Professional Documents

Culture Documents

250 PSI WWP Iron Body Gate Valves

250 PSI WWP Iron Body Gate Valves

Uploaded by

stalin vCopyright:

Available Formats

You might also like

- Wps 141 PA #5Document2 pagesWps 141 PA #5cosmo5555No ratings yet

- Valvula Compuerta NibcoDocument1 pageValvula Compuerta NibcoRobertoNo ratings yet

- Ductile Iron Gate ValveDocument4 pagesDuctile Iron Gate ValveShuvro Soikot0% (1)

- 300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureDocument1 page300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureayaNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- Valvula OS&Y 2-1.2 y Mas (175 Psi WWP)Document1 pageValvula OS&Y 2-1.2 y Mas (175 Psi WWP)Paul Gide Lopez ZarateNo ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Compuerta RoscadaDocument1 pageCompuerta RoscadajuandenismamanihuancaNo ratings yet

- Nibco 14 and 16 Gate ValvesDocument1 pageNibco 14 and 16 Gate ValvesNarendra Reddy BhumaNo ratings yet

- F607OTSFP Válvula de Compuerta NibcoDocument1 pageF607OTSFP Válvula de Compuerta NibcoAlberth Rojas CastellanosNo ratings yet

- F 607 OtsDocument1 pageF 607 OtsLuis VazquezNo ratings yet

- Nibco 609Document1 pageNibco 609juanbcarrizales08No ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Ncmii AppnNo ratings yet

- Ficha NibcoDocument1 pageFicha NibcoMilagros Camacho HuizaNo ratings yet

- 250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureDocument1 page250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureStephanie AdkinsNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Valvula Compuerta F607RWSFPDocument1 pageValvula Compuerta F607RWSFPDonny Quispe SilvetsreNo ratings yet

- F 908 WDocument1 pageF 908 WHaythem AhmedNo ratings yet

- Valvula Check Wafer 250psiDocument1 pageValvula Check Wafer 250psiOscar Fernandez SanchezNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- GD486548NFPDocument1 pageGD486548NFPNoe ANo ratings yet

- Class 125 3% Nickel Iron Body Gate ValvesDocument1 pageClass 125 3% Nickel Iron Body Gate ValvesBureau VeritasNo ratings yet

- Valvula Globo en AnguloDocument1 pageValvula Globo en AnguloRobertoNo ratings yet

- Class 125 Iron Y-StrainerDocument1 pageClass 125 Iron Y-StrainerNarendra Reddy BhumaNo ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- Check Valves WaferDocument1 pageCheck Valves WaferwfjerrNo ratings yet

- Valvula Supervisada Ranurada GD47658NFPDocument1 pageValvula Supervisada Ranurada GD47658NFPOscar Fernandez SanchezNo ratings yet

- Valvula de Compuerta Crane 2.5Document1 pageValvula de Compuerta Crane 2.5Juan Arturo Hernandez RuizNo ratings yet

- Lead-Free 250 PSI WWP Iron Body Check Valves: Material ListDocument1 pageLead-Free 250 PSI WWP Iron Body Check Valves: Material ListArturo JimenezNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- T-413-B, Class 125 Bronze Check ValvesDocument1 pageT-413-B, Class 125 Bronze Check ValvesBalderas Rosas WilibaldoNo ratings yet

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- Ficha Tecnica de Valvula Tfp600alf Nibco LF No PBDocument1 pageFicha Tecnica de Valvula Tfp600alf Nibco LF No PBSantos Saba EffioNo ratings yet

- Class 150 Bronze Gate ValvesDocument1 pageClass 150 Bronze Gate Valvescristian villegasNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- Valvula Globo Ang Nibco - 230614 - 100826Document2 pagesValvula Globo Ang Nibco - 230614 - 100826Pedro Jose Garces AlarconNo ratings yet

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- Valv. Bola Bronce T580-85-70Document1 pageValv. Bola Bronce T580-85-70byron_a24No ratings yet

- Silent Check Valve W 960Document1 pageSilent Check Valve W 960eatsomethailandNo ratings yet

- F535S6F6BVDocument1 pageF535S6F6BVVictor Hugo ZabalaNo ratings yet

- Brass Ball Valves: Material ListDocument1 pageBrass Ball Valves: Material ListBrayan CJNo ratings yet

- Ball Valve TFP600ADocument1 pageBall Valve TFP600AGustavo J. RafaelNo ratings yet

- KT-403-WFP Bronze Check ValveDocument1 pageKT-403-WFP Bronze Check ValveIlyas sagriNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- TS413BIDocument1 pageTS413BILawrenceNo ratings yet

- Gate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesGate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsJavier Hinojosa Garrido LeccaNo ratings yet

- Flowcom - Bridada y BridadaDocument1 pageFlowcom - Bridada y BridadaErickNo ratings yet

- LDWD3510C8FPDocument1 pageLDWD3510C8FPanuarsgNo ratings yet

- T-29 & T-29-K - 200 PSI CWP Bronze Gate ValvesDocument1 pageT-29 & T-29-K - 200 PSI CWP Bronze Gate ValvesIlyas sagriNo ratings yet

- ECOLINE GL - 7247.11-10 - Type Series BookletDocument8 pagesECOLINE GL - 7247.11-10 - Type Series BookletpauloNo ratings yet

- KG-900-W-350 - 350 PSI CWP Iron Body Grooved Silent Check ValveDocument1 pageKG-900-W-350 - 350 PSI CWP Iron Body Grooved Silent Check ValveIlyas sagriNo ratings yet

- Gate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesGate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature Ratingsjaponesito01No ratings yet

- Butterfly ValveDocument1 pageButterfly ValveDnyaneshwar0% (1)

- Flowcom - Ranurada y RanuradaDocument1 pageFlowcom - Ranurada y RanuradaErickNo ratings yet

- CS Ball Valve TM-590Document1 pageCS Ball Valve TM-590Hector Dario Tobon BenjumeaNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- Class 125 Bronze Gate Valves: Material ListDocument1 pageClass 125 Bronze Gate Valves: Material ListJeffry GabilanNo ratings yet

- 856278 check swinDocument2 pages856278 check swinricardojavierjulca1130No ratings yet

- Butterfly ValvesDocument4 pagesButterfly ValvesrahulNo ratings yet

- Vacuum MicroelectronicsFrom EverandVacuum MicroelectronicsWei ZhuNo ratings yet

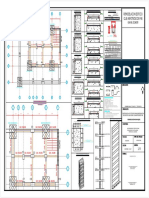

- Losa de Entre Piso - Bloque de Laboratorio - Nivel +4.48 (+15.16)Document1 pageLosa de Entre Piso - Bloque de Laboratorio - Nivel +4.48 (+15.16)stalin vNo ratings yet

- GA01 / GD01: Hernan TapiaDocument1 pageGA01 / GD01: Hernan Tapiastalin vNo ratings yet

- Losa de Cubierta - Bloque de Laboratorio - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en AtacamesDocument1 pageLosa de Cubierta - Bloque de Laboratorio - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Losa de Entre Piso - Bloque de Aulas - Nivel +4.48 (+15.16) : Instituto Superior Tecnológico en AtacamesDocument1 pageLosa de Entre Piso - Bloque de Aulas - Nivel +4.48 (+15.16) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Losa de Cubierta - Bloque de Aulas - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en AtacamesDocument1 pageLosa de Cubierta - Bloque de Aulas - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Commercial Catalogue Jib Cranes Low ResDocument32 pagesCommercial Catalogue Jib Cranes Low Resstalin vNo ratings yet

- CUADRO DE VIGAS LOSA +10.12 (+20.80) : Instituto Superior Tecnológico en AtacamesDocument1 pageCUADRO DE VIGAS LOSA +10.12 (+20.80) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Tolva AutovolteoDocument1 pageTolva Autovolteostalin vNo ratings yet

- Guayas, Ecuador: Remodelacion Edificio Club Aerotecnicos FaeDocument1 pageGuayas, Ecuador: Remodelacion Edificio Club Aerotecnicos Faestalin vNo ratings yet

- Table 2-3 Rated Lifting Weight of Main Cargo Boom of QY50C Crane (Unit: KG)Document5 pagesTable 2-3 Rated Lifting Weight of Main Cargo Boom of QY50C Crane (Unit: KG)stalin vNo ratings yet

- Applied Sciences: Perspective On Double Pulsed Gas Metal Arc WeldingDocument18 pagesApplied Sciences: Perspective On Double Pulsed Gas Metal Arc Weldingstalin vNo ratings yet

- Sistema Diesel 1 PDFDocument13 pagesSistema Diesel 1 PDFstalin vNo ratings yet

- PH Project Meeting MintuesDocument2 pagesPH Project Meeting Mintuesstalin vNo ratings yet

- P2020-0001-M-001 Rev CDocument1 pageP2020-0001-M-001 Rev Cstalin vNo ratings yet

- Datasheet: IN LINE Range of Deflagration Flame ArrestersDocument1 pageDatasheet: IN LINE Range of Deflagration Flame Arrestersstalin vNo ratings yet

- Datasheet: END OF LINE Range of Deflagration Flame ArrestersDocument1 pageDatasheet: END OF LINE Range of Deflagration Flame Arrestersstalin vNo ratings yet

- Hoja para EstimarDocument15 pagesHoja para Estimarstalin vNo ratings yet

- DU BushesDocument56 pagesDU BushesBlashko GjorgjievNo ratings yet

- Lesson-1-3 (CE 321C)Document81 pagesLesson-1-3 (CE 321C)Andjie LeeNo ratings yet

- Ornek WPS (ASME IX)Document1 pageOrnek WPS (ASME IX)kaynakteknolojiNo ratings yet

- GP 09-04-01Document31 pagesGP 09-04-01Anbarasan Perumal100% (1)

- Strategic Planning of Steel IndustryDocument122 pagesStrategic Planning of Steel Industrysachin1065100% (2)

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Document116 pagesCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangNo ratings yet

- Heat Input RecordDocument1 pageHeat Input RecordBOBNo ratings yet

- Scope TC 7845Document35 pagesScope TC 7845Venky ChbNo ratings yet

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UNo ratings yet

- 516 Vs 515Document2 pages516 Vs 515Madan YadavNo ratings yet

- DSM-0302.1 Am 15-5PH SSDocument3 pagesDSM-0302.1 Am 15-5PH SSadrianosoNo ratings yet

- Specification.: Steel ScrapDocument24 pagesSpecification.: Steel ScrapKalpeshNo ratings yet

- Allied International - BrochureDocument24 pagesAllied International - Brochurekhan4luvNo ratings yet

- A675/A675MDocument5 pagesA675/A675Mpavan_joshi_5100% (1)

- Evaporation Crystallization GPCVC0Document2 pagesEvaporation Crystallization GPCVC0Todor JivkovNo ratings yet

- Welding MIL STD PDFDocument157 pagesWelding MIL STD PDFAnonymous L0ChmPGNo ratings yet

- TemperingDocument14 pagesTemperingAdibah AliasNo ratings yet

- Discuss and Sharing CSWIP 3.1 (Duties and TerminologyDocument48 pagesDiscuss and Sharing CSWIP 3.1 (Duties and Terminologyuntoro firdausNo ratings yet

- East SinghbhumDocument12 pagesEast SinghbhumadhunikmicaNo ratings yet

- Spot Welding PDFDocument6 pagesSpot Welding PDFjames.anitNo ratings yet

- Lowara z8 z10 z12 Technical Datasheet PDFDocument108 pagesLowara z8 z10 z12 Technical Datasheet PDFArif MahendraNo ratings yet

- Surface Preparation and Protective Coating Procedure (R03) CivilDocument116 pagesSurface Preparation and Protective Coating Procedure (R03) CivilMogul KhanNo ratings yet

- SS012-22-FAB-007-Rev CDocument1 pageSS012-22-FAB-007-Rev Cayman sharafNo ratings yet

- Interstitial Free Steels - IspatGuruDocument6 pagesInterstitial Free Steels - IspatGuruSilverio AcuñaNo ratings yet

- (R) Terminal Report. (Workshop On Maintenance and Manufacturing of Permanent Way (Railway) Material) (19423.en)Document53 pages(R) Terminal Report. (Workshop On Maintenance and Manufacturing of Permanent Way (Railway) Material) (19423.en)Ahmed GamalNo ratings yet

- Enabling Lightweight Design Structural Tapes Patches PresentationDocument30 pagesEnabling Lightweight Design Structural Tapes Patches Presentationjasonguo901No ratings yet

- Non Ferrous Metals and Alloys CH5 DDUDocument97 pagesNon Ferrous Metals and Alloys CH5 DDUPratik ThakerNo ratings yet

- 2 - 2011 570 Closed Book Exam (75Qs)Document15 pages2 - 2011 570 Closed Book Exam (75Qs)Sunny Thundil100% (3)

- Practical Data For MetallurgistsDocument37 pagesPractical Data For MetallurgistsmetallurgistNo ratings yet

250 PSI WWP Iron Body Gate Valves

250 PSI WWP Iron Body Gate Valves

Uploaded by

stalin vOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

250 PSI WWP Iron Body Gate Valves

250 PSI WWP Iron Body Gate Valves

Uploaded by

stalin vCopyright:

Available Formats

www.nibco.

com

AHEAD OF THE F L O W® Revision 4/20/2009

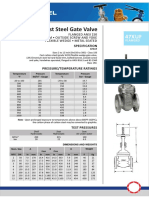

250 PSI WWP Iron Body Gate Valves

Fire Protection Valve • Outside Screw and Yoke • Resilient Wedge •

Epoxy Coated Interior/Exterior • Pre-Grooved Stem for Supervisory Switch •

Drilled, Tapped and Plugged at Boss Location A**

250 PSI/17.2 Bar Non-Shock Cold Working Pressure

(160º F/71º C max. operating temperature)

UL/ULC LISTED • FM APPROVED •

AWWA C509 & 515 •NEW YORK CITY

M.E.A. APPROVED 236-93E

MATERIAL LIST

PART SPECIFICATION

1. Valve Body Ductile Iron ASTM A 536

2. Resilient Wedge Ductile Iron ASTM A 536/EPDM ASTM D 2000 F-607-RW

3. Wedge Nut Bronze ASTM B 584 UNS C83600 Flanged

4. Dowel Pin Stainless Steel ASTM A 276 UNS S42000

5. Stem Back Seat O-Ring EPDM ASTM D 2000

6. Bonnet Gasket EPDM ASTM D 2000

7. Bonnet Ductile Iron ASTM A 536

8. Stem Packing EPDM ASTM D 2000

9. Threaded Rod Carbon Steel Zinc Plated

10. Gland Bushing Bronze ASTM B 584

11. Gland Cast Iron ASTM A 126-B

12. Gland Nut Stainless Steel 18-8

13. Yoke Screw Alloy Steel ASTM A 574M Zinc Plated

14. Yoke Cast Iron ASTM A 126-B

15. Yoke Bushing Bronze ASTM B 584

16. Flat Point Set Screw Alloy Steel ASTM F 912M Black Oxide

17. Yoke Bushing Retainer Cast Iron ASTM A 126-B

18. Handwheel Ductile Iron ASTM A 536

19. Handwheel Nut Carbon Steel Zinc Plated

20. Flat Head Screw Carbon Steel Zinc Plated

21. Stem Bronze ASTM B 150 UNS C61400

22. Bonnet Screw Alloy Steel ASTM A 574M Zinc Plated

23. NPT Pipe Plug Malleable Iron ANSI B16.3 (Epoxy Coated)

24. UL/FM Label (not shown) Aluminum

F-607-RW

* Electrostatically applied fusion-bonded epoxy coated inside and outside per AWWA C-550.

Flg x Flg

Epoxy NSF and FDA certification

** Drilled, tapped and plugged at Position A with ¹⁄₂" valve sizes 2¹⁄₂"–4",

³⁄₄" on 6"–8", 1" on 10"–12".

NOTE: Valve flanges are consistent with ANSI B16.1 Class 125.

DIMENSIONS—WEIGHTS—QUANTITIES

Dimensions Bolt

Size A B Open B Closed C D E F G Circle Flange Turns Weight

In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. Holes To Open Lbs. Kg.

2¹⁄₂ 65 7.5 190 17.8 453 14.9 378 0.69 17.5 7.0 178 7.9 200 1.50 38 1.6 40 5.50 140 4 8.8 45 20

3 80 8.0 203 19.7 500 15.9 405 0.75 19.0 7.5 191 7.9 200 1.73 44 2.1 54 6.00 152 4 10.5 53 24

4 100 9.0 229 21.0 534 16.6 422 0.94 24.0 9.0 229 10.2 260 2.13 54 2.1 54 7.50 191 8 10.4 94 43

6 150 10.5 267 29.3 744 22.9 581 1.00 25.4 11.0 279 12.4 315 2.24 57 2.5 64 9.50 241 8 15.7 154 70

8 200 11.5 292 37.0 939 28.5 724 1.13 28.6 13.5 343 14.8 375 2.48 63 2.8 70 11.75 298 8 17.2 247 112

10 250 13.0 330 44.8 1139 34.5 877 1.19 30.2 16.0 406 16.4 416 2.56 65 2.8 70 14.25 362 12 21.4 349 159

12 300 14.0 356 52.2 1326 39.9 1014 1.25 31.8 19.0 483 17.5 445 2.91 74 3.4 86 17.00 432 12 25.5 484 220

FREEZING WEATHER PRECAUTION: Subsequent to

testing a piping system, valves should be left in an

open position to allow complete drainage.

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

22 TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.336.4226 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

You might also like

- Wps 141 PA #5Document2 pagesWps 141 PA #5cosmo5555No ratings yet

- Valvula Compuerta NibcoDocument1 pageValvula Compuerta NibcoRobertoNo ratings yet

- Ductile Iron Gate ValveDocument4 pagesDuctile Iron Gate ValveShuvro Soikot0% (1)

- 300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureDocument1 page300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureayaNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- Valvula OS&Y 2-1.2 y Mas (175 Psi WWP)Document1 pageValvula OS&Y 2-1.2 y Mas (175 Psi WWP)Paul Gide Lopez ZarateNo ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Compuerta RoscadaDocument1 pageCompuerta RoscadajuandenismamanihuancaNo ratings yet

- Nibco 14 and 16 Gate ValvesDocument1 pageNibco 14 and 16 Gate ValvesNarendra Reddy BhumaNo ratings yet

- F607OTSFP Válvula de Compuerta NibcoDocument1 pageF607OTSFP Válvula de Compuerta NibcoAlberth Rojas CastellanosNo ratings yet

- F 607 OtsDocument1 pageF 607 OtsLuis VazquezNo ratings yet

- Nibco 609Document1 pageNibco 609juanbcarrizales08No ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Ncmii AppnNo ratings yet

- Ficha NibcoDocument1 pageFicha NibcoMilagros Camacho HuizaNo ratings yet

- 250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureDocument1 page250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureStephanie AdkinsNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Valvula Compuerta F607RWSFPDocument1 pageValvula Compuerta F607RWSFPDonny Quispe SilvetsreNo ratings yet

- F 908 WDocument1 pageF 908 WHaythem AhmedNo ratings yet

- Valvula Check Wafer 250psiDocument1 pageValvula Check Wafer 250psiOscar Fernandez SanchezNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- GD486548NFPDocument1 pageGD486548NFPNoe ANo ratings yet

- Class 125 3% Nickel Iron Body Gate ValvesDocument1 pageClass 125 3% Nickel Iron Body Gate ValvesBureau VeritasNo ratings yet

- Valvula Globo en AnguloDocument1 pageValvula Globo en AnguloRobertoNo ratings yet

- Class 125 Iron Y-StrainerDocument1 pageClass 125 Iron Y-StrainerNarendra Reddy BhumaNo ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- Check Valves WaferDocument1 pageCheck Valves WaferwfjerrNo ratings yet

- Valvula Supervisada Ranurada GD47658NFPDocument1 pageValvula Supervisada Ranurada GD47658NFPOscar Fernandez SanchezNo ratings yet

- Valvula de Compuerta Crane 2.5Document1 pageValvula de Compuerta Crane 2.5Juan Arturo Hernandez RuizNo ratings yet

- Lead-Free 250 PSI WWP Iron Body Check Valves: Material ListDocument1 pageLead-Free 250 PSI WWP Iron Body Check Valves: Material ListArturo JimenezNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- T-413-B, Class 125 Bronze Check ValvesDocument1 pageT-413-B, Class 125 Bronze Check ValvesBalderas Rosas WilibaldoNo ratings yet

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- Ficha Tecnica de Valvula Tfp600alf Nibco LF No PBDocument1 pageFicha Tecnica de Valvula Tfp600alf Nibco LF No PBSantos Saba EffioNo ratings yet

- Class 150 Bronze Gate ValvesDocument1 pageClass 150 Bronze Gate Valvescristian villegasNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- Valvula Globo Ang Nibco - 230614 - 100826Document2 pagesValvula Globo Ang Nibco - 230614 - 100826Pedro Jose Garces AlarconNo ratings yet

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- Valv. Bola Bronce T580-85-70Document1 pageValv. Bola Bronce T580-85-70byron_a24No ratings yet

- Silent Check Valve W 960Document1 pageSilent Check Valve W 960eatsomethailandNo ratings yet

- F535S6F6BVDocument1 pageF535S6F6BVVictor Hugo ZabalaNo ratings yet

- Brass Ball Valves: Material ListDocument1 pageBrass Ball Valves: Material ListBrayan CJNo ratings yet

- Ball Valve TFP600ADocument1 pageBall Valve TFP600AGustavo J. RafaelNo ratings yet

- KT-403-WFP Bronze Check ValveDocument1 pageKT-403-WFP Bronze Check ValveIlyas sagriNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- TS413BIDocument1 pageTS413BILawrenceNo ratings yet

- Gate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesGate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsJavier Hinojosa Garrido LeccaNo ratings yet

- Flowcom - Bridada y BridadaDocument1 pageFlowcom - Bridada y BridadaErickNo ratings yet

- LDWD3510C8FPDocument1 pageLDWD3510C8FPanuarsgNo ratings yet

- T-29 & T-29-K - 200 PSI CWP Bronze Gate ValvesDocument1 pageT-29 & T-29-K - 200 PSI CWP Bronze Gate ValvesIlyas sagriNo ratings yet

- ECOLINE GL - 7247.11-10 - Type Series BookletDocument8 pagesECOLINE GL - 7247.11-10 - Type Series BookletpauloNo ratings yet

- KG-900-W-350 - 350 PSI CWP Iron Body Grooved Silent Check ValveDocument1 pageKG-900-W-350 - 350 PSI CWP Iron Body Grooved Silent Check ValveIlyas sagriNo ratings yet

- Gate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesGate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature Ratingsjaponesito01No ratings yet

- Butterfly ValveDocument1 pageButterfly ValveDnyaneshwar0% (1)

- Flowcom - Ranurada y RanuradaDocument1 pageFlowcom - Ranurada y RanuradaErickNo ratings yet

- CS Ball Valve TM-590Document1 pageCS Ball Valve TM-590Hector Dario Tobon BenjumeaNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- Class 125 Bronze Gate Valves: Material ListDocument1 pageClass 125 Bronze Gate Valves: Material ListJeffry GabilanNo ratings yet

- 856278 check swinDocument2 pages856278 check swinricardojavierjulca1130No ratings yet

- Butterfly ValvesDocument4 pagesButterfly ValvesrahulNo ratings yet

- Vacuum MicroelectronicsFrom EverandVacuum MicroelectronicsWei ZhuNo ratings yet

- Losa de Entre Piso - Bloque de Laboratorio - Nivel +4.48 (+15.16)Document1 pageLosa de Entre Piso - Bloque de Laboratorio - Nivel +4.48 (+15.16)stalin vNo ratings yet

- GA01 / GD01: Hernan TapiaDocument1 pageGA01 / GD01: Hernan Tapiastalin vNo ratings yet

- Losa de Cubierta - Bloque de Laboratorio - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en AtacamesDocument1 pageLosa de Cubierta - Bloque de Laboratorio - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Losa de Entre Piso - Bloque de Aulas - Nivel +4.48 (+15.16) : Instituto Superior Tecnológico en AtacamesDocument1 pageLosa de Entre Piso - Bloque de Aulas - Nivel +4.48 (+15.16) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Losa de Cubierta - Bloque de Aulas - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en AtacamesDocument1 pageLosa de Cubierta - Bloque de Aulas - Nivel +8.82 (+19.50) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Commercial Catalogue Jib Cranes Low ResDocument32 pagesCommercial Catalogue Jib Cranes Low Resstalin vNo ratings yet

- CUADRO DE VIGAS LOSA +10.12 (+20.80) : Instituto Superior Tecnológico en AtacamesDocument1 pageCUADRO DE VIGAS LOSA +10.12 (+20.80) : Instituto Superior Tecnológico en Atacamesstalin vNo ratings yet

- Tolva AutovolteoDocument1 pageTolva Autovolteostalin vNo ratings yet

- Guayas, Ecuador: Remodelacion Edificio Club Aerotecnicos FaeDocument1 pageGuayas, Ecuador: Remodelacion Edificio Club Aerotecnicos Faestalin vNo ratings yet

- Table 2-3 Rated Lifting Weight of Main Cargo Boom of QY50C Crane (Unit: KG)Document5 pagesTable 2-3 Rated Lifting Weight of Main Cargo Boom of QY50C Crane (Unit: KG)stalin vNo ratings yet

- Applied Sciences: Perspective On Double Pulsed Gas Metal Arc WeldingDocument18 pagesApplied Sciences: Perspective On Double Pulsed Gas Metal Arc Weldingstalin vNo ratings yet

- Sistema Diesel 1 PDFDocument13 pagesSistema Diesel 1 PDFstalin vNo ratings yet

- PH Project Meeting MintuesDocument2 pagesPH Project Meeting Mintuesstalin vNo ratings yet

- P2020-0001-M-001 Rev CDocument1 pageP2020-0001-M-001 Rev Cstalin vNo ratings yet

- Datasheet: IN LINE Range of Deflagration Flame ArrestersDocument1 pageDatasheet: IN LINE Range of Deflagration Flame Arrestersstalin vNo ratings yet

- Datasheet: END OF LINE Range of Deflagration Flame ArrestersDocument1 pageDatasheet: END OF LINE Range of Deflagration Flame Arrestersstalin vNo ratings yet

- Hoja para EstimarDocument15 pagesHoja para Estimarstalin vNo ratings yet

- DU BushesDocument56 pagesDU BushesBlashko GjorgjievNo ratings yet

- Lesson-1-3 (CE 321C)Document81 pagesLesson-1-3 (CE 321C)Andjie LeeNo ratings yet

- Ornek WPS (ASME IX)Document1 pageOrnek WPS (ASME IX)kaynakteknolojiNo ratings yet

- GP 09-04-01Document31 pagesGP 09-04-01Anbarasan Perumal100% (1)

- Strategic Planning of Steel IndustryDocument122 pagesStrategic Planning of Steel Industrysachin1065100% (2)

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Document116 pagesCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangNo ratings yet

- Heat Input RecordDocument1 pageHeat Input RecordBOBNo ratings yet

- Scope TC 7845Document35 pagesScope TC 7845Venky ChbNo ratings yet

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UNo ratings yet

- 516 Vs 515Document2 pages516 Vs 515Madan YadavNo ratings yet

- DSM-0302.1 Am 15-5PH SSDocument3 pagesDSM-0302.1 Am 15-5PH SSadrianosoNo ratings yet

- Specification.: Steel ScrapDocument24 pagesSpecification.: Steel ScrapKalpeshNo ratings yet

- Allied International - BrochureDocument24 pagesAllied International - Brochurekhan4luvNo ratings yet

- A675/A675MDocument5 pagesA675/A675Mpavan_joshi_5100% (1)

- Evaporation Crystallization GPCVC0Document2 pagesEvaporation Crystallization GPCVC0Todor JivkovNo ratings yet

- Welding MIL STD PDFDocument157 pagesWelding MIL STD PDFAnonymous L0ChmPGNo ratings yet

- TemperingDocument14 pagesTemperingAdibah AliasNo ratings yet

- Discuss and Sharing CSWIP 3.1 (Duties and TerminologyDocument48 pagesDiscuss and Sharing CSWIP 3.1 (Duties and Terminologyuntoro firdausNo ratings yet

- East SinghbhumDocument12 pagesEast SinghbhumadhunikmicaNo ratings yet

- Spot Welding PDFDocument6 pagesSpot Welding PDFjames.anitNo ratings yet

- Lowara z8 z10 z12 Technical Datasheet PDFDocument108 pagesLowara z8 z10 z12 Technical Datasheet PDFArif MahendraNo ratings yet

- Surface Preparation and Protective Coating Procedure (R03) CivilDocument116 pagesSurface Preparation and Protective Coating Procedure (R03) CivilMogul KhanNo ratings yet

- SS012-22-FAB-007-Rev CDocument1 pageSS012-22-FAB-007-Rev Cayman sharafNo ratings yet

- Interstitial Free Steels - IspatGuruDocument6 pagesInterstitial Free Steels - IspatGuruSilverio AcuñaNo ratings yet

- (R) Terminal Report. (Workshop On Maintenance and Manufacturing of Permanent Way (Railway) Material) (19423.en)Document53 pages(R) Terminal Report. (Workshop On Maintenance and Manufacturing of Permanent Way (Railway) Material) (19423.en)Ahmed GamalNo ratings yet

- Enabling Lightweight Design Structural Tapes Patches PresentationDocument30 pagesEnabling Lightweight Design Structural Tapes Patches Presentationjasonguo901No ratings yet

- Non Ferrous Metals and Alloys CH5 DDUDocument97 pagesNon Ferrous Metals and Alloys CH5 DDUPratik ThakerNo ratings yet

- 2 - 2011 570 Closed Book Exam (75Qs)Document15 pages2 - 2011 570 Closed Book Exam (75Qs)Sunny Thundil100% (3)

- Practical Data For MetallurgistsDocument37 pagesPractical Data For MetallurgistsmetallurgistNo ratings yet