoanNo ratings yet

- LME EV3 Coding Activities 1.1 en GBDocument217 pagesLME EV3 Coding Activities 1.1 en GBdamarcrazyNo ratings yet

- Fr-E700 Instruction Manual (Basic)Document155 pagesFr-E700 Instruction Manual (Basic)DeTiEnamoradoNo ratings yet

- SINEE InverterDocument137 pagesSINEE InverterrahimgrouptransportNo ratings yet

- PECOMP PalmerMI Bedienungsanleitung en de FR ESDocument72 pagesPECOMP PalmerMI Bedienungsanleitung en de FR ESluisNo ratings yet

- Mitsubishi A800 Plus Installation GuideDocument66 pagesMitsubishi A800 Plus Installation GuidejgpazdNo ratings yet

- Manual InverterDocument215 pagesManual InverterAdrianto GNo ratings yet

- Root Effects - SOLID METAL: User S Manual Bedienungsanleitung Manuel D'Utilisation Manual de UsuarioDocument72 pagesRoot Effects - SOLID METAL: User S Manual Bedienungsanleitung Manuel D'Utilisation Manual de UsuarioluisNo ratings yet

- FR-E520-0.1KN To 7.5K-KNDocument196 pagesFR-E520-0.1KN To 7.5K-KNZoTech MadagascarNo ratings yet

- Mitsubishi E500 Series ManualDocument225 pagesMitsubishi E500 Series ManualtoanchiNo ratings yet

- Mitsubishi E500 Series Technical Manual EuropeanDocument218 pagesMitsubishi E500 Series Technical Manual Europeanmoh shoNo ratings yet

- Manual Servo Drive Ib1500025enghDocument566 pagesManual Servo Drive Ib1500025enghSousaFV0% (1)

- JFE-380 Instruction ManualDocument80 pagesJFE-380 Instruction ManualDonny W MiazNo ratings yet

- MR J3 MR J4 Transisition GuideDocument708 pagesMR J3 MR J4 Transisition GuideTAN SAU LIANGNo ratings yet

- Mitsubishi E700 Variable Frequency Drive (VFD) Instruction ManualDocument322 pagesMitsubishi E700 Variable Frequency Drive (VFD) Instruction ManualMROstop.com75% (4)

- Directional Power Sensors: Operation Manual Model 5009, 5010B, and 5014Document23 pagesDirectional Power Sensors: Operation Manual Model 5009, 5010B, and 5014Emilio EscalanteNo ratings yet

- Manual Bien Tan Mitsubishi E500Document221 pagesManual Bien Tan Mitsubishi E500Vy Nguyễn thảoNo ratings yet

- FR-BU2-1.5K To 55K FR-BU2-H7.5K To H280K: Inverter Instruction ManualDocument71 pagesFR-BU2-1.5K To 55K FR-BU2-H7.5K To H280K: Inverter Instruction ManualFabian MogroNo ratings yet

- BNP C3015 PDFDocument231 pagesBNP C3015 PDFibraheemNo ratings yet

- MT-35MK2 (PLU S) 说明书英文版Document15 pagesMT-35MK2 (PLU S) 说明书英文版kaamelott1966No ratings yet

- MS2651B Vol.3 ProgrammingDocument638 pagesMS2651B Vol.3 ProgrammingDevinNo ratings yet

- Mitsubishi A100 ManualDocument225 pagesMitsubishi A100 ManualKen Lam100% (1)

- Ti-E Instruction ManualDocument132 pagesTi-E Instruction ManualbuzimirNo ratings yet

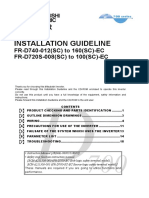

- FR-D700 Installation Guideline Inverter: FR-D740-012 (SC) To 160 (SC) - EC FR-D720S-008 (SC) To 100 (SC) - ECDocument30 pagesFR-D700 Installation Guideline Inverter: FR-D740-012 (SC) To 160 (SC) - EC FR-D720S-008 (SC) To 100 (SC) - ECugas666999No ratings yet

- FR-D700 Installation Guideline Inverter: FR-D740-012 (SC) To 160 (SC) - EC FR-D720S-008 (SC) To 100 (SC) - ECDocument30 pagesFR-D700 Installation Guideline Inverter: FR-D740-012 (SC) To 160 (SC) - EC FR-D720S-008 (SC) To 100 (SC) - ECLászló LósNo ratings yet

- 15p0072b1 Sinus N en r00Document142 pages15p0072b1 Sinus N en r00Maher JarrarNo ratings yet

- 2398 Operations XDocument184 pages2398 Operations Xeuchuma100% (1)

- MitsubishiDocument300 pagesMitsubishijuan_oliva_41No ratings yet

- Advantest - Corporation R4131C User ID5731Document444 pagesAdvantest - Corporation R4131C User ID5731Vanor CastroNo ratings yet

- Rigol DS1054Z ManualDocument258 pagesRigol DS1054Z Manualandrew mantikNo ratings yet

- FR-DU04Document225 pagesFR-DU04Angel Montellano100% (2)

- Ib 0600368 EngdDocument295 pagesIb 0600368 EngdAnonymous FqWJo7No ratings yet

- Mitsubhishi S500 ManualDocument200 pagesMitsubhishi S500 ManualDeepak GuptaNo ratings yet

- jma3910 25安装使用手册Document256 pagesjma3910 25安装使用手册bg2ttNo ratings yet

- FR-S 520 S EC/ECR, FR-S 540 EC/ECR: Frequency Inverter Instruction Manual (Basic)Document66 pagesFR-S 520 S EC/ECR, FR-S 540 EC/ECR: Frequency Inverter Instruction Manual (Basic)marianoNo ratings yet

- Electricity Unplugged: A Beginner's Guide to Electrical SafetyFrom EverandElectricity Unplugged: A Beginner's Guide to Electrical SafetyNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- Major Project - Grid Solving RobotDocument84 pagesMajor Project - Grid Solving RobotAshish Bharade57% (7)

- AC Motor, Servo Motor and Stepper MotorDocument12 pagesAC Motor, Servo Motor and Stepper MotorAhmedSayedNo ratings yet

- Mock Defense Parcon 1Document19 pagesMock Defense Parcon 1Nash Gemar Braga EvangelistaNo ratings yet

- Brochures DEAM-0377 GenericDocument6 pagesBrochures DEAM-0377 GenericSergio aldoNo ratings yet

- Gas Dynamics and Jet Propulsion-Jit CollegeDocument210 pagesGas Dynamics and Jet Propulsion-Jit CollegeJogarao BikkavoluNo ratings yet

- Vendor Document Epc CPF Phase 2Document9 pagesVendor Document Epc CPF Phase 2Mohammed AbdallaNo ratings yet

- How To Check An Electric Motor - 12 Steps (With Pictures) - WikihowDocument9 pagesHow To Check An Electric Motor - 12 Steps (With Pictures) - WikihowAlamin SiddiqueNo ratings yet

- SINAMICS-V90 Connecting-STO-function FAQ enDocument11 pagesSINAMICS-V90 Connecting-STO-function FAQ enJosé AngeloNo ratings yet

- Contoh REPORT Open Ended CONTROLDocument32 pagesContoh REPORT Open Ended CONTROLtiko lolipopNo ratings yet

- VRV IV S Didvs2001 PDFDocument14 pagesVRV IV S Didvs2001 PDFmas zak danielNo ratings yet

- Iris Power Agtracii: Continuous On-Line Air Gap Monitoring For Hydro GeneratorsDocument4 pagesIris Power Agtracii: Continuous On-Line Air Gap Monitoring For Hydro GeneratorsRamón GuillánNo ratings yet

- Tokimec PR 6000Document43 pagesTokimec PR 6000ЕВГЕНИЙ СЕРГЕЕВ100% (1)

- Assured Automation Automated Valves OxlerDocument26 pagesAssured Automation Automated Valves OxlerMarcio RochaNo ratings yet

- BSM - R - Series - 3AUA0000142014 REVDDocument28 pagesBSM - R - Series - 3AUA0000142014 REVDhome madeNo ratings yet

- Traditional Chocolate PDFDocument9 pagesTraditional Chocolate PDFRaúl Velarde OsunaNo ratings yet

- Gambro BCT Trima Apheresis System - Service ManualDocument27 pagesGambro BCT Trima Apheresis System - Service ManualMagdiNo ratings yet

- A of Possibilities A of Possibilities World World For Any For Any Motion Motion A of Possibilities For AnyDocument8 pagesA of Possibilities A of Possibilities World World For Any For Any Motion Motion A of Possibilities For AnyAmit VermaNo ratings yet

- Indonesia RTGC Retrifit 22 Unit - NewDocument189 pagesIndonesia RTGC Retrifit 22 Unit - NewMechatronic EngineeringNo ratings yet

- Electrical SyllabusDocument2 pagesElectrical Syllabusharsh dubeyNo ratings yet

- Motor Protection Relay Using Thermal ModelsDocument7 pagesMotor Protection Relay Using Thermal ModelsAlexander ToyoNo ratings yet

- Gearlec - Tractelec 6,5 - 10 - 15 - 20 - 30 Kva (Lsa 3537)Document11 pagesGearlec - Tractelec 6,5 - 10 - 15 - 20 - 30 Kva (Lsa 3537)Anas BasarahNo ratings yet

- SafetyDocument6 pagesSafetyRishabhNo ratings yet

- Aib - DZS 065-300 - Eng - 6996022370Document56 pagesAib - DZS 065-300 - Eng - 6996022370Francisco CairoNo ratings yet

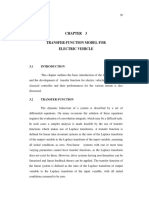

- Transfer Function Model For Electric VehicleDocument10 pagesTransfer Function Model For Electric VehicleFarhan MalikNo ratings yet

- VFD Wiring Diagram With Motor, Switches, and External Devices - ETechnoGDocument4 pagesVFD Wiring Diagram With Motor, Switches, and External Devices - ETechnoGTakesure MarizaniNo ratings yet

- Hardware Manual ACS800-04 Drive Modules (0.55 To 200 KW) ACS800-U4 Drive Modules (0.75 To 200 HP)Document164 pagesHardware Manual ACS800-04 Drive Modules (0.55 To 200 KW) ACS800-U4 Drive Modules (0.75 To 200 HP)andreiandrei573No ratings yet

- 2 - Brief - Review - of - Motor - Current - Signature - Analysis TESIS PDFDocument13 pages2 - Brief - Review - of - Motor - Current - Signature - Analysis TESIS PDFLuis MonzonNo ratings yet

- BRP Bee Module 5Document16 pagesBRP Bee Module 5priyaNo ratings yet

- C. 500w C. One Amp - OhmDocument4 pagesC. 500w C. One Amp - Ohmfiraol100% (2)

Transistorized Inverter: Instruction Manual (Detailed)

Transistorized Inverter: Instruction Manual (Detailed)

Uploaded by

Alcides AnjosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transistorized Inverter: Instruction Manual (Detailed)

Transistorized Inverter: Instruction Manual (Detailed)

Uploaded by

Alcides AnjosCopyright:

Available Formats

T R A N S IS T O R IZ E D IN V E R T E R

F R - S 5 0 0

IN S T R U C T IO N M A N U A L (D e ta ile d )

W IR IN G C hapter 1

F U N C T IO N S C hapter 2

P R O T E C T IV E

F U N C T IO N S C hapter 3

H E A D O F F IC E :M IT S U B IS H I D E N K I B L D G M A R U N O U C H I T O K Y O 1 0 0 -8 3 1 0

S P E C IF IC A T IO N S C hapter 4

P r in te d in J a p a n

More user manuals on ManualsBase.com

Thank you for choosing this Mitsubishi Transistorized inverter.

This instruction manual (detailed) provides instructions for advanced use of the

FR-S500 series inverters.

Incorrect handling might cause an unexpected fault. Before using the inverter, always

read this instruction manual and the instruction manual (basic) [IB-0600026] packed

with the product carefully to use the equipment to its optimum.

This instruction manual uses the International System of Units (SI). The measuring

units in the yard and pound system are indicated in parentheses as reference values.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have

read through the instruction manual (basic) and appended documents carefully and

can use the equipment correctly. Do not use the inverter until you have a full

knowledge of the equipment, safety information and instructions.

In this instruction manual, the safety instruction levels are classified into

"WARNING" and "CAUTION".

Assumes that incorrect handling may cause hazardous

WARNING conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

CAUTION conditions, resulting in medium or slight injury, or may

cause physical damage only.

Note that even the CAUTION level may lead to a serious consequence according to

conditions. Please follow the instructions of both levels because they are important

to personnel safety.

1. Electric Shock Prevention

WARNING

While power is on or when the inverter is running, do not open the front cover.

You may get an electric shock.

Do not run the inverter with the front cover removed. Otherwise, you may access

the exposed high-voltage terminals or the charging part of the circuitry and get

an electric shock.

If power is off, do not remove the front cover except for wiring or periodic

inspection. You may access the charged inverter circuits and get an electric

shock.

Before starting wiring or inspection, check for residual voltages with a meter etc.

more than 10 minutes after power-off.

Earth the inverter.

Any person who is involved in wiring or inspection of this equipment should be

fully competent to do the work.

Always install the inverter before wiring. Otherwise, you may get an electric

shock or be injured.

Perform setting dial and key operations with dry hands to prevent an electric shock.

Do not subject the cables to scratches, excessive stress, heavy loads or

pinching. Otherwise, you may get an electric shock.

Do not change the cooling fan while power is on.

It is dangerous to change the cooling fan while power is on.

When you have removed the front cover, do not touch the connector above the

3-digit monitor LED display. You will get an electric shock.

A-1

More user manuals on ManualsBase.com

2. Fire Prevention

CAUTION

Mount the inverter to incombustible material. Mounting it to or near combustible

material can cause a fire.

If the inverter has become faulty, switch off the inverter power. A continuous flow

of large current could cause a fire.

Do not connect a resistor directly to the DC terminals P(+), N(−). This could

cause a fire.

3. Injury Prevention

CAUTION

Apply only the voltage specified in the instruction manual to each terminal to

prevent damage etc.

Ensure that the cables are connected to the correct terminals. Otherwise,

damage etc. may occur.

Always make sure that polarity is correct to prevent damage etc.

While power is on and for some time after power-off, do not touch the inverter or

brake resistor as they are hot and you may get burnt.

4. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.

(1) Transportation and installation

CAUTION

When carrying products, use correct lifting gear to prevent injury.

Do not stack the inverter boxes higher than the number recommended.

Ensure that installation position and material can withstand the weight of the

inverter. Install according to the information in the Instruction Manual.

Do not operate if the inverter is damaged or has parts missing.

When carrying the inverter, do not hold it by the front cover or setting dial; it may fall off

or fail.

Do not stand or rest heavy objects on the inverter.

Check the inverter mounting orientation is correct.

Prevent screws, wire fragments, other conductive bodies, oil or other flammable

substances from entering the inverter.

Do not drop the inverter, or subject it to impact.

Use the inverter under the following environmental conditions:

Ambient

-10°C to +50°C (14°F to 122°F) (non-freezing)

temperature

Ambient humidity 90%RH or less (non-condensing)

Storage

Environment

-20°C to +65°C * (-4°F to 149°F)

temperature

Indoors (free from corrosive gas, flammable gas,

Ambience

oil mist, dust and dirt)

Maximum 1000m (3280.80feet) above sea level for

standard operation. After that derate by 3% for

Altitude, vibration every extra 500m (1640.40feet) up to 2500m

(8202.00feet) (91%).

5.9m/s2 or less (conforming to JIS C 0040)

*Temperatures applicable for a short time, e.g. in transit.

A-2

More user manuals on ManualsBase.com

(2) Wiring

CAUTION

Do not fit capacitive equipment such as power factor correction capacitor, radio

noise filter or surge suppressor to the output of the inverter.

The connection orientation of the output cables U, V, W to the motor will affect

the direction of rotation of the motor.

(3) Trial run

CAUTION

Check all parameters, and ensure that the machine will not be damaged by a

sudden start-up.

When the load GD2 is small (at the motor GD2 or smaller) for 400V from 1.5K to

3.7K, the output current may vary when the output frequency is in the 20Hz to

30Hz range.

If this is a problem, set the Pr. 72 "PWM frecuency selection" to 6kHz or higher.

When setting the PWM to a higher frequency, check for noise or leakage current

problem and take countermeasures against it.

(4) Operation

WARNING

When you have chosen the retry function, stay away from the equipment as it will

restart suddenly after an alarm stop.

The [STOP] key is valid only when the appropriate function setting has been

made. Prepare an emergency stop switch separately.

Make sure that the start signal is off before resetting the inverter alarm. A failure

to do so may restart the motor suddenly.

The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the equipment.

Do not modify the equipment.

CAUTION

The electronic overcurrent protection does not guarantee protection of the motor

from overheating.

Do not use a magnetic contactor on the inverter input for frequent

starting/stopping of the inverter.

Use a noise filter to reduce the effect of electromagnetic interference. Otherwise

nearby electronic equipment may be affected.

Take measures to suppress harmonics. Otherwise power harmonics from the

inverter may heat/damage the power capacitor and generator.

When a 400V class motor is inverter-driven, it should be insulation-enhanced or

surge voltages suppressed. Surge voltages attributable to the wiring constants

may occur at the motor terminals, deteriorating the insulation of the motor.

When parameter clear or all clear is performed, each parameter returns to the

factory setting. Re-set the required parameters before starting operation.

The inverter can be easily set for high-speed operation. Before changing its

setting, fully examine the performances of the motor and machine.

In addition to the inverter's holding function, install a holding device to ensure

safety.

Before running an inverter which had been stored for a long period, always

perform inspection and test operation.

A-3

More user manuals on ManualsBase.com

(6) Maintenance, inspection and parts replacement

CAUTION

Do not carry out a megger (insulation resistance) test on the control circuit of the

inverter.

(7) Disposing of the inverter

CAUTION

Treat as industrial waste.

(8) General instructions

Many of the diagrams and drawings in this instruction manual show the inverter

without a cover, or partially open. Never operate the inverter like this. Always

replace the cover and follow this instruction manual when operating the inverter.

A-4

More user manuals on ManualsBase.com

CONTENTS

1. WIRING 1

1.1 Japanese Version.....................................................................................2

Contents

1.1.1 Terminal connection diagram .................................................................... 2

1.1.2 Layout and wiring of main circuit terminals............................................... 3

1.2 North America Version .............................................................................4

1.2.1 Terminal connection diagram .................................................................... 4

1.2.2 Layout and wiring of main circuit terminals............................................... 5

1.3 European Version.....................................................................................7

1.3.1 Terminal connection diagram .................................................................... 7

1.3.2 Layout and wiring of main circuit terminals............................................... 8

1.4 Description of I/O Terminal Specifications ...............................................9

1.4.1 Main circuit .................................................................................................. 9

1.4.2 Control circuit .............................................................................................. 9

1.5 How to Use the Main Circuit Terminals..................................................11

1.5.1 Cables, wiring lengths, crimping terminals, etc. ..................................... 11

1.5.2 Wiring instructions .................................................................................... 12

1.5.3 Peripheral devices .................................................................................... 13

1.5.4 Leakage current and installation of earth leakage circuit breaker...... 15

1.5.5 Power-off and magnetic contactor (MC) ................................................. 17

1.5.6 Regarding the installation of the power factor improving reactor ....... 18

1.5.7 Regarding noise and the installation of a noise filter.............................. 18

1.5.8 Grounding precautions............................................................................. 19

1.5.9 Regarding power harmonics..................................................................... 20

1.5.10 Japanese power harmonic suppression guideline............................... 20

1.6 How to Use the Control Circuit Terminals ..............................................24

1.6.1 Terminal block layout................................................................................ 24

1.6.2 Wiring instructions .................................................................................... 24

1.6.3 Changing the control logic........................................................................ 25

1.7 Input Terminals.......................................................................................28

1.7.1 Run (start) and stop (STF, STR, STOP)................................................. 28

1.7.2 Connection of frequency setting potentiometer and output frequency

meter (10, 2, 5, 4, AU).............................................................................. 31

1.7.3 External frequency selection (REX, RH, RM, RL).................................. 32

1.7.4 Indicator connection and adjustment ...................................................... 34

1.7.5 Control circuit common terminals (SD, 5, SE)........................................ 37

1.7.6 Signal inputs by contactless switches ..................................................... 37

1.8 How to Use the Input Signals

(Assigned Terminals RL, RM, RH, STR)................................................38

1.8.1 Multi-speed setting (RL, RM, RH, REX signals): Setting "0, 1, 2, 8"

Remote setting (RL, RM, RH signals): Setting "0, 1, 2"......................... 38

1.8.2 Second function selection (RT signal): Setting "3"................................. 38

I

More user manuals on ManualsBase.com

1.8.3 Current input selection "AU signal": Setting "4"...................................... 38

1.8.4 Start self-holding selection (STOP signal): Setting "5"........................... 38

1.8.5 Output shut-off (MRS signal): Setting "6"................................................ 39

1.8.6 External thermal relay input: Setting "7".................................................. 39

1.8.7 Jog operation (JOG signal): Setting "9" .................................................. 40

1.8.8 Reset signal: Setting "10"......................................................................... 40

1.8.9 PID control valid terminal: Setting "14".................................................... 41

1.8.10 PU operation/external operation switching: Setting "16" ..................... 41

1.9 Handling of the RS-485 Connector

(Type with RS-485 Communication Function) .......................................41

1.10 Design Information ...............................................................................44

2. FUNCTIONS 45

2.1 Function (Parameter) List.......................................................................46

2.2 List of Parameters Classified by Purpose of Use...................................56

2.3 Explanation of Functions (Parameters)..................................................58

2.3.1 Torque boost ........................................................................... 58

2.3.2 Maximum and minimum frequency ....................................... 59

2.3.3 Base frequency, Base frequency voltage .................... 59

2.3.4 Multi-speed operation to to ....... 61

2.3.5 Acceleration/deceleration time ................... 62

2.3.6 Electronic overcurrent protection .................................................... 64

2.3.7 DC injection brake ......................................................... 64

2.3.8 Starting frequency ........................................................................... 65

2.3.9 Load pattern selection ..................................................................... 66

2.3.10 Jog frequency ....................................................................... 67

2.3.11 RUN key rotation direction selection ............................................. 67

2.3.12 Stall prevention function and current limit function ...................... 68

2.3.13 Stall prevention ............................................................ 69

2.3.14 Acceleration/deceleration pattern ................................................. 71

2.3.15 Extended function display selection ............................................. 72

2.3.16 Frequency jump to ............................................................... 72

2.3.17 Speed display ................................................................................ 73

2.3.18 Biases and gains of the frequency setting voltage (current)

to .......................................................................... 74

2.3.19 Start-time ground fault detection selection .................................. 78

2.4 Output Terminal Function Parameters ...................................................78

2.4.1 Up-to-frequency sensitivity .............................................................. 78

2.4.2 Output frequency detection .................................................... 79

2.5 Current Detection Function Parameters.................................................80

2.5.1 Output current detection functions ........................................ 80

2.5.2 Zero current detection ............................................................ 81

2.6 Display Function Parameters .................................................................82

2.6.1 Monitor display ........................................................................ 82

II

More user manuals on ManualsBase.com

2.6.2 Setting dial function selection ......................................................... 83

2.6.3 Monitoring reference .............................................................. 84

2.7 Restart Operation Parameters ...............................................................84

2.7.1 Restart setting ......................................................................... 84

2.8 Additional Function Parameters .............................................................86

Contents

2.8.1 Remote setting function selection .................................................. 86

2.9 Terminal Function Selection Parameters ...............................................88

2.9.1 Input terminal function selection .......................... 88

2.9.2 Output terminal function selection ......................................... 90

2.10 Operation Selection Function Parameters ...........................................91

2.10.1 Retry function ..................................................... 91

2.10.2 PWM carrier frequency ........................................................ 92

2.10.3 Applied motor ................................................................................. 93

2.10.4 Voltage input selection .................................................................. 93

2.10.5 Input filter time constant ................................................................ 94

2.10.6 Reset selection/PU stop selection ................................................ 94

2.10.7 Cooling fan operation selection .................................................... 96

2.10.8 Parameter write inhibit selection .................................................. 97

2.10.9 Reverse rotation prevention selection .......................................... 98

2.10.10 Operation mode selection ........................................................... 98

2.10.11 PID control to .................................................................... 101

2.11 Auxiliary Function Parameters ...........................................................109

2.11.1 Slip compensation ..................................................... 109

2.11.2 Automatic torque boost selection ............................................... 109

2.11.3 Motor primary resistance ............................................................ 111

2.12 Calibration Parameters ......................................................................111

2.12.1 Meter (frequency meter) calibration (Japanese version) ......... 111

2.12.2 Meter (frequency meter) calibration (NA and EC version) ...... 113

2.13 Clear Parameters ...............................................................................115

2.13.1 Parameter clear ........................................................................... 115

2.13.2 Alarm history clear ....................................................................... 115

2.14 Communication Parameters

(Only for the type having the RS-485 communication function)...........116

2.14.1 Communication settings to , ...................................... 118

2.14.2 Operation and speed command write ............................... 130

2.14.3 Link start mode selection ............................................................ 131

2

2.14.4 E PROM write selection .............................................................. 132

2.15 Parameter Unit (FR-PU04) Setting ....................................................133

2.15.1 Parameter unit display language switching ............................... 133

2.15.2 Buzzer sound control .................................................................. 133

2.15.3 PU contrast adjustment ............................................................... 134

2.15.4 PU main display screen data selection ...................................... 134

2.15.5 PU disconnection detection/PU setting lock .............................. 135

III

More user manuals on ManualsBase.com

3. PROTECTIVE FUNCTIONS 136

3.1 Errors (Alarms) .....................................................................................137

3.1.1 Error (alarm) definitions.......................................................................... 137

3.1.2 To know the operating status at the occurrence of alarm

(Only when FR-PU04 is used)............................................................... 145

3.1.3 Correspondence between digital and actual characters...................... 145

3.1.4 Resetting the inverter ............................................................................. 145

3.2 Troubleshooting....................................................................................146

3.2.1 Motor remains stopped .......................................................................... 146

3.2.2 Motor rotates in opposite direction ........................................................ 147

3.2.3 Speed greatly differs from the setting.................................................... 147

3.2.4 Acceleration/deceleration is not smooth ............................................... 147

3.2.5 Motor current is large.............................................................................. 147

3.2.6 Speed does not increase ....................................................................... 147

3.2.7 Speed varies during operation............................................................... 147

3.2.8 Operation mode is not changed properly.............................................. 148

3.2.9 Operation panel display is not operating............................................... 148

3.2.10 Parameter write cannot be performed ................................................ 148

3.2.11 Motor produces annoying sound......................................................... 148

3.3 Precautions for Maintenance and Inspection .......................................149

3.3.1 Precautions for maintenance and inspection........................................ 149

3.3.2 Check items ............................................................................................ 149

3.3.3 Periodic inspection.................................................................................. 149

3.3.4 Insulation resistance test using megger................................................ 150

3.3.5 Pressure test........................................................................................... 150

3.3.6 Daily and periodic inspection ................................................................. 150

3.3.7 Replacement of parts ............................................................................. 154

3.3.8 Measurement of main circuit voltages, currents and powers .............. 157

4. SPECIFICATIONS 160

4.1 Specification List ..................................................................................161

4.1.1 Ratings .................................................................................................... 161

4.1.2 Common specifications .......................................................................... 165

4.2 Outline Drawings ..................................................................................167

5. INSTRUCTIONS 170

5.1 Selecting Instructions ...........................................................................171

5.2 Peripheral Selecting Instructions..........................................................171

5.3 Operating Instructions ..........................................................................173

5.4 Inverter-driven 400V class motor .........................................................175

APPENDIX 176

APPENDIX 1 PARAMETER DATA CODE LIST ........................................177

IV

More user manuals on ManualsBase.com

1. WIRING

This chapter explains the basic "wiring" for use of this

product. Always read the instructions before use.

For description of "installation", refer to the instruction

manual (basic).

1.1 Japanese Version ......................................................2

1.2 North America Version...............................................4

1.3 European Version ......................................................7

1.4 Description of I/O Terminal specification ....................9

1.5 How to Use the Main Circuit Terminals ....................11

1.6 How to Use the Control Circuit Terminals ................24

1.7 Input Terminals ........................................................28

1.8 How to Use the Input Signals

(Assigned Terminals RL, RM, RH, STR) ..................38

1.9 Handling of the RS-485 Connector

(Type with RS-485 Communication Function) ..........41

1.10 Design Information.................................................44

<Abbreviations>

PU Chapter11

Control panel and parameter unit (FR-PU04)

Inverter

Mitsubishi transistorized inverter FR-S500 series

FR-S500 Chapter 2

Mitsubishi transistorized inverter FR-S500 series

Pr.

Parameter number

Chapter 3

Chapter 4

More user manuals on ManualsBase.com

1.1 Japanese Version

1.1.1 Terminal connection diagram

FR-S520-0.1K to 3.7K (-R) (-C)

FR-S540-0.4K to 3.7K (-R)

NFB MC Inverter Motor

3-phase AC R U

power supply S V IM

T W

External transistor common Ground

P1

24VDC power supply PC Power factor improving

Contact input common (source) DC reactor

(FR-BEL: Option)

Be careful not to short P

terminals PC-SD. Jumper: Remove this

N jumper when FR-BEL

Forward rotation start STF is connected.

Reverse rotation start STR *5 *6 A

High RH *5 *6 B Alarm

*6 C output

Multi-speed selection Middle RM *5

Low RL *5 Operation status

*6RUN Running

Contact input common SD output

(Note) SE Open collector Open

output common collector

Control input signals SINK outputs

(No voltage input allowed) (*3)

SOURCE

Frequency setting signals (Analog) Indicator

1mA full-scale

Frequency 3 10 (+5V) Analog meter

setting 2 (Digital indicator)

2 DC 0 to 5V Selected

potentiometer DC 0 to 10V FM 1mA

1/2W1k 1 5 (Common) (+) (-)

(*4) Calibration

Current input (-) resistor (*2)

4 to 20mADC (+) 4 (4 to 20mADC)

SD

When using the current input as

the frequency setting signal, set

"4" in any of Pr. 60 to Pr. 63 (input

terminal function selection), assign RS-485 Connector (*1)

AU (current input selection) to any

of terminals RH, RM, RL and STR, Earth (Ground)

and turn on the AU signal.

Main circuit terminal Control circuit input terminal Control circuit output terminal

REMARKS

*1 Only the type with RS-485 communication function.

*2 Not needed when the setting dial is used for calibration. This resistor is used

when calibration must be made near the frequency meter for such a reason as a

remote frequency meter. Note that the needle of the frequency meter may not

deflect to full-scale when the calibration resistor is connected. In this case, use

both the resistor and setting dial for calibration.

*3 You can switch between the sink and source logic positions. Refer to page 25.

*4 When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

*5 The terminal functions change with input terminal function selection (Pr. 60 to

Pr. 63). (Refer to page 38, 88) (RES, RL, RM, RH, RT, AU, STOP, MRS, OH,

REX, JOG, X14, X16, (STR) signal selection)

*6 The terminal functions change with output terminal function selection (Pr. 64,

Pr. 65). (Refer to page 90) (RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL,

LF, ABC signal selection)

More user manuals on ManualsBase.com

CAUTION

To prevent a malfunction due to noise, keep the signal cables more than 10cm (3.94inches)

away from the power cables.

FR-S520S-0.1K to 1.5K (-R) (-C)

FR-S510W-0.1K to 0.75K (-R)

NFB MC

Motor

R U

Power supply V IM

S

W Earth

(Ground)

REMARKS

• To ensure safety, connect the power input to the inverter via a magnetic contactor and earth

leakage circuit breaker or no-fuse breaker, and use the magnetic contactor to switch power on-off.

• The output is three-phase 200V.

1.1.2 Layout and wiring of main circuit terminals

FR-S520-1.5K, 2.2K, 3.7K (-R) (-C)

FR-S520-0.1K, 0.2K, 0.4K, 0.75K (-R) (-C) FR-S540-0.4K, 0.75K, 1.5K, 2.2K, 3.7K (-R)

Jumper

Jumper

N P

N P1 P

P1

R S T U V W

R S T U V W

IM

IM

Power supply Motor

Power supply Motor

FR-S520S-0.1K, 0.2K, 0.4K, 0.75K (-R) FR-S520S-1.5K (-R)

Jumper

Jumper

N P

N P1 P

P1

R S U V W

R S U V W

IM

IM 1

Power supply Motor

Power supply Motor

FR-S510W-0.1K, 0.2K, 0.4K (-R) FR-S510W-0.75K (-R)

N P N P

R S U V W

R S U V W

IM

IM

Power supply Motor

Power supply Motor

CAUTION

• The power supply cables must be connected to R, S, T. If they are connected to U, V, W,

the inverter will be damaged. (Phase sequence need not be matched.)

For use with a single-phase power supply, the power supply cables must be connected to

R and S.

• Connect the motor to U, V, W.

Turning on the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

More user manuals on ManualsBase.com

1.2 North America Version

1.2.1 Terminal connection diagram

FR-S520-0.1K to 3.7K-NA

FR-S540-0.4K to 3.7K-NA (R)

Inverter

NFB MC Motor

3-phase AC R U

power supply S V IM

T W

Earth

(Ground)

External transistor common P1

24VDC power supply PC Power factor improving

Contact input common (source) DC reactor

(FR-BEL: Option)

Take care not to short P

terminals PC-SD. Jumper: Remove this

N jumper when FR-BEL

Forward rotation start STF is connected.

Reverse rotation start STR *4 *5 A

High RH *4 *5 B Alarm

*5 C output

Multi-speed selection Middle RM *4

Low RL *4 Operation status

*5RUN Running

Contact input common SD output

SE Open collector Open

Control input signals output common collector

(No voltage input allowed) outputs

SINK

(*2)

Frequency setting signals (Analog) SOURCE

Frequency 3 10 (+5V)

setting 2

2 DC 0 to 5V Selected

potentiometer DC 0 to 10V

1/2W1k 1 5 (Common)

(*3) Current input (-) AM (+) Analog signal

4 to 20mADC (+) 4 (4 to 20mADC) output

When using the current input as 5 (-) (0 to 5VDC)

the frequency setting signal, set

"4" in any of Pr. 60 to Pr. 63 (input RS-485 Connector (*1)

terminal function selection), assign

AU (current input selection) to any Earth (Ground)

of terminals RH, RM, RL and STR,

and turn on the AU signal.

Main circuit terminal Control circuit input terminal Control circuit output terminal

REMARKS

*1 Only the type with RS-485 communication function.

*2 You can switch between the sink and source logic positions. Refer to page 25.

*3 When the setting potentiometer is used frequently, use a 2W 1kΩ potentiometer.

*4 The terminal functions change with input terminal function selection (Pr. 60 to

Pr. 63). (Refer to page 38, 88) (RES, RL, RM, RH, RT, AU, STOP, MRS, OH,

REX, JOG, X14, X16, (STR) signal selection)

*5 The terminal functions change with output terminal function selection (Pr. 64,

Pr. 65). (Refer to page 90) (RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL,

LF, ABC signal selection)

More user manuals on ManualsBase.com

NOTE

To prevent a malfunction due to noise, keep the signal cables more than 10cm

(3.94inches) away from the power cables.

FR-S510W-0.1K to 0.75K-NA

NFB MC

Motor

Power supply R U

S V IM

W

Earth

(Ground)

REMARKS

• To ensure safety, connect the power input to the inverter via a magnetic contactor

and earth leakage circuit breaker or no-fuse breaker, and use the magnetic

contactor to switch power on-off.

• The output is three-phase 200V.

1.2.2 Layout and wiring of main circuit terminals

FR-S520-1.5K, 2.2K, 3.7K-NA

FR-S520-0.1K, 0.2K, 0.4K, 0.75K-NA

FR-S540-0.4K, 0.75K, 1.5K, 2.2K, 3.7K-NA (R)

Jumper

Jumper

N P

N P1 P

P1

R S T U V W

R S T U V W

IM

IM

Power Motor

Power Motor supply

supply

FR-S510W-0.1K, 0.2K, 0.4K-NA FR-S510W-0.75K-NA

1

N P N P

R S U V W

R S U V W

IM

Power Motor IM

supply Power Motor

supply

CAUTION

• The power supply cables must be connected to R, S, T. If they are connected to

U, V, W, the inverter will be damaged. (Phase sequence need not be matched.)

• Connect the motor to U, V, W.

Turning on the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

More user manuals on ManualsBase.com

<When single-phase power input is provided for three-phase power input

inverter (NA version only)>

Reduce the output current.

FR-S520- K-NA inverter 0.1 0.2 0.4 0.75 1.5 2.2 3.7

Rated output current (A) 0.4 0.8 1.5 2.5 4.0 5.0 7.0

Power supply capacity (kVA) 0.4 0.8 1.5 2.5 4.5 5.5 9.0

AC input current (A) 1.1 2.4 4.5 6.4 11.2 12.9 17.4

Set m9 (Pr. 637) "current detection filter".

Setting "801" in the manufacturer setting parameter C8 enables you to set the m9

parameter.

CAUTION

Parameters other than m9 can also be made to be displayed, but never alter these

since they are manufacturer setting parameters.

m9 Setting Description

0 Single-phase power input

---

Three-phase power input

(Factory setting)

CAUTION

Always return the C8 parameter to 0 (factory setting) after you have finished the

setting of m9.

More user manuals on ManualsBase.com

1.3 European Version

1.3.1 Terminal connection diagram

FR-S540-0.4K to 3.7K-EC(R)

NFB MC Inverter Motor

3-phase AC L1 U

power supply L2 V IM

L3 W

Earth

Control input signals (Ground)

(No voltage input allowed) P1

Power factor improving

Contact input common PC DC reactor

(FR-BEL: Option)

Forward rotation start STF

Jumper: Remove this

Reverse rotation start STR *4 jumper when FR-BEL

is connected.

High RH *4

Multi-speed selection Middle RM *4 *5 A

Low RL *4 *5 B Alarm

*5 C output

External transistor common

24VDC power supply SD Operation status

Contact input common (sink)

*5RUN Running

output

SE Open collector Open

Take care not to short output common collector

terminals PC-SD. outputs

SINK

(*2)

Frequency setting signals (Analog) SOURCE

Frequency 3 10 (+5V)

setting 2

2 DC 0 to 5V Selected

potentiometer DC 0 to 10V

1/2W1k 1 5 (Common)

(*3) Current input (-) AM (+) Analog signal

4 to 20mADC (+) 4 (4 to 20mADC) output

5 (-) (0 to 5VDC)

When using the current input as

the frequency setting signal, set 1

"4" in any of Pr. 60 to Pr. 63 (input RS-485 Connector (*1)

terminal function selection), assign

Earth (Ground)

AU (current input selection) to any

of terminals RH, RM, RL and STR,

and turn on the AU signal.

Main circuit terminal Control circuit input terminal Control circuit output terminal

REMARKS

*1 Only the type with RS-485 communication function.

*2 You can switch between the sink and source logic positions. Refer to page 25.

*3 When the setting potentiometer is used frequently, use a 2W 1kΩ potentiometer.

*4 The terminal functions change with input terminal function selection (Pr. 60 to

Pr. 63). (Refer to page 38, 88) (RES, RL, RM, RH, RT, AU, STOP, MRS, OH,

REX, JOG, X14, X16, (STR) signal selection)

*5 The terminal functions change with output terminal function selection (Pr. 64,

Pr. 65). (Refer to page 90) (RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL,

LF, ABC signal selection)

More user manuals on ManualsBase.com

FR-S520S-0.2K to 1.5K-EC (R)

NFB MC

Motor

Power supply L1 U

N V IM

W

Earth

(Ground)

REMARKS

• To ensure safety, connect the power input to the inverter via a magnetic

contactor and earth leakage circuit breaker or no-fuse breaker, and use the

magnetic contactor to switch power on-off.

• The output is three-phase 200V.

NOTE

• To prevent a malfunction due to noise, keep the signal cables more than 10cm

(3.94inches) away from the power cables.

1.3.2 Layout and wiring of main circuit terminals

FR-S540-0.4K, 0.75K, 1.5K, 2.2K, 3.7K-EC (R)

Jumper

- +

P1

L1 L2 L3 U V W

IM

Power Motor

supply

FR-S520S-0.2K, 0.4K, 0.75K-EC (R) FR-S520S-1.5K-EC (R)

Jumper

Jumper

- +

- P1 +

P1

L1 N U V W

L1 N U V W

IM

IM

Power Motor

Power Motor supply

supply

CAUTION

• Connect the motor to U, V, W.

Turning on the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

• For power input wiring, connect L1 to R/L1 of the terminal block and N to S/L2 of

the terminal block.

• Do not connect the power supply to U, V and W.

More user manuals on ManualsBase.com

1.4 Description of I/O Terminal Specifications

1.4.1 Main circuit

Symbol Terminal Name Description

R, S, T * AC power input Connect to the commercial power supply.

<L1, L2, L3>

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

DC voltage DC voltage common terminal. Not isolated from the

N<-> power supply and inverter output.

common

Power factor Disconnect the jumper from terminals P<+>-P1 and

improving DC connect the optional power factor improving DC reactor

P<+>, P1 (FR-BEL). (The single-phase 100V power input model

reactor connection

cannot be connected.)

Earth (Ground) For grounding the inverter chassis. Must be earthed.

* R, S <L1, N> terminals for single-phase power input.

CAUTION

< >Terminal names in parentheses are those of the EC version.

1.4.2 Control circuit

Symbol Terminal Name Description

Turn on the STF signal When the STF and STR

Forward rotation to start forward rotation signals are turned on

STF start and turn it off to stop. simultaneously, the stop

Contact input

Turn on the STR signal command

Reverse rotation to start reverse rotation is given.

STR start and turn it off to stop. Input terminal

function selection

Turn on the RH, RM and RL signals (Pr. 60 to Pr. 63)

in appropriate combinations to select changes the

RH Multi-speed multiple speeds.

RM terminal functions.

selection The priorities of the speed commands (*4)

RL are in order of jog, multi-speed setting

(RH, RM, RL, REX) and AU.

Common terminal for contact inputs (terminals STF, STR,

SD Contact input RH, RM, RL) and indicator connection (terminal FM).

(*1) common (sink) Isolated from terminals 5 and SE.

When connecting the transistor output (open collector 1

Input signals

External output), such as a programmable controller (PLC),

transistor connect the positive external power supply for transistor

common output to this terminal to prevent a malfunction caused by

PC undesirable current.

(*1) 24VDC power

supply This terminal can be used as a 24V 0.1A DC power

Contact input output across terminals PC-SD.

common (source) When source logic is selected, this terminal serves as a

contact input signal common.

10 Frequency setting 5VDC. Permissible load current 10mA.

power supply

By entering 0 to 5VDC (0 to 10VDC), the maximum

Frequency output frequency is reached at 5V (10V) and I/O are

Frequency setting

2 setting proportional. Use Pr. 73 "0-5V/0-10V selection" to switch

(Voltage signal) between 5V and 10V.

Input resistance 10kΩ. Maximum permissible voltage 20V.

Enter 4-20mADC. This signal is factory-adjusted to reach

0Hz at 4mA and 60Hz at 20mA. Maximum permissible

Frequency input current 30mA. Input resistance approximately 250Ω.

4 setting For current input, turn on the signal AU.

(Current signal) Set the AU signal in any of Pr. 60 to Pr. 63 (input

terminal function selection).

More user manuals on ManualsBase.com

Symbol Terminal Name Description

Input signals

Frequency Common terminal for the frequency setting signals

5 setting input (terminals 2, 4) and indicator connection (terminal AM).

common Isolated from terminals SD and SE. Do not earth.

Change-over contact output indicating

that the output has been stopped by the

A inverter's protective function activated.

B Alarm output 230V 0.3A AC, 30V 0.3A DC. Alarm: Output

C discontinuity across B-C (continuity terminal

across A-C), normal: continuity across function

B-C (discontinuity across A-C). (*6) selection

Open collector

(Pr. 64, Pr. 65)

Switched low when the inverter output changes the

frequency is equal to or higher than the terminal

RUN Inverter running starting frequency (factory set to 0.5Hz, functions. (*5)

variable). Switched high during stop or

Output signals

DC injection brake operation. (*2)

Permissible load 24VDC 0.1A DC.

SE Open collector Common terminal for inverter running terminal RUN.

output common Isolated from terminals 5 and SD.

<Japanese>

Factory setting of output item:

Pulse

Frequency

FM

For meter One selected from

output frequency Permissible load current 1mA

1440 pulses/s at 60Hz

Indicator

and motor current is

output.

The output signal is

<NA, EC>

proportional to the Factory setting of output item:

Analog

Analog signal magnitude of each Frequency

AM

output monitoring item. Output signal 0 to 5VDC

Permissible load current 1mA

Communication

Using the parameter unit connection cable (FR-CB201 to

RS-485 connector 205), the parameter unit (FR-PU04) is connectable.

−− (*3) Communication operation can be performed through

RS-485.

*1. Do not connect terminals SD and PC each other or to the earth.

For sink logic, terminal SD acts as the common terminal of contact input. For

source logic, terminal PC acts as the common terminal of contact input. (Refer

to page 25 for the way to switch between them.)

*2. Low indicates that the open collector outputting transistor is on (conducts).

High indicates that the transistor is off (does not conduct).

*3. Compatible with only the type having RS-485 communication function.

(Refer to page 41.)

*4. RL, RM, RH, RT, AU, STOP, MRS, OH, REX, JOG, RES, X14, X16, (STR)

signal selection (Refer to page 88.)

*5. RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL, LF, ABC signal selection

(Refer to page 90.)

*6. To be compatible with the European Directive (Low Voltage Directive), the

operating capacity of relay outputs (A, B, C) should be 30V 0.3A DC.

10

More user manuals on ManualsBase.com

1.5 How to Use the Main Circuit Terminals

1.5.1 Cables, wiring lengths, crimping terminals, etc.

The following selection example assumes the wiring length of 20m (65.62feet).

1) FR-S520-0.1K to 3.7K (-R) (-C)

FR-S520-0.1K to 3.7K-NA

PVC

Applicable Terminal Tightening Crimping Cables Insulated

Inverter Screw Torque Terminals Cables

Model Size Nm mm2 AWG mm2

R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W

FR-S520-0.1K

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

to 0.75K

FR-S520-

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

1.5K, 2.2K

FR-S520-3.7K M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 2.5

2) FR-S540-0.4K to 3.7K (-R)

FR-S540-0.4K to 3.7K-NA (R)

FR-S540-0.4K to 3.7K-EC (R)

PVC

Crimping Cables Insulated

Applicable Terminal Tightening Terminals Cables

Inverter Screw Torque mm2 AWG mm2

Model Size Nm R, S, T R, S, T R, S, T R, S, T

<L1, L2, U, V, W <L1, L2, U, V, W <L1, L2, U, V, W <L1, L2, U, V, W

L3> L3> L3> L3>

FR-S540-0.4K

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

to 3.7K

3) FR-S520S-0.1K to 1.5K (-R)

FR-S520S-0.2K to 1.5K-EC (R)

PVC

Crimping Cables Insulated

Applicable Terminal Tightening Terminals Cables

Inverter Screw Torque 2

mm AWG mm2

Model Size Nm

R, S R, S R, S R, S 1

U, V, W U, V, W U, V, W U, V, W

<L1, N> <L1, N> <L1, N> <L1, N>

FR-S520S-

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

0.1K to 0.75K

FR-S520S-

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

1.5K

4) FR-S510W-0.1K to 0.75K (-R)

FR-S510W-0.1K to 0.75K-NA

PVC

Crimping Cables Insulated

Applicable Terminal Tightening Terminals Cables

Inverter Screw Torque

Model Size Nm mm2 AWG mm2

R, S

R, S U, V, W R, S U, V, W R, S U, V, W U, V, W

<L1, N>

FR-S510W-

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

0.1K to 0.4K

FR-S510W-

M4 1.5 5.5-4 2-4 3.5 2 12 14 4 2.5

0.75K

11

More user manuals on ManualsBase.com

Wiring length

100m (328.08feet) maximum. (50m (164.04feet) maximum for the FR-S540-0.4K.)

CAUTION

• When the wiring length of the 0.1K or 0.2K is 30m (98.43feet) or more, use the

carrier frequency to 1kHz.

• Use the carrier frequency of 1kHz when the wiring length of the FR-S540-0.4K,

0.75K is 30m (98.43feet) or more.

• The wiring length should be 30m (98.43feet) maximum when automatic torque

boost is selected in Pr. 98 "automatic torque boost selection (motor capacity)".

(Refer to page 109)

1.5.2 Wiring instructions

1) Use insulation-sleeved crimping terminals for the power supply and motor cables.

2) Application of power to the output terminals (U, V, W) of the inverter will damage

the inverter. Never perform such wiring.

3) After wiring, wire off-cuts must not be left in the inverter.

Wire off-cuts can cause an alarm, failure or malfunction. Always keep the inverter

clean.

When drilling a control box etc., take care not to let wire off-cuts enter the inverter.

4) Use cables of the recommended size to make a voltage drop 2% maximum.

If the wiring distance is long between the inverter and motor, a main circuit cable

voltage drop will cause the motor torque to decrease especially at the output of a

low frequency.

5) For long distance wiring, the fast-response current limit function may be reduced or

the devices connected to the secondary side may malfunction or become faulty

under the influence of a charging current due to the stray capacity of wiring.

Therefore, note the maximum overall wiring length.

6) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes harmonic components, which

may interfere with the communication devices (such as AM radios) used near the

inverter. In this case, install the optional FR-BIF radio noise filter (for use in the

input side only) or FR-BSF01 or FR-BLF line noise filter to minimize interference.

7) Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF

option) in the output side of the inverter.

This will cause the inverter to trip or the capacitor and surge suppressor to be

damaged. If any of the above devices are connected, remove them. (When using

the FR-BIF radio noise filter with a single-phase power supply, connect it to the

input side of the inverter after isolating the T <L3> phase securely.)

8) Before starting rewiring or other work after performing operation once, check the

voltage with a meter etc. more than 10 minutes after power-off. For some time after

power-off, there is a dangerous voltage in the capacitor.

12

More user manuals on ManualsBase.com

1.5.3 Peripheral devices

(1) Selection of peripheral devices

Check the capacity of the motor applicable to the inverter you purchased. Appropriate

peripheral devices must be selected according to the capacity.

Refer to the following list and prepare appropriate peripheral devices:

1) FR-S520-0.1K to 3.7K (-R) (-C)

FR-S520-0.1K to 3.7K-NA

Rated current of Magnetic

Power Power Cables (mm2)

Motor Factor Factor (*2)

Circuit Breaker Contactor

Output Inverter Improving Improving

(Refer to (MC)

(kW Model AC Reactor DC Reactor

page 15) (Refer to R, S, T U, V, W

(HP)) (Refer to (Refer to

(*1) page 17)

page 18) page 18)

0.1 FR-S520- FR-BAL-0.4K FR-BEL-0.4K

30AF/5A S-N10 2 2

(1/8) 0.1K (*3) (*3)

0.2 FR-S520- FR-BAL-0.4K FR-BEL-0.4K

30AF/5A S-N10 2 2

(1/4) 0.2K (*3) (*3)

0.4 FR-S520-

30AF/5A S-N10 FR-BAL-0.4K FR-BEL-0.4K 2 2

(1/2) 0.4K

0.75 FR-S520- FR-BAL- FR-BEL-

30AF/10A S-N10 2 2

(1) 0.75K 0.75K 0.75K

1.5 FR-S520-

30AF/15A S-N10 FR-BAL-1.5K FR-BEL-1.5K 2 2

(2) 1.5K

2.2 FR-S520- S-N11,

30AF/20A FR-BAL-2.2K FR-BEL-2.2K 2 2

(3) 2.2K S-N12

3.7 FR-S520-

30AF/30A S-N20 FR-BAL-3.7K FR-BAL-3.7K 3.5 3.5

(5) 3.7K

2) FR-S540-0.4K to 3.7K (-R)

FR-S540-0.4K to 3.7K-NA (R)

FR-S540-0.4K to 3.7K-EC (R)

Power Power Cables (mm2)

Motor

Rated current of Magnetic

Factor Factor (*2)

1

Circuit Breaker Contactor

Output Inverter Improving Improving

(Refer to (MC) R, S, T

(kW Model AC Reactor DC Reactor

page 15) (Refer to <L1, L2, U, V, W

(HP)) (Refer to (Refer to

(*1) page 17) L3>

page 18) page 18)

0.4 FR-S540- FR-BAL- FR-BEL-

30AF/5A S-N10 2 2

(1/2) 0.4K H0.4K H0.4K

0.75 FR-S540- FR-BAL- FR-BEL-

30AF/5A S-N10 2 2

(1) 0.75K H0.75K H0.75K

1.5 FR-S540- FR-BAL- FR-BEL-

30AF/10A S-N10 2 2

(2) 1.5K H1.5K H1.5K

2.2 FR-S540- FR-BAL- FR-BEL-

30AF/15A S-N20 2 2

(3) 2.2K H2.2K H2.2K

3.7 FR-S540- FR-BAL- FR-BAL-

30AF/20A S-N20 2 2

(5) 3.7K H3.7K H3.7K

13

More user manuals on ManualsBase.com

3) FR-S520S-0.1K to 1.5K (-R)

FR-S520S-0.2K to 1.5K-EC (R)

Power Power Cables (mm2)

Rated current of Magnetic Factor Factor (*2)

Motor

Circuit Breaker Contactor Improving Improving

Output Inverter

(Refer to (MC) AC Reactor DC Reactor

(kW Model R, S

page 15) (Refer to (Refer to (Refer to U, V, W

(HP)) <L1, N>

(*1) page 17) page 18) page 18)

(*3) (*3)

0.1 FR-S520S-

30AF/5A S-N10 FR-BAL-0.4K FR-BEL-0.4K 2 2

(1/8) 0.1K

0.2 FR-S520S-

30AF/10A S-N10 FR-BAL-0.4K FR-BEL-0.4K 2 2

(1/4) 0.2K

0.4 FR-S520S- FR-BAL- FR-BEL-

30AF/10A S-N20 2 2

(1/2) 0.4K 0.75K 0.75K

0.75 FR-S520S-

30AF/15A S-N20 FR-BAL-1.5K FR-BEL-1.5K 2 2

(1) 0.75K

1.5 FR-S520S-

30AF/20A S-N21 FR-BAL-2.2K FR-BEL-2.2K 2 2

(2) 1.5K

4) FR-S510W-0.1K to 0.75K (-R)

FR-S510W-0.1K to 0.75K-NA

Power Power Cables (mm2)

Rated current of Magnetic Factor Factor (*2)

Motor

Circuit Breaker Contactor Improving Improving

Output Inverter

(Refer to (MC) AC Reactor DC Reactor

(kW Model R, S

page 15) (Refer to (Refer to (Refer to U, V, W

(HP)) <L1, N>

(*1) page 17) page 18) page 18)

(*3) (*4)

0.1 FR-S510W- FR-BAL-

30AF/10A S-N10 −− 2 2

(1/8) 0.1K 0.75K

0.2 FR-S510W-

30AF/15A S-N10 FR-BAL-1.5K −− 2 2

(1/4) 0.2K

0.4 FR-S510W-

30AF/20A S-N20 FR-BAL-2.2K −− 2 2

(1/2) 0.4K

0.75 FR-S510W-

30AF/30A S-N20 FR-BAL-3.7K −− 3.5 2

(1) 0.75K

*1 For installations in the United States or Canada, the circuit breaker must be

inverse time or instantaneous trip type.

*2 The size of the cables assume that the wiring length is 20m (65.62feet).

*3 The power factor may be slightly less.

*4 The single-phase 100V power input model does not allow the power factor

improving DC reactor to be fitted.

14

More user manuals on ManualsBase.com

1.5.4 Leakage current and installation of earth leakage circuit breaker

Due to static capacitances existing in the inverter I/O wiring and motor, leakage

currents flow through them. Since their values depend on the static capacitances,

carrier frequency, etc., take the following counter measures.

(1) To-ground leakage currents

Leakage currents may flow not only into the inverter's own line but also into the

other line through the ground cable, etc.

These leakage currents may operate earth leakage circuit breakers and earth

leakage relays unnecessarily.

Counter measures

If the carrier frequency setting is high, decrease the carrier frequency (Pr. 72) of

the inverter.

Note that motor noise increases. Selection of Soft-PWM control (Pr. 70) will make

it unoffending. (Factory setting)

By using earth leakage circuit breakers designed for harmonic and surge

suppression (e.g. Mitsubishi's Progressive Super Series) in the inverter's own line

and other line, operation can be performed with the carrier frequency kept high

(with low noise).

(2) Line-to-line leakage currents

Harmonics of leakage NFB Thermal relay Motor

currents flowing in static Power

capacities between the Inverter IM

supply

inverter output cables

Line static

may operate the external

capacitances

thermal relay

unnecessarily. Line-to-Line Leakage Current Path

Counter measures

Use the electronic overcurrent protection of the inverter.

Decrease the carrier frequency. Note that motor noise increases. Selection of

Soft-PWM (Pr. 70) makes it unoffending.

To ensure that the motor is protected against line-to-line leakage currents, it is 1

recommended to use a temperature sensor to directly detect motor temperature.

Installation and selection of no-fuse breaker

On the power receiving side, install a no-fuse breaker (NFB) to protect the primary

wiring of the inverter. Which NFB to choose depends on the power supply side

power factor (which changes with the power supply voltage, output frequency and

load) of the inverter. Especially as the completely electromagnetic type NFB

changes in operational characteristic with harmonic currents, you need to choose

the one of a little larger capacity. (Check the data of the corresponding breaker.)

For the earth leakage circuit breaker, use our product designed for harmonic and

surge suppression (Progressive Super Series). (Refer to page 13 for the

recommended models.)

CAUTION

Choose the NFB type according to the power supply capacity.

15

More user manuals on ManualsBase.com

(3) Selecting the rated sensitivity current for the earth leakage circuit

breaker

When using the earth leakage circuit breaker with the inverter circuit, select its rated

sensitivity current as follows, independently of the PWM carrier frequency:

Progressive Super Series Example of leakage Leakage current

(Type SP, CF, SF, CP) current per 1km in cable example of 3-phase

Rated sensitivity current: path during commercial induction motor

I∆n ≥ 10 × (lg1+Ign+lg2+lgm) power supply operation during commercial

Conventional NV series (Type CA, when the CV cable is power supply

CS, SS produced prior to '91) routed in metal conduit operation

Rated sensitivity current: (200V 60Hz) (200V 60Hz)

I∆n ≥ 10 × {lg1+lgn+3 × (lg2+lgm)} 2.0

Leakage current (mA)

Leakage current (mA)

120

lg1, lg2 : Leakage currents of cable 100 1.0

path during commercial 80 0.7

0.5

power supply operation 60

0.3

lgn* : Leakage current of noise 40

0.2

filter on inverter input side 20

0 0.1

lgm : Leakage current of motor 2 3.5 8 142238 80150 1.5 3.7 7.5 152237 55

during commercial power 5.5 30 60100 2.2 5.5 1118.5 3045

supply operation Cable size (mm 2 ) Motor capacity (kW)

<Example>

2mm2 ×5m 2mm2 ×70m

(16.40feet) (229.66feet)

Noise

NV filter 3

Inver- IM 200V

ter 1.5kW

(2HP)

Ig1 Ign Ig2 Igm

CAUTION

• The earth leakage circuit breaker should be installed to the primary (power

supply) side of the inverter.

• In the connection neutral point grounded system, the sensitivity current

becomes worse for ground faults in the inverter secondary side. Hence, the

protective grounding of the load equipment should be 10Ω or less.

• When the breaker is installed in the secondary side of the inverter, it may be

unnecessarily operated by harmonics if the effective value is less than the rating. In this

case, do not install the breaker since the eddy current and hysteresis loss increase and

the temperature rises.

* Note the leakage current value of the noise filter installed on the inverter input

side.

Progressive Super Series Conventional NV

(Type SP, CF, SF,CP) (Type CA, CS, SS)

5m (16.40feet)

Leakage current (Ig1) (mA) 20 × = 0.10

1000m (3280.80feet)

Leakage current (Ign) (mA) 0 (without noise filter)

70m (229.66feet)

Leakage current (Ig2) (mA) 20 × = 1.40

1000m (3280.80feet)

Motor leakage 0.14

current (Igm) (mA)

Total leakage current (mA) 1.66 4.78

Rated sensitivity current 30 100

(mA) ( ≥ Ig × 10)

16

More user manuals on ManualsBase.com

1.5.5 Power-off and magnetic contactor (MC)

CAUTION

Do not use the inverter power supply side magnetic contactor to start or stop the

inverter.

As shown on the right, NFB MC

always use the start signal R<L1> U

(ON or OFF across Power To

S<N> V

supply motor

terminals STF or STR-SD)

T W

to make a start or stop.

F

(Refer to page 28)

B

ON OFF

OFF

MC

MC C

ON Inverter

MC

RA

OFF RA

RA

STF (STR)

SD

Inverter Start/Stop Circuit Example

(1) Inverter's primary side magnetic contactor (MC)

On the inverter's primary side, it is recommended to provide an MC for the following

purposes (Refer to page 13 for selection.):

1) To release the inverter from the power supply when the inverter's protective

function is activated or when the drive is not functioning (e.g. emergency stop

operation).

2) To prevent an accident caused by an automatic restart made at power restoration 1

after an inverter stop due to a power failure.

3) To rest the inverter for a long time.

The control power supply for inverter is always running and consumes a little

power. When stopping the inverter for a long time, switching inverter power off

saves power slightly.

4) To separate the inverter from the power supply to ensure safety of

maintenance/inspection work.

As the inverter's primary MC is used for the above purposes, it is equivalent to the

standard duty and select the one of class JEM1038-AC3 for the inverter input side

current.

17

More user manuals on ManualsBase.com

1.5.6 Regarding the installation of the power factor improving reactor

When the inverter is installed near a large-capacity power transformer (500kVA or

more at the wiring length of 10m (32.81feet) or less) or the power capacitor is to be

switched, an excessive peak current will flow in the power supply input circuit,

damaging the converter circuit. In such a case, always install the power factor

improving reactor (FR-BEL or FR-BAL).

Power supply equipment

FR-BAL Inverter

NFB

R X 1500 Power factor

R<L1> U

Power improving reactor

S Y 1000

S<N> V

capacity (kVA)

supply installation range

T Z T W 500

P<+>P1

0 10

FR-BEL(*) Wiring length (m)

REMARKS

* When connecting the FR-BEL, remove the jumper across terminals P<+>-P1.

The wiring length between FR-BEL and inverter should be 5m (16.40feet)

maximum and as short as possible.

Use the cables which are equal in size to those of the main circuit. (Refer to page

11)

1.5.7 Regarding noise and the installation of a noise filter

Some noise enters the inverter causing it to malfunction and others are generated by

the inverter causing the malfunction of peripheral devices. Though the inverter is

designed to be insusceptible to noise, it handles low-level signals, so it requires the

following general counter measures to be taken.

General counter measures

Do not run the power cables (I/O cables) and signal cables of the inverter in

parallel with each other and do not bundle them.

Use twisted shield cables for the detector connecting and control signal cables

and connect the sheathes of the shield cables to terminal SD.

Ground the inverter, motor, etc. at one point.

Capacitances exist between the inverter's I/O wiring, other cables, earth and

motor, through which leakage currents flow to cause the earth leakage circuit

breaker, earth leakage relay and external thermal relay to operate unnecessarily.

To prevent this, take appropriate measures, e.g. set the carrier frequency in Pr. 72

to a low value, use an earth leakage circuit breaker designed for suppression of

harmonics and surges, and use the electronic overcurrent protection built in the

inverter.

18

More user manuals on ManualsBase.com

Noise reduction examples

FR-BLF Control Reduce carrier

Install filter FR-BLF

FR-BSF01 box frequency. Install filter

FR-BSF01

on inverter's input side. on inverter's output side.

Inverter FR- FR-

power supply BLF Inverter BLF IM Motor

Install filter FR-BIF

on inverter's input side. FR- Use 4-core cable for motor

BIF power cable and use one

Separate inverter and power

cable as earth cable.

line more than 30cm (3.94inches)

(at least 10cm (11.81inches)) Use twisted pair shielded cable.

from sensor circuit. Sensor

Control Power

supply

power supply Do not earth control for sensor

box directly. Do not earth shield but connect

Do not earth it to signal common cable.

control cable.

1.5.8 Grounding precautions

Leakage currents flow in the inverter. To prevent an electric shock, the inverter and

motor must be grounded.

Use the dedicated ground terminal to ground the inverter. (Do not use the screw in

the casing, chassis, etc.)

Use a tinned* crimping terminal to connect the earth cable. When tightening the

screw, be careful not to break the threads.

*Plating should not include zinc.

Use the thickest possible ground cable. Use the cable whose size is equal to or

greater than that indicated in the following table, and minimize the cable length. 1

The grounding point should be as near as possible to the inverter.

(Unit: mm2)

Ground Cable Size

Motor Capacity

200V, 100V class 400V class

2.2kW (3HP) or less 2 (2.5) 2 (2.5)

3.7kW (5HP) 3.5 (4) 2 (4)

For use as a product compliant with the Low Voltage Directive, use PVC cable