Professional Documents

Culture Documents

Runciman Mineral Recycling Forum 2019 Imformed

Runciman Mineral Recycling Forum 2019 Imformed

Uploaded by

Saszet RékaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Runciman Mineral Recycling Forum 2019 Imformed

Runciman Mineral Recycling Forum 2019 Imformed

Uploaded by

Saszet RékaCopyright:

Available Formats

A MULTI PHASE RECLAMATION PROJECT WITH

COMMODITY RECOVERY:

Recovering Value from a Chemical Processing

Waste

by Wastes Ecotech Srl (WET), Tarnaveni, Mures County, Romania

Commodities

45% vol

Target reduction

Mures MgO

County

Waste

Material Cr2O3 Final

1.95m m3 Waste

Bucharest

Material

3,5m t CaCl2

NH3

CONFIDENTIALITY AND DISCLAIMER STATEMENTS

This document is strictly confidential and may be legally privileged. It is intended solely to be received by the person(s) or organisation(s) to whom it is addressed. If you are not the

intended recipient of this document retaining, using, disseminating, distributing, copying or taking any actions in reliance upon any information or documents contained in it is strictly

prohibited and will constitute a breach of confidentiality. If you have received this document(s) in error, please immediately inform the owner : Wastes Ecotech Srl –

office@wastesecotech.ro and delete it.

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 1

Denotes a CONTROLLED document

1 History of Site / Current Ownership

Former State Owned Fine Chemical (multiple) production site – operating from

1916 – 2006

1916 – 1922 - Gases & explosives

1922-1948 - Nitrates & fertilisers

1939- 1948 - Ceramics, Gold, Silver, Copper and Lead refining

1950 – 1975 - Bichromate 1 (built 1959-1955) & closed 1978

1968 – 1986 – Zinc Oxides, Barium salts, Formic & Hydrofluoric acid, Creolite,

Freon 11 & 12

1971 - 2006 - Bichromate 2 (built 1971 – 1972)

WSF built at the same time

Located in Mures County, central Romania.

Assets purchased (130ha site) via public auction in Oct 2012.

3 years spent uniting the 110 land parcels – separation into new plots ongoing

All plant has been demolished. Clean up of demolition wastes ongoing.

100% private ownership & unencumbered.

No Royalties apply to the Project Phase 1.

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 2

Denotes a CONTROLLED document

2 Background Dichromate Process

Chromite ore is roasted

4FeCr2O4 + 8Na2CO3 + 7O2 → 8Na2CrO4 + 2Fe2O3 +

8CO2

Lime is also added to ensure the products do not

agglomerate

However, at Bicapa a local Mg rich dolomite was

utilised

Soluble chromium salts are then mobilised and further

refined by either:

2Na2CrO4 + 2CO2 + H2O → Na2Cr2O7 + 2NaHCO3

or

2Na2CrO4 + H2SO4 + 2O2 → Na2Cr2O7 + Na2SO4 + H2O

Wastes are in the form of insoluble components such as

iron, aluminium, calcium, magnesium and silicon oxides

or hydroxides

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 3

Denotes a CONTROLLED document

3 The Asset

Target Asset for this project : 1.95m m3 of Sodium Dichromate Waste Tailings

(“COPR”) - Chromium Ore Processing Residue – stored in 2 purpose built Waste

Storage Facilities (WSF) 18.7 ha (510 x 320m & ave. height @ 12m)

COPR contains Hexavalent Chrome (Cr6+) hence the asset has a environmental

liability (on an RO/EU watch list) > previously resulted in caution from others

when wanting to deal with the site.

Options for the site are :

Cap WSF (Do “nothing” approach) > risk remains > costs estimated at EUR

20m

Reprocessing, Reclaim and Monetise (WET option).

BENEFITS : from this novel approach of remediation through reprocessing.

• Monetisation of the remaining minerals.

• Eliminates the contaminant materials – inert waste returned to WSF

• Reduces the volume by 48% & mass by 76%

• Providing a fully EU compliant revamped WSF (dangerous wastes)

• Provides long term employment for up to 360 direct FTE’s

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 4

Denotes a CONTROLLED document

4 Short Project Introduction

Environmental Remediation Project

Project consists of a 2 phase approach :

Phase 1 (years 1-9) >

Environmental remediation of cca. 3.5m tonnes (1.95m m3) of COPR on fully

owned company property.

Project involves reprocessing the stored wastes and extracting the minerals

as Chrome Oxide Green, Fused Magnesia, Calcium Chloride and Liquid

Ammonia (as a by-product).

Phase 1 has followed the JORC reporting method which will result in a JORC

2012 format report expected end April 2019.

Based on 100% debt finance…i.e. for the exercise no new equity has been

assumed

Environmental topic resolved via reprocessing of waste, conversion of

Chrome 6 > Chrome 3 and renovation of the Waste Storage Facility over

Phase 1 project life.

Strong local and federal government support for the project.

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 5

Denotes a CONTROLLED document

5 Short Project Introduction

Phase 2 (years 10-20)

Continue processing locally sourced micronized dolomite into the existing

plant (minor mods req’d) post reprocessing to produce FM or MgO (only).

All required plant will be in place from Phase 1 – assumed FM output of 3,85

t/hr on a 24/7 & 330 day yr. basis.

Project Plan assumes additional 11 year processing life but 20 + year plant

life is possible.

Additional Phase 2 EBIT of cca. 250m USD for the period with flat product

pricing but inflation adjusted OPEX.

Continued employment for 85% of staff.

Keep paid for assets working.

NB – Pinch analysis and detailed design still to be done on Project Phase 1&2

hence costs are not as yet optimised.

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 6

Denotes a CONTROLLED document

6 Short Project Introduction

Approach and Status

WET followed the JORC Reporting path to obtain a Certified JORC 2012

Report based on Estimated Resource, Probable Reserve.

Inferred JORC obtained in 2014

Current work aimed at upgrade to Estimated – Bankable Feasibility

Study

Drilled 50 x 50m grid (72 holes) and at 1m intervals (902 samples to ACME

Vancouver for assaying).

3D modelled the resource.

Pilot work done over past 5 years on simple pilot plant on site

BFD for plant design including 3D layout completed.

Excavation (“Mining”) planning done – to month by month level.

TEM (Techno Economic Model) done.

Urbanism Certificate in place.

EIA submittal will be done end March 2019

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 7

Denotes a CONTROLLED document

7 Drill hole locations - WSF

A B

WSF

Nr 3

Project Summary - Key Financials

WSF

Nr 2

WSF

Nr 1

WSF denotes

Waste Storage Facility

(Batal in Romanian)

Project includes : Exploratory drill holes

WSF 2&3 - 18.7 ha only. Not in model

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 8

Denotes a CONTROLLED document

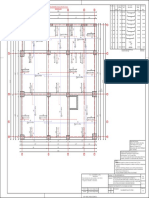

8 Project Site Plan - WSF & Plant

N

Process

Admin Site

Logistics

Sites

Coffer

Dam line

Tabel 1 - C ladiri T abel 4 - C onstructii Industriale

WET Dam

site WSF 2&3

Tabel 2 - D rum uri de incinta, exterioare si parcari

WSF 1 Clear zones =

Tabel 3 - P latform e betonate, piatra sparta si spatii tehnologice

WET property

(eg)

Beneficiar: Plansa

S .C . G E O C O N S E X P E R T P R O IE C T S .R .L N r.

B U C U R E S TI SC WASTES ECOTECHSRL F aza

Ing.V lad R adulescu BUCURESTI SF

N um ele Sem natura S cara Proiect de inchidere dupa post utilizare la nivel de studiu de fezabilitate

1:2000 (SF) pentru batalurile de deseuri nr. 1, 2, 3 si a batalului rezultat dupa

P roiectat Ing. A ndronache I. procesare - Bicapa - Tarnaveni

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Dec 2018 – v6 D esenat Ing. A ndronache I.

V erificat Ing. V lad R adulescu

A probat Ing. Luca D aniela

D ata

04.2018

Fila

1/2

9

PLAN DE AMPLASARE

VARIANTA V_6

REVIZIE APRILIE 2018

Denotes a CONTROLLED document

9 Project Site Plan - WSF & Plant

N

Haul

road

CONVEYOR LENGHTS

C1=29.5 m

C2=59.5 m

C3=103.5 m

C4=107.8 m

C5=55.4 m

C6=103.5 m

C7=107.8 m

C8=136.4 m

C9=103.5 m

C10=107.8 m

HAUL ROADS

A=2292 m2 A=327 m

B=2350 m2 B=336 m

C=2180 m2 C=311 m

0 15.10.2018 FOR REWIEW C.C. D.R. I.P. D.R.

Name Signed Name Signed Name Signed Name Signed

REV. DATE/DATA DESCRIPTION Nume Semnat Nume Semnat Nume Semnat Nume Semnat

DES/DESENAT BY/PROIECTAT CHK'D/VERIFICAT APP'D/APROBAT

WASTES ECOTECH S.R.L.

WET MINING PLAN

FINAL WASTE MATERIAL(FWM)

DWG'S LEGAL OWNER/PROPIETAR LEGAL DESEN SCALE/SCARA DWG. NUMBER/NUMAR DESEN SHEET/FILA REV.

ALCONEX METROLOGY & SERVICES S.R.L. 1:1000 WET-1604-MIN-001 1/1 0

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 10

Denotes a CONTROLLED document

10 Trenching locations – post DPT work

T1-5 ARE TRENCHES FROM JAN 22 2019

T2

T1

T5

T3

T4

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 11

Denotes a CONTROLLED document

11 Trenching Exercise

Trench – 4,7 m Original Angle of repose

T3 T2

Disturbed Angle of repose

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 12

Denotes a CONTROLLED document

12 Pre-Excavation Works – Haul Road A

For the JCB JS160 assuming a cycle time of 40 seconds and a

bucket size of 0.85m3.

Assuming 85% utilisation of a 9 hour shift and that the

excavator can move waste for 90% of the time, 10% to allow

for repositionable movements, then the JS160 can move (0.85

x 3600 x 90% / 40) m3/hr or 69 m3/hr. And 527 m3 in a shift.

The Hydrema 922F has a payload capacity of 12m3, therefore

need 5.7 trucks per hour and 10min 30sec turnaround time.

JCB JS160

JCB 457 Hydrema

922F

COPR

Working Face Long Term Face

35o 10m Haul 26o

Road

Clay Basal Layer

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 13

Denotes a CONTROLLED document

13 Pre-Excavation Works – Haul Road A

Hitachi ZX670 LRE has a cycle time of 40 seconds, from

YouTube video

Assuming 85% utilisation of a 9 hour shift and that the

excavator can move waste for 90% of the time, 10% to allow

for repositionable movements, then the ZX670 can move (3

x 3600 x 90% / 40) m3/hr or 243 m3/hr. And 1,859 m3 in a

Rented shift.

LRE The Hydrema 922F has a payload capacity of 12m3,

therefore need 20.3 trucks per hour and 3min turnaround

time. JCB 457 Hydrema

922F

COPR 35o

Face

Working Face Long Term Face

35o 10m Haul 26o

Road

Clay Basal Layer

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 14

Denotes a CONTROLLED document

14 Pre-Excavation Works – Haul Road A

With both units working simultaneously

and assuming a split between the JS160

and the ZX670 of 5% and 95%,

respectively, the excavation would

require 25 shifts

Rented

LRE

Hydrema

JCB 457 922F

COPR 35o

Face

Working Face

Long Term Face

35o

10m Haul 26o

Road

Clay Basal Layer

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 15

Denotes a CONTROLLED document

15 Pre-Excavation Works – Haul Road A

The JCB JS160 would also be used to clean the northern

perimeter dyke

JCB JS160

Hydrema

JCB 457

922F

Working Face

35o

Level of N Perimeter Level of N Perimeter

Dyke Working Face Dyke

10m Haul 35o

Road

Clay Basal Layer

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 16

Denotes a CONTROLLED document

16 Basal Layer Effectiveness

Cr2O3 (wt%)

0 5 10 15

0%

F01

10% F02

F03

20% F04

F05

30% F06

F07

F08

40%

F09

Depth (%)

F10

50%

60%

Clay base is effective

70% barrier

80%

90%

100%

Cr is mobilised within

the WSF

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 17

Denotes a CONTROLLED document

17 Basal Layer Effectiveness

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 18

Denotes a CONTROLLED document

18 Mining Progress

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 19

Denotes a CONTROLLED document

19 WSF Images

Original Clay Dyke Overfill Dyke (COPR)

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 20

Denotes a CONTROLLED document

20 WSF Images

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 21

Denotes a CONTROLLED document

21 WSF Images

6m

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 22

Denotes a CONTROLLED document

22 Key Project info

Key Financial Info - Impact on EBIT (Phase 1 only)

600

550

500

450

EBIT USD Million

400

350

300

250

200

150

100

-20% -15% -10% -5% 0% 5% 10% 15% 20%

Percent Variation

CAPEX OPEX Revenue MgO Cr2O3 CaCl2 NH4

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 23

Denotes a CONTROLLED document

23 Key Project info

Project Summary – Key Tech Points

Simple form of exploitation using Long Reach Excavators, Wheeled Loaders and low ground

pressure dump trucks . “ Mining” study completed by Belevion (RO) Srl with review by SRK

UK Ltd.

Automated return of Final Waste Material post processing via Portal Reclaimer, Conveyors

& Tracked Stacker in WSF.

Moveable Road matting to be used

where humidity may impede vehicle

movement

HEPA Air Filters to be retrofitted to

equipment in the work front (HSE)

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019– v7 24

Denotes a CONTROLLED document

24 Key Project info

Project Summary – Key Tech Points

All possible measures to be taken for site / environmental safety are planned. Dry misting water to

suppress dust, remote monitoring stations, Phonic protections where needed. LGP type vehicles

Labour required 292 FTE Direct Plant, 28 FTE External contractors, 27 FTE Exploitation Contractors

(“mining” planned to be outsourced) employed over a 10 year operating period. Expected 2:1

additional employment ratio for other support parties (further 714 FTE external supplier support).

> Project will provide employment for Circa 1000 people (direct / indirect) when in full operation.

Environmental cost est. of USD32M over Life of Project (LOP) + post closure monitoring period (30

years). Post closure costs allowed for in TEM Phase 1.

Logistics, Admin and parts of the site post decontamination will be repurposed post closure.

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 25

Denotes a CONTROLLED document

25 Key Project info

Project Summary – Salient talking Points

No mining required (all material above “ground” hence simple loader/truck exploitation)

hence certified by ANMR (Romanian Mineral Resource Authority) as not under the RO

mining law (no royalties).

WET process tech eliminates current environmental concerns (Cr6+) while producing

multiple product streams. Appealing option by Local EPA / authorities vs std remediation.

Full EIA submittal in June 2018, initial stage EIA visa received.

The Project has strong local / state authority support due to WET continued forward

momentum and EU pressure on RO to clean up historical sites. Its profile benefits the

level of support not normally seen on such projects.

Site utilities, road, rail and water infrastructure (WET owns a dam on the River) in place or

at boundary

Provides significant long term employment

Presents itself as a model method for elimination of dangerous wastes.

Model is repeatable on other sites – but we have learnt some clear (and costly) lessons

along the way.

EU needs to look harder at support methods to such projects.

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 26

Denotes a CONTROLLED document

26 Key Project info

Block Flow Diagram – prior to

introduction of Fused Magnesia (FM)

step. Presently being updated and

initial development underway in a

PFD.

Plant has multi product potential on

Cr, MgO & Ca product streams with

simple changes.

WET will look to submit for an

applications Patent based around

the the Cr module upgrade.

Data pack includes significant pre-

feasibility engineering done

Significant Plant unit relocation

possible post completion of the .

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 27

Denotes a CONTROLLED document

27 Full BFD Overview

21.2.62

19.1.23

18.1.20

11.1.17

Water to 11.2.30 5.2.14

recirculation 1.1.1

Water

Feed

5.1.25 5.2.64 5.2.64 5.1.26 River Tarnava Mica

20.2.60 1.1.1 1.1.2 1.1.2

11.1.15

WSF REGENERANT SOL. TEHNICAL GRADE PROCESS GRADE

0101 HYDRATION 0502 0505 0501

PREPARATION WATER WATER

1.2.2 1.2.1 5.1.7 7.1.12 19.1.21 5.2.65 16.2.48 5.1.27

Filtrate Wet cake

SOW - P01

HCl (aq) 3% 11.1.16 11.1.17 H2O

NH4 OH (aq) 6% 11.1.15 1.2.2 1.2.1 2.1.3 CO2

2.1.4 Demineralized grade water

8.2.26 2.1.4 H2O

6.2.17 HCl 35% (l) 5.2.67 5.2.67

5.1.28 5.2.66

ACTIVATION SOL. DEMINERALIZED

0211 IEX 3 0302 CARBONATION 0503 0510 GRADE WATER

PREPARATION

11.2.33 11.2.32 11.2.31 11.2.30 2.2.4 2.2.3 7.1.13 19.1.22 11.1.16 5.2.65

Water to Wet cake Filtrate

recirculation

11.2.32

5.2.68 5.2.68

5.2.16

7.2.22 10.1.5

3.2.7 CO2 5.1.8

19.2.58 12.2.64 NH3 10.1.5 H2O 3.2.8

12.2.34 H2O 3.2.8 H2O

5.2.15 5.1.29 NH4 Cl (s)

NH4Cl (aq)

0212 CONCENTRATION 0310 WASHING 2 0303 PRECIPITATION 1 0504

PREPARATION

12.2.35 10.2.6 10.2.5 3.2.10 3.2.9 7.2.21 17.1.19 19.2.57

Wet cake Filtrate Filtrate Wet cake

CO2 13.2.36 13.1.18 H2C2O4

H2O 13.2.37

4.1.6 H2O 4.1.6

0213 MIXING 5.1.30 H2C2O4 (s)

13.2.38 N2

14.2.40

INITIATOR

14.2.39 CO2 0304 WASHING 1 0511

SOL. PREPARATION

14.2.41 NH3

14.2.42 H2O 4.2.12 4.2.11

Filtrate Wet cake 13.1.18 5.2.69

3.2.10

0214 VACUUM HEATING

10.2.5

14.2.43

H2O 15.2.45 15.2.44 CO2 HCl (aq) 3% 5.1.8 5.1.9 H2O 5.1.9

NH4OH (aq) 6% 5.1.7

0215 CALCINATION 3

0305 IEX 1

15.2.46

5.2.16 5.2.15 5.2.14 5.2.13

FINISHED PRODUCT FP2

Cr2O3 4.2.11

SOW - P02

6.1.10 CO2

6.1.11

10.2.6 6.1.11 H2O

16.2.47 CO2

0306 RECARBONATION

16.2.48 H2O

6.2.18 6.2.17

Filtrate Wet cake (Waste RC) 16.2.48

0416 CALCINATION 2

16.2.49 HCl (aq) 3% 7.1.13 11.2.31

Calcinated cake

7.1.12 NH4OH (aq) 6%

7.1.14 H2O 7.1.14

NH4Cl (aq) 17.1.19 17.2.50 NH3 0307 IEX 2 0509 W.W.T.

7.2.22 7.2.21 7.2.19 5.2.13 7.2.19 19.2.55

0417 LEACHING - NH4 Cl

7.2.20

17.2.52 17.2.51

Wet cake Filtrate

2.1.3

8.2.23 CO2

8.2.24

8.2.24 H2O

H2O 18.1.20 0308 PRECIPITATION 2 0506 CO2 STORAGE

8.2.26 8.2.25 5.1.32

Filtrate Wet cake

0418 WASHING 3 6.1.10

8.2.23

18.2.54 18.2.53

Filtrate Final Waste 9.2.27 CO2 9.2.27

9.2.28

H2O 19.1.23 9.2.28 H2O

HCl (aq) 3% 3.2.7

19.1.22

NH4 OH (aq) 6% 19.1.21 17.2.51

0309 CALCINATION 1 0506 CO2 RECOVERY

9.2.29 5.2.71

Calcinated cake

16.2.47

0419 IEX 4

5.2.72 CO2

13.2.37

19.2.58 19.2.57 19.2.56 19.2.55

PRODUS FINIT FP1 BY - PRODUCT BP1 CARBONATED

MgO LIQUID NH3 WATERS

SOW - P03

Lime 20.1.24 20.2.59 NH3 5.1.31 5.1.27

12.2.64

12.2.34

14.2.40

0420 PURIFICATION CaCl2

14.2.39

20.2.61 20.2.60

Filtrate Wet cake

14.2.41

14.2.42

H2O 21.2.62

17.2.50

5.2.73 5.2.73

20.2.59

0421 CONCENTRATION 5.1.33 Quick Lime (s)

21.2.63

QUICK LIME

0508 NH3 RECOVERY 0507

PREPARATION

18.2.53 5.2.70

FINISHED PRODUCT FP3/3 (FP3/2; FP3/1) BY - PRODUCT BP2

CaCl2 Anhydrous FWS AMMONIA WATERS

(CaCl2 x 2 H2O; CaCl2 x 6 H2O) (NH4 OH)

SOW - P04 5.1.25

20.1.24

SOW - P05

11 09-2018 FOR REWIEW - - I.Peleanu I.Peleanu D.Runciman

NAME / NAME / NAME / NAME /

DATE / DESCRIPTION / NUME NUME NUME NUME

REV.

DATA DESCRIERE DRAFTED / ENGINEERED / CHECKED / APPROVED /

LEGEND: Process Utilities Legend: Notes: DESENAT PROIECTAT VERIFICAT APROBAT

Plants Legend: 0501 - Preparation of Process Grade Water Continuous Processes Line " "

P01 - Crushing/Milling & Hydration 0502 - Preparation of NH4OH (aq) Regenerant Solution Discontinuous Processes Line (batch type) " "

P02 - Fabrication of Cr2O3 0503 - Preparation of HCl (aq) Activation Solution Discontinuous Processes Line (batch type) " "

P03 - Fabrication of MgO 0504 - Preparation of NH4Cl (aq) Reagent Solution Discontinuous Processes Line (batch type) " "

P04 - Fabrication of CaCl2 Anhydrous 0505 - Preparation of Tehnical Grade Water Abbreviations:

WASTES ECOTECH S.R.L.

(CaCl2 x 2H2O; CaCl2 x 6H2O) 0506 - Recovery & Storage of CO2 (as gaseous CO2) ''WSF'' - Waste Storage Facility

P05 - Process Utilities 0507 - Preparation of Lime Solution

0508 - Recovery & Storage of NH3 (as liquid NH 3)

''FWS'' - Final Waste Storage

''IEX'' - Ion Exchange

BLOCK FLOW DIAGRAM

0509 - Waste Water Treatment (W.W.T.) ''FP1'' - Finished Product 1 WET WSF - REPROCESSING PLANT

0510 - Preparation of Demineralized Grade Water ''FP2'' - Finished Product 2

0511 - Preparation of H2C2O4 (aq) Initiator Solution ''FP3'' - Finished Product 3

''BP1'' - By Product 1 DWG'S LEGAL OWNER/PROPIETAR LEGAL DESEN SCALE/SCARA DWG. NUMBER/NUMAR DESEN SHEET/FILA REV.

''BP2'' - By Product 2

WASTES ECOTECH S.R.L. 1:1 WET-1604-WRP-BFD-01_E 1/10 11

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019– v7 28

Denotes a CONTROLLED document

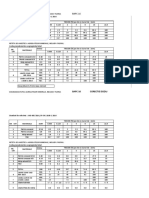

28 Preliminary TEM Assessment

Key Financial Elements Key Elements of TEM

Phase 1 EBIT = 422m USD • 100% debt finance basis for TEM

Phase 2 EBIT = 250m USD • Discount rate of 7%

CAPEX = 148m USD • Assumed Int. rate of 9.92% on finance

Phase 1 IRR = 32% (7% above USD LIBOR)

OPEX not yet optimised • 15 year repayment of CAPEX

Assumes 100% debt finance • NO State Aid factored in

Possibility / probability of State Aid • 30 year post completion funding

& EU funding allowed for.

• Full 4 months working capital assumed

• 330 days / year operation (90%

EMPLOYMENT for circa 360 FTE efficiency assumed)

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019– v7 29

Denotes a CONTROLLED document

29 Project Status

Upside Potential / Risks

Strong probability to access •Delays (highly unlikely) on

significant (30-50m EUR) State Aid permitting – WET in advanced

due to Project nature, size and state already and project has high

Upside Potential

location (employment). profile.

Access to EU Funding pool for Upward pressure on local

environmental projects (est 22m economy causes price / wage

Risks & Mitigation

EUR of works to be done) growth – WET allowed 2%

compounding inflation (not usual

Optimization will lower CAPEX & in JORC reports).

OPEX and improve returns

Staffing availability locally. WET

Additional / other Mineral recovery has assumed high automation

made possible (Ga/Fe)

08/03/2019 Wastes Ecotech Srl – Project Presentation Update Mar 2019 – v7 30

Denotes a CONTROLLED document

You might also like

- MIL-STD-1689 Reva PDFDocument185 pagesMIL-STD-1689 Reva PDFcostantin2100% (2)

- Manual JJRC X16 RO - CompressedDocument21 pagesManual JJRC X16 RO - CompressedcentrulknowledgeNo ratings yet

- Q150R 5 PDFDocument67 pagesQ150R 5 PDFale403100% (1)

- Alfa - 159 - Service ScheduleDocument3 pagesAlfa - 159 - Service ScheduleDanut - Florian TiparuNo ratings yet

- BS 598-107-2004 - (2022-06-24 - 02-58-16 Am)Document28 pagesBS 598-107-2004 - (2022-06-24 - 02-58-16 Am)Heyson JayNo ratings yet

- Material Safety Data Sheet Stearall LQDDocument4 pagesMaterial Safety Data Sheet Stearall LQDfs1640No ratings yet

- 12-02-15 Z250 Users GuideDocument63 pages12-02-15 Z250 Users GuideTin Win HtutNo ratings yet

- Polita CITYDocument1 pagePolita CITYGheorghita DobreNo ratings yet

- Infratest - Automatic Asphalt AnalyzerDocument22 pagesInfratest - Automatic Asphalt AnalyzerSupriyo PNo ratings yet

- Sist en 12371 2010Document9 pagesSist en 12371 2010AnelNo ratings yet

- Hettiarachchi Brown 2009Document6 pagesHettiarachchi Brown 2009Seraj S. JebrilNo ratings yet

- Chapter 7 SolutionsDocument21 pagesChapter 7 SolutionsARSYIAN RIZKI PRATAMANo ratings yet

- Calculation Procedure For Variable Area Flowmeters According To Vdi/Vde 3513 Part 1Document1 pageCalculation Procedure For Variable Area Flowmeters According To Vdi/Vde 3513 Part 1Anuj SinghNo ratings yet

- 25477standardmotorcarburetionft - 97 Reduce 2 PDFDocument204 pages25477standardmotorcarburetionft - 97 Reduce 2 PDFSaszet RékaNo ratings yet

- RPDIR-P12.1 Shielding Calculation WEBDocument23 pagesRPDIR-P12.1 Shielding Calculation WEBPici-pici BaliNo ratings yet

- Sharan JSWDocument30 pagesSharan JSWLAXMI GUNTUKNo ratings yet

- Corrosivity of SoilsDocument5 pagesCorrosivity of SoilsMorched TounsiNo ratings yet

- Stas 7184 7 1997 enDocument15 pagesStas 7184 7 1997 enCheran Florin TiberiuNo ratings yet

- Scientific Conference of Doctoral Schools: ProgrammesDocument39 pagesScientific Conference of Doctoral Schools: ProgrammesDrăghici Ionut-Alex100% (1)

- Sampling and Examination of Bituminous Mixtures For Roads and Other Paved AreasDocument10 pagesSampling and Examination of Bituminous Mixtures For Roads and Other Paved AreasPPLLMMNNBBNo ratings yet

- Dando Terrier and Tooling OverviewDocument17 pagesDando Terrier and Tooling Overviewkillaruna04No ratings yet

- As 2219.1.1-2002 Methods of Test For Vitreous Enamel Coatings Chemical Tests - Determination of Resistance ofDocument4 pagesAs 2219.1.1-2002 Methods of Test For Vitreous Enamel Coatings Chemical Tests - Determination of Resistance ofSAI Global - APACNo ratings yet

- KHATIR CFDOptimisation BreadBakingDocument7 pagesKHATIR CFDOptimisation BreadBakingraduonoNo ratings yet

- Drenante g9Document16 pagesDrenante g9Joel Alfonso Manurung100% (1)

- En Iso 17892-4土的筛分试验Document36 pagesEn Iso 17892-4土的筛分试验yangNo ratings yet

- SR en 1504-4Document29 pagesSR en 1504-4Malak HindiNo ratings yet

- Sist en 13892 1 2003Document9 pagesSist en 13892 1 2003AnelNo ratings yet

- Density of KOH SolutionsDocument1 pageDensity of KOH SolutionsjohnihaasNo ratings yet

- Corectie Dozaj Bapc 16 - 05,05,2020Document30 pagesCorectie Dozaj Bapc 16 - 05,05,2020Carmen MantaNo ratings yet

- Elastopor H 2130-38 Material CertificateDocument3 pagesElastopor H 2130-38 Material Certificatejithinjose860% (2)

- Lista Completă A Lucrarilor PublicateDocument5 pagesLista Completă A Lucrarilor Publicatebasliu vasileNo ratings yet

- 4-Physical PropertiesDocument98 pages4-Physical PropertiesZahoor AhmadNo ratings yet

- 水泥生产工艺Document36 pages水泥生产工艺ZHAN JIMMY100% (1)

- DEEE, Organizaţii Colective in RomaniaDocument3 pagesDEEE, Organizaţii Colective in RomaniasimonamemetNo ratings yet

- TL Gestein-Stb 04: Technical Delivery Terms For Aggregates in Road ConstructionDocument64 pagesTL Gestein-Stb 04: Technical Delivery Terms For Aggregates in Road ConstructionChakir KasdarliNo ratings yet

- Halcrow Romania SRLDocument33 pagesHalcrow Romania SRLSerban IonescuNo ratings yet

- Is Coarse Aggregate and Fine AggregateDocument21 pagesIs Coarse Aggregate and Fine AggregateVishow SharmaNo ratings yet

- Norme Deviz If Imbunatatiri Funciare Si Corectia TorentilorDocument189 pagesNorme Deviz If Imbunatatiri Funciare Si Corectia TorentilorCatalin GudeiNo ratings yet

- Chemical Attack On Concrete - Determination of Aggressive Carbon Dioxide Content in WaterDocument12 pagesChemical Attack On Concrete - Determination of Aggressive Carbon Dioxide Content in WaterashrafNo ratings yet

- En 1426 2015Document14 pagesEn 1426 2015AndraNo ratings yet

- Soil Contamination With Cadmium, Consequences and Remediation UsingDocument15 pagesSoil Contamination With Cadmium, Consequences and Remediation UsingsalmanNo ratings yet

- General Directorate of Dams and Reservoirs/ Construction of Gomaspan DamDocument3 pagesGeneral Directorate of Dams and Reservoirs/ Construction of Gomaspan Damako DhahirNo ratings yet

- Silica: For Water and Seawater Silicomolybdate/Heteropoly Blue MethodDocument1 pageSilica: For Water and Seawater Silicomolybdate/Heteropoly Blue Methodhakim1702No ratings yet

- BS en 1367-5 2002Document12 pagesBS en 1367-5 2002XaviorNo ratings yet

- R06 - Plan Armare Placa Peste Etaj Tehnic - 420X420 - 6Document1 pageR06 - Plan Armare Placa Peste Etaj Tehnic - 420X420 - 6Bogdan ParaschivNo ratings yet

- DDDDDDDDDDDDDDDocument1 pageDDDDDDDDDDDDDDadrianaandriesiNo ratings yet

- F 24 Raport de Neconformitate Produs KDocument2 pagesF 24 Raport de Neconformitate Produs KPetrisor IonelNo ratings yet

- OSIM April 2008 PDFDocument394 pagesOSIM April 2008 PDFjamjam75No ratings yet

- J424manual Incendiu BentelDocument64 pagesJ424manual Incendiu BentelAndreea PocotilaNo ratings yet

- As 4816.1-2002 Determination of Particle Size Distribution by Gravitational Liquid Sedimentation Methods GeneDocument8 pagesAs 4816.1-2002 Determination of Particle Size Distribution by Gravitational Liquid Sedimentation Methods GeneSAI Global - APACNo ratings yet

- Comandos RuptelaDocument38 pagesComandos RuptelaJulio Putuquia100% (1)

- Environment & Energy Aspects of Corex at JSW Steel LTDDocument19 pagesEnvironment & Energy Aspects of Corex at JSW Steel LTDkumarcv89No ratings yet

- WPL LTD Percolation Tunnel ManualDocument2 pagesWPL LTD Percolation Tunnel Manualanca_mlajiceanu8696No ratings yet

- A Review of Direct Z-Scheme Photocatalysis PDFDocument21 pagesA Review of Direct Z-Scheme Photocatalysis PDFAjay Peter ManuelNo ratings yet

- 23-30479679 DC BS en 1998-1-2. Eurocode 8. Design of Structures For Earthquake Resistance. Part 1-2. BuildingsDocument394 pages23-30479679 DC BS en 1998-1-2. Eurocode 8. Design of Structures For Earthquake Resistance. Part 1-2. BuildingsJ MrNo ratings yet

- Roof Tiles Prepared by Using Fly Ash and Analyzing Mechanical PropertiesDocument8 pagesRoof Tiles Prepared by Using Fly Ash and Analyzing Mechanical PropertiesTJPRC PublicationsNo ratings yet

- European Standard Norme Européenne Europäische NormDocument27 pagesEuropean Standard Norme Européenne Europäische NormАлександра Костенко100% (1)

- Mastertop 200 TDSDocument5 pagesMastertop 200 TDSpria prcNo ratings yet

- Manual Terratest 3000Document59 pagesManual Terratest 3000salpacheNo ratings yet

- Zinc Deposition Dorsman Rgd25Document6 pagesZinc Deposition Dorsman Rgd25han.velthuis431No ratings yet

- ISO TC 071 Concrete Reinforced Concrete and Pre-Stressed Concrete PDFDocument11 pagesISO TC 071 Concrete Reinforced Concrete and Pre-Stressed Concrete PDFLRF2014No ratings yet

- Lucrarea RevDocument72 pagesLucrarea RevValentin Gherman100% (1)

- Curba Ba 8 - 27,04,2020Document27 pagesCurba Ba 8 - 27,04,2020Carmen Manta100% (1)

- Project Design Document (PDD) : CDM - Executive BoardDocument76 pagesProject Design Document (PDD) : CDM - Executive BoardPradeep DubeyNo ratings yet

- Sika SolarMount 1Document4 pagesSika SolarMount 1Saszet RékaNo ratings yet

- Masterseal 545 en 1Document3 pagesMasterseal 545 en 1Saszet RékaNo ratings yet

- Appendix A: Construction Management Plan TemplateDocument13 pagesAppendix A: Construction Management Plan TemplateSaszet RékaNo ratings yet

- Basement Construction and Underpinning MDocument25 pagesBasement Construction and Underpinning MSaszet RékaNo ratings yet

- 005642en Floor Conductive Floor Coating 04 03-21 72dpiDocument16 pages005642en Floor Conductive Floor Coating 04 03-21 72dpiSaszet RékaNo ratings yet

- Spring 2020 ROADHOUSE CatalogDocument33 pagesSpring 2020 ROADHOUSE CatalogSaszet RékaNo ratings yet

- Illustrated Connector Guide: SocketDocument2 pagesIllustrated Connector Guide: SocketSaszet RékaNo ratings yet

- PDFDocument1,952 pagesPDFSaszet RékaNo ratings yet

- ChromiumDocument29 pagesChromiumjosevitorromualdoNo ratings yet

- MEC Powder List dt.20.08.2021Document12 pagesMEC Powder List dt.20.08.2021dileep mNo ratings yet

- CHEM-E6155 Minerals Engineering Project WorkDocument5 pagesCHEM-E6155 Minerals Engineering Project WorkEngineering Office ShahrakNo ratings yet

- The Basic Oxygen SteelmakingDocument13 pagesThe Basic Oxygen SteelmakingEhsanulhaq786No ratings yet

- Samm0384 Myco2Document25 pagesSamm0384 Myco2ediasianagriNo ratings yet

- Material ASTMDocument14 pagesMaterial ASTMAdit NugrahaNo ratings yet

- Unit-4 - Tool Materials Cutting Fluids and MachinabilityDocument63 pagesUnit-4 - Tool Materials Cutting Fluids and MachinabilityTharunNo ratings yet

- Waste Production and Utilization in The Metal Extraction Industry - Optimized PDFDocument531 pagesWaste Production and Utilization in The Metal Extraction Industry - Optimized PDFNgoni MhondeNo ratings yet

- Bombas de Desagüe Sumergibles SJ 150-400Document2 pagesBombas de Desagüe Sumergibles SJ 150-400Dennis MedinaNo ratings yet

- Sree Eco ProjDocument4 pagesSree Eco Projsteevejan541No ratings yet

- Civil Engineering Objective Type QuestionDocument764 pagesCivil Engineering Objective Type QuestionMuhammad Umar FarooqNo ratings yet

- Technical Data PDFDocument41 pagesTechnical Data PDFrachitmailNo ratings yet

- November 2020 (v1) QP - Paper 2 CIE Chemistry GCSEDocument16 pagesNovember 2020 (v1) QP - Paper 2 CIE Chemistry GCSEmercy.cyfn.109No ratings yet

- Learning Unit 1 - MetallographyDocument20 pagesLearning Unit 1 - Metallographykhumalosafu17No ratings yet

- G8 CHM Periodic - Table WorksheetDocument4 pagesG8 CHM Periodic - Table Worksheetrose roseyNo ratings yet

- CSA 165.1 Specifications & General Specifications Notes: Canadian Concrete Masonry Producers' AssociationDocument17 pagesCSA 165.1 Specifications & General Specifications Notes: Canadian Concrete Masonry Producers' AssociationZebNo ratings yet

- PANER, CM - Structure and Material Composition of A PaintingDocument47 pagesPANER, CM - Structure and Material Composition of A PaintingCrisencio M. PanerNo ratings yet

- Lalith Castle International SchoolDocument3 pagesLalith Castle International Schoolkashishsoni1011No ratings yet

- Science - IV: 3 QuarterDocument31 pagesScience - IV: 3 QuarterMelanie Dela Cruz CayabyabNo ratings yet

- TelluriumProject PDFDocument18 pagesTelluriumProject PDFRalph Carlo EvidenteNo ratings yet

- Aluminum 6061 vs. Aluminum 6063Document4 pagesAluminum 6061 vs. Aluminum 6063Vipin JoseNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- DRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Document37 pagesDRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Kannan MurugesanNo ratings yet

- Leaderkam Kammprofile Gasket Style FDocument2 pagesLeaderkam Kammprofile Gasket Style FRahul HariNo ratings yet

- Properties of Engineering Materials Lesson 3 (I)Document11 pagesProperties of Engineering Materials Lesson 3 (I)Douglas Kufre-Abasi GilbertNo ratings yet

- Main Group ElementsDocument8 pagesMain Group ElementsSharlene RobertsNo ratings yet

- BOARD - MinMethod Board (Answ)Document9 pagesBOARD - MinMethod Board (Answ)Joanna Marie MalateNo ratings yet

- Hand Book-GalvanizingDocument9 pagesHand Book-GalvanizingSreedhar Patnaik.M100% (1)