Professional Documents

Culture Documents

Jsa Camp Engine Service 350 HRS

Jsa Camp Engine Service 350 HRS

Uploaded by

Adel AlKhedawyCopyright:

Available Formats

You might also like

- LA County Dept of Public Health EHS Employee Morale SurveyDocument11 pagesLA County Dept of Public Health EHS Employee Morale SurveyJennifer Van LaarNo ratings yet

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- Mazak Programing Class BookDocument510 pagesMazak Programing Class BookBriciu Teofil Mihail100% (7)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Mazatrol T-Plus Diagnostic Servo CodesDocument284 pagesMazatrol T-Plus Diagnostic Servo CodesMACKAY9999100% (8)

- M-Plus Maintenance and Operation C430M526Document235 pagesM-Plus Maintenance and Operation C430M526MACKAY9999100% (5)

- Sally Sore Loser Sample PagesDocument8 pagesSally Sore Loser Sample PageslensNo ratings yet

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Khawater Makki Cover Letter.ADocument1 pageKhawater Makki Cover Letter.AAnonymous miK3qJxNo ratings yet

- Scope of WorkDocument7 pagesScope of WorkKriengsak Ruangdech100% (3)

- Jsa Rig Engine Service 750 HRSDocument1 pageJsa Rig Engine Service 750 HRSAdel AlKhedawyNo ratings yet

- Jsa Pulsation Dampener Maintenance and N2 Fill UpDocument2 pagesJsa Pulsation Dampener Maintenance and N2 Fill UpAdel AlKhedawyNo ratings yet

- Job Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksDocument1 pageJob Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksAdel AlKhedawyNo ratings yet

- 4 JHA On Erection of Auxilary Transformers and Main TransformersDocument4 pages4 JHA On Erection of Auxilary Transformers and Main TransformersPiyush SinghNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- Risk Assessment - Al EthihadDocument6 pagesRisk Assessment - Al EthihadKrishnan GreeshmaNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash Rai0% (1)

- DLPS JsaDocument23 pagesDLPS JsaDLPS HSENo ratings yet

- Bs 25100Document32 pagesBs 25100nikolaydeyanovNo ratings yet

- RADocument2 pagesRAalisheeraz0302No ratings yet

- Parker Hiross Polestar - Secadores NitrogenoDocument72 pagesParker Hiross Polestar - Secadores NitrogenoMartínez Rodriguez DiegoNo ratings yet

- Jsa For Cutting, Grinding and Welding For GulfconDocument3 pagesJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- 25 JHA On Erection of Cabling, Cable Trays, Cable Supports Inside TunnelsDocument3 pages25 JHA On Erection of Cabling, Cable Trays, Cable Supports Inside TunnelsPiyush SinghNo ratings yet

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- PST070 - Rev 19Document36 pagesPST070 - Rev 19ingprijonNo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- Air Jsa ExcavationsDocument13 pagesAir Jsa ExcavationsNIdhinNo ratings yet

- DRD1200 6000 Rev23Document76 pagesDRD1200 6000 Rev23alanfbventuraNo ratings yet

- Air CompressorDocument4 pagesAir CompressorLajapathi RaiNo ratings yet

- JSA For Internals Installation - 2230-31Document8 pagesJSA For Internals Installation - 2230-31Khalid IrfanNo ratings yet

- Mechanical Demolish JhaDocument2 pagesMechanical Demolish JhafatimahNo ratings yet

- SSERC RAPillar Drill 011015Document3 pagesSSERC RAPillar Drill 011015Maged AliNo ratings yet

- Pipe Spool Replacement by Mobile CraneDocument8 pagesPipe Spool Replacement by Mobile CraneManikandanNo ratings yet

- DRD1200 6000 Rev29Document74 pagesDRD1200 6000 Rev29ThiagoNo ratings yet

- HIRA of FTC Erection.Document3 pagesHIRA of FTC Erection.Gyanendra SrivastavaNo ratings yet

- Instructions For Safe Use: Toughpix DigithermDocument7 pagesInstructions For Safe Use: Toughpix DigithermHodril Anam RifaieNo ratings yet

- Swing Grinding JhaDocument6 pagesSwing Grinding JhaDwitikrushna RoutNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Lizof Jsa For ExcavationDocument2 pagesLizof Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- Jha JiggingDocument4 pagesJha Jiggingsyed aquibNo ratings yet

- Toaz - Info 5 Jsa Rebar Cutting Amp Bending PRDocument2 pagesToaz - Info 5 Jsa Rebar Cutting Amp Bending PRthennarasuNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- Job Safety Analysis: Date:27-05-2022Document2 pagesJob Safety Analysis: Date:27-05-2022Mohammad HussainNo ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Work Instruction NPF STRETCH FILM (Stretch Film Operation)Document5 pagesWork Instruction NPF STRETCH FILM (Stretch Film Operation)Jed BrionesNo ratings yet

- Jha Unitec Repair of CR 4 Acs 012123Document7 pagesJha Unitec Repair of CR 4 Acs 012123JulzNo ratings yet

- Sop Handout For EtpDocument12 pagesSop Handout For Etpalazarlemma5No ratings yet

- Maintenance Manual For MDS A MDS B and MDocument242 pagesMaintenance Manual For MDS A MDS B and MWaldo LaunspachNo ratings yet

- Engineering Principles - PEO 19 2023Document54 pagesEngineering Principles - PEO 19 2023Christopher RedfernNo ratings yet

- Job Safety Analysis: Date:02-05-2022Document3 pagesJob Safety Analysis: Date:02-05-2022Mohammad HussainNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Ladder Diagram For Quick Turn 8N - 40N (T32-2) Publication: DL341LMB400Document146 pagesLadder Diagram For Quick Turn 8N - 40N (T32-2) Publication: DL341LMB400Jay Jay100% (1)

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- Jsa Cable LayingDocument2 pagesJsa Cable LayingAbcd efgh100% (1)

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- WDM Technologies: Passive Optical ComponentsFrom EverandWDM Technologies: Passive Optical ComponentsAchyut K. DuttaNo ratings yet

- HEALTH MELCs Grade 3 PDFDocument3 pagesHEALTH MELCs Grade 3 PDFMarcelina Ellar50% (2)

- Science 7-LONG QUIZ 4Document4 pagesScience 7-LONG QUIZ 4Filii ZamorensisNo ratings yet

- Section-1: Drilling Fluids CriteriaDocument8 pagesSection-1: Drilling Fluids CriteriaMohamed AbozeimaNo ratings yet

- Comparacion Polar y VO2 MaxDocument3 pagesComparacion Polar y VO2 MaxZilanyaid MontoyaNo ratings yet

- IDC 4U2 - Unit 3 Task 5 - SSDocument4 pagesIDC 4U2 - Unit 3 Task 5 - SSsavannah.e.stonehouseNo ratings yet

- Mens's 6-8 Minute WorkoutDocument3 pagesMens's 6-8 Minute WorkoutVictor WoodsNo ratings yet

- DO Transfer PumpDocument40 pagesDO Transfer PumpUdana HettiarachchiNo ratings yet

- CARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700Document1 pageCARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700megawhat115No ratings yet

- 6N3 (5670) Tube Buffer User ManualDocument4 pages6N3 (5670) Tube Buffer User Manual王宗超No ratings yet

- Cmo 14Document33 pagesCmo 14Geraldine CaneteNo ratings yet

- Basics of EKG InterpretationDocument132 pagesBasics of EKG InterpretationArif Imam HidayatNo ratings yet

- Horno de Microondas Sharp R352daDocument36 pagesHorno de Microondas Sharp R352daErick RodriguezNo ratings yet

- Cinta Tanpa SyaratDocument12 pagesCinta Tanpa SyaratMas DozoNo ratings yet

- Earth HistoryDocument6 pagesEarth HistoryAna ArgonzaNo ratings yet

- Iso 27001 ChecklistDocument8 pagesIso 27001 ChecklistALEX COSTA CRUZNo ratings yet

- Environmental Problems WorksheetDocument2 pagesEnvironmental Problems WorksheetAnnamária Polacsek100% (1)

- Rewards and Recognition in DR Reddy's by Zeba FathimaDocument82 pagesRewards and Recognition in DR Reddy's by Zeba Fathimazebafathima100% (1)

- Knitjoy ManufacturingDocument2 pagesKnitjoy ManufacturingVenti S. GoNo ratings yet

- Emkay Insurance Final ReportDocument73 pagesEmkay Insurance Final Reportrahulsogani123No ratings yet

- Polyethylene Glycol vs. Lactulose in Infants and Children With Functional ConstipationDocument5 pagesPolyethylene Glycol vs. Lactulose in Infants and Children With Functional ConstipationGabriela Peláez silvaNo ratings yet

- Virtual Flight Planning SolutionsDocument1 pageVirtual Flight Planning SolutionsBruno GasperinNo ratings yet

- Technical Report PeDocument75 pagesTechnical Report Penur hidayatiNo ratings yet

- Regla de Ergonomía 1Document15 pagesRegla de Ergonomía 1Valeria RincónNo ratings yet

- Activity No. 4 Module Cell Types and Cell ModificationsDocument7 pagesActivity No. 4 Module Cell Types and Cell ModificationsAryan Jovic DomingoNo ratings yet

- Table 5.1-2 Minnesota Multiphasic Personality Inventory Validity and Clinical Scales ValidityDocument4 pagesTable 5.1-2 Minnesota Multiphasic Personality Inventory Validity and Clinical Scales ValidityReisya GinaNo ratings yet

- Abstract Book IccDocument97 pagesAbstract Book IccHasnain GoharNo ratings yet

Jsa Camp Engine Service 350 HRS

Jsa Camp Engine Service 350 HRS

Uploaded by

Adel AlKhedawyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Camp Engine Service 350 HRS

Jsa Camp Engine Service 350 HRS

Uploaded by

Adel AlKhedawyCopyright:

Available Formats

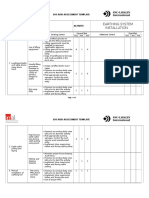

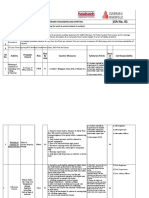

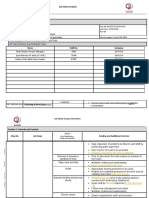

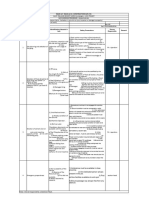

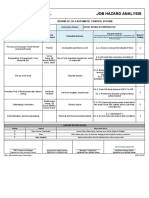

Job Safety Analysis (JSA )

Rig: T853 Main Job: 350 HOURLY SERVICE OF CAMP ENGIN#2 7465

Location: THYFOOT Working Area: CAMP ENGINE#MAIN CAMP ENGINE ROOM Review date: 8-9-2021

Hazards involved Effects of Hazards Recommended Cotrols

1) Ensure Isolations are proper

PIC not aware about the job/Task and kept warning tags

2) Assign enough employees to

Inform PIC about the Task, and get approval and 1) Employee may not isolate the power supply to the carry the tires to work place

make valid PTW. Isolate equipment and ensure equipment or isolated wrong equipment understand that how to do in

isolation is proper. 2) Not conducted tool box talk and explained the job. safe way.

Ensure that proper tools are

3) Used improper tools for the job. used fro the job.

4) Not taken due care for pinch points.

secure the covers to avoid

1) Pinch points sudden closer due to wind.

prepare tools and Proper body positiojn, Replace 2) Ingress of flying derbies Use proper eye protection.

crank case oil and filters, prowide drip tray to

avoide oil spill.

3) Improper maintenance procedure. Follow maintenance instruction.

may be oil spillage, diesel spillage follow the safe procedue.

TBT, PPE and follow

Fixe all Fasteners Proper Tightening and adjust cut, pinch point, fall, trip procedure.

V-Belt Tension and clean air filters and

radiator,grease fan pulley bearing

deisolated and equipment is

Power not deisolated ready for use

Carry out housekeeping of the

Improper

Readyness of the equiupment is not informed to user area.

housekeeping of the area. Inform user or resume

completion of the job

or put equipment in operation again operation of the equipment.

Deisulate the camp engine.

Signatures:

Toolpusher: ABDALLAH Workparty: HUMAID

2)

Task supervi

HUMAID

You might also like

- LA County Dept of Public Health EHS Employee Morale SurveyDocument11 pagesLA County Dept of Public Health EHS Employee Morale SurveyJennifer Van LaarNo ratings yet

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- Mazak Programing Class BookDocument510 pagesMazak Programing Class BookBriciu Teofil Mihail100% (7)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Mazatrol T-Plus Diagnostic Servo CodesDocument284 pagesMazatrol T-Plus Diagnostic Servo CodesMACKAY9999100% (8)

- M-Plus Maintenance and Operation C430M526Document235 pagesM-Plus Maintenance and Operation C430M526MACKAY9999100% (5)

- Sally Sore Loser Sample PagesDocument8 pagesSally Sore Loser Sample PageslensNo ratings yet

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Khawater Makki Cover Letter.ADocument1 pageKhawater Makki Cover Letter.AAnonymous miK3qJxNo ratings yet

- Scope of WorkDocument7 pagesScope of WorkKriengsak Ruangdech100% (3)

- Jsa Rig Engine Service 750 HRSDocument1 pageJsa Rig Engine Service 750 HRSAdel AlKhedawyNo ratings yet

- Jsa Pulsation Dampener Maintenance and N2 Fill UpDocument2 pagesJsa Pulsation Dampener Maintenance and N2 Fill UpAdel AlKhedawyNo ratings yet

- Job Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksDocument1 pageJob Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksAdel AlKhedawyNo ratings yet

- 4 JHA On Erection of Auxilary Transformers and Main TransformersDocument4 pages4 JHA On Erection of Auxilary Transformers and Main TransformersPiyush SinghNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- Risk Assessment - Al EthihadDocument6 pagesRisk Assessment - Al EthihadKrishnan GreeshmaNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash Rai0% (1)

- DLPS JsaDocument23 pagesDLPS JsaDLPS HSENo ratings yet

- Bs 25100Document32 pagesBs 25100nikolaydeyanovNo ratings yet

- RADocument2 pagesRAalisheeraz0302No ratings yet

- Parker Hiross Polestar - Secadores NitrogenoDocument72 pagesParker Hiross Polestar - Secadores NitrogenoMartínez Rodriguez DiegoNo ratings yet

- Jsa For Cutting, Grinding and Welding For GulfconDocument3 pagesJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- 25 JHA On Erection of Cabling, Cable Trays, Cable Supports Inside TunnelsDocument3 pages25 JHA On Erection of Cabling, Cable Trays, Cable Supports Inside TunnelsPiyush SinghNo ratings yet

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- PST070 - Rev 19Document36 pagesPST070 - Rev 19ingprijonNo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- Air Jsa ExcavationsDocument13 pagesAir Jsa ExcavationsNIdhinNo ratings yet

- DRD1200 6000 Rev23Document76 pagesDRD1200 6000 Rev23alanfbventuraNo ratings yet

- Air CompressorDocument4 pagesAir CompressorLajapathi RaiNo ratings yet

- JSA For Internals Installation - 2230-31Document8 pagesJSA For Internals Installation - 2230-31Khalid IrfanNo ratings yet

- Mechanical Demolish JhaDocument2 pagesMechanical Demolish JhafatimahNo ratings yet

- SSERC RAPillar Drill 011015Document3 pagesSSERC RAPillar Drill 011015Maged AliNo ratings yet

- Pipe Spool Replacement by Mobile CraneDocument8 pagesPipe Spool Replacement by Mobile CraneManikandanNo ratings yet

- DRD1200 6000 Rev29Document74 pagesDRD1200 6000 Rev29ThiagoNo ratings yet

- HIRA of FTC Erection.Document3 pagesHIRA of FTC Erection.Gyanendra SrivastavaNo ratings yet

- Instructions For Safe Use: Toughpix DigithermDocument7 pagesInstructions For Safe Use: Toughpix DigithermHodril Anam RifaieNo ratings yet

- Swing Grinding JhaDocument6 pagesSwing Grinding JhaDwitikrushna RoutNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Lizof Jsa For ExcavationDocument2 pagesLizof Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- Jha JiggingDocument4 pagesJha Jiggingsyed aquibNo ratings yet

- Toaz - Info 5 Jsa Rebar Cutting Amp Bending PRDocument2 pagesToaz - Info 5 Jsa Rebar Cutting Amp Bending PRthennarasuNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- Job Safety Analysis: Date:27-05-2022Document2 pagesJob Safety Analysis: Date:27-05-2022Mohammad HussainNo ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Work Instruction NPF STRETCH FILM (Stretch Film Operation)Document5 pagesWork Instruction NPF STRETCH FILM (Stretch Film Operation)Jed BrionesNo ratings yet

- Jha Unitec Repair of CR 4 Acs 012123Document7 pagesJha Unitec Repair of CR 4 Acs 012123JulzNo ratings yet

- Sop Handout For EtpDocument12 pagesSop Handout For Etpalazarlemma5No ratings yet

- Maintenance Manual For MDS A MDS B and MDocument242 pagesMaintenance Manual For MDS A MDS B and MWaldo LaunspachNo ratings yet

- Engineering Principles - PEO 19 2023Document54 pagesEngineering Principles - PEO 19 2023Christopher RedfernNo ratings yet

- Job Safety Analysis: Date:02-05-2022Document3 pagesJob Safety Analysis: Date:02-05-2022Mohammad HussainNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Ladder Diagram For Quick Turn 8N - 40N (T32-2) Publication: DL341LMB400Document146 pagesLadder Diagram For Quick Turn 8N - 40N (T32-2) Publication: DL341LMB400Jay Jay100% (1)

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- Jsa Cable LayingDocument2 pagesJsa Cable LayingAbcd efgh100% (1)

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- WDM Technologies: Passive Optical ComponentsFrom EverandWDM Technologies: Passive Optical ComponentsAchyut K. DuttaNo ratings yet

- HEALTH MELCs Grade 3 PDFDocument3 pagesHEALTH MELCs Grade 3 PDFMarcelina Ellar50% (2)

- Science 7-LONG QUIZ 4Document4 pagesScience 7-LONG QUIZ 4Filii ZamorensisNo ratings yet

- Section-1: Drilling Fluids CriteriaDocument8 pagesSection-1: Drilling Fluids CriteriaMohamed AbozeimaNo ratings yet

- Comparacion Polar y VO2 MaxDocument3 pagesComparacion Polar y VO2 MaxZilanyaid MontoyaNo ratings yet

- IDC 4U2 - Unit 3 Task 5 - SSDocument4 pagesIDC 4U2 - Unit 3 Task 5 - SSsavannah.e.stonehouseNo ratings yet

- Mens's 6-8 Minute WorkoutDocument3 pagesMens's 6-8 Minute WorkoutVictor WoodsNo ratings yet

- DO Transfer PumpDocument40 pagesDO Transfer PumpUdana HettiarachchiNo ratings yet

- CARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700Document1 pageCARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700megawhat115No ratings yet

- 6N3 (5670) Tube Buffer User ManualDocument4 pages6N3 (5670) Tube Buffer User Manual王宗超No ratings yet

- Cmo 14Document33 pagesCmo 14Geraldine CaneteNo ratings yet

- Basics of EKG InterpretationDocument132 pagesBasics of EKG InterpretationArif Imam HidayatNo ratings yet

- Horno de Microondas Sharp R352daDocument36 pagesHorno de Microondas Sharp R352daErick RodriguezNo ratings yet

- Cinta Tanpa SyaratDocument12 pagesCinta Tanpa SyaratMas DozoNo ratings yet

- Earth HistoryDocument6 pagesEarth HistoryAna ArgonzaNo ratings yet

- Iso 27001 ChecklistDocument8 pagesIso 27001 ChecklistALEX COSTA CRUZNo ratings yet

- Environmental Problems WorksheetDocument2 pagesEnvironmental Problems WorksheetAnnamária Polacsek100% (1)

- Rewards and Recognition in DR Reddy's by Zeba FathimaDocument82 pagesRewards and Recognition in DR Reddy's by Zeba Fathimazebafathima100% (1)

- Knitjoy ManufacturingDocument2 pagesKnitjoy ManufacturingVenti S. GoNo ratings yet

- Emkay Insurance Final ReportDocument73 pagesEmkay Insurance Final Reportrahulsogani123No ratings yet

- Polyethylene Glycol vs. Lactulose in Infants and Children With Functional ConstipationDocument5 pagesPolyethylene Glycol vs. Lactulose in Infants and Children With Functional ConstipationGabriela Peláez silvaNo ratings yet

- Virtual Flight Planning SolutionsDocument1 pageVirtual Flight Planning SolutionsBruno GasperinNo ratings yet

- Technical Report PeDocument75 pagesTechnical Report Penur hidayatiNo ratings yet

- Regla de Ergonomía 1Document15 pagesRegla de Ergonomía 1Valeria RincónNo ratings yet

- Activity No. 4 Module Cell Types and Cell ModificationsDocument7 pagesActivity No. 4 Module Cell Types and Cell ModificationsAryan Jovic DomingoNo ratings yet

- Table 5.1-2 Minnesota Multiphasic Personality Inventory Validity and Clinical Scales ValidityDocument4 pagesTable 5.1-2 Minnesota Multiphasic Personality Inventory Validity and Clinical Scales ValidityReisya GinaNo ratings yet

- Abstract Book IccDocument97 pagesAbstract Book IccHasnain GoharNo ratings yet