Professional Documents

Culture Documents

Poster Cannabis Terpenes

Poster Cannabis Terpenes

Uploaded by

Eduardo ArroyoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster Cannabis Terpenes

Poster Cannabis Terpenes

Uploaded by

Eduardo ArroyoCopyright:

Available Formats

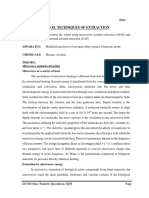

ISOLATION OF STRAIN SPECIFIC 2.

Close the reactor with its glass cover, place it

inside the ETHOS X, assemble the stainless-steel

REACTOR SIZE SAMPLE AMOUNT MICROWAVE POWER

HIGH QUALITY TERPENES distillation module and connect to the water chiller.

3. Run the microwave program as shown in table

Small (2 l) up to 400 g 400 W

THROUGH MICROWAVE ASSISTED EXTRACTION Medium (4 l) up to 1500 g 1500 W

4. Pure terpene products are collected into the

Diego Carnaroglio , Ryan Boyle , Stephen Markle

1 2 3 stainless-steel distillation module. Large (12 l) Up to 3000 g 1800 W

1

Milestone Srl, via Fatebenefratelli, 1/5, 24010 Sorisole (BG), Italy Table 1 - ETHOS X suggested working conditions

2

Milestone Inc, 25 Controls Drive, Shelton, CT 06484, USA

Medizin/Planet 13 Holdings,4850W Sunset Rd #130,LasVegas,NV89118

RESULTS AND DISCUSSION

3

In this specific work, terpene extraction was

performed on fresh frozen OGKB 2.0 strain working

on 1 kg of cannabis with the 5 L ETHOS X reactor. The

sample was microwave treated at constant power

for 40 min. After 10 min, the terpene fraction started

to be collected in the distillation module, above the

INTRODUCTION water layer. The extraction was completed after 40

min when the terpenes were completely extracted.

Many technologies are available to produce cannabis ETHOS X into their process, maximizing the extraction

At the end of the extraction, the terpene fraction was

derived products to satisfy an exponentially increasing capabilities, and therefore profitability, of their entire

collected from the glass distillation module, frozen

demand. In addition to the cannabinoids market, the process as represented in the Figure 1.

for 30 min to remove extra water and then stored in

market for end products having the fresh taste and This poster describes how the cannabis plant can

a fridge at 4°C.

smell of specific cannabis strains is also sharply be processed using ETHOS X to produce high quality

Figure 2 - GC-MS profile of the ETHOS X extract

increasing. The addition of terpene, small molecules flavoring terpenes, while preserving the quality of the

synthesized by the cannabis plant, to these end cannabis plant material for the further processing ETHOS X EXTRACT - Total Yield* 1.59%

products results in a very real, fresh aroma experience for THC and CBDs extraction with conventional δ-Limonene trans-Nerolidol The potency analysis (Table 3) shows that the ETHOS

for the final consumer. techniques. X did not affect the yield or quality of the cannabinoids

β-Myrcene β-Pinene

To address the limitations of the conventional (78% in the raw material vs 77% in the processed

extraction techniques, Milestone has developed and Milestone

Conventional Linalool cis-Nerolidol material). Moreover, the extract is free of cannabinoids,

Extraction

ETHOS X

patented (EP 1 439 218, EP 1 618 798 and EP 1 629 System

α-Humulene Camphene avoiding the need of a purification step.

725) the ETHOS X for the Microwave Green Extraction

α-Pinene trans-Nerolidol

of Natural Products. Its process leads in the efficient Plant Raw ETHOS X Processed

and fast production of terpenes, providing a complete Table 2 - List of the main terpenes in the ETHOS X extract (from Materialb Extract plant materiald

terpene profile with with a pure smell and taste over OGKB 2.0 strain) Terpenesa 1.4 1.6 0.1

Cannabis Plant Terpene Cannabinoids *by weight

all the other extraction techniques. Total

78 -c 77

Cannabis extract producers can integrate Milestone’s Cannabinoidsa

Figure 1 - Cannabis processing diagram with Milestone ETHOS X

The terpene fraction was analyzed via GC-MS Table 3 - Recovery data of terpene and total cannabinoids from the

providing the fingerprint of the extract. described processing step in Figure 1

To conclude the evaluation, the cannabis material a

Data are calculated in yield by weight

has been extracted before and after the ETHOS X

b

Extracted with close-loop hydrocarbon extraction system

EXPERIMENTAL c

Not detected (<LOQ)

treatment with closed-loop hydrocarbon extraction d

Cannabis plant material extracted with close-loop hydrocarbon ex-

INSTRUMENT to collect the cannabinoids. traction system after ETHOS X process.

Developed and patented by Milestone, the ETHOS

X is the unique benchtop microwave extraction

system able to provide production scale capability

in the shortest processing time. Some of its unique CONCLUSIONS

benefits are:

- Solvent-free extraction for highest quality The data shown in this work, demonstrates that efficiency in the cannabis processing industry and

- Shorter run-times combined with user-friendly the ETHOS X maximizes the extraction of terpenes ensuring fast return on investment.

platform from cannabis material, without compromising the Milestone’s ETHOS X is proven to be a unique and

- Flexible configuration for the lab needs quality of the THC and other cannabinoids extracted beneficial tool for cannabis processors, allowing

- Market-leading innovation, safety, and in the following process. Its ability to work with fresh them to obtain terpenes with unmatched quality

technology material produces a superior terpene profile that is and completeness in 40 minutes, ready to use for

unmatched by conventional extraction techniques. flavoring in edible and recreational products without

SAMPLES AND REAGENTS Moreover, the fast processing times ensures the effecting the cannabinoid quality and extraction

- Cannabis sample: OGKB 2.0 strain integrity of all cannabinoids, enhancing the overall process.

- Distilled water.

TYPICAL PROCEDURE

1.Cannabis sample weight vary based on the ETHOS ETHOS X glass extraction reactor, wait 30 min

X reactor volume, (see the table 1) to thaw before proceeding with the extraction

- Dry material, the plant material has to be

MILESTONE

- Fresh material, weight it directly in the 5 L ETHOS H E L P I N G

X glass extraction reactor moistened prior to start the microwave C H E M I S T S

- Fresh frozen material, weight it directly in the 5 L extraction.

You might also like

- Mushrooms of The MidwestDocument441 pagesMushrooms of The MidwestEduardo Arroyo100% (2)

- The Higher TasteDocument128 pagesThe Higher TasteHari Chandana K100% (1)

- Science Yearly Lesson Plan Form 2Document10 pagesScience Yearly Lesson Plan Form 2NorelyanaAli100% (2)

- 12-Piller-Energy Savings Via Steam RegenerationDocument16 pages12-Piller-Energy Savings Via Steam RegenerationAndrew Xuguoming100% (1)

- LC Vapors-Phenomonex-FusionDocument8 pagesLC Vapors-Phenomonex-Fusionpraveen.singh.rajput21No ratings yet

- LAB REPORT - RNA Extraction & ElectrophoresisDocument23 pagesLAB REPORT - RNA Extraction & ElectrophoresisEzad juferiNo ratings yet

- Materials Letters: Tao Mei, Wenbo Pi, Liu Zhang, Jianying Wang, Jinhua Li, Xianbao WangDocument4 pagesMaterials Letters: Tao Mei, Wenbo Pi, Liu Zhang, Jianying Wang, Jinhua Li, Xianbao WangEesha BhattyNo ratings yet

- Articulo 9Document6 pagesArticulo 9Kevin Andrés VgNo ratings yet

- Laboratory Notes The Alkahest: by Dr. Fabrizio TonnaDocument6 pagesLaboratory Notes The Alkahest: by Dr. Fabrizio TonnaOmorogah HagmoNo ratings yet

- Enterococci AgarDocument2 pagesEnterococci Agartevy101No ratings yet

- CHAPTER 2 AnachemDocument5 pagesCHAPTER 2 AnachemrhymeNo ratings yet

- Effects of Dry Heat and Saturated Steam On The Physical Properties of ChitosanDocument6 pagesEffects of Dry Heat and Saturated Steam On The Physical Properties of ChitosanJan ChadaratNo ratings yet

- 9194 E.v1101da 1803Document11 pages9194 E.v1101da 1803AmandaNo ratings yet

- Simple Isolation and Inoculation Methods For Fungal CulturesDocument4 pagesSimple Isolation and Inoculation Methods For Fungal Culturesamire PaulNo ratings yet

- A Rapid Method For The Assay of Dextranase-Koh1970Document3 pagesA Rapid Method For The Assay of Dextranase-Koh1970ratu yulianiNo ratings yet

- Encapsulation Zno Nanoparticles by Using Beeswax: Roya Namdariyan, Afshin Farahbakhsh and Hossain Alizade GolestaniDocument3 pagesEncapsulation Zno Nanoparticles by Using Beeswax: Roya Namdariyan, Afshin Farahbakhsh and Hossain Alizade GolestaniSahil GuptaNo ratings yet

- Poly (N-Isopropylacrylamide) Microgels For Organic Dye Removal From WaterDocument6 pagesPoly (N-Isopropylacrylamide) Microgels For Organic Dye Removal From WaterIolanda VeronicaNo ratings yet

- BeaverBeads Viral DNA RNA KitDocument4 pagesBeaverBeads Viral DNA RNA KitangelinaNo ratings yet

- Antimicrobial Screening and Stability Studies of The Crude Extract of Jatropha Curcas Linn Latex (Euphorbiaceae)Document7 pagesAntimicrobial Screening and Stability Studies of The Crude Extract of Jatropha Curcas Linn Latex (Euphorbiaceae)Yuwinda Ayu LestariNo ratings yet

- Degree of Deacetylation of Chitosan Extracted From White Snapper (Lates SP.) Scales WasteDocument4 pagesDegree of Deacetylation of Chitosan Extracted From White Snapper (Lates SP.) Scales WasteMinou MakhloufNo ratings yet

- IJETR031157Document3 pagesIJETR031157erpublicationNo ratings yet

- Fair Cap PresentationDocument8 pagesFair Cap Presentationinstrumed_globalNo ratings yet

- This Study Resource Was: Experiment 3Document6 pagesThis Study Resource Was: Experiment 3U2103536 STUDENTNo ratings yet

- Work ReportDocument12 pagesWork ReportFahim Abyan Makarim - 馬柏彥No ratings yet

- Bac KitDocument2 pagesBac KitKiran MandapatiNo ratings yet

- Diosdado Banatao: Aisa Mijeno She Is A Professor of Engineering at de La Salle University - Lipa in The PhilippinesDocument2 pagesDiosdado Banatao: Aisa Mijeno She Is A Professor of Engineering at de La Salle University - Lipa in The PhilippinesJonathan M. AbelleraNo ratings yet

- MUlecular Distilation UnitDocument6 pagesMUlecular Distilation UnitElly SufriadiNo ratings yet

- IPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249Document3 pagesIPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249LoisirsNo ratings yet

- 23 45 1 SM PDFDocument7 pages23 45 1 SM PDFArreza Hamsyah FernandaNo ratings yet

- Rnaqueous - Micro: Instruction ManualDocument20 pagesRnaqueous - Micro: Instruction ManualLolaNo ratings yet

- Membrane Filtration - PPT IMPDocument35 pagesMembrane Filtration - PPT IMP19-810Anitha bhukya100% (2)

- Life Estimation and Investigation of Dielectric Strength of Multistressed High Voltage Epoxy Micro and NanocompositesDocument4 pagesLife Estimation and Investigation of Dielectric Strength of Multistressed High Voltage Epoxy Micro and NanocompositesFahim asgharNo ratings yet

- Caracterizacion de Drogas Por DSCDocument3 pagesCaracterizacion de Drogas Por DSCLady DuqueNo ratings yet

- HVC - App-Notes - Low - Temp - Analysis - of - Kaolin - Using - Diffuse - ReflectanceDocument2 pagesHVC - App-Notes - Low - Temp - Analysis - of - Kaolin - Using - Diffuse - ReflectanceMichelleNo ratings yet

- Cannabis-Science-and-Tech 082019 Ezine ArticleDocument9 pagesCannabis-Science-and-Tech 082019 Ezine ArticleJUAN BAUTISTA POLO VIDALNo ratings yet

- The Density of Aqueous Hydrogen Peroxide Solutions PDFDocument4 pagesThe Density of Aqueous Hydrogen Peroxide Solutions PDFVictor VazquezNo ratings yet

- Ethanol Extraction Membrane During Supported Liquid Ferment at IonDocument8 pagesEthanol Extraction Membrane During Supported Liquid Ferment at Ionapi-26678889No ratings yet

- Rettori and Duran, 1998Document4 pagesRettori and Duran, 1998pendikNo ratings yet

- Preparation and Characteristics of Polyvinyl Alcohol-Based Hydrogel Containing Natural MicrobentoniteDocument5 pagesPreparation and Characteristics of Polyvinyl Alcohol-Based Hydrogel Containing Natural MicrobentoniteMawarani ManullangNo ratings yet

- Guo2018 PDFDocument6 pagesGuo2018 PDFTomGaliciaNo ratings yet

- EPQ Presentation-Cloud GuoDocument32 pagesEPQ Presentation-Cloud Guo070808008No ratings yet

- Block-It U6 Rnai Entry Vector Kit: User GuideDocument56 pagesBlock-It U6 Rnai Entry Vector Kit: User GuideGarbuz ElenaNo ratings yet

- Green Synthesis of Iron Oxide (Fe2O3) Nanoparticles Using Neolamarckia Cadamba Leaves Extract and Photocatalytic Degradation of Malachite GreenDocument4 pagesGreen Synthesis of Iron Oxide (Fe2O3) Nanoparticles Using Neolamarckia Cadamba Leaves Extract and Photocatalytic Degradation of Malachite GreenInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chemical & Mechanical Effects of Fiber Networks On WettabilityDocument5 pagesChemical & Mechanical Effects of Fiber Networks On Wettabilityapi-402557994No ratings yet

- D7206D7206M-06 (2013) E1 Standard Guide For Cyclic DeactivationDocument5 pagesD7206D7206M-06 (2013) E1 Standard Guide For Cyclic Deactivationastewayb_964354182No ratings yet

- App 41236Document7 pagesApp 41236Dr Mujahid MehdiNo ratings yet

- PBL1 Week1 Lab InstructionsDocument10 pagesPBL1 Week1 Lab InstructionsJIN YuNo ratings yet

- Manual T 1020Document8 pagesManual T 1020حميد حميدNo ratings yet

- INFILTRATIONDocument6 pagesINFILTRATIONHenry ChenNo ratings yet

- Flow Microwave Technology and MicroreactorsDocument14 pagesFlow Microwave Technology and MicroreactorscarloarchivioNo ratings yet

- Chapter 09Document6 pagesChapter 09Astri Yul FitrianaNo ratings yet

- Proposal Manuscript ExampleDocument10 pagesProposal Manuscript ExampleEmy SacredfieldNo ratings yet

- Nitroglycerin CapsuleDocument13 pagesNitroglycerin CapsuleADVOCATE ASHUTOSH SHARMANo ratings yet

- Preparation of Activated Carbon From SilDocument5 pagesPreparation of Activated Carbon From SilDewiNo ratings yet

- Biological LaboratoryDocument36 pagesBiological LaboratoryTota ShihabNo ratings yet

- Continuous Separation of Fermentation Broth Using A CEPA LE Laboratory Centrifuge SystemDocument2 pagesContinuous Separation of Fermentation Broth Using A CEPA LE Laboratory Centrifuge SystemjdNo ratings yet

- Foreign Trade of The DPRK 4-2017Document19 pagesForeign Trade of The DPRK 4-2017StirlitzNo ratings yet

- 6 Novel Extraction Technique-FinalDocument5 pages6 Novel Extraction Technique-FinalRNo ratings yet

- Brief Notes: A Simple Metitod For Removing The Resin From Epoxy-Embedded TissueDocument2 pagesBrief Notes: A Simple Metitod For Removing The Resin From Epoxy-Embedded TissueVansala GanesanNo ratings yet

- 09 - Chapter 3Document47 pages09 - Chapter 3bijesh babuNo ratings yet

- The Separation and Isolation of Proteins: a Laboratory Manual of Analytical Methods of Protein Chemistry (Including Polypeptides)From EverandThe Separation and Isolation of Proteins: a Laboratory Manual of Analytical Methods of Protein Chemistry (Including Polypeptides)No ratings yet

- Biomedical Electron Microscopy: Illustrated Methods and InterpretationsFrom EverandBiomedical Electron Microscopy: Illustrated Methods and InterpretationsNo ratings yet

- Structure of Molecules and Internal Rotation: Physical Chemistry: A Series of MonographsFrom EverandStructure of Molecules and Internal Rotation: Physical Chemistry: A Series of MonographsNo ratings yet

- Comparison of Different Methods For The Extraction of Cannabinoids From CannabisDocument9 pagesComparison of Different Methods For The Extraction of Cannabinoids From CannabisEduardo ArroyoNo ratings yet

- Mushroom Polysaccharides As Potential Prebiotics With Theirantitumor and Immunomodulating Properties 2016Document14 pagesMushroom Polysaccharides As Potential Prebiotics With Theirantitumor and Immunomodulating Properties 2016Eduardo ArroyoNo ratings yet

- Forests 09 00732Document9 pagesForests 09 00732Eduardo ArroyoNo ratings yet

- Infections PDFDocument29 pagesInfections PDFLoudry ElfaNo ratings yet

- Rovos BrochureDocument36 pagesRovos Brochuremonique5617No ratings yet

- Intel System Management Specification - Rev2p0Document63 pagesIntel System Management Specification - Rev2p0Nisarg UpadhyayNo ratings yet

- Thermodynamics Onkar SinghDocument18 pagesThermodynamics Onkar SinghSaurabh JainNo ratings yet

- Sustainability PackagingDocument3 pagesSustainability Packagingdong.quan.1705No ratings yet

- Sav 4752Document39 pagesSav 4752tlidiaNo ratings yet

- Presec Legon ProspectusDocument2 pagesPresec Legon ProspectusChristian Joel Mawuli Donkoh100% (1)

- Text 1 (A & B)Document2 pagesText 1 (A & B)ifx leeNo ratings yet

- Lecture 7 Adjusted Present ValueDocument19 pagesLecture 7 Adjusted Present ValuePraneet Singavarapu100% (1)

- Lab. 12 NylonDocument4 pagesLab. 12 NyloncsnNo ratings yet

- Three Phase Induction Motors: List of FormulaeDocument9 pagesThree Phase Induction Motors: List of FormulaekkkNo ratings yet

- Interview Questions and AnswersDocument3 pagesInterview Questions and AnswersPradeep KumarNo ratings yet

- Module 4 2ndqtDocument83 pagesModule 4 2ndqtJanelle RegachoNo ratings yet

- An Overview of Sugar Sector in IndonesiaDocument6 pagesAn Overview of Sugar Sector in IndonesiaAnggit Saputra DwipramanaNo ratings yet

- Cad Cam Lab VivaDocument9 pagesCad Cam Lab VivaAnonymous dYDY4Eha100% (2)

- Paper 2Document15 pagesPaper 2lutfi istiqomahNo ratings yet

- LELO - TOR 3 - Online Manual - ENGDocument20 pagesLELO - TOR 3 - Online Manual - ENGebercueNo ratings yet

- Learning Packet in Level 1-Anatomy and Physiology: College of Nursing School Year 2021-2022Document18 pagesLearning Packet in Level 1-Anatomy and Physiology: College of Nursing School Year 2021-2022Zyke NovenoNo ratings yet

- Prevention of Foodborne Disease: The Five Keys To Safer FoodDocument2 pagesPrevention of Foodborne Disease: The Five Keys To Safer FoodZubda ButtNo ratings yet

- 16.21.1814 EbookDocument442 pages16.21.1814 EbookSutadi Triputra100% (1)

- Line Dance ModuleDocument34 pagesLine Dance ModuleMarie Antionette MondragonNo ratings yet

- 2TG - (Catalog) Towing Tractor EngineDocument4 pages2TG - (Catalog) Towing Tractor EngineAhmad FirdausNo ratings yet

- Amniotic Fluid PDFDocument24 pagesAmniotic Fluid PDFJoshua Ty CayetanoNo ratings yet

- Common Female Ancestor Test 2: African L2 Haplogroups Pereira Et Al (2001)Document7 pagesCommon Female Ancestor Test 2: African L2 Haplogroups Pereira Et Al (2001)Mwiinga JnrNo ratings yet

- Fiitjee Aits 16Document17 pagesFiitjee Aits 16VatsalNo ratings yet

- Final Year Project SPYBOTDocument7 pagesFinal Year Project SPYBOTFaizanAhmedNo ratings yet

- 102 MW GHPP - Submission of FPFO For November 2022Document62 pages102 MW GHPP - Submission of FPFO For November 2022m.h ssNo ratings yet

- Parking Guidance September 2015Document47 pagesParking Guidance September 2015Alexandra KropokNo ratings yet