Professional Documents

Culture Documents

Pressure Controls, Type KP, With Enclosure IP 33, IP 44 or IP 54

Pressure Controls, Type KP, With Enclosure IP 33, IP 44 or IP 54

Uploaded by

Evandro Jva compressoresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Controls, Type KP, With Enclosure IP 33, IP 44 or IP 54

Pressure Controls, Type KP, With Enclosure IP 33, IP 44 or IP 54

Uploaded by

Evandro Jva compressoresCopyright:

Available Formats

Pressure controls,

type KP, with enclosure IP 33, IP 44 or IP 54

Introduction

KP pressure controls are used as protection KP pressure controls are fitted with a single pole

against too low a suction pressure or too high double throw (SPDT) changeover switch. The

a discharge pressure on compressors in position of the switch is determined by the

refrigeration and air conditioning plant. pressure control setting and the pressure at the

KP pressure controls are also used for starting connector.

and stopping refrigeration compressors and fans KP pressure controls can be supplied with

for air-cooled condensers. enclosures IP 33, IP 44 and IP 54.

Features • Ultra-short bounce times • Vibration and shock resistant

Reduces wear to a minimum and

increases reliability. • Compact design

• Manual control • Laser welded bellows

Testing the electrical contact function can be

performed without the use of tools.

Approvals M DEMKO, Denmark DnV, Det norske Veritas, Norway

O NEMKO, Norway RINA, Registro Italiano Navale, Italy

W FIMKO, Finland BV, France

C SEV, Switzerland LR, England

F Germanischer Lloyd, Germany MRS, Maritime Register of Shipping, Russia

D DIN 32733, Germany EZU, Czech Republic

(KP 7W, 7B, 7S; KP 7B, 7 ABS; KP 17W, 17B) CE marked according to EN 60947-4, -5

P Polski Rejestr Statków, Poland

Versions with UL and CSA approvals can be

supplied to special order.

Materials in contact Unit type Material

with the medium

KP 1, 2, 5, 7, 15 Tinbronze, no. 2.1020 acc. to DIN 17662

and 17 Free cutting steel, no. 1.0737 / 1.0718 acc. to DIN 1651

KP 1A, 5A, 7A Stainless steel 18/8, no. 1.0737 / 1.0718 acc. to DIN 17440

and 15A only Free cutting steel, no. 1.0719 acc. to DIN 1651

Steel, no. 1.0330 acc. to DIN 1624

Aluminium, no. 3.0255 acc. to DIN 1712

Danfoss 9/96 Catalogue RK.00.H5.02 - Page 294

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

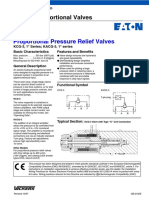

Technical data Ambient temperature Contact systems

−40 → +65°C (+80°C for max. 2 hours).

DIN-approved units:

−25 → +65°C (+80°C for max. 2 hours).

Max. working pressure

LP: PB = 17 bar Low pressure (LP)

HP: PB = 32 bar

Max. test pressure

LP: p’ = 20 bar

HP: p’ = 35 bar

Contact load

Alternating current:

AC1: 16 A, 400 V High pressure (HP)

AC3: 16 A, 400 V

AC15: 10 A, 400 V

Max. starting current (L.R.): 112 A, 400 V

Direct current:

DC13: 12 W, 220 V control current

Dual pressure

(HP/HP)

Cable connection

The cable entry can be used for 6 → 14 mm dia.

cables.

A Pg 13.5 screwed cable entry can also be used

for 6 → 14 mm cable. With 8 → 16 mm cable a

standard Pg 16 screwed cable entry can be used.

Enclosure

Dual pressure

IP 33 to EN 60529 / IEC 529 (LP/HP)

Enclosure IP 33 is obtained when the units

without top cover are mounted on a flat surface

or bracket. The bracket must be fixed to the unit

so that all unused holes are covered.

IP 44 to EN 60529 / IEC 529

Enclosure IP 44 is obtained when the units

with top cover are mounted on a flat surface or

bracket. The bracket must be fixed to the unit so

that all unused holes are covered.

KP pressure controls with auto reset are supplied Dual pressure

(LP/HP)

with top cover. For KP pressure controls with

manual reset, the top cover must be separately

ordered.

IP 54 to EN 60529 / IEC 529

IP 54 is obtained when the KP pressure controls

are mounted in an IP 54 enclosure, (code no.

60-0330 for single pressure controls and code

no. 60-0350 for dual pressure controls).

IP 54 enclosure has to be ordered separately.

Catalogue RK.00.H5.02 - Page 295 Danfoss 9/96

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

Ordering

Low pressure (LP) High pressure (HP) Reset Code no.

Regulating Differential Regulating Differential Low High Contact 1/4 in. 1/4

in. 6 mm 6 mm

Pressure Type

range ∆p range ∆p pressure pressure system 6 mm ODF ODF cutting

bar bar bar bar LP HP flare solder solder ring

For fluorinated refrigerants

Low KP 1 −0.2 → 7.5 0.7 → 4.0 Aut. 60-1101 60-1112 60-1110 60-5051

Low KP 1 −0.2 → 7.5 0.7 → 4.0 Aut. 60-1141 1)

Low KP 1 −0.9 → 7.0 Fixed 0.7 Man. 60-1103 60-1111 60-1109 60-5052

Low KP 2 −0.2 → 5.0 0.4 → 1.5 Aut. SPDT 60-1120 60-1124 60-1123

High KP 5 8 → 32 1.8 → 6.0 Aut. 60-1171 60-1179 60-1177 60-5053

High KP 5 8 → 32 1.8 → 6.0 Aut. 60-1142 1)

High KP 5 8 → 32 Fixed 3 Man. 60-1173 60-1180 60-1178 60-5054

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. Aut. 60-1241 60-1254 60-1249 60-5055

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. Aut. 60-1119 1)

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. Man. SPDT + 60-1243 60-1255 60-1250 60-5056

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. Man. LP signal 60-11481)3)

Dual KP 15 −0.9 → 7.0 Fixed 0.7 8 → 32 Fixed 4 Man. Man. 60-1245

Dual KP 15 −0.9 → 7.0 Fixed 0.7 8 → 32 Fixed 4 Conv.2) Conv.2) 60-1261 60-1263 60-1262

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. Aut. 60-1265 60-1299 60-1297

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. Man. SPDT + 60-1264 60-1284 60-1298 60-5057

LP and HP

Dual KP 15 −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Conv.2) Conv.2) signal 60-1154 60-0010

Dual KP 15 −0.9 → 7.0 Fixed 0.7 8 → 32 Fixed 4 Conv.2) Conv.2) 60-1220

Low pressure (LP) High pressure (HP) Reset Code no.

Contact

Pressure Type Regulating Differential Regulating Differential M10 × 0.75 6 mm cutting ring 1 m cap.

range ∆p range ∆p LP / HP system tube with

bar bar bar bar IP 44 IP 54 IP 44 IP 54 M10 × 0.75

For fluorinated refrigerants and R 717 (NH3)

Low KP 1A −0.2 → 7.5 0.7 → 4.0 Aut. / - 60-1162 60-5200 60-5005 60-5201 60-1160 4)

Low KP 1A −0.2 → 7.5 0.7 → 4.0 Aut. / - 60-1146 1) 4)

Low KP 1A −0.9 → 7.0 Fixed 0.7 Man. / - 60-1163 3) 60-5202 60-5004 3) 60-5203 60-1161 3)

Low KP 2A −0.2 → 5.0 0.4 → 1.5 Aut. / - SPDT 60-5015 60-5204 60-5006 60-5205

High KP 5A 8 → 32 1.8 → 6.0 - / Aut. 60-1232 60-5206 60-5008 60-5207 60-1230 4)

High KP 5A 8 → 32 1.8 → 6.0 - / Aut. 60-1147 1) 4)

High KP 5A 8 → 32 Fixed 3 - / Man. 60-1153 3) 60-5208 60-5007 3) 60-5209 60-1231 3)

Dual KP 15A −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. / Aut.SPDT + LP 60-1295 60-5210 60-5012 60-5211 60-1293 4)

Dual KP 15A −0.2 → 7.5 0.7 → 4.0 8 → 32 Fixed 4 Aut. / Man. & HP signal 60-1296 3) 60-5212 60-5010 3) 60-5213 60-1294 3)

Dual KP 15A −0.9 → 7.0 Fixed 0.7 8 → 32 Fixed 4 Man. / Man. SPDT 60-1292 3) 60-5214 60-5011 3) 60-5215 60-1287 3)

Dual KP 15A −0.9 → 7.0 Fixed 0.7 8 → 32 Fixed 4 Conv. / Conv.2) LP signal 60-5016 3) 60-5216 60-5009 3) 60-5217 60-1283 3)

1) Pressure controls with gold-plated contacts

2) Conv.: optional automatic or manual reset

3) Enclosure IP 33

4) Enclosure IP 44

Accessories for KP pressure controls with M10 × 0.75 connections:

Weld connections: M10 × 0.75 nut and ∅6 × 150 mm seamless steel pipe, code no. 60-0057

Steel cap. tube: 1 m with 2 × M10 × 0.75 nuts, code no. 60-0078

Steel cap. tube: 1 m with 1 × M10 × 0.75 and G 3/8 nut, code no. 60-0082

Adaptor: 1/4 to 1/8 NPT int. thread, code no. 60-0141

IP 54 enclosure for single pressure controls, code no. 60-0330

IP 54 enclosure for dual pressure controls, code no. 60-0350

For other accessories: see "Spare parts and accessories", RK.0X.G2.02.

Danfoss 9/96 Catalogue RK.00.H5.02 - Page 296

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

Ordering Pressure control setting with convertible reset

(continued)

Low press. Manual reset 1) Automatic reset Automatic reset Manual reset

High press. Manual reset 1) Manual reset Automatic reset Automatic reset

1) Factory setting

Pressure controls with DIN 32733 approval 1)

Low pressure (LP) High pressure (HP) Reset Code no.

Regulating Differential Regulating Differential Contact DIN 1/4in. 6 mm

Pressure Type 2)

range ∆p range ∆p LP / HP system approvals 6 mm M10 × 0.75 ODF

bar bar bar bar flare solder

Anvendes til fluorerede kølemidler

Low KP 1W −0.2 → 7.5 0.7 → 4.0 Aut. / - SPDT DWFK 4B06895 60-5101 4) 60-5110 4)

Low KP 1W −0.5 → 3.0 Fixed 0.7 Aut. / - SPDT DWFK 4B06895 60-1113 4) 60-1117 4)

Low KP 1B −0.9 → 7.0 Fixed 0.7 Man. / - SPDT DBFK 4B06995 60-5103 3) 60-5109 3)

Low KP 2W −0.2 → 5.0 0.2 → 1.5 Aut. / - SPDT DWFK 4B07095 60-5120 4) 60-5123 4)

High KP 7W 8 → 32 4 → 10 - / Aut. SPDT DWK 4B00194 60-1190 4) 60-1203 4)

High KP 7W 8 → 32 4 → 10 - / Aut. SPDT DWK 4B00194 60-5021 4) 6) 60-1203 4)

High KP 7B 8 → 32 Fixed 4 - / Man. SPDT DBK 4B00394 60-1191 3)

High KP 7B 8 → 32 Fixed 4 - / Man. SPDT DBK 4B00394 60-5022 3) 6)

High KP 7S 8 → 32 Fixed 4 - / Man. SPDT DBK 4B00394 60-1192 3) 60-1213 3)

High KP 7S 8 → 32 Fixed 4 - / Man. SPDT DBK 4B00394 60-5023 3) 6)

Dual KP 7BS 8 → 32 Fixed 4 Man. / Man. SPST DBK 4B00294 60-1200 3) 60-1214 3)

SPDT +

Dual KP 17W −0.2 → 7.5 0.7 → 4 8 → 32 Fixed 4 Aut. / Aut. LP and HP DWK 4B00594 60-1275 4) 60-1276 4)

signal

Dual KP 17W −0.2 → 7.5 0.7 → 4 8 → 32 Fixed 4 Aut. / Aut. SPDT DWK 4B00594 60-1267 4) 60-1272 4)

Dual KP 17B −0.2 → 7.5 0.7 → 4 8 → 32 Fixed 4 Aut. / Man. SPDT DBK 4B00494 60-1268 3) 60-1274 3)

Pressure controls with DIN 32733 approval 1)

Low pressure (LP) High pressure (HP) Reset Code no.

Contact DIN

Pressure Type Regulat. Different. Regulat. Different. M10 × 0.75 6 mm cutting ring 1 m cap.

range ∆p range ∆p LP / HP system approvals tube with

bar bar bar bar IP 44 IP 54 IP 44 IP 54 M10 × 0.75

For ammonia

Low KP 1AW 0.2 → 7 0.7 → 4 Aut. / - SPDT DWFK 4B06895 60-5127 5) 60-5218 5)

Low KP 1AB 0.9 → 7 Fixed 0.7 Man. / - SPDT DBFK 4B06995 60-5128 5) 60-5219 5)

High KP 7AS 8 → 32 Fixed 4 - / Man. SPDT DBK 4B00294 60-1155 60-5014

High KP 7ABS 8 → 32 Fixed 4 - / Man. SPST DBK 4B00294 60-5017 3) 60-5221 60-5013 3) 60-5220 60-1205 3)

1) Meets the requirements in VBG 20 dealing with safety equipment and excess pressures.

2) W = Wächter (pressostat), B = Begrenzer (pressure control with ext. reset), S = Sicherheitsdruckbegrenzer (pressure control with int. reset).

A bellows rupture in inner bellows will cause the refrigeration plant compressor to stop.

A rupture of the outer bellows will cause the stop pressure to fall approx. 3 bar under the set value.

3) Enclosure IP 33.

4) Enclosure IP 44.

5) With ∅6 × 150 mm weld connection.

6) KP with goldplated contacts.

Catalogue RK.00.H5.02 - Page 297 Danfoss 9/96

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

Design

Capillary tube

Key sketch of KP pressure control

Capillary tube for KP 1A, 5A and 15A

KP 1

1. Low pressure setting spindle, LP

2. Differential setting spindle, LP

3. Main arm

5. High pressure setting spindle, HP

7. Main spring

8. Differential spring

9. Bellows

10. LP connection

11. HP connection Cutting ring connection

12. Switch

13. Terminals

14. Earth terminal

15. Cable entry

16. Tumbler

18. Locking plate

19. Arm KP 15 Weld nipple for KP

30. Reset button

The switch in the KP has a snap-action function The design of the KP affords the following

and the bellows moves only when the cutin or advantages:

cutout value is reached. − high contact load

− ultra-short bounce time

The bellows becomes connected to the low − high resistance to pulsation

or high pressure side of the plant through − vibration resistance up to 4 g in the range

connection (10) or (11). 0-1000 Hz

− long mechanical and electrical life

Danfoss 9/96 Catalogue RK.00.H5.02 - Page 298

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

Design The KP with letters W, B or S have been tested Versions with designation W or AW cut in again

(continued) and approved by J (Technischer Über- automatically when the pressure has fallen to

wachungs Verein, Federal Republic of Germany) the set value minus the differential.

in accordance with DIN 32733. Versions with designation B or AB can be cut in

W = Wächter (pressure control) manually with the external reset button when the

B = Begrenzer pressure in KP 1 has raised 0.7 bar above set

(pressure control with external reset) value and in KP 7 has fallen 4 bar under the set

S = Sicherheitsdruckbegrenzer value.

(pressure control with internal reset).

Versions with designation S or AS can be cut in

KP 7 and KP 17 have a double bellows, an manually with the internal reset arm when the

outer bellows and a regulating bellows. When pressure has fallen 4 bar under the set value.

pressure in the plant exceeds the set value, the

KP will automatically stop the plant. The double All KP pressure controls, including those which

bellows system prevents loss of system charge are DIN-approved, operate independently of

in the event of bellows rupture. changes in the ambient temperature around

the control housing. Therefore the set cut-out

A rupture in the outer bellows will cause the pressure and differential are held constant

cut-out pressure of the unit to fall to about 3 bar provided the permissible ambient temperatures

under the set value, and thus provides a are not exceeded.

fail-safe function.

KP 7W, flare

KP 7W, solder

1. Pressure setting spindle

2. Differential setting spindle

3. Main arm

5. Pressure setting spindle, DBK

15. Cable entry

18. Locking plate

19. Arm

25. Int. reset arm KP 7BS

30. Ext. reset button

Catalogue RK.00.H5.02 - Page 299 Danfoss 9/96

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

Terminology Reset Test pressure

1. Manual reset: The test pressure is the pressure used in strength

Units with manual reset can only be reset tests and/or leakage tests on refrigerating

during operation by activation of the reset systems or individual parts in systems. The test

button. pressure is designated p’.

2. Automatic reset:

After operational stop, these units reset "Snap function"

automatically. A certain contact force is maintained until

3. Convertible reset: irrevocable "snap" is initiated. The time during

Units with optional reset can be activated by which the contact force approaches zero is thus

automatic and/or manual reset. limited to a very few milliseconds. Therefore

contact bounce cannot occur as a result of, for

Permissible working pressure example, slight vibrations, before the cut-out

The permissible working pressure is determined point. Contact systems with "Snap function" will

by the pressure that can be safely allowed in the change over even when micro-welds are created

refrigerating system or any of the units within it. between the contacts during cut-in. A very high

The permissible working pressure is designated force is created during cut-out to separate the

PB (Der zulässige Betriebsüberdruck). contacts. This force immediately shears off all the

welds. Thus the cut-out point of the unit remains

very accurate and completely independent of the

magnitude of the current load.

Setting Pressure controls with automatic reset - LP: Pressure controls with automatic reset - HP:

Set the LP start pressure on the "CUT-IN" scale Set the HP pressure on the "CUT-OUT" scale.

(range scale). One rotation of the HP spindle ∼ 2.3 bar.

One rotation of the low pressure spindle ∼ Set the HP differential on the "DIFF" scale.

0.7 bar. One rotation of the differential spindle ∼ 0.3 bar.

Set the LP differential on the "DIFF" scale. One The HP start pressure is the HP stop pressure

rotation of the differential spindle ∼ 0.15 bar. minus the differential.

The LP stop pressure is the LP start pressure Start and stop pressures for both the LP and HP

minus the differential. sides of the system should always be checked

with an accurate pressure gauge.

Note:

The LP stop pressure must be above Pressure controls with manual reset

absolute vacuum (pe = −1 bar)! Set the stop pressure on "CUT-OUT" scale

(range scale).

If with low stop pressure the refrigeration Low pressure controls can be manually reset

compressor will not stop, check to ensure that when the pressure is equal to the stop pressure

the differential value has not been set too high! plus the differential.

High pressure controls can be manually reset

when the pressure is equal to the stop pressure

minus the differential.

Danfoss 9/96 Catalogue RK.00.H5.02 - Page 300

Pressure controls, type KP, with enclosure IP 33, IP 44 or IP 54

Dimensions and weights

Flare connection KP with top cover

KP 1, 2, 5, 7B, 7S and 7W KP 15 and 17W

M10 × 0.75 connection KP with IP 54 enclosure

KP 1A, 2A og 5A KP 15A, 7 AS and 7ABS

Cutting ring connection KP with IP 54 enclosure

KP 1A, 2A and 5A KP 15A, 7 AS and 7ABS

Solder connection IP 54 enclosure

IP 54 enclosure

KP 1, 2, 5, 7B, 7S and 7W KP 15, 17W

Weld nipple Weight

KP 1, 2, 5 and 7: approx. 0.3 kg

KP 15, 17 and 7BS: approx. 0.5 kg

KP 1A and 5A: approx. 0.3 kg

KP 15A and 7ABS: approx. 0.5 kg

Catalogue RK.00.H5.02 - Page 301 Danfoss 9/96

You might also like

- Arctic Cat Parts Manual 2012 Atv 425 CR Black A2012irk4cuspDocument72 pagesArctic Cat Parts Manual 2012 Atv 425 CR Black A2012irk4cuspyewlimNo ratings yet

- Data Sheet Pressure Controls, Type KP, With Enclosure IP 33 or IP 44Document12 pagesData Sheet Pressure Controls, Type KP, With Enclosure IP 33 or IP 44beu catalinNo ratings yet

- Dwyer kp15 BrochureDocument13 pagesDwyer kp15 BrochurePT VeritasNo ratings yet

- Danfoss 2 PsDocument13 pagesDanfoss 2 PsRoshan JaiswalNo ratings yet

- Danfoss - Pressure Control KP1, KP5Document8 pagesDanfoss - Pressure Control KP1, KP5Parinpa Ketar100% (1)

- Pressure Switch: Data SheetDocument4 pagesPressure Switch: Data SheettauNo ratings yet

- Features: IC - PD.P10.F1.02 - 520B2008 11Document5 pagesFeatures: IC - PD.P10.F1.02 - 520B2008 11Knuth SchellstedeNo ratings yet

- KP ThermostatsDocument9 pagesKP ThermostatsMargaret DaughertyNo ratings yet

- Dunham Bush High Efficiency Air-Cooled ChillerDocument35 pagesDunham Bush High Efficiency Air-Cooled ChillerAmro Metwally El HendawyNo ratings yet

- Danfoss Pressure SwitchDocument10 pagesDanfoss Pressure SwitchRoshan JaiswalNo ratings yet

- LG Beko 28cz10rx Service ManualDocument32 pagesLG Beko 28cz10rx Service ManualAlan ScarfidiNo ratings yet

- Technical Leaflet: Liquid Level TransmitterDocument8 pagesTechnical Leaflet: Liquid Level TransmitterAnderengNo ratings yet

- Beko 14.2 PDFDocument33 pagesBeko 14.2 PDFMos CraciunNo ratings yet

- ABB Industrial Plugs & Sockets CatalogueDocument130 pagesABB Industrial Plugs & Sockets CataloguegabrielaNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizNo ratings yet

- Presostato Danfoss KP 15Document10 pagesPresostato Danfoss KP 15RolandoNo ratings yet

- Danfoss Pressure Switch Type KPDocument9 pagesDanfoss Pressure Switch Type KPMohammed RayanNo ratings yet

- Engineering: GREAT SolutionsDocument10 pagesEngineering: GREAT SolutionsDanielNo ratings yet

- 2700ADDocument2 pages2700ADJulio GodinezNo ratings yet

- 2700ARDocument2 pages2700ARJulio GodinezNo ratings yet

- FlowmeterDocument8 pagesFlowmeterNest Automation GroupNo ratings yet

- Catalogue - Air Cooled Condensers HCL M NV NW V BVDocument16 pagesCatalogue - Air Cooled Condensers HCL M NV NW V BVdavid hNo ratings yet

- Evap. KeeprideDocument44 pagesEvap. KeeprideAbdiel Kadir Martinez MendozaNo ratings yet

- Products 362Document2 pagesProducts 362abuzer1981No ratings yet

- Cartridge Pressure Switch Type ACB and CCB: Data SheetDocument12 pagesCartridge Pressure Switch Type ACB and CCB: Data Sheetlazar.bulovanNo ratings yet

- Hydro-Electric Pressure Switch: Replaces: 07.06Document16 pagesHydro-Electric Pressure Switch: Replaces: 07.06mvarsani74No ratings yet

- Apl5916 AnpecDocument20 pagesApl5916 Anpecايهاب فوزيNo ratings yet

- DK CP enDocument20 pagesDK CP enbrilian pungkyNo ratings yet

- Beko 14.2 Chassis Full TV SMDocument34 pagesBeko 14.2 Chassis Full TV SMJosep Maria Bargallo MoyaNo ratings yet

- Service Manual MDF-594 MDF-594AT MDF-593 (N) : Ultra-Low Temperature FreezerDocument29 pagesService Manual MDF-594 MDF-594AT MDF-593 (N) : Ultra-Low Temperature FreezerАНДРЕЙNo ratings yet

- MDFU443 Service ManualDocument81 pagesMDFU443 Service ManualtonyNo ratings yet

- Julabo Corio CD-600fDocument4 pagesJulabo Corio CD-600fAlexander AndikaNo ratings yet

- Válvula KCG 03Document11 pagesVálvula KCG 03CristianNo ratings yet

- b1x b2x Ds PDFDocument2 pagesb1x b2x Ds PDFscibduser001No ratings yet

- Anpec Elec APW7301KAI TRG - C115136Document20 pagesAnpec Elec APW7301KAI TRG - C115136Bawantha Prasad MihirangaNo ratings yet

- RWF40 Technical LiteratureDocument6 pagesRWF40 Technical LiteratureRamadanNo ratings yet

- CR 9 KCDocument4 pagesCR 9 KCLiviu ToaderNo ratings yet

- Sanyo MDF-U4186S Service ManualDocument30 pagesSanyo MDF-U4186S Service ManualEmRe OflazNo ratings yet

- Data Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Document8 pagesData Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Abdeldjalil AchourNo ratings yet

- EMCODocument12 pagesEMCOesen hawerNo ratings yet

- A9L15692Document2 pagesA9L15692Rizal MeifanNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- Instructions AK-PC 351 (Інструкція)Document6 pagesInstructions AK-PC 351 (Інструкція)nikolaNo ratings yet

- Rslogix 5xxx-176 - Rev5Document20 pagesRslogix 5xxx-176 - Rev5Ahmed GomaaNo ratings yet

- (Top View) (Top View) : 1.5Mhz Synchronous Step-Down DC-DC ConverterDocument12 pages(Top View) (Top View) : 1.5Mhz Synchronous Step-Down DC-DC ConverterRenato HernandezNo ratings yet

- SBS Tech ChillerDocument1 pageSBS Tech ChillerYang John (Rich-Tech1688)No ratings yet

- Samsung Wall Mouted Classic Heat PumpsDocument6 pagesSamsung Wall Mouted Classic Heat Pumpse-ComfortUSANo ratings yet

- Service Manual: MDF-U73V MDF-U73VCDocument76 pagesService Manual: MDF-U73V MDF-U73VCfelix bazanNo ratings yet

- Enye Product Knowledge-RevnewDocument101 pagesEnye Product Knowledge-RevnewJon Elmer DelgadoNo ratings yet

- AP1000 Air Purger PUBL-7890 2021 ENDocument2 pagesAP1000 Air Purger PUBL-7890 2021 ENSalahNo ratings yet

- Samsung Neo Forte Wall Mounted Heat PumpsDocument5 pagesSamsung Neo Forte Wall Mounted Heat Pumpse-ComfortUSANo ratings yet

- Danfoss RTDocument12 pagesDanfoss RTSerge Yannick MimboeNo ratings yet

- The Industrial Range Offers Numerous Ádqjhfrpelqdwlrqv: Type A 22C 04 - For General PurposeDocument1 pageThe Industrial Range Offers Numerous Ádqjhfrpelqdwlrqv: Type A 22C 04 - For General PurposeBaoLCNo ratings yet

- FB-7000 Series Catalog (2013)Document4 pagesFB-7000 Series Catalog (2013)Luis MataNo ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- KP 15Document4 pagesKP 15Brian ByengaboNo ratings yet

- 1U24+AB24 Service Manual2 NtoDocument71 pages1U24+AB24 Service Manual2 NtoTudorCristeaNo ratings yet

- MDFu 74Document47 pagesMDFu 74Rhishidas PuthiyavalappilNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- K 350 1 2560 20290-01 01useDocument40 pagesK 350 1 2560 20290-01 01useEvandro Jva compressoresNo ratings yet

- Service Manual: Sigma Air Manager 16/8Document192 pagesService Manual: Sigma Air Manager 16/8Evandro Jva compressoresNo ratings yet

- KCD 1 3568 0-00 01eDocument38 pagesKCD 1 3568 0-00 01eEvandro Jva compressoresNo ratings yet

- 1 2810 2-000 00useDocument160 pages1 2810 2-000 00useEvandro Jva compressoresNo ratings yet

- Asd 2C 10224114 10-000 00useDocument136 pagesAsd 2C 10224114 10-000 00useEvandro Jva compressoresNo ratings yet

- Service Manual Sigma Air Control Plus: Article Number: 7.7740.0 7.7741.0 7.7742.0Document47 pagesService Manual Sigma Air Control Plus: Article Number: 7.7740.0 7.7741.0 7.7742.0Evandro Jva compressoresNo ratings yet

- 7 - 5250 - 01880 - 01E NachrüstsatzDocument11 pages7 - 5250 - 01880 - 01E NachrüstsatzEvandro Jva compressoresNo ratings yet

- Technical Description Sigma Air Manager: GSM Modem Retrofit KitDocument20 pagesTechnical Description Sigma Air Manager: GSM Modem Retrofit KitEvandro Jva compressoresNo ratings yet

- 7 - 7740 - 0 - 14E SIGMA AIR CONTROL PlusDocument85 pages7 - 7740 - 0 - 14E SIGMA AIR CONTROL PlusEvandro Jva compressoresNo ratings yet

- 9 - 9450 - 01USE Steuerung Zu ASD.2CDocument182 pages9 - 9450 - 01USE Steuerung Zu ASD.2CEvandro Jva compressoresNo ratings yet

- TW 100 Maintenance ScheduleDocument1 pageTW 100 Maintenance ScheduleEvandro Jva compressoresNo ratings yet

- CPF-175-200-CPVS-200-250 ManualDocument28 pagesCPF-175-200-CPVS-200-250 ManualEvandro Jva compressoresNo ratings yet

- Model:: AE4425Y-GS1ADocument8 pagesModel:: AE4425Y-GS1AEvandro Jva compressoresNo ratings yet

- W Series Maintenance ScheduleDocument13 pagesW Series Maintenance ScheduleEvandro Jva compressoresNo ratings yet

- EMP2Document6 pagesEMP2Evandro Jva compressoresNo ratings yet

- W Series Maintenance ScheduleDocument13 pagesW Series Maintenance ScheduleEvandro Jva compressoresNo ratings yet

- GS Setup Table (ABB ACS550) 2010.09.15Document1 pageGS Setup Table (ABB ACS550) 2010.09.15Evandro Jva compressoresNo ratings yet

- THB1548AG Ventilador InversorDocument11 pagesTHB1548AG Ventilador InversorEvandro Jva compressoresNo ratings yet

- Performance: Technical Leaflet Pressure Transmitters, Type AKS 32 and AKS 33Document3 pagesPerformance: Technical Leaflet Pressure Transmitters, Type AKS 32 and AKS 33Evandro Jva compressoresNo ratings yet

- Tcw413y Ds8eDocument2 pagesTcw413y Ds8eEvandro Jva compressoresNo ratings yet

- Characteristic Value: Product SpecificationsDocument1 pageCharacteristic Value: Product SpecificationsEvandro Jva compressoresNo ratings yet

- Tubulacao Dimensioes Globais Valvulas e ConexoesDocument3 pagesTubulacao Dimensioes Globais Valvulas e ConexoesEvandro Jva compressoresNo ratings yet

- Cpe100, Cpe120, CPVS100, CPVS120 - A Partir Api170897 - 05-2013Document108 pagesCpe100, Cpe120, CPVS100, CPVS120 - A Partir Api170897 - 05-2013Evandro Jva compressores100% (1)

- Thermostats,: Type KPDocument12 pagesThermostats,: Type KPEvandro Jva compressoresNo ratings yet

- CEMA Standard 501.1-2015Document16 pagesCEMA Standard 501.1-2015MNo ratings yet

- G3516 Engine Electronic Ignition System 4EK00001-UP (SEBP2185 - 98) - Basic SearchDocument128 pagesG3516 Engine Electronic Ignition System 4EK00001-UP (SEBP2185 - 98) - Basic SearchDjebali MouradNo ratings yet

- Safety & Health - Aalborg Portland MalaysiaDocument1 pageSafety & Health - Aalborg Portland MalaysiaSamundeswaran SatiwasilanNo ratings yet

- Starter Relay Starter Cut RelayDocument1 pageStarter Relay Starter Cut RelayThong ChanNo ratings yet

- 502 FDocument21 pages502 Fjomer0411No ratings yet

- LG400P 50Hz 2206CE13TAG2Document4 pagesLG400P 50Hz 2206CE13TAG2Brown builderNo ratings yet

- Training Materials Alternator 200mw Power PlantDocument31 pagesTraining Materials Alternator 200mw Power PlantLio MessiNo ratings yet

- Xbox 360 Hacking GuideDocument49 pagesXbox 360 Hacking GuideN193746100% (2)

- HTTP Electrical Engineering Portal Com Types of Residual Current Devices RCDDocument8 pagesHTTP Electrical Engineering Portal Com Types of Residual Current Devices RCDSurangaGNo ratings yet

- CD 3 ProjectdocumentationpdfDocument49 pagesCD 3 ProjectdocumentationpdfKHoirul Imam75% (8)

- Rs4-Cargo Stowage and StoresDocument14 pagesRs4-Cargo Stowage and StoresGerald Bawalan100% (1)

- An 41299Document3 pagesAn 41299Herb UlyssesNo ratings yet

- 1N5758 Etc PDFDocument3 pages1N5758 Etc PDFPedro lealNo ratings yet

- Multiple RS-232 Drivers & Receivers: Product Description FeaturesDocument9 pagesMultiple RS-232 Drivers & Receivers: Product Description Features40818248No ratings yet

- Easa Sib Upn2008-S20080411011 1Document20 pagesEasa Sib Upn2008-S20080411011 1Marco TrankNo ratings yet

- DC Machine 1Document5 pagesDC Machine 1amiteetumtech2013No ratings yet

- Genadvisor Shaft Volt Current Mon PSPG b10244 00 7600 en LR Fina PDFDocument2 pagesGenadvisor Shaft Volt Current Mon PSPG b10244 00 7600 en LR Fina PDFSourav RanaNo ratings yet

- Sebu7763-03 BDocument4 pagesSebu7763-03 BHernan SanchezNo ratings yet

- Burgi Motor 140S Oil-OilDocument1 pageBurgi Motor 140S Oil-OilAry KassaNo ratings yet

- Roman ReignsDocument2 pagesRoman ReignsrushiNo ratings yet

- Quiz CSADocument9 pagesQuiz CSAMichael John PedrasaNo ratings yet

- Annex 4.30 Training Material For O&M of Electrical Equipment in Spring 2018Document194 pagesAnnex 4.30 Training Material For O&M of Electrical Equipment in Spring 2018Johmar JavierNo ratings yet

- 712U0201 Rev 16 - Blastmate II Operator ManualDocument68 pages712U0201 Rev 16 - Blastmate II Operator ManualAmilcar MendozaNo ratings yet

- 7900 - HYBRID BrochureDocument14 pages7900 - HYBRID BrochureКонстантин КосаревNo ratings yet

- DLP ProjectorDocument24 pagesDLP ProjectordanyNo ratings yet

- 12-2010 09a, Jf506eDocument17 pages12-2010 09a, Jf506eAleNo ratings yet

- Interview QuestionsDocument7 pagesInterview Questionssrinath sai100% (1)

- Fuse Bible CompleteDocument164 pagesFuse Bible CompleterbucholzNo ratings yet