Professional Documents

Culture Documents

Operating Manual 1

Operating Manual 1

Uploaded by

Ngà Nguyễn0 ratings0% found this document useful (0 votes)

234 views22 pagesOriginal Title

operating manual 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

234 views22 pagesOperating Manual 1

Operating Manual 1

Uploaded by

Ngà NguyễnCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 22

~~

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Table of Contents

1

2.

24

22

23

24

25

26

3.

3.1

3.2

3.3

4,

4a

42

43

44

45

46

4.6.1

47

48

“4.9

5.

54

5.11

BAZ

513

5.14

524

522

5.23

61

614

6.1.2

6.1.3

6.1.4

6.21

6.2.2

6.2.3

6.24

6.2.5

6.2.6

6.27

How to Use this Manual..

General Notes

Preface

General Safety Instructions.

Hints on Saving Energy

Description of the Crane

Technical Data.

Lifting Capacity Chart.

General Drawing with Dimensions

Start-up

General Drawing with Check Locations

Requirements for Travel Operation

Requirements for Crane Operation

Generator / Mains Changeover Switch

Main Battery Switch ..

Starting / Stopping the Diesel Engin

Log-in.

Crane Master Switch ON / OFF.

Maintenance / Inspection Switch

Visumatic Symbols

Travel Operation..

Conditions for Travel Operation

‘Superstructure / Chassis Locking for Travel Operation

Radius for Travel Operation

Operating the Stabisers for Travel Operation from the Tower Cab

Operating the Stabilsers for Travel Operation from the Driver's Cab.

Travelling .....

Steering

Braking

Crane Operation...

Conditions for Crane Operation

Automatic Propping for Crane Operation...

Levelling the Crane ..

Manual Propping for Crane Operation

Superstructure / Chassis Locking for Crane Operation .

Slewing

Hoisting / Loweri

Luffing in / Luffing out.

Boom Cable Reel

Safe Load Indicator:

Wind Load Table ..

Parking the Crane Safe!

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Table of Contents

63

6.3.2

6.3.3

634

635

6.3.6

6.37

638

6.3.9

6.3.10

63.11

6.3.14

iz

TA

72

73

74

75

76

77

78

79

7M

7A2

7A3

TA4

TAS

7.16

TAT

718

7.19

7.20

721

7.22

8.

8.2

8.24

8.3

84

85

8.6

9.

11.

Lifting Gear .

‘Attaching the Hook Rotator.

Rotator Hook Rotating / Fixed / Freewheeling ..

‘Attaching the Automatic Spreader

Telescoping the Automatic Spreader to Container Size .

‘Automatic Spreader Centre of Gravity Compensation

‘Automatic Spreader Flippers UP / DOWN..

Locking / Unlocking Automatic Spreader Twistiocks

Picking Up / Setting Down Containers with the Automatic

Spreader.

‘Attaching the Grat

Opening / Closing the Gral

Setting Down the Lifting Gear Safely..

General Operating Functions 90

the Tower Cab Windscreen.

Emergency Stop Buttons ..

Earth Fault Warnin

Tower Cab Seat Adjustment

Fault Messages..

Locking System.

Work Monitor.

Driver's Cab Seat Adjust men

Selecting Language / Setting the Time.

Fault Statistics.

Production Statistics

‘Smoke Detector System

Lightning Protection

Emergency Descent Device.

Slewing Gear Speed...

Limit Switch Preset

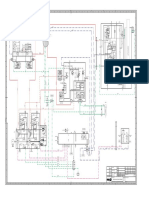

General Diagrams

Diagram of Tower Cab Control Panels

Diagram of Tower Cab Operating Panel

‘Superstructure Diagram

Chassis Diagram

Diagram of Diesel Engine Room Control Box

Diagram of Machinery Room Control Box

Remote Control

Final Disposal

G HMK 4406 Mobile Harbour Crane

Operating Manual

How to Use this Manual 1.

‘This Operating Manual is the first part of the User's Manual for the harbour crane

you have purchased. There are two possibilities for finding the information you

require.

4. tfyou are unfamiliar with the crane and wish to familiarise yourself in 1

‘yh all the controls, you should refer to the sections in the order in which

they are listed in the Table of Contents. You will then be introduced if

2 eystematic manner to all the safety instructions, the checks required

before daily start-up, and the individual operating steps.

it must be noted that the section numbering may not be continuous; certain

sections may not be included in the manual ifthe features they describe

are not present in your crane. The section number in the grey bar at the

top of each page is also given in the Table of Contents and in the diagrams

in section 8 at the end of the manual.

2. Ifyou are familiar with the crane and wish to find out about a particular

procedure, turn to the index or Table of Contents. Then refer to the page.

FF section indicated in this manual to find the information or operating

function you require.

(On each page in these sections, the location of

the control is indicated by a red arrow in the

diagram.

Each operating description is preceded by the

A necessary safety instructions for the operations

described. The safety instructions are highlighted

with the attention symbol shown adjacent.

. ‘Adjacent to many of the operating descriptions,

you will see symbols that correspond to those

beside the joystick or button in question.

The serial number of your crane is shown in the

bottom left comer of each page.

Thus, you can either start at the beginning and

work your way through the manual, or - after

consulting the Table of Contents - go straight to

those sections of the manual that contain the

specific information you seek.

Se Ten Mag Harbour Crane

parang

Section Diagram

24 1704 00

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Preface

24

The documentation supplied with your crane comprises the following books,

which will either be delivered with the crane or sent to Gottwald Port

‘Technology's local representative or direct to you.

User's Manual Part | (Operating Manual), User's Manual Part I! (Maintenance

Manual); manual for the diesel engine, manuals for the generator and the drive

motors of the hoist, slewing gear and hydraulic pump, manual for lifting gear,

manuals — depending on the crane model — for the control components, PLC S7,

software and printer, spare parts catalogue and electrical drawings.

Please note that, in the case of a legal dispute, only the official German version

of this document / manual / contract shall apply. Translations are intended for

information purposes only.

Correct usage and regular maintenance in accordance with the manuals are

prerequisites for trouble-free operation of the crane. The manuals must therefore

be available to the operating and maintenance personnel at all times. This is

especially important as incorrect usage and irregular maintenance can result in

major consequential damage not covered by the warranty. You should therefore

read this Operating Manual carefully before starting the crane, and always follow

the instructions in each section.

However, correct usage and maintenance of the crane are imperative not only

for reasons of cost-effectiveness but also for safety reasons. Only if the crane is

ina perfect technical condition can it be ensured that persons and property will

not be injured or damaged. The built-in safety equipment cannot, however,

‘eliminate all risks. If clearly visible or otherwise evident deviations occur, have

the equipment checked.

During operation and maintenance, always observe the safety instructions

given. By exercising caution and observing the instructions, you can help

prevent accidents. As different tasks require different precautionary measures,

special safety instructions are given before each operating description.

Each set of safety instructions is highlighted with an attention sign.

Continued on next page

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Preface

24

When carrying out the maintenance work indicated in this Operating Manual,

please refer to the Service Fluids Table in the Maintenance Manual. Please use

only the lubricants indicated in the table. Use of unsuitable lubricants and fuels

can result in major consequential damage to the crane, which will not be covered

by the warranty. You must therefore consult the maintenance manual before

carrying out such work.

Once you have read "How to Use the Operating Manual’, you should have no

difficulty finding the operating instructions you require and performing the

operations described.

This manual is based on the information available at the time of writing, i.e. when

the crane was dispatched from the factory. If any changes, retrofits or

modifications are subsequently made that need to be documented here, the

operating company must ensure that the manuals are ‘supplemented or adapted.

‘Terex MHPS GmbH

Terex Port Solutions

Forststrasse 16

40597 Disseldorf

Germany

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

General Safety Instructions 2.2

Operating Personnel

‘Acrane is a technically complex machine. Safe, competent operation requires

skill and a sense of responsibility on the part of the crane operator. Also, to

‘ensure safe operation, the crane operator must be in a good mental and physical

state. In addition, the crane operator must not be under the influence of alcohol

or drugs, and he must be at least 18 years old. The operating company must

select a crane operator who can be expected to carry out his duties reliably.

The crane operator must also

+ be instructed in the operation or maintenance of the crane and have

provided valid qualification of his skills to the operating company

In addition, the crane operator must be made familiar with the material in the

following manual

+ *Safe Operation of Cranes in accordance with ISO 12480"

“This means that the Accident Prevention Regulations and training requirements

applicable in the respective country of operation must be fulfiled.

Use for the intended purpose

The crane must only be used for lifting loads.

The attachment and proper use of all lifting gear not approved by the

manufacturer and compliance with national regulations during operation of this

‘equipment is the responsibility of the operator.

The information provided by the lifting gear manufacturer must be observed.

{tis prohibited to use the crane for any other purpose than that for which it was

designed, It is assumed that the working environment of the crane complies with

the regulations of your country.

You may leave the crane only when itis propped. Please note that, during crane

work, the crane must be propped, and the permissible maximum loadings in the

various operating situations given in the Technical Data must not be exceeded.

The crane may be propped only at the propping base specified in the Technical

Data. When operating the stabilisers manually, ensure that the stabiliser beams

are evenly and fully extended. Limit switches must not be bypassed. The data

given are based on average values of outside temperature, air humidity and dust

joad. If the actual values are higher, the maintenance intervals must be reduced

to prevent damage to the crane.

Transporting persons

Conveying persons in or on lifting gear is prohibited. Transport of persons in

baskets or work on work platforms is only permitted if the crane is certified for

this purpose.

Continued on next page

24 1704 00

G HMK 5506 Mobile Harbour Crane

Operating Manual

General Safety Instructions 22

Tandem Lifting

The crane is not prepared for tandem lifting operation, i.e. lifting a load with

several cranes. For this, adjustments must be made based on country-specific

regulations.

Use of qualified personnel

Maintenance, servicing and repairs may be carried out only by specially trained

or instructed personnel. Appropriately qualified personnel are those who due to

their technical training, knowledge and experience and their familiarity with the

relevant regulations can evaluate the tasks they are given and recognise

potential dangers. It must be ensured that the qualified personnel used not only

have the requisite technical knowledge but are also familiar with, and can apply,

all relevant safety and accident prevention regulations. If the tower has to be set

down on the ground for repairs, this is only permitted in the presence of the

manufacturer's qualified personnel.

unauthorised persons to be in or on the crane during operation, which

includes travel operation. When the crane is being operated from the

tower cab, controls elsewhere on the crane must not be used. Driving or

walking in, flying above and tunnelling below the standing / danger area

of the crane are prohibited even when the crane is shut down. The

standing / danger area of the crane is the area around the crane enclosed

within a circle defined by the boom radius. The standing / danger area of

the crane must not overlap any other danger areas.

Loads must be lifted vertically, diagonal pull and pulling loads loose are

prohibited.

N Standing in the slewing range is prohibited. It is likewise prohibited for

Hardware and software

The hardware installed in the crane is designed exclusively for the control

software. No other software may be installed. Furthermore, the drives are to be

used only for the installation of the control software. Failure to comply with the

above will result in the warranty becoming void.

External conditions

It must be ensured that the ground under the crane can withstand the propping

pressure of the crane. If the crane is to be travelled, the route must be checked

beforehand, Please take into consideration clearance widths, heights and the

crane weight.

Continued on next page

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

General Safety Instructions

2.2

Safety instructions for operation, maintenance and servicing

In this Operating Manual, special safety instructions are given before each

operating instruction. These instructions are supplementary to - and do not

invalidate - the general safety instructions given here.

Before work is carried out on the electrical system, ensure that the system is not

under power. This means the auxiliary power supply is not connected and the

external power supply is switched off. It must be ensured that the diesel engine

cannot be started. If the power supply has to be connected for function tests, it

is imperative that the entire power supply be disconnected again before the work

is continued.

The entire hydraulic system is under pressure. In addition, the hydraulic oll

becomes hot during operation. Hydraulic oil is flammable and can be ignited by

fire, naked lights, sparks and hot lamps. As the crane must be operational for

pressure, temperature and leak checks, such checks will involve an increased

danger of accidents. The pressures occurring are given in the hydraulic plans.

The hydraulic pressures set must not be changed. It is essential that all

personnel are appropriately qualified and work extremely carefully. Before other

work is started, the hydraulic pump must be switched off. It must be ensured that

‘the pump cannot be switched on by unauthorised persons. Please note that

some sections of the system remain pressurised even after it has been shut

down.

When undoing connections, please note that hydraulic oll could drain out of

components above the connections. Therefore, ensure an adequately sized drip

pan is positioned appropriately to prevent hydraulic oll escaping and harming the

environment.

It is important that waste oll from the hydraulic system is disposed of in

accordance with local regulations.

Special caution is required if maintenance work is to be performed on the diesel

engine directly after operation. The engine oll, engine casing, cooling system

‘and exhaust system wil stil be hot. As the crane must be operational for function

and leak tests, such tests will involve an increased danger of accidents, as will

work on the hydraulic system. When work is being done on the diesel engine

system, it must be ensured that the engine cannot be started by unauthorised

persons.

For all other work, the relevant legislation on safety must be observed.

Continued on next page

G HMK 4406 Mobile Harbour Crane

Operating Manual

Legend for Notices and Warning and Prohibition Signs 23

Danger due to drawing in or coiling

Danger of being crushed or struck

Danger of falling

Flammable materials

Suspended load

Danger area

Danger of being crushed

First-aid kit

oPPPPPPP

Diesel engine emergency off

De-energise

24 1704 00

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

General Safety Instructions

Crane inspection book

22

Every non-rail-mounted mobile crane has a crane inspection book. The technical

data of the crane in as-delivered condition are entered on the data sheets of the

crane inspection book by the crane manufacturer or supplier. If significant

changes are made, the data sheets must be amended or supplemented

accordingly.

The operating company must ensure that the results of the following inspections

are entered in the inspection book by an officially appointed crane expert:

+ before the crane is operated for the first time,

+ after major modifications are made,

+ after recurring inspections.

The inspection results must indicate:

+ the scope of the inspection,

+ information on whether any parts of the inspection still need to be

performed,

+ faults detected,

+ an evaluation as to whether there is any reason not to perform the next

inspection step or to operate the crane,

+ adecision as to whether reinspection is required.

Walking on the crane

Only qualified personnel are permitted to walk on the crane and only under the

conditions prescribed for qualified personnel. When ascending and descending

stairways and ladders, hold onto the handrails with both hands. Ladders must be

descended backwards only. If walking on the chassis, stay in the middle and

keep away from the edges to prevent falling off.

When climbing onto or off the chassis, use only the main access route (beside

the chassis driver's cab). The access route via the rear, i.e. at the opposite end

of the chassis to the driver's cab, may only be used

‘emergencies, e.g. in the

‘event of an emergency stop resulting from a fault which prevents the chassis

and superstructure being aligned and locked in the direction of travel, that is,

towards the main access route.

it is only permitted to access the crane if the crane driver has consented.

The driver must actively give consent BEFORE anyone accesses the crane.

It is expressly forbidden to attempt to access the crane before the driver has

given his approval. Notifying the crane driver of your wish to access the crane is

fot sufficient. A further condition is that the crane is at a complete standstill.

It is absolutely forbidden to jump onto or off the crane while it is in motion or

working.

‘At the end of the shift, the crane must be left in its secured position to enable

personnel to leave and access the crane safely via the main a

coess route.

The crane driver must also ensure that other people can also access and leave

the crane safely.

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Legend for Notices and Warning and Prohibition Signs 2.3

> @2O@P CE

®

Fire extinguisher

Hang-up sign: do not switch

Hazardous voltage

No admittance for unauthorised persons

Fire, naked lights, sparks, hot lamps and smoking prohibited

No admittance for pedestrians

Hearing protection to be worn

Boom: danger of crushing

‘Smoking prohibited

No entry for persons with pacemakers

"

G HMK 4406 Mobile Harbour Crane

Operating Manual

Dead Man Circuit (Option) 24

Safety instructions:

This crane can optionally be equipped with a dead man circuit. The circuit is an

additional safety device designed to prevent accidents in the event that the

crane operator loses control over the crane due to reasons of ill health.

Operation:

The system is designed in such a way that crane operation is stopped if the

relevant deadman switch is not pressed. There are two buttons in the crane, one

in each of the joysticks for the crane functions in the tower cab. When a crane

function is carried out with one of these joysticks, the button in the joystick must

always be kept depressed.

24 1704 00 12

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Description of Slinger Hand Signals

Designation

Down

Up

Caution

wies- ‘Stop

=r — Stop - danger

zg Up slowly

A\ > Move towards

% me

25

Description

Move arm in circular motion with hand pointing

down

Move arm in circular motion with hand pointing up

Hold arm extended up with palm of hand facing

forwards

Extend both arms out horizontally to the side

Extend both arms out horizontally to the side and

alternately bend and straighten them

Extend both arms out horizontally with palms of

hands facing down and move them up and down

slightly

Forearm horizontal with palm of hand facing up;

move forearm up and down slightly

Beckon with both arms with palms of hands

pointing towards body

13

G HMK 4406 Mobile Harbour Crane

Operating Manual

Description of Slinger Hand Signals

Designation

Drive off

Open, release, unlock

Close, grasp, lock

Indication of position

Direction indication

Indication of distance

to stopping position

Down slowly

25

Description

‘Arm extended up with palm of hand facing

forwards; move arm from side to side

Hold arm extended horizontally to the side

with half-open hand pointing down

Hold arm extended horizontally to the side

with closed hand pointing down

Point to destination position with both

hands

Bend the arm showing the direction of

motion and move it from side to side

Hold palms of hands facing each other at

distance to be indicated

Forearm horizontal with palm of hand

facing down; move forearm up and down

slightly

14

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Hints on Saving Energy 26

Optimising crane operation

Position the crane in the best possible place for the job to reduce the extent of

slewing and luffing motions.

= Always use the most suitable lifting gear so you do not move heavy

weights unnecessarily.

= Avoid accelerating and decelerating the drives unnecessarily.

= Do not raise loads higher than necessary.

On the work site

= As soon as itis light enough outside, turn off external lighting.

~ Only switch on the stairway lighting if it is needed.

= Since you will only be using the chassis or tower cab at any one time, turn

down the heating or air conditioner in the cab you are not using.

During breaks

- For short breaks, switch off the crane master switch.

= Ifthe break is a longer one, turn off both the crane master switch and the

diesel engine.

15

G HMK 4406 Mobile Harbour Crane

Operating Manual

Technical Data 34

Dimensions

Chassis length approx. 16.5 m

Chassis width (without stabiliser pads) approx. 9.04 m

Propping base, longitudinal / transverse 13.0 mx 12.5m

Stabiliser pad size 4 x 2.0mx4.5m

‘Superstructure overhang to rear 715m

Boom pivot point height approx. 16.7 m

‘Tower cab operator viewing height approx. 19.1 m

Working range

Max. radius 46.0m

Min. radius 11.0m

Hoisting height

Hoisting height above quay level, radius 11 - 34m 420m

Hoisting height above quay level, radius 35 m 415m

Hoisting height above quay level, radius 36 m 40.5 m

Hoisting height above quay level, radius 38 m 38.5 m

Hoisting height above quay level, radius 40 m 36.0 m

Hoisting height above quay level, radius 42 m 33.0 m

Hoisting height above quay level, radius 43 m 31.5m

Hoisting height above quay level, radius 44 m 29.5 m

Hoisting height above quay level, radius 45 m 275m

Hoisting height above quay level, radius 46 m 25.0m

Hoisting height below quay level 120m

Weights

Total weight of crane including hook in operational state approx. 365.0 t

Fixed counterweight approx. 95.4 t

Wind loads

Wind speed

Crane in travel condition 24.4 mis

Crane, propped, in operation 24.4 mis

Crane, propped, out of operation 46.1 mis

Tipping load utilisation

Normal load 75.0%

Special load 75.0%

Grab operation 50.0%

Electrical data

Nominal voltage 440 V / 60 Hz / max. current input, auxiliary power supply, 63 A/ clearance

between crane and overhead high-voltage lines up to 420 kV = 20 m.

24 1704 00

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Technical Data

Diesel Engine

Make

Model

Cylinders

Type of engine

Cooling system

Output

Fuel consumption

Fuel tank

Capacity, main tank

Capacity, day tank

Possible operating time with full tank

Generator

Make

Type

Speeds

Hoist

Lifting capacity, high-speed 15

Lifting capacity,, high-speed 45

Lifting capacity,, high-speed 63

Lifting capacity,, low-speed 40

Lifting capacity,, low-speed 70

Lifting capacity, low-speed 100

Slewing Gear

Superstructure slewing speed in normal operation

Maximum peripheral speed

‘Superstructure slewing speed in heavy-load operation

Luffing gear

LLuffing speed in normal operation

Luffing speed in heavy-load operation

Travel gear

Travel speed including hook in operational state

Longitudinal inclination during travel

Lateral inclination during travel

Inclination of the propping surface

Inner turning radius

Outer turing radius

Crab steering angle

Climatic operating conditions

Absolute maximum day temperature

Absolute minimum day temperature:

‘Max. air humidity

34

MAN

D 2842 LE 211

wiz

diesel

water-cooled

765 KW / 1800 rpm

approx. 205 g/kWh

Approx. 7800 |

4301.

up to 220 hours

Marelli

MJB 400/LA4

440 V / 60 Hz

0-68 m/min

0-38 m/min

0-31 m/min

0-42 m/min

0-28 m/min

0-18 m/min

0 - 1.95 rpm

300 m/min

0-0.6 rpm

0-65 m/min

0-27 m/min

0-60 m/min

max. 6%

max. 2.5%

max. 2.5%

max. 4.3m

max. 13.5 m

max. 22.6°

45°C

-20°C

100%

17

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Technical Data 34

Noise level

For this product, we guarantee a noise power level of L wa = 109 dB.

The measured values were determined in accordance with DIN EN ISO 3744 for the operating

conditions indicated in this manual.

in accordance with EU Directive 2006/42/EC, the mean sound pressure level in the tower cab

is Lpa = 70 dB.

The values were determined in accordance with DIN EN 1SO 3744 for the operating

conditions indicated in this manual and with the fan running at level 2.

Vibrations

The total of all vibrations to which the upper limbs are subjected is less than 2.5 m/s*.

‘The highest effective value of weighted acceleration to which the whole body is subjected Is

less than 0.5 m/s*.

EU Directive 2006/42/EC

You will find the EC Declaration of Conformity at the end of this Operating Manual.

This is a translation of the original German Operating Manual for your harbour crane.

18

G HMK 4406 Mobile Harbour Crane

Operating Manual

Lifting Capacity Chart

Spreader | = EH5U = 9.0t

The lifting capacities are to be understood as follows:

4. Normal load, heavy load, special load = Load below hook rotator

2. Grab on ropes = Load on ropes

24170400. 3. Spreader operation = Load below spreader

3.2

mr aN

24 1704 00

G HMK 4406 Mobile Harbour Crane

Operating Manual

Start-up

This section describes the checks that must be pet

that must be met, if you ‘wish to start work with

numbers below refer to the iter

Locations” in section 4.1. “the drawing shows the Insta!

components to be checked. ‘Before the checks are start

master switch

running (section 4.6).

44. General Drawing with Check Locations

4.2 Requirements for Travel Operation.

4.3. Requirements for Crane Operation

44 Generator / Mains Changeover switch:

45 Main Battery Switch...

4.6 Starting / Stopping the Diesel Engi

47 Crane Master Switch ON / OFF...

4.8 Maintenance | Inspection switch

4.9 Visumatic Symbols.

ine.

formed, and requirements

travel operation. The item

mm numbers in the “General Drawing with Check

lation location:

.g, switch off the crane

‘fit is on (section 4.7) and then ‘switch off the diesel engine if itis

G HMK 4406 Mobile Harbour Urane

Operating Manual

Lifting Capacty Chart

| Lifting capacities t

permissible wind speed in|

operation}

Tipping load utilisation

poleanceeesadessseeasanessss

‘Spreader |

Manufacturer: Bromma The lifting capacities ¢

Type: EHSU 4, Normal load, heavy

Spreader dead wight 9,0 2. Grab on ropes = Lt

24170400 Spreader liting capacity: Att 3, Spreader operatior

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- User and Driving TFC 45 2002 PPM11Document363 pagesUser and Driving TFC 45 2002 PPM11Ngà Nguyễn75% (16)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Dana 36000 Service Manual PDFDocument156 pagesDana 36000 Service Manual PDFNgà Nguyễn100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BT3398 Approval Drawings 1stDocument171 pagesBT3398 Approval Drawings 1stNgà NguyễnNo ratings yet

- List Sensor IFM 01 QC ZPMCDocument8 pagesList Sensor IFM 01 QC ZPMCNgà NguyễnNo ratings yet

- HeadblockDocument1 pageHeadblockNgà NguyễnNo ratings yet

- Spelling Bee ContestDocument25 pagesSpelling Bee ContestNgà NguyễnNo ratings yet

- Speader ppm09Document4 pagesSpeader ppm09Ngà NguyễnNo ratings yet

- File - 20200925 - 215658 - SMV Te17,27,32Document167 pagesFile - 20200925 - 215658 - SMV Te17,27,32Ngà Nguyễn100% (2)

- Bromma TukanDocument430 pagesBromma TukanNgà NguyễnNo ratings yet

- APC200 ECM-ECI Error Codes Ver1.8Document11 pagesAPC200 ECM-ECI Error Codes Ver1.8Ngà NguyễnNo ratings yet

- How To Use Interlock BypassDocument2 pagesHow To Use Interlock BypassNgà NguyễnNo ratings yet

- OPERATOR'S MANUAL - 065826en - SMV 4127-4545TB - RST - Volvo TAD 1340 VE - Dana TE27-32 - MDL2 - Elme 817Document78 pagesOPERATOR'S MANUAL - 065826en - SMV 4127-4545TB - RST - Volvo TAD 1340 VE - Dana TE27-32 - MDL2 - Elme 817Ngà NguyễnNo ratings yet

- Operating Manual 3Document64 pagesOperating Manual 3Ngà NguyễnNo ratings yet

- Annexes TrootbeshopDocument84 pagesAnnexes TrootbeshopNgà Nguyễn100% (1)

- Operating Manual 2Document102 pagesOperating Manual 2Ngà Nguyễn100% (2)

- BT3326 3.2 (B) Manual (Electrical) PDFDocument1,520 pagesBT3326 3.2 (B) Manual (Electrical) PDFNgà NguyễnNo ratings yet

- Idrt02 01GB PDFDocument198 pagesIdrt02 01GB PDFsudaryanto100% (2)

- Complimenting Others Role Plays Drama and Improvisation Activities - 31091Document2 pagesComplimenting Others Role Plays Drama and Improvisation Activities - 31091Ngà NguyễnNo ratings yet

- Fuji Micrex-Sph Fuji Micrex-SphDocument53 pagesFuji Micrex-Sph Fuji Micrex-SphNgà Nguyễn100% (1)

- Cable Reel / Engine Selector Key Switch For Power Source: (In The Cabin) (In The Cabin)Document2 pagesCable Reel / Engine Selector Key Switch For Power Source: (In The Cabin) (In The Cabin)Ngà NguyễnNo ratings yet

- ARRANGEMENT of L/S Location: Leg2 Leg3 Leg4Document1 pageARRANGEMENT of L/S Location: Leg2 Leg3 Leg4Ngà NguyễnNo ratings yet

- Apc200 Ecm/Eci: User ManualDocument137 pagesApc200 Ecm/Eci: User ManualNgà Nguyễn67% (3)

- How To Use Loader Software - Rev3Document19 pagesHow To Use Loader Software - Rev3Ngà NguyễnNo ratings yet

- Hydraulic Plans GHMK4406Document10 pagesHydraulic Plans GHMK4406Ngà Nguyễn100% (1)