Professional Documents

Culture Documents

Toaz - Info Lifting Beam Design PR

Toaz - Info Lifting Beam Design PR

Uploaded by

Hari KiranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toaz - Info Lifting Beam Design PR

Toaz - Info Lifting Beam Design PR

Uploaded by

Hari KiranCopyright:

Available Formats

PT.

TECHNICs

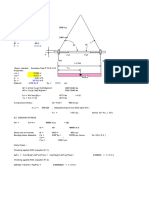

SPREADER BEAM CALCULATION

XXX METERING SKID : Tc- 14015

BEAM CHECKING

Total Weight (Wt) = 22046 lbs 10000.0 kgs

Safety Factor (SF) = 1.5

Test Load / Cal culated Weight (Wtc) = 33069 lbs 15000.0 kgs

Length to CoG (Lc.g) = 71 in 180.3 cm # 70.62992

Total Length (Lt) = 152 in 386.1 cm # 152.8346

Height to Center (Hc) = 12.4 in 31.5 cm ## 12.40157

Angle 1 (A1) = 68 degree 0

Angle 2 (A2) = 65 degree 0

0

Selected Beam : WF 300X150X6.5X9

Area A = 7.25 in^2 46.8 cm^2 ## 7 #REF!

Elastic Modulus (Sx) = 29.35 in^3 481.0 cm^3 ##### 1.155607

Elastic Modulus (Sy) = 4.09 in^3 67.0 cm^3 ### 4 0.160968

Modulus of gyrat ion (r xx) = 4.88 in 12.4 cm ## 5 0.1922

Modulus of gyrat ion (r yy) = 1.30 in 3.3 cm 3 1

Material A 36

Max. Yied (Ym) = 36000 psi 2531.1 kg/cm^2

E= 29000000 psi 2038922.7 kg/cm^2

K= 1

W1 = ((Lt-Lc.g)/Lt)*Wtc = 17622.2961 lbs 7993.4 kgs

W2 = (Lc.g/Lt)*Wtc = 15446.7039 lbs 7006.6 kgs

Fh1 = W1/tan(A1) = 7120 lbs 3229.6 kgs

Fh2 = W2/tan(A2) = 7203 lbs 3267.2 kgs

Fh = Biggest (Fh1,Fh2) = 7203 lbs 3267.2 kgs

COMPRESSION STRESS

Compression Stress, fa = Fh/A = 993 psi 69.8 kg/cm^2

Cc '= 126.1 (For A 36 & 107 for A 50)

(Pls. See tabel 5 of App. A Page 5.76)

KLx/r xx '= 31

KLy/r yy '= 117

(KLx/r xx)/Cc '= 0.25

(KLy/r yy)/Cc '= 0.93

Govern '= 0.93

Ca = from table 4 '= 0.444

All. Compression (Fa) = 15984 psi 1123.8 kg/cm^2

Check Compres sion fa < Fa = OK

BENDING STRESS

M1 = Fh1*Hc = 88286 lb/in 15766.3 kg.cm

M2 = Fh2*Hc = 89316 lb/in 15950.2 kg.cm

Moment (Mx) = biggest (M1,M2) = 89316 lb/in 15950.2 kg.cm

Moment (My) = 5% * Mx = 4466 lb/in 797.5 kg.cm

Stress due to moment

fbx = Mx/Sx = 3043 psi 213.9 kg/cm^2

fby = My/Sy = 1092 psi 76.8 kg/cm^2

All. Bending Stre ss (Fb) = 0.6*Ym = 21600 psi 1518.6 kg/cm^2

Check Bending, fb < Fb = OK

Cm = 1

F'e = (12*pi^2*E)/(23(KL/r)^2 =

F'ex = ###

F'ey = 10,852.70

UNITY CHECK

Checking against formula 1.6-1a

fa/Fa + Cmx*fbx/((1-fa/F'ex)*Fbx) + Cmy*fby/((1-fa/F'ey)*Fby) = 0.25957 < 1 OK

Checking against formula 1.6-1b

fa/0.6Ym + fbx/Fbx + fby/Fby = 0.23741 < 1 OK

LIFTING LUG CALCULATION :

Material of lug IS 2062 Gr A

Yield Stress Sy 350 N/mm2

Width of lifting lug b 400 mm

Height of lifting lug H 250 mm

mm

Thickness of lifting lug t 50 mm

Distance of hole from the top of the

lifting lug R 150 mm

Diameter of hole in the lifting lug d 80 mm

bottom of the welding to the center of hole s 100 mm

Total weld length on lifting lug Lw 900 mm

Fillet weld size on lifting lug w 12 mm

Result of the lifting lug

Weight to be lifted W 150000 KG

Jerk factor j 2 PASS

Number of lugs n 4

Force acting on the lug = w * j / n F 735750 N

Double shear

C/S area at sec a-a = (R - d/2) * t Aa 5500 mm2

C/S area at sec b-b = (b-d) * t Ab 16000 mm2

Shear stress at area a-a = F / Aa

(double shear) Ssa 133.77 N/mm2

Permissible shear stress 0.4 * Sy Ss 140 N/mm2

RESULT PASS

Tenisile stress

Tenisile stress at area b-b = F / Ab Stb 45.98 N/mm2

Permissible tenisile stress = 0.66 * Sy Stb 231 N/mm2

RESULT PASS

Bending stress

Horizontal force on lifting lug (assuming

150 sling angle) Fh 190355.48 N

Bending moment at base of Bracing =F*h Mo 19035548 N-mm

Section modulus of bracing = b * t2 / 6 z 166666.67 mm3

Bending stress Mo / z Sbw 114.21 N/mm2

Permissible bending stress 0.66 * Sy Sbw 231 N/mm2

RESULT PASS

Bearing stress

Force on Lug Fh 735750 N

bearing area of hole 4000.00 mm3

Bearing stress Sbw 183.94 N/mm2

Permissible bending stress 0.66 * Sy Sbw 231 N/mm2

RESULT PASS

Weld check of the lug

Total weld area of fillet of lifting lug

= ( Lw * w ) / 1.414 Aw 7637.91 mm2

Shear stress = F / Aw Ssw 96.33 N/mm2

Permissible shear stress = 0.4 * Sy Ss 100 N/mm2

RESULT PASS

You might also like

- Monorail Crane CalculationDocument5 pagesMonorail Crane CalculationSulakxan Kuru100% (2)

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- Demag - Crane Designer 1Document1 pageDemag - Crane Designer 1Bang OchimNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- Spreader Beam CalculationDocument4 pagesSpreader Beam CalculationMateen KhanNo ratings yet

- Spreader Bar CalculationDocument1 pageSpreader Bar Calculationjirrsama100% (1)

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Padeye DesignDocument2 pagesPadeye DesignChiedu Okondu100% (2)

- Instruc. MEPADSDocument46 pagesInstruc. MEPADSAnderzon Mora100% (1)

- Nanometer Scale Multilayered Hard CoatingsDocument12 pagesNanometer Scale Multilayered Hard CoatingsBojan PodgornikNo ratings yet

- Classical Applications of The Klein-Gordon EquationDocument7 pagesClassical Applications of The Klein-Gordon Equationapuntesfisymat100% (1)

- Lifting/Tailing Lug Calculation: Design DataDocument3 pagesLifting/Tailing Lug Calculation: Design DataMr IncognitoNo ratings yet

- Spreader Beam For Vessel323Document7 pagesSpreader Beam For Vessel323Anonymous sSRMFcNo ratings yet

- Spreader BarDocument5 pagesSpreader BarSteve MoonNo ratings yet

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Spreader Calculation (ISMC-200)Document4 pagesSpreader Calculation (ISMC-200)mechmohan26No ratings yet

- Calculation PadeyeDocument6 pagesCalculation PadeyeAddy Sumoharjo ST100% (1)

- LiftingDocument13 pagesLiftingrichardchiamNo ratings yet

- Lifting Lug CalcDocument1 pageLifting Lug CalcshazanNo ratings yet

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDocument3 pages8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshNo ratings yet

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthNo ratings yet

- Lifting Sling Load EquationsDocument2 pagesLifting Sling Load EquationsFabio Okamoto100% (1)

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationhuangjlNo ratings yet

- Pad Eye DesignFDocument8 pagesPad Eye DesignFRajasekar MeghanadhNo ratings yet

- 01 Horizontal Angle CalculationDocument3 pages01 Horizontal Angle CalculationMbalekelwa MpembeNo ratings yet

- RD339 (1MB File) Spreader BeamsDocument20 pagesRD339 (1MB File) Spreader Beamsnamasral100% (1)

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationMohamed NkNo ratings yet

- Latest Lifting LugDocument8 pagesLatest Lifting Lugjagannadha varmaNo ratings yet

- Spreader Beam Calculation ReportDocument15 pagesSpreader Beam Calculation ReportGurhan Atalay100% (1)

- Sparta Spreader Bar CalculatorDocument1 pageSparta Spreader Bar CalculatorNalini MathuraNo ratings yet

- Skid Lifitng Lug CalculationsDocument5 pagesSkid Lifitng Lug CalculationsinnovativekarthiNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document6 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Enrique BarajasNo ratings yet

- Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation SheetDocument28 pagesCalculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheethyoung65No ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNo ratings yet

- Slings Length CalculationDocument3 pagesSlings Length CalculationJaya Prakash100% (1)

- PadEye Genset 300kvaDocument3 pagesPadEye Genset 300kvadandy imam fauziNo ratings yet

- Spreader BarDocument2 pagesSpreader BarAmi PutraNo ratings yet

- Specialist Services: Force Resolution CalculationDocument5 pagesSpecialist Services: Force Resolution CalculationNaresh KumarNo ratings yet

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Document7 pagesLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonNo ratings yet

- Selecting Spreader Beam Check Beam For ES/EEC 1 Compression StressDocument2 pagesSelecting Spreader Beam Check Beam For ES/EEC 1 Compression StressSudar MyshaNo ratings yet

- Pad-Eye MainDocument8 pagesPad-Eye MainPradeep ChitluriNo ratings yet

- Padeye 7Document24 pagesPadeye 7Ramesh SelvarajNo ratings yet

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Calculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessDocument6 pagesCalculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessErin JohnsonNo ratings yet

- Stability CritariaDocument9 pagesStability CritariaAbu Bakar Siddke RumiNo ratings yet

- SWI PadeyeDocument11 pagesSWI PadeyeFian ArdiyanaNo ratings yet

- Design Lifting Beam (80 MT)Document10 pagesDesign Lifting Beam (80 MT)hardeep Singh100% (1)

- Lifting Lug Design SheetDocument6 pagesLifting Lug Design SheetIjaz AhmedNo ratings yet

- Padeye DesignDocument32 pagesPadeye DesignMuhammad Iqbal100% (1)

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- Book 3Document6 pagesBook 3Sasikumar Jothi100% (1)

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Fabrication Hook CalculationsDocument10 pagesFabrication Hook Calculationsprajakt_pieNo ratings yet

- Wire Rope CalculationDocument1 pageWire Rope CalculationSavin TimofteNo ratings yet

- Spreader BarDocument5 pagesSpreader Barmramico100% (1)

- Base Plate, Anchor & Foundation (Pipe)Document39 pagesBase Plate, Anchor & Foundation (Pipe)nizardsouissiNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Polyphenylene Sulfide (PPS) Plastic - Properties & ApplicationsDocument8 pagesPolyphenylene Sulfide (PPS) Plastic - Properties & ApplicationsHari KiranNo ratings yet

- Hppclengmeshift12021www Exambook CoDocument48 pagesHppclengmeshift12021www Exambook CoHari KiranNo ratings yet

- Sikb 18 F: Rod Ends With A Female ThreadDocument3 pagesSikb 18 F: Rod Ends With A Female ThreadHari KiranNo ratings yet

- Varieties and Applications 1: 1.general Steel Materials 3.aluminum Alloy MaterialsDocument1 pageVarieties and Applications 1: 1.general Steel Materials 3.aluminum Alloy MaterialsHari KiranNo ratings yet

- Modelling of A Standalone Photovoltaic System With Charge Controller For Battery Energy Storage SystemDocument10 pagesModelling of A Standalone Photovoltaic System With Charge Controller For Battery Energy Storage SystemHari KiranNo ratings yet

- An Approach To The Calculation of Process Forces During The Precision Honing of Small BoresDocument6 pagesAn Approach To The Calculation of Process Forces During The Precision Honing of Small BoresHari KiranNo ratings yet

- 3 Soudotec p20 Et h13 FT Web AnglaisDocument1 page3 Soudotec p20 Et h13 FT Web AnglaisHari KiranNo ratings yet

- JNTUK B.Tech 2-2 Sem (R19, R16, R13, R10) Regular/Supply Time Tables Aug/Sept 2021Document5 pagesJNTUK B.Tech 2-2 Sem (R19, R16, R13, R10) Regular/Supply Time Tables Aug/Sept 2021Hari KiranNo ratings yet

- VO14642AT, VO14642AABTR 1 Form A Solid-State Relay: Vishay SemiconductorsDocument10 pagesVO14642AT, VO14642AABTR 1 Form A Solid-State Relay: Vishay SemiconductorsHari KiranNo ratings yet

- High Reliability Hall Effect Sensor, Latching OutputDocument2 pagesHigh Reliability Hall Effect Sensor, Latching OutputHari KiranNo ratings yet

- Jawaharlal Nehru Technological University KakinadaDocument2 pagesJawaharlal Nehru Technological University KakinadaHari KiranNo ratings yet

- A Review of Elastic-Plastic Contact Mechanics: Applied Mechanics Reviews October 2017Document31 pagesA Review of Elastic-Plastic Contact Mechanics: Applied Mechanics Reviews October 2017Hari KiranNo ratings yet

- Axisymmetric Deformations of Circular Rings Made of Linear and Neo-Hookean Materials Under Internal and External Pressure: A Benchmark For Finite Element CodesDocument8 pagesAxisymmetric Deformations of Circular Rings Made of Linear and Neo-Hookean Materials Under Internal and External Pressure: A Benchmark For Finite Element CodesHari KiranNo ratings yet

- Meshing StiffnessDocument36 pagesMeshing StiffnessHari KiranNo ratings yet

- Properties of Maraging SteelsDocument3 pagesProperties of Maraging SteelsHari KiranNo ratings yet

- A Study of Cylindrical Shells Under Global Bending in The Elastic Plastic RangeDocument8 pagesA Study of Cylindrical Shells Under Global Bending in The Elastic Plastic RangeHari KiranNo ratings yet

- C349a - 171110 RFQ WH RentalDocument22 pagesC349a - 171110 RFQ WH RentalHari KiranNo ratings yet

- Solution of Spur Gear Meshing Stiffness and Analysis of Degradation CharacteristicsDocument8 pagesSolution of Spur Gear Meshing Stiffness and Analysis of Degradation CharacteristicsHari KiranNo ratings yet

- Circular Ring Stress and Deformations Formulae and Calculator - Engineers EdgeDocument6 pagesCircular Ring Stress and Deformations Formulae and Calculator - Engineers EdgeHari KiranNo ratings yet

- Development of Truss EquationsDocument63 pagesDevelopment of Truss EquationszcdscNo ratings yet

- Downloaded/printed by Universidad de Chile Pursuant To License Agreement. No Further Reproductions AuthorizedDocument224 pagesDownloaded/printed by Universidad de Chile Pursuant To License Agreement. No Further Reproductions AuthorizedFelipe ArceNo ratings yet

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsDocument34 pagesStrength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsAnonymous Qm0zbNkNo ratings yet

- Wocke Auc2008Document16 pagesWocke Auc2008klomps_jrNo ratings yet

- FEA Lab Manual PDFDocument49 pagesFEA Lab Manual PDFAdithya KashyapNo ratings yet

- Stephane - Mespoulet 1998 PHD Thesis PDFDocument246 pagesStephane - Mespoulet 1998 PHD Thesis PDFJavicontryNo ratings yet

- Biomaterial and Biomechanics in Dental Implant DesignDocument30 pagesBiomaterial and Biomechanics in Dental Implant DesignramaNo ratings yet

- 9702 - p1 - Elastic - Properties (Finished Upto May-June 2012)Document30 pages9702 - p1 - Elastic - Properties (Finished Upto May-June 2012)Asha D'saNo ratings yet

- Effect of Fiber Length and Placement Method On Flexural BehaviorDocument15 pagesEffect of Fiber Length and Placement Method On Flexural BehaviorHanumaNo ratings yet

- Materials Engineering: Mechanical PropertiesDocument26 pagesMaterials Engineering: Mechanical PropertiesJeromeDelCastilloNo ratings yet

- Design of Industrial Building Using ETABSDocument34 pagesDesign of Industrial Building Using ETABSNivan Rolls100% (5)

- Rules For Classification and Construction V Analysis TechniquesDocument60 pagesRules For Classification and Construction V Analysis TechniquesMarco MorrisNo ratings yet

- Lifting I Beam DesignDocument7 pagesLifting I Beam DesignGamsan MNo ratings yet

- T494Document28 pagesT494FERNANDO VALERA RUIZNo ratings yet

- Beam-Column-Design-SBC-306-2007-by KoushikDocument37 pagesBeam-Column-Design-SBC-306-2007-by KoushikSuperkineticNo ratings yet

- Imperial College PHD Thesis GuidelinesDocument5 pagesImperial College PHD Thesis Guidelinesfygynejoheg2100% (2)

- Model Prediction of Rutting in Asphalt Concrete by D. V. Ramsamooj P.E., J. Ramadan/ and G. S. Lin, 3 P.EDocument9 pagesModel Prediction of Rutting in Asphalt Concrete by D. V. Ramsamooj P.E., J. Ramadan/ and G. S. Lin, 3 P.EdedyNo ratings yet

- Kwak FilippouSEMM9014Document125 pagesKwak FilippouSEMM9014Stefano BarbieriNo ratings yet

- Timber Structure Calculations: Code: Analysis TypeDocument5 pagesTimber Structure Calculations: Code: Analysis TypehamzaNo ratings yet

- Module-Wise Questions (Prev Exams)Document10 pagesModule-Wise Questions (Prev Exams)Kiran ChristopherNo ratings yet

- Variational Asymptotic BeamDocument43 pagesVariational Asymptotic BeamAdimasu AyeleNo ratings yet

- Thermal Properties of GlassDocument4 pagesThermal Properties of Glasssewwan7653No ratings yet

- Structural Design PracticeDocument74 pagesStructural Design PracticeIp Siu Hei100% (2)

- Application of Rheology To PolymersDocument6 pagesApplication of Rheology To PolymersEhteshamul IslamNo ratings yet

- Deflections Using Energy MethodsDocument28 pagesDeflections Using Energy MethodsAndy AmatoNo ratings yet

- Strength Of Materials Review: α with the longitudinalDocument5 pagesStrength Of Materials Review: α with the longitudinalGee - FNo ratings yet

- Orthotropic Homogenized Modeling of Masonry Wall Panels: October 2020Document17 pagesOrthotropic Homogenized Modeling of Masonry Wall Panels: October 2020vadaleNo ratings yet