Professional Documents

Culture Documents

Handloom Clusters - Critique 2011

Handloom Clusters - Critique 2011

Uploaded by

Narasimha Reddy DonthiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handloom Clusters - Critique 2011

Handloom Clusters - Critique 2011

Uploaded by

Narasimha Reddy DonthiCopyright:

Available Formats

Integrated Handloom Cluster Development Programme

Is it responding to the learning’s from UNIDO Approach?

Introduction

The profound political and economic changes that have taken place over the last decade

pose serious challenges for governments, private business, and the civil society. The

conversion of command systems to more open markets and the restructuring of

enterprises, with the consequent need to find employment outside big government and

large corporations, have given rise to a tide of entrepreneurism.

Times change so rapidly and running a business is so complex these days that owner-

managers can easily find things getting out of control if adequate planning and control are

not undertaken and implemented. Competition seems to be getting tougher all the time. In

most cases, small businesses find themselves competing with much larger companies -

ones that know the benefits of long range planning and practice it. Yet, case studies have

emerged from various parts of the world showing that clusters of small enterprises have

broken into international markets. The best-known cases are the Italian industrial districts

and similar cases come from other advanced countries. But perhaps the most interesting

come from less developed countries. For example, Brazil is today a major shoe exporter.

Pakistan is today one of the world's main exporters of surgical instruments.

Integrated Handloom Cluster Development Programme was taken up by the government

of India in the backdrop of crisis in handloom sector, marked by suicides by handloom

weavers, and subsequent advocacy by various individuals and institutions. It is also one

positive programme of the government aimed to help in the development of handloom

sector. Given the circumstances in which programme has been thought of, it is imperative

that one should look at how this programme is being organized.

Cluster Development Programme

The history of Cluster development programme can be traced to 1995 when UN

Industrial Development Organisation to strengthen the competitive advantage of SSI

clusters. From a UNIDO survey of the largest Indian clusters conducted in 1996 it

emerges that the majority of them comprise small-scale enterprises which perform the

entire production process in-house, and that subcontracting (to other small, medium or

large-scale firms) is relatively less frequent. It is estimated that over 60% of the Indian

manufacturing exports are generated by clusters (UNIDO, 1997).

The Abid Hussain ‘Expert Committee on Small Enterprises’ constituted by the

Government of India in December 1995) explicitly endorsed cluster support initiatives.

Subsequently, UNIDO was requested by government to promote pilot projects in selected

clusters, and to help the Ministry formulate a national cluster development programme.

The initial project had a proposed duration of four years but was later extended to seven

years (1997-2002).

1 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

What is a cluster?

Small-scale enterprises (SSEs) operating in the same or in related industrial sectors tend

to cluster close to one another (Sengenberger, Loveman, and Piore, 1990). This tendency

to bunch in well-defined areas, often called clusters or industrial districts, has been

observed in different environments in both developed and developing countries, and in

different historical periods (Sabel, 1989; Marshall, 1990; UNIDO, 1995). SSEs operating

in such clusters derive a clear competitive advantage from:

• Proximity to sources of raw inputs

• Availability of suitably customised business development services (BDS)

• Abundance of clients attracted by the cluster tradition in that industry

• Presence of a skilled labour force

In India, numerous clusters have been found to operate in the machinery, textile, food

processing and chemical sectors. The UNIDO Survey identified 350 SSE clusters. This

figure does not include the craft-based clusters the total number of which is

approximately 2,000.

Cluster Approach

The cluster approach has been developed to address knowledge fragmentation, lack of

coordination and joint action. It is based upon the realization that the lack of

communication among the various cluster actors and their skepticism towards joint

endeavors are deeply entrenched within traditional business practices and that the latter

cannot be replaced without the investment of significant resources.

Traditional Indian clusters are characterized by environments where information does not

flow easily and where the various actors are not accustomed to talking with each other.

Entrepreneurs in Indian clusters rarely, if ever, meet each other, do not usually have

ongoing relationships with Business Development Service (BDS) providers and are not

accustomed to presenting articulated calls for actions to the local policy makers. These

clusters are often characterized by extremely fragmented knowledge, latent conflicts, and

an absence of discussion forums. The units in these clusters therefore have very poor

perceptions about the feasibility of joint actions.

It emphasizes the three phases which each cluster project is expected to undergo over the

lifetime of the UNIDO support initiative, namely:

1. Preparation of a diagnostic study and formulation of a cluster action plan

2. Implementation of pilot and strategic projects

3. The self-management phase

Activities or outcomes would include initiatives to build awareness and trust,

dissemination of best practices, creation of suitable discussion forums and, ultimately, of

a governance framework for the cluster as a whole. However, these are not only subject

2 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

to a high degree of uncertainty but are also largely indivisible and non-excludable (i.e.

once provided, are available to all).

The cluster approach aims to achieve these outcomes by helping the various cluster actors

to develop a consensus-based vision for the cluster as a whole and by strengthening their

capacity to act upon such vision. The first component is aimed mainly at reducing the

fragmentation of knowledge, but also provides an extremely valuable opportunity to draw

attention to a common and often very innovative agenda, so that each cluster actor (and,

above all, each SSE owner) has an opportunity to test the reliability and trustworthiness

of its partners on “fresh” ground. The second component aims at enabling the various

cluster actors to overcome traditional practices and put in place a sustainable,

autonomous governance framework which is expected to keep dynamizing the local

economy long after UNIDO will have withdrawn from the cluster.

A key tool for cluster development is the diagnostic study. This study gathers previously

dispersed and fragmented knowledge about the economic and social conditions of the

cluster and its development potential, as well as the state of inter-firm relationships and

the existing institutional support mechanisms.

The elaboration of an action plan is meant as the initial step to the development of pilot

projects where groups of are formed and specific initiatives are formulated and

implemented. During this phase, cooperation starts bearing concrete results to the

participating weavers. The initiatives are generally of a commercial and/or promotional

nature (e.g. joint participation in fairs, joint purchase of raw materials, design of a

collective catalogue). The idea is to generate visible results (although of a short-term

nature) to engender optimism and trust. At the same time, the pilot projects consolidate

willingness of the networks and associations to undertake long-term strategic initiatives

around an increasingly shared vision for the cluster as a whole.

These projects generally entail an increase in the degree of specialization by process

and/or product of the firms involved (e.g. restructuring or creation of common service

facilities, new product lines, common brands). At this stage the involvement of both

technical and financial institutions becomes essential and the initiatives are meant to

contribute more directly to the creation of capacities at the cluster level. UNIDO

therefore tried to ensure that the networks/associations supported by the projects can

draw assistance from the available institutions. This task often implies upgrading the

capacity of Business Development Service (BDS) providers or even initiating their

establishment, especially in clusters characterized by a relatively weak support

framework.

Finally, the intervention gives way to a self-management phase, as the networks/

associations gain greater autonomy from CDP (cluster development programme)

assistance and the capacity to undertake further joint activities independently. During this

phase it can be tested if the earlier investment on vision- and capacity-building has

delivered the expected results and if the cluster approach has won the endorsement of the

various cluster actors. Self-management is not always easily achieved. Often the

3 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

networks/associations tend to lean on CDPs assistance for a longer time than initially

envisaged. In order to avoid dependency the work plan established by the network

members and the Focal Point must have a specific time frame. The cluster actors thus

know from the beginning that they can count on assistance only for a limited period of

time. As the various networks/associations develop, CDPs intervention shifts towards

softer coordination, ensuring a progressive transfer of responsibilities to the cluster

actors.

Handloom Cluster Development Programme

The Working Group for the X Five Year Plan had proposed focus on cluster development

in handloom sector. However, this was taken up only towards the end of the Tenth Five

Year Plan. Finance Minister in his budget speech for the financial year 2005-06 stated

that: "The Government proposes to adopt the cluster development approach for the

production and marketing of handloom products. The Ministry of Textiles will take up 20

clusters in the first phase at a cost of Rs.40 crore, and the amount will be provided during

the course of the year".

Initially 20 clusters were selected across India on the basis of their uniqueness of design

and product, capacity to cater to a niche market as well as resilience to survive in a

fiercely competitive environment. This scheme defined handloom cluster as a place

where there is a large concentration of handlooms producing fabrics of niche varieties on

Handlooms which are in demand in the market. These handlooms could be located in

close proximity in two adjoining revenue sub-divisions within an administrative district

or across two (mostly adjoining) districts.

The main objectives of this Scheme are:

1. To empower handloom weavers and build their capacity to meet the challenges of

the market and global competition in a sustainable and self reliant manner;

2. To facilitate collectivization of handloom weavers and service providers for

procurement, production, marketing and other support activities to promote

sustainable growth and diversification;

3. To provide for common infrastructure and activities in a viable format in the

cluster.

4. To provide for development of handloom clusters in an inclusive and holistic

manner in an environment of empowered and participative decision making;

5. To encourage convergence of schematic assistance and support services from

various schemes and programmes of various government and other agencies in

the cluster to optimize resource utilization for betterment of the livelihood and

quality of life of handloom weavers.

However, the scheme despite the above objectives limits its support to the following:

o Assistance for setting up of Dyeing Unit, Common facility Centre, Quality

Control Lab & Setting up of Showroom

4 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

o Organisation/participation in Exhibitions/Fairs

o Organisation/participation in Buyer-Seller Meets, including inviting retailers &

Merchandisers etc.

o Assistance for publicity (printing of brochures, catalogues, documentation of

samples etc.), Developing frequently asked questionnaires etc

o Assistance for declaring the Cluster as Legal entity, it’s capacity building &

networking, strengthening of local associations, backward – forward linkages,

Brand Building etc.

o Assistance for organization of at least 20 workshops and seminars,

demonstrations etc. in 3 years

o Market Research & Technical Consultancy- for studying the market & technical

advice

o Engaging Designer for design input for diversification of products

o Institutional cost of implementing agency, including Enterprise up-gradation

programme, cluster visits, development of consortium, personal counseling,

intervention in the areas of occupational health/ergonomics etc.

o Operational Cost

o Fee for National Resource Agency for handloom cluster

The total budget for each cluster was worked out to Rs.2 crores. The above programme of

assistance presupposes that the objectives envisaged above would be achieved by

organizing a few workshops/seminars, and engagement of a designer. As it is most of the

Rs.2 crores to be invested per cluster relates to administration and consultancies. With

complete dearth of trained capacity (with knowledge and skills related to each identified

handloom product), and information on the particular products, this scheme intends to

enable the empowerment of the weavers in the market.

UNIDO experience identifies diagnostic study as the key tool for cluster development.

Majority of the diagnostic studies on the 20 clusters do not make the mark at all. Thus,

the handloom cluster development programme is now balanced on diagnostic studies,

which do not have either information or detailed analysis of the problems in the particular

cluster. Most of the studies do not rise above the standards of administrative reports

prepared by government functionaries. UNIDO further said that ‘the diagnostic study also

provides a valuable opportunity to enforce awareness about the approach and to promote

trust among the cluster actors. Moreover, it helps to identify potential leaders from within

the cluster and, more generally, suitable counterparts to assist implementation’. However,

this did not happen in the IHCDP scheme. In many places, leaving alone the weavers,

their representatives in various forms, were not aware of the process of the diagnostic

study. Thus, this scheme has lost an opportunity.

UNIDO says the diagnostic phase ends with the preparation of a broad action plan for the

cluster. This document offers a vision around which to gather the support and

collaboration of the various cluster actors. The preparation of such a plan is the essential

first step in developing long-term local capacities for responding to evolving economic

and technical circumstances, rather than as a once-for-all prescription.

5 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

In IHCDP, the action plans developed from the diagnostic studies are mere one-page

tables. These tables simply list activities and the budgets required. These action plans are

nowhere near to offer a vision of development for each cluster.

The first draft of the cluster action plan, according to UNIDO, is a working document

which must be revised as more information about the cluster is disclosed and on the basis

of the results of the initial interventions. Nevertheless, it is expected that the information

gained as a result of the diagnostic study and the joint preparation of the action plan

(especially concerning the competitive position of the cluster in the national and

international market) will suffice to identify the potentialities of the cluster as well as the

key obstacles which prevent it from taking up the opportunities provided by the

globalization of the Indian economy. As these obstacles are identified, a key task of the

Focal Point is to help the partner institutions to prioritize them (both in terms of their

importance and the capacity of the cluster actors to jointly tackle them) and to identify

the initiatives which can overcome these obstacles including the utilization of existing

BDS and the development of new ones.

However, such a process is not being followed in the IHCDP programme. As a result, the

action plans developed for development in each cluster, end up merely doing the same as

before. Ministry of Textiles, through Office of DCH, has been implementing certain

schemes related to markets, designs and cooperatives. The action plans of each cluster

simply repeat the same pattern of activities. Thus, no positive results are likely from this

IHCDP. However, expenditure on the programmes is happening. None of the cluster

development programme in 20 clusters is moving towards the envisaged objectives.

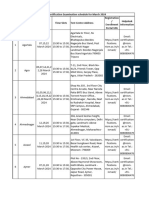

Expenditure and Activity analysis

Two activities have been identified under ‘dissemination of information’, in this

programme, namely awareness meetings and baseline survey. Among 17 clusters, whose

action plans are available, except in Nadia and Trichy, awareness meetings were

organized in all. One is not sure how many meetings were organized, what was the

content of the meetings, participant levels and profile etc. However, the expenditure on

awareness meetings varies from as low as Rs.20,000 to as high as Rs.2,00,000. Also, the

expenditure on baseline survey varies from Rs.50,000 to Rs.2,00,000.

Under market linkages, six activities were identified, namely Export procedure training,

Exposure visit, Buyers-Sellers Meet, Exhibitions outside cluster, Product catalogue

development and study on handloom markets. All the clusters organized exhibitions.

Majority of them did organize buyers-sellers meet, and product catalogue development.

Such achievements show that Focal points are doing what they know and can do the best,

and not activities that are required.

Under financial linkages, the only activity was meeting with bankers for finance. The

expenditure on this single activity varies from as low as Rs.9,000 to as high as

Rs.1,00,000. In some clusters, such meetings were held at all. Apart from the need for

6 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

such high expenditures on meetings with bankers, one need to question what purpose

such meetings have.

Under product development, three kinds of activities were done – engaging designer, skill

upgradation training and workshop on value addition. This activity presupposes that

product development can happen only by appointing an external designer and paying

them exorbitant contracts. Government was doing similar activities before through

National Institute of Fashion Technology, with poor results. Training programmes are

organized without any information or expertise development. It is unbelievable that

without basic knowledge of the handloom product this programme found it necessary to

organize skill upgradation programme for skilled weavers.

Under quality upgradation, two activities were taken up such as orientation workshop on

dyes and workshop for dyers. Thus, this programme seems to believe that quality

upgradation would happen through workshops. There are many issues which impinge on

the quality of handloom products. This programme merely addresses the capacity issues.

However, one is not sure what kind of information database on dyes and dyes procedures

these workshops depend on, to pass onto their clientele weavers.

Total expenditure in all the clusters over a period of one year, by 31st March, 2007, was

Rs.1.66 crores. However, expenditure varies in each cluster. Maximum expenditure of

Rs.18 lakhs was in Imphal and the lowest expenditure of Rs.1 lakh in Nadia.

However, in many places, Focal points of respective clusters seem to have problems in

expending the funds allocated. The expenditure is way below the action plans submitted

by them. Many could not complete the activities they promised to do. Expenditure was

haphazard. There is no uniformity. Expenditure on some activities was higher than

necessary.

Though the entire programme was planned to enable the development of handloom

weavers, most of the funds do not help in building physical assets, nor do they ‘touch’ the

weavers. Most funds are spent on meetings and workshops, with obviously no definite

outcomes.

It is known that women constitute more than 60 percent of the labour force in handloom

sector. However, there is no specific focus on enabling participation of women in

handloom cluster development programme.

Conclusion

Here we are concerned with the ability of handloom sector to grow and to export. More

precisely, the purpose is to present some conceptual and theoretical ideas which help to

analyse and explain their success. The objective is more about prompting a debate on

cluster development programme. There is a need to build a bridge with mainstream

economics which, with few exceptions, has ignored the connection between clustering

7 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

and growth. Low wages have helped the clusters in India, but increasing returns to scale

and product differentiation are essential to explain their exports.

A failure of the IHCD programme, ensured by lack of application, shoddy procedures and

improper studies, is likely to be seen as the failure of the handloom sector and not

necessarily attributed to the inability of the implementing agencies. If it happens, once

again, handloom weavers are likely to be blamed for failures of the government. Policy

makers, especially bureaucrats, from this failure would convince themselves that

handloom weavers are rigid and not ready for change. They would opine that ‘it is time

that the government moved on from handloom to more modern textile mills’.

Design and implementation of IHCDP is probably meant to make this a failure, given the

control of anti-handloom lobby in the Ministry of Textiles. There is also definite

downsizing of the investment on this programme. For 20 clusters, government promised

Rs.40 crores in 2005-06, and Rs.50 crores for an additional 100 clusters in 2006-07. This

is one indication that there is not much interest in qualitative implementation of

handloom cluster development programme.

The IHCD project's purpose can be to improve the image of Indian handlooms as a

source of reliable producers of high-quality handloom products, an image which had been

tarnished in recent years by a preponderance of imitations; threatening the handloom

industry's capacity to respond to opportunities for growth. The project should address the

critical question of how to preserve the heritage of traditional labour-intensive handloom

techniques and its ethnic character, while demonstrating that high quality is not only to be

found in antiques or in fine reproductions, but also in contemporary objects. Handloom

products redefined as cultural products could open up perpetual possibilities for the

private sector, including the rural families, women and young people for whom this

industry has been an important source of employment.

Governments in Italy, Germany and Sweden have provided effective institutional support

and institutional networks to guarantee the success of small-scale enterprises. Experience

suggests that the services offered to such enterprises need to be accessible and provided

in an integrated manner. In other words, the provision of the tools for improving

productivity and quality cannot be isolated from the need for working capital. Secondly,

promotion efforts must not be exclusive to the Central Government, but must also be

made by State governments and local bodies, in a coordinated fashion.

Handloom clusters taken up after these initial 20 clusters require more modification, as

they have lesser resources, and have been working on short-term goals and objectives.

Both the government and implementing agencies do not show faith in cluster

development programmes, as a vehicle to resurrect handloom sector and the develop

fortunes for handloom weavers. Proper and a rigorous diagnostic study holds the key to

improvement of handloom cluster development programme.

8 Dr. D. Narasimha Reddy, E-mail: nreddy.donthi@gmail.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hindu Website ListDocument12 pagesHindu Website ListHaindava Keralam100% (5)

- Promiment Sobriquets (World) : S.No. Place SobriquetDocument6 pagesPromiment Sobriquets (World) : S.No. Place Sobriquetkausik nath100% (1)

- TamilnaduDocument12 pagesTamilnaduNimit MalhotraNo ratings yet

- Yavatmal Report PAN India Oct 2017 WebDocument57 pagesYavatmal Report PAN India Oct 2017 WebNarasimha Reddy DonthiNo ratings yet

- Philosophy of World Handloom DayDocument7 pagesPhilosophy of World Handloom DayNarasimha Reddy Donthi100% (1)

- Handloom Census 2017 - QuestionnaireDocument9 pagesHandloom Census 2017 - QuestionnaireNarasimha Reddy DonthiNo ratings yet

- Green Manifesto For HyderabadDocument17 pagesGreen Manifesto For HyderabadNarasimha Reddy DonthiNo ratings yet

- Seed Price Regulation in IndiaDocument5 pagesSeed Price Regulation in IndiaNarasimha Reddy DonthiNo ratings yet

- Indian AgricultureDocument13 pagesIndian AgricultureNarasimha Reddy DonthiNo ratings yet

- Ennikala Mungita Chenetha 2014Document5 pagesEnnikala Mungita Chenetha 2014Narasimha Reddy DonthiNo ratings yet

- 5th IFOAM-Asia Conference Programme enDocument9 pages5th IFOAM-Asia Conference Programme enNarasimha Reddy DonthiNo ratings yet

- TDP Haami Patram - DNRDocument5 pagesTDP Haami Patram - DNRNarasimha Reddy DonthiNo ratings yet

- APCC Discussions On Land Acquisition, 2011Document7 pagesAPCC Discussions On Land Acquisition, 2011Narasimha Reddy DonthiNo ratings yet

- Handloom VisionDocument14 pagesHandloom VisionNarasimha Reddy DonthiNo ratings yet

- Note On Cotton - RaichurDocument11 pagesNote On Cotton - RaichurNarasimha Reddy Donthi100% (1)

- National Textile Policy 2000-ReviewDocument20 pagesNational Textile Policy 2000-ReviewNarasimha Reddy DonthiNo ratings yet

- UPSC Civil Services Examination: UPSC Notes (GS-I) Topic: Mauryan Empire - Ancient Indian History NCERT Notes For UpscDocument3 pagesUPSC Civil Services Examination: UPSC Notes (GS-I) Topic: Mauryan Empire - Ancient Indian History NCERT Notes For UpscpranayNo ratings yet

- HE Conomic Imes: Flipkart May Seal Myntra Deal SoonDocument16 pagesHE Conomic Imes: Flipkart May Seal Myntra Deal SoonBiswajit DasNo ratings yet

- 1701860471TABLE1A1Document1 page1701860471TABLE1A1Prayag DasNo ratings yet

- Notes On Early Problems of PakistanDocument3 pagesNotes On Early Problems of PakistanAhsan HaroonNo ratings yet

- Amma PDFDocument7 pagesAmma PDFKavimozhiNo ratings yet

- Tribes of BangladeshDocument3 pagesTribes of BangladeshMashfiqur R. RashediNo ratings yet

- The Bombay Custom House Agents' AssociationDocument2 pagesThe Bombay Custom House Agents' Association1461987syamNo ratings yet

- ISSO Worksheet - I: 2021-2022 Class - VDocument3 pagesISSO Worksheet - I: 2021-2022 Class - VSAURA KUNTALNo ratings yet

- Icc-2020 Model Making Class 6 To 8 ResultsDocument20 pagesIcc-2020 Model Making Class 6 To 8 ResultsDeepak SabharwalNo ratings yet

- Indian Economy: An OverviewDocument46 pagesIndian Economy: An OverviewArpit Srivastava100% (2)

- Venkatagiri Road, Yerpedu Mandal, Chittoor (Dist.) - 517 619, A.PDocument1 pageVenkatagiri Road, Yerpedu Mandal, Chittoor (Dist.) - 517 619, A.PAbhishekNo ratings yet

- Uttar Pradesh Assembly Elections 2022 Analysis of Vote Share and Margin of Victory of Winners EnglishDocument50 pagesUttar Pradesh Assembly Elections 2022 Analysis of Vote Share and Margin of Victory of Winners EnglishSabrang IndiaNo ratings yet

- Faremaker Mall SMC Challan For CTCDocument1 pageFaremaker Mall SMC Challan For CTCwaqasmohammad944No ratings yet

- March 2024Document32 pagesMarch 2024SHUBHAM STAR PatilNo ratings yet

- Costrol India Ltd-Monarch ResearchDocument14 pagesCostrol India Ltd-Monarch ResearchAvinash KamathNo ratings yet

- TCS & EVADocument10 pagesTCS & EVARitesh MintuNo ratings yet

- Territory AddressDocument2 pagesTerritory Addresspraveen gautamNo ratings yet

- Constitutional Design Day 5 2024Document2 pagesConstitutional Design Day 5 2024Mehak DahiyaNo ratings yet

- Pakistan History Notes (712 To 2019)Document12 pagesPakistan History Notes (712 To 2019)imranNo ratings yet

- IPL@Dream 11Document1 pageIPL@Dream 11PrantikNo ratings yet

- Quaid e Azam 14 Points in UrduDocument2 pagesQuaid e Azam 14 Points in Urduhello4u738No ratings yet

- Sino-Pakistan Relations: A Chinese PerspectiveDocument17 pagesSino-Pakistan Relations: A Chinese Perspectivearun1974No ratings yet

- Social Science 2023-24 SyllabusDocument16 pagesSocial Science 2023-24 SyllabusOnly for studyNo ratings yet

- 09 Social Science Key Notes Pol SC Ch3 Constitutional DesignDocument2 pages09 Social Science Key Notes Pol SC Ch3 Constitutional DesignJIO CINEMA0% (1)

- Decline of Wooden Furniture IndustryDocument22 pagesDecline of Wooden Furniture IndustryAmardeep BhogalNo ratings yet

- A Research Report On Advertising Effectiveness of SbiDocument11 pagesA Research Report On Advertising Effectiveness of SbiYuvraj GajjarNo ratings yet

- Vishalandhra Is An Idea Bearing A Taint of Expansionist ImperialismDocument1 pageVishalandhra Is An Idea Bearing A Taint of Expansionist Imperialismgskn4u7183No ratings yet